Table des matières

Conduit électrique plays a vital role in protecting and routing wiring in a wide range of environments, from homes and offices to hospitals, data centers, and industrial sites. The right conduit ensures electrical safety, prevents damage, and supports long-term system reliability. But with a variety of conduit materials available, such as EMT, RMC, IMC, FMC, ENT, and PVC, knowing which one to use can be challenging.

Each conduit type comes with specific advantages, limitations, and code considerations based on installation environments, voltage levels, and mechanical or fire protection needs. Among them, PVC conduit has become one of the most popular choices due to its lightweight design, corrosion resistance, cost-efficiency, and ease of installation.

This guide will help you better understand all the common electrical conduit types, and get to know about PVC conduit’s specifications, standards, applications, and installation best practices etc. Whether you’re a contractor, engineer, facility planner, or a procurement specialist, this guide will help you choose the right PVC conduit solution for your project safely, effectively, and in compliance with code.

Comprendre les conduits électriques

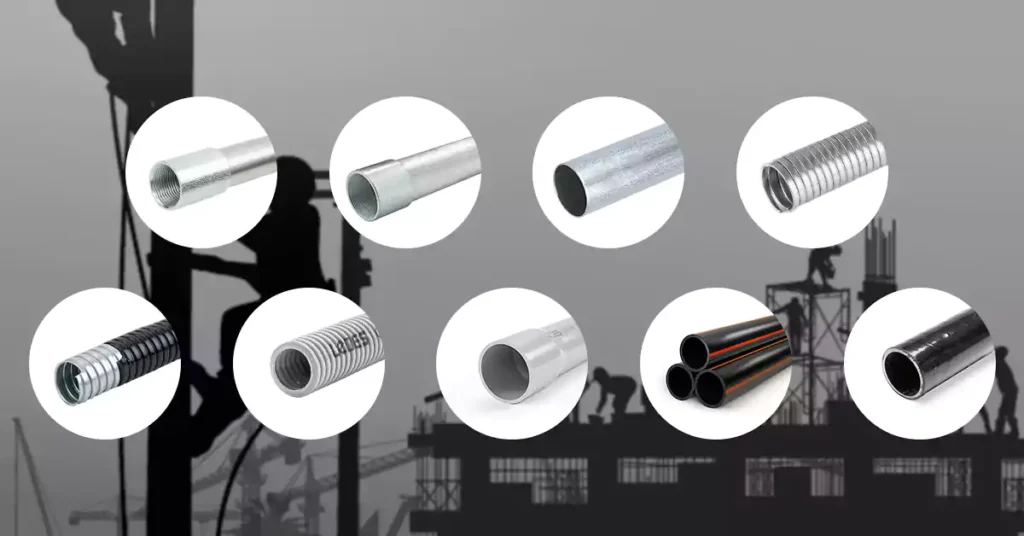

There are many different types of electrical conduits, and each conduit type is designed to meet specific environmental, mechanical, and regulatory requirements. Better understand the suitable applications of each type before buying them for your project.

Conseils de pro : Want to know the top 10 types of electrical conduit features and applications? You can click the link above to read our last post.

9 Common Types of Electrical Conduit

Conduit métallique rigide (RMC)

Made of galvanized steel or aluminum, RMC is the heaviest and most durable metal conduit, offering superior protection in high-risk or exposed environments.

Avantages:

Excellent mechanical strength

Strong resistance to physical damage

Suitable for outdoor and hazardous locations

Can be used as a grounding conductor

Les inconvénients:

Heavy and difficult to install

Expensive

Requires threading tools and fittings

Conduit métallique intermédiaire (IMC)

IMC is made of steel, it is a lighter alternative to RMC, offering a balance between strength and ease of handling.

Avantages:

Plus léger que le RMC mais toujours solide

Approved for indoor and outdoor use

Lower cost than RMC

Les inconvénients:

Still requires special tools for cutting and threading

Heavier than nonmetallic options

Tubes métalliques électriques (EMT)

Made of steel (sometimes aluminum), also called “thin-wall” conduit, EMT is lightweight and easy to bend, widely used in commercial and light industrial settings for indoor applications.

Avantages:

Lightweight and easy to bend

Cost-effective

Clean appearance for exposed runs

Recyclable and easy to ground

Les inconvénients:

Susceptible to corrosion in wet environments

Not rated for direct burial

Lower mechanical strength than RMC/IMC

Conduit métallique flexible (FMC)

A spiral metal conduit that allows flexibility. Commonly used in short runs to connect fixtures or motors to rigid conduits.

