Table of Contents

Whether you’re a DIY enthusiast upgrading your home or a professional installer working on a new build, knowing how to run conduit through walls is essential for both aesthetics and safety. Proper conduit installation not only protects your electrical wiring from damage, moisture, and interference, but it also ensures compliance with building codes – an important factor in both residential and commercial projects.

This comprehensive guide walks you through everything you need to know about running conduit through walls, from planning to final touches. You’ll learn:

- What conduit is and why it matters in modern electrical systems

- The different types of conduit (metallic, non-metallic, rigid, flexible) and which are best for in-wall installations

- How to stay compliant with NEC and other regional electrical codes

- Step-by-step instructions for planning, measuring, drilling, and installing

- Safety precautions and tool recommendations

- How to troubleshoot tricky scenarios like corners, fire-rated walls, or retrofitting

- When to call a licensed electrician for help

- And a brief look at underground conduit runs and trusted product options like Ledes conduit systems

What Is Electrical Conduit

Electrical conduit is a protective tubing designed to route and safeguard electrical wiring. Think of it as a durable shell that shields wires from physical damage, moisture, heat, and electromagnetic interference. It also helps keep installations neat and organized, especially in environments where aesthetics and accessibility are important.

Why Electrical Conduit Matters

Proper use of conduit isn’t just about keeping things tidy, it’s about safety, longevity, and compliance:

- Fire Protection: Conduit helps contain electrical sparks or heat, reducing the risk of fire spread, especially when installed within or through flammable wall materials.

- Mechanical Protection: Wires are vulnerable to punctures, pinches, or abrasion from nails, screws, or sharp surfaces inside walls. Conduit provides a physical barrier.

- Moisture and Corrosion Resistance: In damp or outdoor environments, conduit prevents wire insulation from breaking down due to moisture or chemical exposure.

- Code Compliance: Most building codes, including the National Electrical Code (NEC), require conduit in specific situations to meet safety standards.

- Future Maintenance: Running conduit makes it easier to replace or upgrade wiring later without tearing down walls.

Why Run Conduit Through Walls?

There are several scenarios where running conduit through walls is not only practical—but often necessary:

- Aesthetic Improvements: Concealed conduit creates a clean, seamless look without visible wire clutter.

- Safety & Code Requirements: In finished spaces or multi-family units, running exposed wires may violate local code.

- Remodels & Retrofits: When upgrading or expanding circuits, routing new conduit through walls can avoid surface-mount clutter or damage to existing finishes.

- Protection in High-Traffic or Hazardous Areas: In homes, offices, garages, or workshops, wall-routed conduit shields wiring from daily wear and tear.

In short, if you’re serious about doing electrical work that’s safe, compliant, and built to last, conduit through walls is often the smartest route.

Common Types of Electrical Conduit

Choosing the right type of conduit is crucial for a successful and code-compliant installation, especially when you’re running it through walls. Not all conduit types are created equal, and some are far better suited for in-wall applications than others. In this section, we’ll break down the most common conduit types, including their material, benefits, drawbacks, and typical use cases, and highlight which are best for running through walls.

EMT (Electrical Metallic Tubing)

Material: Galvanized steel or aluminum

Also known as: Thin-wall conduit

Pros:

Lightweight but rigid

Easy to bend with the right tools

Offers good mechanical protection

Non-combustible and suitable for exposed or concealed use

Widely accepted by the NEC for in-wall installations

Cons:

Can corrode in damp environments if not properly treated

Requires cutting and threading tools

Conductive – requires grounding

Best Used For:

Commercial and residential interior walls

Indoor dry locations

Environments where fire resistance and mechanical protection are priorities

RMC (Rigid Metal Conduit)

Material: Galvanized steel or stainless steel

Heavy-wall conduit

Pros:

Extremely durable and impact-resistant

Excellent grounding path

Offers maximum protection for wiring

Suitable for hazardous and outdoor environments

Cons:

Very heavy and more difficult to install

Requires threading and special fittings

More expensive than other options

Best Used For:

Industrial facilities

Service entrances and exposed locations

Areas requiring high mechanical protection

IMC (Intermediate Metal Conduit)

Material: Coated steel

Pros:

Lighter than RMC but still strong

Cost-effective alternative to RMC

NEC-approved for both exposed and concealed (in-wall) applications

Corrosion-resistant coating

Cons:

Heavier than EMT

Requires threading

Conductive – must be grounded

Best Used For:

Commercial and industrial walls

Outdoor and wet environments (with proper fittings)

Rigid PVC Conduit

Material: Rigid plastic (Polyvinyl Chloride)

Pros:

Lightweight and easy to work with

Non-conductive (no grounding needed)

Corrosion-resistant

Inexpensive

Ideal for underground and outdoor use

Cons:

Can become brittle in cold temperatures

Not fire-resistant (must follow code restrictions in wall cavities)

Expands/contracts with temperature changes

Not suitable for use in plenum spaces unless specifically rated

Best Used For:

Underground runs (especially with Schedule 80)

Moist or corrosive environments

Some indoor walls (if allowed by code and protected from heat sources)

ENT (Electrical Nonmetallic Tubing)

Material: Corrugated plastic (usually PVC-based)

Also known as: “Smurf Tube”

Pros:

Lightweight and flexible

Easy to install without special tools

Non-metallic and corrosion-resistant

Can be installed in walls, ceilings, and floors

Approved by NEC for concealed work in dry locations

Cons:

Lower mechanical strength compared to EMT or RMC

Not suitable for exposed locations

Not fire-resistant (requires protection in fire-rated assemblies)

Best Used For:

Residential and light commercial wall installations

Dry interior locations

Tight spaces or curved routing needs

FMC (Flexible Metal Conduit)

Material: Helically wound metal strip

Pros:

Highly flexible—great for navigating bends or vibrations

Provides some mechanical protection

NEC-approved for certain concealed installations

Cons:

Not watertight unless using Liquidtight type

Limited use in long or permanent wall runs

Requires additional grounding

Can be noisy in vibrating environments

Best Used For:

Final connections to equipment

Short, flexible runs inside walls (e.g., between boxes and panels)

LFMC (Liquidtight Flexible Metal Conduit)

Material: Flexible metal with waterproof thermoplastic coating

Pros:

Water-resistant

Good flexibility and durability

Suitable for outdoor and damp environments

Some fire resistance depending on rating

Cons:

Bulkier and harder to route through tight walls

More expensive than standard FMC

Best Used For:

Outdoor or wet-area connections

Condensers, pumps, or AC units

Limited interior wall use (typically at entry/exit points)

Pro Tips: Want to learn the pros and cons of all top 10 types of electrical conduit? Click the link above to read our expert guide.

✅ Best Conduits for Running Through Walls

When it comes to running conduit through walls, the most commonly accepted and effective types include:

EMT – Ideal balance of protection, ease of use, and code compliance

IMC – A tougher alternative to EMT for industrial or outdoor wall runs

ENT – Suitable for running through walls in dry, protected environments, quick installations

PVC – Use with caution; suitable only if code allows and proper fire barriers are used

Code Requirements for Running Conduit Through Walls

Before grabbing your tools, it’s critical to understand the electrical code requirements that govern conduit installations through walls. These codes aren’t just formalities, they exist to ensure safety, fire prevention, mechanical protection, and long-term system performance. Whether you’re doing a DIY home upgrade or working on a commercial job site, compliance with the National Electrical Code (NEC) and local building codes is a must.

NEC Rules for Concealed Conduit Runs

The National Electrical Code (NEC) lays out the general rules for installing conduit in walls. Here are some key takeaways:

1. Secure Support & Spacing Requirements

Conduit must be securely fastened within 3 feet (0.91 m) of each electrical box and at regular intervals along its run.

For most conduit types (like EMT or PVC), support spacing is typically every 10 feet or less—refer to specific code tables per conduit type.

2. Protection Against Physical Damage

If conduit passes through wood or metal studs, protection plates (nail guards) are often required to prevent screw or nail penetration.

The NEC typically requires 1¼ inches of space from the edge of framing members for embedded conduit—otherwise, a protective plate must be installed.

3. Fire-Rated Assemblies & Firestopping

If you’re running conduit through fire-rated walls or floors (common in multi-family, commercial, or apartment buildings), you must use approved firestop materials to restore the wall’s fire resistance rating.