Avantages:

Flexible and easy to route in tight spaces

Quick to install

Absorbs vibration

Les inconvénients:

Not waterproof

Lower crush resistance

Requires careful grounding

Liquid-Tight Flexible Conduit (LFMC)

Similar to FMC but with a waterproof plastic jacket. It is used in wet or outdoor locations requiring flexibility and moisture protection.

Avantages:

Water-resistant and weatherproof

Maintains flexibility

Suitable for outdoor, wet, or oily environments

Les inconvénients:

Expensive compared to standard FMC

Heavier than nonmetallic flexible options

Requires watertight fittings

Tubes électriques non métalliques (ENT)

Made of PVC, is a pliable, conduit en plastique ondulé, mainly for indoor, in-wall, or ceiling installations in residential and light commercial construction. ENT is quick to install but limited to certain environments.

Avantages:

Lightweight and easy to install

No need for bending tools

Non conducteur et résistant à la corrosion

Les inconvénients:

Not UV-resistant

Limited to dry, protected areas

Lower mechanical strength

Conduits en PVC

Made of rigid PVC, Conduit en PVC is nonmetallic and widely used for underground, outdoor, or corrosive environments due to its affordability and corrosion resistance.

Avantages:

Corrosion-resistant and non-conductive

Lightweight and inexpensive

Easy to cut and join with solvent cement

Available in rigid and flexible forms

Ideal for underground or wet locations

Les inconvénients:

Limited temperature resistance

Less impact-resistant than metal

Requires expansion joints in long runs

Fire-rated types needed for some environments

High-Density Polyethylene (HDPE) Conduit

Made of HDPE plastic, best for Long underground duct runs (telecom, power, fiber)

Avantages:

Excellent chemical and moisture resistance

Long coil lengths reduce jointing

Flexible and crush-resistant

Suitable for trenchless installations (e.g., directional drilling)

Les inconvénients:

Requires fusion welding or special fittings

Not suitable for high-temperature areas

Higher initial equipment cost (fusion tools)

Fiberglass Reinforced Conduit (FRC or RTRC)

Matériel: Fiberglass-reinforced thermosetting resin

Best for: Corrosive, high-temperature, or chemically aggressive environments

Avantages:

Exceptional corrosion and heat resistance

Lightweight compared to metal

Fire-resistant options available

Suitable for utilities, chemical plants, tunnels

Les inconvénients:

High material and installation cost

Brittle under impact

Specialized fittings and adhesives needed

Summary Table:

Here are 9 common types of electrical conduit comparing list.

Type de conduit | Matériel | Flexibilité | Avantages | Inconvénients | Best Use |

RMC | Acier galvanisé | Rigide | Maximum strength, fire-rated | Heavy, expensive | Heavy-duty, outdoor, industrial |

IMC | Acier | Rigide | Lighter than RMC, corrosion resistant | Still heavy, requires threading | Commercial/industrial |

EMT | Steel/Aluminum | Semi-rigid | Lightweight, easy to bend | Not for wet or buried use | Indoor exposed runs |

FMC | Acier | Flexible | Flexible, vibration absorption | Not waterproof, weak to impact | Motors, lights |

LFMC | Metal + Jacket | Flexible | Water/oil resistant, flexible | High cost, heavy | Outdoor, wet areas |

ORL | PVC Plastic | Flexible | Quick install, lightweight | Indoor use only, low strength | In-wall, residential |

PVC | PVC Plastic | Rigide | Lightweight, low-cost, corrosion-proof | Limited heat/fire resistance | Underground, outdoor, corrosive |

PEHD | HDPE Plastic | Flexible | Long runs, crush-resistant, corrosion-proof | Fusion tools needed, not fire-rated | Underground ducts |

RTRC | Resin + Fiberglass | Rigide | Excellent chemical/fire resistance | Expensive, brittle under impact | Harsh chemical/high-heat |

Why Choose PVC Conduit?

PVC conduit has earned its reputation as one of the most versatile and cost-effective solutions for electrical wiring protection. It’s ideal for underground ducting, outdoor exposure, and corrosive environments, common in construction, wastewater treatment, agriculture, and solar power systems.

Key Advantages of PVC Conduit:

Corrosion Resistant: Withstands moisture, salts, acids, and chemicals

Rentable: Lower material and labor cost than metallic or specialty conduits

Poids léger: Easier handling reduces labor effort

Non conductrice: Offers built-in electrical insulation

Easy to Join: Simple solvent cement connection method—no threading needed

Direct Burial & UV-Resistant Versions Available

Limitations of PVC Conduit:

Less Impact Resistance: Rigid PVC conduit can not offer high strength as rigid metal conduit, not ideal for high-traffic or exposed mechanical areas

Lower Temperature Tolerance: Deforms at high heat

Thermal Expansion: May require expansion fittings in outdoor runs

Fire Ratings Not Inherent: Must choose fire-rated types for code-critical areas

PVC Vs. EMT Vs. RMC Vs. HDPE Vs. Fiberglass Conduit

Fonctionnalité | PVC | EMT | RMC | PEHD | Fiberglass |

Matériel | PVC Plastic | Steel/Aluminum | Galv. Steel | HDPE Plastic | Resin + Fiberglass |

Résistance à la corrosion | Excellent | Modéré | Good | Excellent | Excellent |

Résistance mécanique | Modéré | Modéré | Excellent | Good | Good |

Flexibilité | Rigide | Semi-rigid | Rigide | Flexible | Rigide |

Temperature Resistance | Limited | Modéré | Excellent | Modéré | Excellent |

Fire Resistance Options | Disponible | Oui | Oui | No | Oui |

Underground Approved | Oui | No | Oui | Oui | Oui |

Installation Complexity | Facile | Moyen | Hard | Modéré | Haut |

Coût | Faible | Moyen | Haut | Moyen | Haut |

In summary, PVC conduit offers the best balance of affordability, corrosion resistance, and installation simplicity, making it a leading choice for a wide range of standard and outdoor wiring needs. While it may not suit high-heat or high-impact environments, it excels in underground, damp, or chemically aggressive installations where nonmetallic performance is key.

Code Compliance for PVC Electrical Conduit

Choosing the right PVC electrical conduit goes beyond just selecting the right type and material, it must also meet local and international electrical codes and product standards to ensure safety, legal compliance, and long-term performance. Authorities in different countries outline specific requirements for conduit systems, including how they are constructed, tested, marked, and installed.

Here’s a brief overview of the major standards that govern PVC conduit:

National Electrical Code (NEC – U.S.)

Published by the National Fire Protection Association (NFPA) as NFPA 70, the NEC sets the foundational rules for electrical wiring and equipment installations in the United States.

Article 352 outlines the requirements for PVC conduit, here are some of them:

- Material must be nonmetallic, flame-retardant, and resistant to sunlight (if exposed)

- Requires use of approved, listed (e.g., UL 651) conduit and fittings

- Expansion fittings are required where significant thermal movement is expected

- Specific support intervals (e.g., every 3 feet for horizontal runs unless otherwise specified)

- Conductors must be rated for the environment (e.g., wet or underground)

Remarques : Are you a builder or electrical contractor in the United States? Read this expert guide to the 2025 edition of the UL 651 standard to quickly understand the sizing, performance and installation requirements of UL and NEC for electrical conduits.

Canadian Electrical Code (CEC – Canada)

The CEC, maintained by the Canadian Standards Association (CSA), is Canada’s equivalent to the NEC and is widely adopted across provinces with minor regional amendments.

Key Requirements for PVC Conduit:

- Recognizes Rigid PVC Conduit and Flexible Nonmetallic Conduit as valid wiring methods

- Product standards include:

CSA C22.2 No. 211.1: Rigid PVC Conduit

CSA C22.2 No. 211.2: DB/ES PVC Conduit

CSA C22.2 No. 227.1: Electrical Nonmetallic Tubing

- Requires:

Use of approved and CSA-certified conduit products

Proper use of solvent-welded joints or CSA-compliant fittings

Compliance with Section 12 of the CEC (Wiring Methods), including permitted locations, fill capacity, and bending radius etc.

- Underground or outdoor conduit installations must be specifically rated for moisture and sunlight exposure

Conseils de pro : Want to know CSA’s performance requirements for PVC rigid conduit and ENT tubing? Click the following links to read our previous content in detail:

AS/NZS Standards (Australia & New Zealand)

The AS/NZS 2053 series and the AS/NZS 3000 Wiring Rules govern conduit systems in Australia and New Zealand. These standards are widely recognized for their stringent mechanical and environmental performance requirements.