The firestop system must be UL-listed or approved by local code authorities.

4. Conduit Fill Limits

When running multiple wires through a single conduit, you must follow conduit fill tables in the NEC (Annex C or Chapter 9, Table 1).

Overfilling a conduit can cause overheating, insulation damage, or failed inspections.

5. Bends and Pulling Rules

The total angle of bends between pull points (boxes, fittings, etc.) must not exceed 360 degrees.

A conduit that runs through a wall cavity with multiple turns must still comply with this limit.

6. Grounding and Bonding Requirements

For metallic conduit systems (e.g., EMT, RMC, IMC, FMC):

Grounding is required. The metal conduit can serve as a grounding path, but all fittings must be tight and secure to maintain electrical continuity.

Bonding jumpers may be required across couplings or boxes where continuity might be broken.

7. Conduit Temperature Ratings

Each type of conduit and wiring must be rated for the expected temperature:

Conductors must not exceed the temperature rating of the conduit system or fittings.

Be especially cautious when running conduit through areas like attics, crawlspaces, or near heating ducts.

8. Expansion and Contraction Considerations

For PVC conduit, especially when run through long spans or between temperature-variable areas (e.g., from a cold wall cavity into a heated room):

Expansion fittings must be installed to account for thermal movement.

Anchoring both ends without allowing for movement can cause warping or joint failure.

9. Use in Plenum Spaces

When running conduit through walls that connect to plenum spaces (e.g., air-handling spaces above ceilings or below floors), the materials used must meet plenum-rated fire and smoke standards.

PVC and ENT are not permitted in plenum spaces unless they are specifically listed for such use.

Metallic conduit is generally acceptable in these areas.

Tips: Click here to read the ultimate guide to NEC code 2025 to ensure your wiring installation is correct.

Local Code Considerations

While the NEC provides a national baseline, local jurisdictions may have their own rules. Common local requirements include:

- Special firestopping materials approved by the Authority Having Jurisdiction (AHJ)

- Restrictions on plastic conduit in certain buildings

- Required permits and inspections for in-wall electrical work

Always check with your local building department before starting a project. A simple call or online inquiry can prevent costly rework later.

Canadian Electrical Code (CEC)

The CEC, used across Canada, is closely aligned with the NEC in many ways, here are some key and common requirements for conduits run through walls;

- Conduit support spacing and secure mounting are required (e.g., EMT must be supported at intervals not exceeding 1.5 m).

- Conduit must be protected from physical damage when passing through wood or metal framing.

- Conduit fill, bending radius, and maximum bend angles must comply with specific limits (e.g., total bends not exceeding 360° between pull points).

- Fire stopping is required when conduit penetrates fire-rated walls, floors, or ceilings.

Pro Tips: Looking to start your electrical distribution business in Canada? Take some time to review the latest CEC guidance to ensure your products and business expand smoothly in Canada.

AS/NZS 3000 (Australian/New Zealand Wiring Rules)

If your audience includes Australian readers, the AS/NZS 3000 standard (also known as the Wiring Rules) includes some guidance for conduit in walls:

- Conduit passing through walls must be installed in a way that maintains mechanical protection and fire barriers.

- Metal or plastic conduit must not compromise the integrity of fire-rated construction.

- Boxes and fittings must remain accessible, unless the conduit terminates at a fixed appliance.

Notes: Not knowledgeable with AS/NZS 3000? No problem! Simply read our expert guide to AS/NZS 3000 to quickly train yourself with the electrical code and improve your business’s performance in Australia.

Pre-Installation Planning & Safety Protocols

Before cutting into walls or feeding conduit through tight spaces, it’s critical to approach the job with a well-thought-out plan, and a firm focus on safety. Skipping these steps can lead to damaged walls, failed inspections, or even serious injury.

1. Understand Your Walls

Running conduit through a wall starts with understanding the wall structure itself. Different wall types require different techniques, tools, and precautions.

• Stud Walls (Wood or Metal Framing)

Most common in residential and light commercial buildings.

Conduit is typically routed between studs, either vertically (floor to ceiling) or horizontally (between outlets/switches).

Use a stud finder to map framing and avoid drilling into structural or load-bearing members unless allowed.