Key Requirements for PVC Conduit:

- AS/NZS 2053.1 (General Requirements):

Defines performance classes for mechanical strength (light, medium, heavy duty)

Specifies tests for flammability, UV resistance, compression, impact, and thermal performance

- AS/NZS 2053.2: Covers rigid plain PVC conduit

- AS/NZS 2053.5: Covers corrugated conduit

- PVC conduit exposed to sunlight must be marked “UV Resistant” or manufactured with carbon black or other stabilizers

- Conduits must meet temperature requirements (typically -15°C to +65°C or higher) and V-0 flammability rating

- Installation practices must conform to AS/NZS 3000, especially for burial depth, mechanical protection, and separation of services

Remarques : Doing business in Australia? No problem, read this expert guide to the AS/NZS 2053 standard to quickly understand the size, performance and installation requirements for PVC conduit in Australia.

IEC Standards (International)

The International Electrotechnical Commission (IEC) provides global baseline standards often used in export projects or multinational infrastructure builds.

Key Requirements for PVC Conduit:

IEC 61386 Series governs conduit systems, segmented by rigidity and application:

IEC 61386-1: General requirements (tests for strength, flame propagation, IP rating etc.)

IEC 61386-21: Rigid conduit systems

IEC 61386-23: Flexible conduit systems

PVC conduit must pass tests for:

Crush resistance

Impact strength

Ingress protection (IP ratings)

Fire performance and glow-wire ignition temperature

Conduit systems are classified by mechanical performance class (e.g., Medium, Heavy, Very Heavy) based on application requirements

Tips: Running business globally? No problem. Read this comprehensive guide to the IEC 61386 electrical codes to quickly understand the IEC requirements for electrical conduit size, performance and installation.

9 Commons Application of PVC Electrical Conduit

PVC conduit’s versatility allows it to serve a broad spectrum of applications across residential, commercial, industrial, and infrastructure environments.

1. Underground Electrical Systems

PVC conduit is extensively used for underground electrical installations, especially for residential and commercial service entrances, utility duct banks, and roadway lighting.

Why PVC?

Rigid PVC conduit is non-corrosive and does not degrade when exposed to moisture or soil chemicals.

It is approved for direct burial without requiring additional protective coatings.

Available in long lengths, minimizing the number of joints (reducing potential failure points).

DB-rated (Direct Burial) and EB-rated (Encased Burial) PVC conduits are specially designed for this purpose.

Applications:

Residential underground service entrance raceways

Power and telecom duct banks

Street lighting circuits

Highway ITS and traffic signal cabling

Utility vaults and manhole raceways

2. Outdoor and Above-Ground Exposed Environments

UV-resistant PVC conduit is ideal for outdoor electrical runs, especially in coastal, humid, or chemically aggressive atmospheres.

PVC conduit is:

Resists corrosion from salt air, moisture, acid rain, and chemicals

UV-stabilized formulas withstand long-term sunlight exposure

Lightweight, easy to install on exterior walls or rooftops

Applications:

Solar PV system conduit runs on rooftops or carports

Agricultural and irrigation pump control wiring

Outdoor lighting or pole bases

Exterior conduit risers and raceways

RV parks, marina shore power, and outdoor recreational areas

3. Endroits mouillés et humides

PVC conduit performs well in areas classified as damp or wet by electrical codes, especially where metallic systems would corrode over time.

Why PVC Conduit?

Nonmetallic construction eliminates risk of rust or galvanic corrosion

Compatible with watertight fittings and gaskets

Non-conductive, reducing shock hazard in wet environments

Applications:

Parking garages

Commercial kitchens

Pools and spas

Cold storage and refrigerated facilities

4. Residential Construction

PVC conduit is commonly used for residential wiring, especially in slab-on-grade homes or areas with corrosive soil or water exposure. Its:

Easy to cut and glue with solvent cement

Inexpensive and simple to route through floors, walls, or slabs

Compatible with NM cable transitions and standard junction boxes

Applications:

Conduit sleeves through concrete slabs

Garage and utility room wiring

Exterior meter-to-panel conduit

Service entrance risers

Ground-mounted AC units and pool panels

5. Commercial and Institutional Buildings

While EMT and MC cable are more common indoors, PVC conduit is often used in commercial buildings in certain areas or for specific systems.

Why PVC Conduit?

Offers nonmetallic raceway option for corrosive or damp spaces

Compatible with ENT (Electrical Nonmetallic Tubing) for concealed walls and ceilings

Fire-rated LSZH and plenum-rated types available for code-required areas

Applications:

Utility rooms, mechanical chases, and crawlspaces

Parking structures and exterior lighting

Fiber and low-voltage system raceways

Fire pump and generator wiring conduits

Commercial rooftop installations

6. Industrial Environments

PVC conduit is well-suited for light-to-medium duty industrial applications, particularly in areas with chemical exposure or moisture.

Why PVC Conduit?

Withstands exposure to oils, acids, salts, and alkalis

Non-conductive for safer installations near combustible materials

Easily integrated with other nonmetallic raceway systems

Applications:

Agriculture and aquaculture environments

Battery storage systems and chemical warehouse

Conveyor or material handling system control wiring

7. Renewable Energy Systems

PVC conduit is a common choice for solar, wind, and EV charging infrastructure.

PVC conduit is:

UV-resistant options for rooftop and outdoor installations

Compatible with direct burial from array to inverter or EV charger

Available in wide diameters to accommodate DC cabling and future upgrades

Applications:

Solar PV combiner to inverter runs

DC and AC conduit between arrays and control panels

Underground feeders to energy storage or transformers

EV charging conduit raceways (Level 2 or DC Fast Charging)

Off-grid system power distribution

9. Hazardous and Classified Locations (Limited Use)

Although metal conduits dominate classified environments, specialized heavy-duty PVC conduit systems may be used in corrosive classified areas when permitted by code.

With proper fittings and enclosure types, PVC conduit can be applied to:

Wastewater lift stations with classified zones

Chemical process areas (Specific class)

Oil field and agricultural gas areas (with approval)

Always consult the NEC, CEC, or local code authority to confirm suitability for hazardous locations.

Ledes' Solution for PVC Conduit Systems

When selecting the right PVC conduit system, choosing a reliable manufacturer is just as important as selecting the right conduit type. With over 10 years of industry expertise, Ledes has become a global name in electrical conduit solutions, recognized for its product breadth, engineering capabilities, and international code compliance.

Whether you’re installing residential underground ducting, industrial wiring, solar energy conduit runs, or large-scale infrastructure, Ledes offers a PVC conduit solution engineered for performance, safety, and long-term reliability.

Comprehensive Product Portfolio

Ledes manufactures a full spectrum of PVC conduit types and accessories, serving both low-voltage and high-voltage systems. The product line includes:

Conduit rigide en PVC :

– Schedule 40 conduit and Schedule 80 electrical conduit (UL 651, CSA C22.2 No. 211.1 compliant)

– AS/NZS 2053-rated PVC conduit for Australian and New Zealand markets

– Rigid PVC conduit that meet IEC standard

Flexible & Corrugated Conduits:

– UL & CSA certified ENT, standard corrugated, and split-type designs

– Ideal for tight installations, low-voltage systems, and control wiring

– Flame-retardant and UV-stabilized options available

Specialty Solutions:

– Low Smoke Zero Halogen (LSZH) conduits for fire-sensitive environments (e.g., data centers, tunnels, rail)

– Solar conduit systems optimized for UV resistance, long-term outdoor exposure, and direct burial

– Direct Burial DB2/ES2 conduits engineered for long underground duct banks and infrastructure raceways

Conduit Fittings & Accessories:

– Elbows, couplings, adaptors, tees, junction boxes, expansion fittings, terminal ends

– Designed for seamless integration and installation efficiency

– Available in standard and customized configurations

Quality You Can Trust

Ledes integrates quality and safety into every stage of the manufacturing process, backed by internationally recognized certifications:

- UL Listed (UL 651 for rigid PVC conduit, UL 514C for fittings)

- CSA Certified for Canadian compliance

- AS/NZS 2053-compliant conduit systems for Australia and New Zealand

- IEC and British Standards compatibility for export and global projects

- NEMA TC-2 and TC-3 compliant for U.S. conduit systems

- ISO 9001:2015 (Quality Management) and ISO 14001:2015 (Environmental Management)

These certifications are supported by a modern production facility that includes:

- Fully automated extrusion lines

- In-house testing for flame resistance, compression, UV aging, and chemical performance

- Custom R&D capabilities for unique formulations, sizes, or color coding

Innovation & Customization

Ledes isn’t just a conduit manufacturer—it’s a solutions partner. The company’s R&D and engineering teams develop custom conduit types for specific regional code needs, emerging industries (like EV and solar), and client-specific branding or logistics.