You must keep conduit at least 1¼ inches away from the surface to prevent drywall screws or nails from puncturing it, use protection plates if needed.

• Masonry or Concrete Walls

Common in basements, commercial buildings, or older homes.

Surface-mounted conduit (e.g., EMT or PVC) is typically used unless chases are built into the wall.

Use hammer drills with masonry bits for any penetration, and ensure all fasteners are designed for concrete anchoring.

Identifying Hidden Obstructions

Use wall scanners or multi-sensor stud finders that can detect:

Water or gas pipes

Electrical cables

HVAC ducts

Reinforcing bars in concrete (rebar)

Mark all detected obstacles clearly before drilling. Damaging pipes or live wires can lead to injury, costly repairs, or both.

2. Electrical Code Compliance: Know Before You Drill

Electrical codes like the NEC (U.S.), CEC (Canada), and others exist for your safety, and failing to follow them can mean rework, fines, or dangerous installations.

• Key Code Considerations

Conduit Fill: Use conductor fill tables to avoid overheating. Don’t overcrowd conduit.

Bend Radius & Limitations: Total bends between pull points must not exceed 360°.

Support Spacing: Follow the code requirements for support distance.

Bonding & Grounding: Metallic conduit must be properly bonded to ensure electrical continuity.

Firestop & Sealing: Any penetrations through fire-rated walls require approved firestop sealants or gaskets.

• Permits & Inspections

Many jurisdictions require permits for in-wall conduit runs, especially if:

You’re adding new circuits.

Running conduit through fire-rated or load-bearing walls.

Always check with your local AHJ (Authority Having Jurisdiction) for inspection timelines and documentation requirements.

3. Safety First: It’s Not Optional

Electrical work is dangerous when shortcuts are taken. Protecting yourself and your space should always be the first priority.

• Power Shutdown & Verification

Always turn off power at the breaker panel before any electrical work.

Use a non-contact voltage tester or multimeter to verify the power is off at the work area.

If working near other circuits, de-energize those too when possible.

• Personal Protective Equipment (PPE)

Safety glasses to protect from dust, flying debris, or wire strands.

Insulated gloves when handling wire or working near panels.

Dust masks if cutting drywall, especially in enclosed spaces.

• Ladder Safety

Use ladders on stable surfaces only—never overreach.

Maintain three points of contact (two hands and one foot, or two feet and one hand).

Don’t place ladders near energized equipment.

❗ Avoid These Common Hazards:

Drilling blindly through walls—always inspect first.

Working in damp areas without GFCI protection.

Overloading a conduit with too many bends or conductors.

4. Mapping Out Your Conduit Run

A well-planned route saves time, reduces the need for couplings or fittings, and makes future maintenance easier.

• Plan the Most Efficient Path

Choose wall cavities that align with the desired outlet or box locations.

Avoid load-bearing studs or post-tension cables (especially in concrete walls).

• Consider Future Access

Use pull boxes in longer runs or where changes may be needed later.

Keep conduit slightly oversized to allow for future wiring changes.

• Mark and Measure

Use a level and chalk line to mark horizontal or vertical conduit paths.

Clearly mark cutouts for outlet boxes or junctions before cutting into the wall.

Measure twice, drill once.

Tools & Materials Checklist

Here’s a basic list to get started:

Category | Examples |

Conduit Types | EMT, PVC, IMC, ENT (as appropriate) |

Inspection Tools | Stud finder, multi-scanner, voltage tester |

Cutting Tools | Hole saws, spade bits, hammer drill (for masonry) |

Fishing Tools | Fish tape, glow rods, string with vacuum assist |

Layout Tools | Tape measure, level, chalk line |

PPE | Gloves, goggles, dust mask, ear protection |

Ladders | Fiberglass ladders preferred near electrical work |

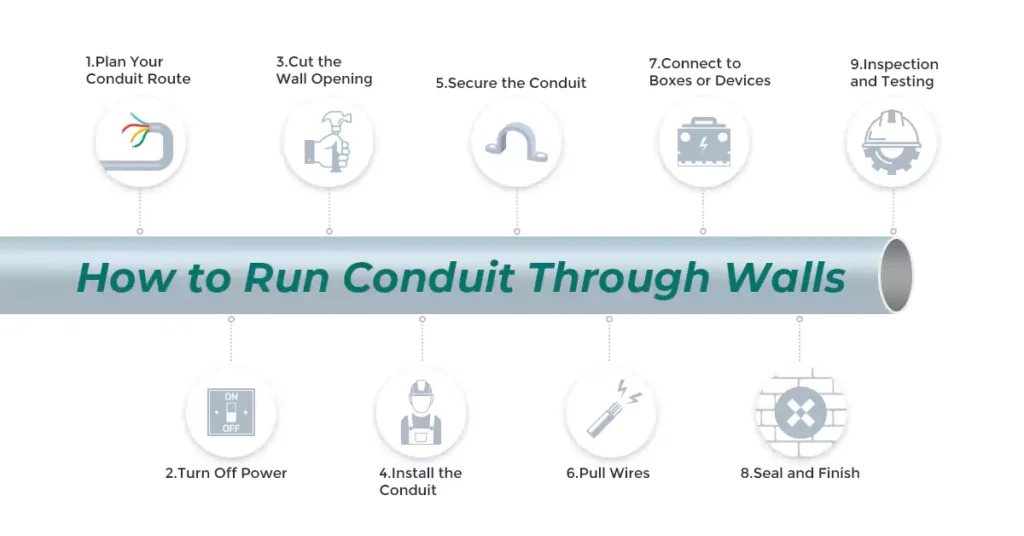

How to Run Conduit Through Walls – Step-by-Step Guide

Running conduit through a wall, whether it’s interior drywall or an exterior surface, requires precision, planning, and code-compliant installation. Below is a general step-by-step guide to help you safely and correctly complete the task.

Step 1: Plan Your Conduit Route

- Mark the entry and exit points where the conduit will pass through the wall.

- Check for obstructions inside the wall (pipes, studs, existing wires) using a stud finder or inspection camera.

- Choose the appropriate conduit type:

PVC or EMT for indoor, concealed wall runs.

Liquid-tight or flexible metal conduit (FMC) if flexibility is needed in tight spots.

- Select the correct conduit size, ensuring it meets the fill capacity for the number and gauge of conductors.

Step 2: Turn Off Power

Before any cutting or wiring begins:

Shut off the power at the breaker panel to avoid shock hazards.

Use a non-contact voltage tester to confirm circuits are de-energized.

Step 3: Cut the Wall Opening

For drywall or wood: Use a hole saw or spade bit to bore a hole slightly larger than the conduit diameter.

For masonry or concrete: Use a hammer drill with a masonry bit. For larger holes, use a core drill.

Ensure the hole is:

Neat and clean.

Sized correctly for the conduit plus any required bushing or sleeve.

Note: If fire-resistance rating of the wall must be preserved, use firestop systems or fire-rated sleeves as required by building/fire codes.

Step 4: Install the Conduit

Measure and cut the conduit to length using a hacksaw (PVC) or tubing cutter (EMT).

Deburr sharp edges using a deburring tool or file.

Dry fit the sections first to ensure alignment.

Run the conduit through the hole, from one side to the other.

- Through Wood or Drywall:

You can run conduit directly through the hole.

Use a plastic bushing or connector to protect the cable from abrasion at entry/exit points.

- Through Concrete or Brick:

Consider using a sleeve (e.g., larger diameter PVC) and sealing the space with non-shrinking grout or urethane sealant.

Seal both ends if exposed to moisture.

Step 5: Secure the Conduit

Use conduit straps or clamps to anchor the conduit within code-required intervals (e.g., within 3 ft of each box, and every 10 ft for PVC per NEC 352.30).

Ensure the conduit is level, flush, and not under tension.

Step 6: Pull Wires

Use fish tape or a pull string to guide wires through the conduit.

Apply wire-pulling lubricant if needed, especially for long runs or bends.

Don’t exceed conduit fill capacity (refer to NEC Chapter 9, Table 1, or CEC Section 12).

Step 7: Connect to Boxes or Devices

Securely attach the conduit to the outlet box, junction box, or enclosure using the correct adapter or connector (e.g., male terminal adapter, compression fitting).

Ensure continuity of grounding if using metal conduit like EMT.

Step 8: Seal and Finish

Use caulk or sealant (fire-rated if needed) around conduit penetrations in fire-rated walls.

For exterior walls, use weatherproof fittings and sealants to prevent water intrusion.

If the conduit passes through an air barrier or vapor barrier, use appropriate sealants or sleeves to maintain envelope integrity.

Step 9: Inspection and Testing

If required, call for electrical inspection before energizing.

Test continuity, polarity, and insulation resistance after wiring.

Common Mistakes & Maintenance Tips

Even with a solid plan, small oversights can cause major headaches, either immediately or years down the road. Knowing the most frequent mistakes and how to prevent them can save you from failed inspections, costly repairs, or unsafe conditions. And once your conduit is installed, basic maintenance keeps it safe and functional for decades.

7 Common Mistakes Need to Avoid

1. Ignoring Electrical Code Requirements

Overfilled conduit, unsupported runs, or excessive bends will fail inspection and make pulling wire nearly impossible.

2. Choosing the Wrong Conduit Type

Using flexible conduit inside a wall cavity where code requires rigid metallic or nonmetallic conduit.

Using indoor-rated PVC for an exterior wall penetration, leading to UV damage and brittleness.

3. Skipping Deburring

Sharp conduit edges can slice insulation during wire pulls, creating hidden faults.

Always smooth cut ends with a file or deburring tool.

4. Poor Sealing at Penetrations

Gaps around conduit where it passes through a wall can allow pests, moisture, or air leaks.

In fire-rated assemblies, failing to use firestop sealants is both unsafe and a code violation.

5. Improper Grounding or Bonding

Metallic conduit that isn’t bonded properly can become energized in a fault condition, posing shock hazards.

6. Routing Through Load-Bearing Structural Elements

Cutting large holes in studs, joists, or beams without reinforcing them can compromise structural integrity.

Always follow building code clearance and boring limitations.

7. Not Labeling Circuits

Skipping wire labeling makes future maintenance and troubleshooting far more difficult.

5 Maintenance Tips for Long-Term Reliability

Unlike exposed cable, conduit systems can last decades if installed and maintained correctly. Here’s how to keep them in top shape:

1. Schedule Periodic Inspections

Every few years, check for:

Loose conduit straps or supports.

Corrosion on metal conduit.

Cracks or brittleness in PVC.

Moisture accumulation in boxes or fittings.

2. Protect Against Corrosion

For EMT or rigid metallic conduit in damp locations, apply anti-corrosion coatings or use stainless steel fittings.

Seal exterior penetrations with weatherproof caulking.

3. Check Seals and Firestopping

Inspect firestop materials for deterioration and replace as needed to maintain wall ratings.

4. Monitor for Wire Movement

In areas with vibration (near HVAC or machinery), ensure conduit fittings remain tight and locknuts are secure.

5. Keep Documentation

Maintain a record of:

Conduit routes.

Circuit numbers.

Pull box and junction box locations.

This makes any future upgrades or troubleshooting easier.

When to Call a Professional

Running conduit through walls can be a manageable project for experienced DIYers, but there are situations where calling a licensed electrician is the safer, faster, and more cost-effective option. Knowing your limits can protect you from electrical hazards, failed inspections, and costly mistakes.

1. Lack of Code Knowledge

If you’re not fully familiar with your local electrical code (NEC in the U.S., CEC in Canada, or other regional standards), you risk non-compliance. Code violations can:

Delay your project during inspection.

Create hidden safety hazards.

Require expensive rework.

2. Service Panel Work

Any work involving:

Installing new breakers.

Expanding service capacity.

Modifying the main service entrance.

These are high-risk tasks that require proper training and certification.

3. Running Conduit in Fire-Rated Walls or Ceilings

These installations demand special materials and sealing methods to maintain the fire-resistance rating. Professionals know the exact firestop products and procedures required.

4. Working in Hazardous or Specialized Environments

Such as:

Wet locations (pools, outdoor, basements prone to flooding).

Explosive or flammable atmospheres (workshops, fuel storage areas).

These require specific conduit types, fittings, and sealing techniques.

5. Complicated Routing Through Finished Walls

If conduit must pass through multiple floors, tight spaces, or around structural elements, a pro can save you from unnecessary demolition or damage.

6. Upgrading or Integrating with Old Wiring

Old wiring may have degraded insulation, hidden splices, or outdated grounding. A professional can safely test, replace, or integrate it into a new conduit system.

7. When Permits & Inspections Are Mandatory

In many jurisdictions, permits for certain conduit runs require work by a licensed electrician to pass inspection.

How to Run Conduit Underground

Underground conduit runs are common when you need to bring power to detached garages, sheds, outdoor lighting, or other structures away from your main building. While similar in principle to in-wall conduit runs, underground installations come with their own set of materials, tools, and code requirements to ensure long-term durability and safety.

What to Know Before Installation

A. Choosing the Right Conduit for Underground Use

Not all conduit types are designed to withstand soil contact and moisture exposure. Common code-approved choices include:

PVC Schedule 40 or 80 (Rigid Nonmetallic Conduit)

Direct Burial PVC Conduit, such as DB conduits and EB conduit for concrete encasement

Rigid Metal Conduit

B. Code-Required Burial Depths

The National Electrical Code sets minimum cover requirements (in inches), but always confirm with your local authority since rules may vary.

Step-by-Step: Running Conduit Underground

1. Plan the Route

Choose the most direct path to minimize bends and fittings.

Mark both ends and intermediate waypoints with stakes or spray paint.

2. Check for Utilities

Call your local “call before you dig” hotline (e.g., 811 in the U.S.) to locate underground gas, water, and communication lines.

3. Dig the Trench

Use a trenching shovel or rental trenching machine.

Maintain consistent depth according to code.

Avoid sharp corners — underground bends should be gradual.

4. Lay the Conduit

Dry-fit all sections first.

For PVC, apply primer and solvent cement at each joint.

For RMC, thread and tighten with approved fittings.

5. Install Pull Strings

Before backfilling, run a fish tape through the conduit and leave a pull string for later wire installation.

6. Backfill Properly

Place 4–6 inches of sand or fine soil over conduit to protect it from rocks.

Backfill with excavated soil, tamping gently to prevent settling.

7. Pull the Conductors

Use wire rated for wet locations (e.g., THWN-2).

Apply wire-pulling lubricant for long runs.

Ledes Electrical Conduit Solutions

When seeking high-quality, versatile, and code-compliant conduit systems, Ledes stands out as a globally recognized manufacturer. With over 16 years of experience, Ledes has earned a reputation for delivering premium PVC conduit and fittings across diverse sectors—from residential and commercial construction to renewable energy and infrastructure projects

Why Choose Ledes?

- Global Certifications & Standards: Ledes products meet UL, ASTM, CSA, ETL, AS/NZS 2053, IEC, CE, RoHS, and ISO standards, ensuring compliance for a wide range of projects and regions.

- Extensive Product Range: Whether you need rigid or corrugated conduit, flexible ENT, low-smoke halogen-free (LSZH), direct burial ducts, solar-grade conduit, or comprehensive fitting lines, Ledes has you covered.

- Custom Solutions: Ledes offers tailored conduit systems for unique applications, helping streamline project delivery and meet specific installation requirements.

- Proven Quality: UL 651-rated Schedule 40 and 80 conduit from Ledes supports 90 °C wiring, ideal for high-demand applications like EV charging, data centers, and smart buildings.

- Competitive Pricing & Support: With wholesale pricing, direct factory supply, and responsive customer service, Ledes aims to offer efficiency and value, especially for large-scale builds.

Ledes Product Series Highlights

- UL & CSA Conduit Series

Includes rigid PVC conduit (Schedule 40/80), ENT tubing, and direct burial duct options, all meeting North American standards. Ideal for both indoor and underground applications.

- LSZH (Low Smoke Zero Halogen) Series

Designed for maximum safety in fire-prone or sensitive environments (e.g., hospitals, tunnels, schools). Features UL 94 V-0 fire rating, UV resistance, and LSZH conduit production—prioritizing occupant safety and environmental compliance.

- Solar & Outdoor Conduit Series

Built for harsh exterior conditions and solar installations, these solar conduits conform to AS/NZS 2053 and IEC standards, offering UV resistance and durable outdoor performance.

- AS/NZS 2053 PVC Conduit Series

Designed specifically for Australian and New Zealand markets.

Includes rigid and corrugated PVC conduit and fittings certified under AS/NZS 2053 and IEC standards.

Includes a tailored LSZH (Low Smoke Zero Halogen) line suitable for safer, greener builds in Australia.

Conclusion

Running conduit through walls isn’t just about hiding wires, it’s about building safety, durability, and compliance into your electrical system from the start. Whether you’re installing a single outlet or wiring an entire property, following best practices ensures your work stands the test of time.

From understanding conduit types and meeting electrical codes to careful pre-installation planning, safety checks, and precise execution, every step matters. Avoiding common mistakes, and knowing when to call an expert can mean the difference between a smooth inspection and a costly redo.

The bottom line: take the time to plan, use the right materials, and never cut corners on safety or compliance. Do it once, do it right, and your conduit installation will deliver safe, clean, and code-compliant wiring for years to come.

FAQs

Can you run conduit through walls?

Yes. You can run conduit through most wall types as long as you follow your local electrical code. The key is choosing the right conduit type, securing it properly, and maintaining the correct bend radius so wires can be pulled easily. Fire-rated walls require special sealing methods to keep their rating intact.

Can you run PVC conduit inside walls?

Yes, rigid PVC conduit can be used inside walls if it’s listed for that purpose. Schedule 40 PVC is common indoors, while Schedule 80 offers more impact resistance. Remember to use PVC cement for secure joints and follow firestop rules when passing through rated walls.

How to bring conduit through drywall?

Mark your opening, cut it neatly with a hole saw or drywall saw, and install a bushing or connector where the conduit exits. Always check the wall with a stud finder first to avoid pipes or existing wires.

Can you run conduit in residential buildings?

Yes. While Romex (NM cable) is often used in homes, conduit offers better mechanical protection and makes rewiring easier later. It’s especially useful in garages, basements, and areas exposed to potential damage.

How to seal conduit through a wall?

Use an appropriate sealant or firestop material, depending on the wall type:

Exterior walls: silicone, polyurethane, or foam sealant.

Fire-rated walls: firestop putty or intumescent sealant.

How to hold conduit to a wall?

Use metal or plastic conduit straps and clamps spaced according to code. Choose anchors that match your wall type, masonry screws for brick, wood screws for studs, or toggle bolts for drywall.

How to install conduit inside a wall?

Plan the route, drill holes through studs or plates, and secure the conduit with straps or staples before closing up the wall. Avoid drilling through load-bearing beams unless approved by a structural engineer.

Can flexible conduit be used in walls?

Some flexible conduit types, such as FMC (Flexible Metal Conduit) or ENT (“smurf tube”), are allowed in walls. Others, like certain non-metallic flex hoses, may only be approved for exposed locations, always check local code.

How to find conduit in walls?

Use a stud finder with AC detection, a borescope inspection camera, or a cable tracer. Avoid drilling until you’re certain where the conduit runs.

How long will PVC conduit last?

When installed indoors and away from UV light, PVC conduit can last decades, often 50 years or more. Outdoor runs should be UV-rated or painted for protection.

Does conduit have to run underground?

No. Conduit can be run above ground, inside walls, or underground. Underground runs require rated conduits or watertight conduit types like PVC, RMC and DB conduits and must be buried at the correct depth.

Can you run conduit through a firewall?

Yes, but any hole through a fire-rated wall must be sealed with an approved firestop system to maintain its fire-resistance rating.

Is surface wiring legal?

Yes, if the wiring is in approved conduit or armored cable and installed to code. Many workshops and utility rooms use surface-mounted conduit.

How to trace conduit wiring through concrete walls?

A signal tone generator with a tracer probe or a professional pipe-and-cable locator can detect conduit paths inside concrete.

Can you run wires without a conduit?

In some residential cases, yes (e.g., NM cable in open stud bays). But in areas exposed to damage, moisture, or where required by code, conduit is mandatory.

Can I run a low-voltage wire through a PVC pipe?

Yes, you can run low-voltage cables (Ethernet, speaker wire, etc.) through PVC conduit. Keep them separate from high-voltage circuits unless rated for the same enclosure.