Customization options include:

Color-coded conduit (e.g., orange for communications, black for solar, gray for general use)

Custom printing and markings for branding or traceability

Special packaging for bulk export or warehouse efficiency

Chamfer design for specific needs

Trusted by Global Infrastructure Projects

Ledes conduit systems have been selected for use in some of the world’s demanding infrastructure and power generation projects:

Champlain Hudson Power Express (CHPE) – United States

A landmark renewable energy transmission line, the CHPE Project is designed to deliver 1,250 MW of clean hydroelectric power from Canada to New York City via a 339-mile HVDC cable.

- Ledes supplied high-performance PVC conduit systems for underground electrical raceways, supporting clean energy transmission infrastructure

- Significance: A major U.S. green infrastructure initiative projected to power over 1 million homes

A.B. Brown Generating Station – Indiana, USA

Located in Posey County, Indiana, the A.B. Brown Station is a 700-MW coal and natural gas power generation facility operated by CenterPoint Energy.

- Ledes’ conduit systems are used for control wiring and infrastructure upgrades during facility modernization

- Environment: Demanding industrial site requiring chemically resistant and direct burial-rated conduit

Al Dhafra PV2 Solar Project – Abu Dhabi, UAE

This is the world’s largest single-site solar photovoltaic project, with a capacity of 2 GW and a project budget exceeding $1 billion USD.

Ledes’ Role: Supply of UV-resistant, heavy-duty solar PVC conduit and fittings for power collection systems, inverters, and monitoring equipment

Installation Conditions: Harsh desert environment with extreme heat, sand exposure, and long cable routing distances

Melbourne Metro Tunnel – Victoria, Australia

A transformative infrastructure project, the Melbourne Metro Tunnel adds two 9-km twin rail tunnels and five new stations to Melbourne’s rail network. With a $12.6 billion AUD budget, it is the largest investment in Melbourne’s public transport system in 40+ years.

Ledes’ Role: Supply of AS/NZS 2053-compliant PVC conduits and fire-rated low-smoke halogen-free (LSZH) systems

9 Things You Need to Know Before Buying an Electrical Conduit

Choosing the correct electrical conduit isn’t just about material or diameter—it’s about aligning technical specifications, safety requirements, code compliance, and installation conditions with your actual project needs. Whether you’re a contractor, engineer, facility manager, or procurement specialist, making an informed purchase decision helps avoid costly replacements, failed inspections, or performance failures down the line.

1. Installation Environment

Your installation location is the single biggest factor influencing conduit type, rating, and accessories.

Always ask, is the conduit run indoor or outdoor?

Is the site exposed to heavy loads, UV radiation, chemicals, moisture, salt air, or extreme temperatures?

Conseils:

Use UV-resistant PVC for outdoor exposure

Select direct-burial (DB2/ES2 or Schedule 40 underground-rated) for soil-embedded installations

For corrosive or damp areas, nonmetallic PVC is ideal

For tunnels, subways, or data centers, consider Low-Smoke Halogen-Free (LSZH) PVC conduit

2. Voltage and System Type

The voltage level and system function (power, communications, control, etc.) impact conduit sizing, material, and separation rules.

Consider:

Is it a low-voltage system (under 1000V), or medium/high-voltage?

Is the conduit for data, fiber, fire alarm, or control circuits?

Are multiple systems being routed together?

Key Tips:

PVC conduit is suitable for low and medium-voltage installations

For high-voltage, verify fire resistance, insulation, and clearance

Always follow code rules for system separation (e.g., power vs. signal)

3. Conduit Size and Cable Fill Capacity

You must match the conduit inner diameter (ID) to the cable type and quantity being pulled. Improper sizing may result in overheating, jamming, or code violations.

Ask:

How many conductors will be installed, and what are their sizes?

Are you planning for future cable capacity?

Key Tips:

Follow NEC Chapter 9 Table 1 or equivalent standards for maximum fill percentage

Oversizing is recommended for easy pulls and future expansion

Include space for pull strings or additional circuits if needed

4. Mechanical and Impact Strength Requirements

Depending on your environment, you may need conduit with extra resistance to physical stress, such as crushing, bending, or surface impact.

Ask:

Will the conduit be driven over, embedded in concrete, or subject to machinery movement?

Is it installed in a public area, plant floor, parking garage or other applications where under heavy loads?

Key Tips:

Use Schedule 80 PVC for greater wall thickness and impact resistance

Consider concrete encasement or steel conduit alternatives for high-impact zones

5. Regulatory Code Compliance

Always verify that the conduit meets applicable electrical codes and national standards for your country or region. Such as UL, CSA, IEC, AS/NZS and other required compliant standards.

6. Fittings and Compatibility

Even the best conduit is only effective if paired with the right fittings, such as connectors, adaptors, junction boxes, and sealing gaskets.

Use same-brand conduit and fittings when possible for guaranteed compatibility

Check fitting material (e.g., PVC, nylon, or polycarbonate) for environmental fit

Consider expansion fittings for long outdoor runs exposed to thermal cycling

7. Fire Safety and Flame Rating

In commercial or enclosed environments, fire resistance and smoke emission are critical safety factors.

Use LSZH conduit and fittings or look for flame-retardant rated conduit, such as V-0, 5VA, or UL 94 rated products.

8. Project Budget and Lifespan Expectations

PVC conduit is generally one of the most cost-effective options on the market. It’s not only affordable upfront, but also saves on labor thanks to its lightweight design and ease of installation.

However, it’s important to consider long-term durability, for applications where exposed extreme heavy loads, temperatures, or with strict fire safety requirements etc, metal conduits maybe more suitable even they are more expensive.

9. Manufacturer and Supply Chain Reliability

Conduit systems are often ordered in large volumes, choosing a trusted brand ensures availability, quality, and technical support.

Choose suppliers who offer certified products, global logistics, and technical engineering consultation

Avoid unknown brands without test reports or regulatory listings

Market Trends and Future Outlook

The global electrical conduit market is evolving rapidly in response to technological demands, safety regulations, and sustainability initiatives. For PVC conduit specifically, opportunities are expanding beyond traditional construction into areas like digital infrastructure, renewable energy, and smart buildings. This section explores the most critical trends shaping the future of conduit systems and what they mean for procurement and product planning.

1. Steady Market Growth with Strategic Shifts

The global electrical conduit pipe market is valued at approximately US$ 34.3 billion in 2024, and is projected to reach US$ 54.8 billion by 2034, with a compound annual growth rate (CAGR) of 4.8%. The U.S. market alone is expected to grow from US$ 6.5 billion in 2024 to over US$ 10.5 billion by 2034, showing strong demand in residential, commercial, and infrastructure sectors.

Meanwhile, countries like China and Japan are showing CAGRs around 5.0%, driven by smart city developments and industrial electrification.

2. IT, Telecom, and Data Centers Drive High-Margin Growth

One of the fastest-growing segments is IT and telecommunications, which includes cloud computing, data centers, streaming infrastructure, and edge computing. The global data center rack market will grow from USD 5.17 billion in 2025 to USD 9.42 billion by 2030 at a compounded annual growth rate (CAGR) of 12.7%. These applications demand nonmetallic conduit with high EMI resistance, fire ratings, and cable density management, making high-spec PVC conduit (e.g., LSZH or fiber-optic-rated) a strong fit.

Buyer Insight:

While general construction projects contribute the most volume, the tech sector represents the most specialized and profitable conduit demand, requiring close technical support and advanced product offerings.

3. Resilient Demand in Building and Construction

The backbone of PVC conduit sales remains the residential, commercial, and institutional building sector. Growth is driven by:

Reinvestment in aging infrastructure

Demand for energy-efficient buildings

Increased emphasis on code-compliant wiring protection in both new builds and retrofits

PVC conduit remains the preferred nonmetallic solution due to its cost-efficiency, corrosion resistance, and compatibility with concrete slab, underground, and outdoor installations.

4. Stricter Electrical Safety Standards

With growing global awareness around electrical safety, regulatory enforcement is tightening:

OSHA and NEC updates in the U.S.

CSA and CE code harmonization in Canada and Europe

AS/NZS 3000 (Australia/NZ) focus on LSZH and fire-safe wiring systems

IEC 61386 global alignment for conduit systems

These changes are driving demand for certified conduit systems, particularly UL- and CSA-listed PVC, flame-retardant, and low-smoke halogen-free options for use in hospitals, transport, and tunnels.

5. Smart Buildings and IoT Integration

The rise of smart buildings and energy-efficient infrastructure is reshaping conduit system needs. Smart lighting, building automation, and energy monitoring systems all rely on low-voltage, sensor-integrated, and modular conduit installations.

PVC conduit plays a key role here due to:

Non-conductive safety

EMI isolation for sensitive control wiring

Compatibility with fiber, CAT6, and low-voltage systems

The ability to route data and control cabling alongside traditional wiring is transforming how PVC is used in commercial and public buildings.

6. Green Energy Projects and Renewable Infrastructure

PVC conduit is increasingly used in:

Utility-scale solar farms

EV charging networks

Battery energy storage systems (BESS)

Off-grid power distribution

As the conduit industry shifts toward more technically complex, code-sensitive, and environmentally conscious applications, the demand for high-quality conduits is growing. To know more about the PVC pipe forecast and market insights to 2031, click here for more information.

Conclusion

Selecting the right PVC electrical conduit is not just about choosing a product, it;s about ensuring electrical safety, regulatory compliance, long-term durability, and project success. As we’ve explored throughout this guide, the best choice depends on a careful evaluation of installation environment, voltage requirements, conduit type, mechanical strength, and certification needs.

PVC conduit stands out in the market for its balance of cost-efficiency, ease of installation, corrosion resistance, and broad code acceptance. From residential wiring to complex infrastructure and renewable energy projects, it remains a dependable choice across sectors.

With increasing global demand for smart buildings, high-performance data systems, and sustainable infrastructure, the conduit market is becoming more specialized. Manufacturers must apply to this transformation to offer conduits that ensure electrical systems’ integrity and longevity for years to come.

FAQ

What’s driving the growth of the electrical conduit market?

Key growth drivers include the expansion of the IT and telecommunications sector, increased construction activity, stricter safety regulations, and rising demand for smart buildings and renewable energy infrastructure. These factors are fueling demand for reliable, code-compliant conduit systems worldwide.

Why is PVC conduit considered a more environmentally friendly choice?

PVC conduit pipes are increasingly seen as a sustainable option due to their durability, corrosion resistance, and lower environmental footprint compared to metal conduits. Their manufacturing requires less energy and emits fewer greenhouse gases, and their lightweight nature reduces transportation emissions. PVC is also 100% recyclable, reducing the need for virgin materials and promoting a circular economy. Furthermore, PVC conduit systems require minimal maintenance, reducing resource consumption over their lifecycle.

What should I consider when choosing the right conduit for my project?

Important factors include:

Installation location (indoor, outdoor, buried)

Voltage and cable type

Mechanical stress exposure

Code compliance

Fire and environmental conditions

Future expansion plans

Costs and budge

Matching conduit specifications to your site requirements ensures safety, durability, and easier inspections.

How do recent NEC updates impact conduit installations?

The NEC updates introduce expanded requirements for surge protection in residential services , new provisions for Energy Management Systems (EMS) and coordination with renewable systems (solar, battery storage, EV chargers). There are also expanded requirements for outdoor emergency systems , and clarifications for branch circuit sizing, AFCI/GFCI placement , and bending space for larger conductors. These changes necessitate careful planning of conduit routing, sizing, and material selection to ensure compliance and avoid costly delays.

How is conduit used in smart buildings and automation systems?

Smart buildings require extensive low-voltage and data cabling for IoT devices, sensors, and control systems. PVC conduit is ideal for protecting these circuits while maintaining EMI isolation and code compliance in energy-efficient, automated environments.

Why is code compliance so important when selecting conduit?

Compliance with electrical codes like NEC, CEC, AS/NZS 3000, or IEC ensures safety, legality, and reliability. Code-listed conduit is tested for flame resistance, mechanical strength, and insulation. Non-compliant installations may lead to project delays, insurance issues, or safety risks.

What services should B2B buyers look for in a conduit manufacturer?

Professional buyers should seek suppliers who offer:

Certified, tested products (UL, CSA, AS/NZS, IEC)

Custom sizes, packaging, and markings

Engineering support for system design

Global logistics and inventory management

Strong after-sales service and technical documentation

What types of PVC conduit are best for underground installations?

For underground use, Schedule 40 or 80, DB2/ES2, or DB and EB conduits are typically recommended. Ensure the conduit is marked for burial use and is UV-stabilized if transitioning to above-ground exposure.

Can PVC conduit be used in high-temperature environments?

Standard PVC conduit normally used in temperature under 75°C, but it can used with 90°C wires if it is certified. For high-heat areas, look for temperature-rated or thermally modified formulations, or consider metal or specialty conduit types rated for thermal stability.

Is PVC conduit flame-retardant or fire-rated?

Standard PVC offers basic flame resistance. For enhanced safety, choose Low-Smoke Halogen-Free (LSZH) PVC or products tested to UL 94 V-0, 5VA, or IEC 61386 fire standards. These are essential for use in tunnels, transport hubs, and enclosed buildings.

Can I mix conduit types in the same installation?

Yes, but all conduits must be compatible with installation standards, conductor ratings, and grounding requirements. Transitions (e.g., from PVC to EMT) must use listed adapters or couplings and meet code.

Les références: