目录

NEC 代码是什么?

美国国家电气规范 (NEC) 是美国安全电气设计、安装和检验的基准标准。它几乎是所有住宅、商业和工业领域电气法规的基础。无论您是为新住宅布线、安装工业电机,还是为太阳能电池阵列铺设导线管,NEC 都制定了相关规则,旨在保护人员和财产免受电气危害。

NEC 正式名称为 NFPA 70,由致力于降低火灾和电气风险的非营利组织美国国家消防协会 (NFPA) 发布。该规范于 1897 年首次发布,并随着电气系统的进步而不断发展,每次更新都变得更加全面。

为了确保 NEC 能够反映现代技术和安全实践,NEC 每三年由专家小组进行修订,专家小组成员包括电工、工程师、检查员、制造商、公用事业代表和安全倡导者。最新版本已被各州和地方司法管辖区采用,这使得 NEC 成为美国大多数地区具有法律效力的标准。

NEC 的范围广泛但定义明确。它涵盖:

- 电导体和设备的安装

- 布线方法,包括电线管和线槽

- 针对不同环境和占用情况的特殊考虑

简而言之,NEC 规定了如何安装电气系统以确保安全和合规。

专业提示: 想快速了解 PVC 导管的 NEC 规范要求?点击此处获取 专家对 PVC 导管 NEC 代码的见解。

NEC 代码的目的和含义

国家电气规范 (NEC) 的核心在于保障安全。其主要目标是保护人员和财产免受触电、火灾、电弧闪光和设备故障等电气危害。NEC 通过为各种场所(从家庭、学校到工厂和发电厂)的电气系统安全安装设定最低要求来实现这一目标。

NEC 的宗旨

NEC 并非旨在过度监管,而是旨在制定最低安全标准。它确保所有持证电工和检查员,无论所在地区或项目类型,都遵守相同的基本规则。通过遵守这些标准,电气专业人员可以降低灾难性事故的风险,并确保系统的长期可靠性。

虽然 NEC 乍一看似乎很复杂,但其结构是有条理的,其目的也很明确:

“切实保障人身和财产安全,避免因使用电力而产生的危害。”(NEC 第 90.1 条)

这份声明概括了 NEC 的使命。无论您是安装导管、设置配电盘,还是连接照明电路,NEC 都能提供清晰的框架,确保安全操作。

理解代码语言

NEC 使用具有法律和技术意义的特定措辞。理解这些措辞是正确应用该准则的关键:

“将” = 强制性的。必须遵守的要求。

“应该” = 推荐。不可强制执行,但被视为最佳实践。

“可能”或“允许” = 在限制范围内可选或允许。

例如,“导管应在每个出线盒 3 英尺范围内得到支撑”意味着该间距是要求,而不是建议。

NEC——一份动态文件

NEC 每三年更新一次,以反映新技术、改进材料、安全发现和行业最佳实践。每个版本都会根据实际反馈和创新进行调整,例如:

- 整合 太阳能光伏(PV)系统

- 规则 电动汽车充电站

- 标准 低压和智能系统

由于这种持续发展,NEC 已不再只是一本静态的规则手册。它是一份充满活力、不断发展的文件,能够适应现代需求,同时始终牢记其使命:保障人民安全。

重要的是要记住,NEC 设定 最低可接受标准在许多情况下,最佳实践或工程规范可能会超出这些要求,以增加安全性、寿命或性能,特别是在关键设施或恶劣环境中。

NEC 法规的关键部分

国家电气规范 (NEC) 分为若干条款,每一条都侧重于电气系统的特定方面。NEC 内容广泛,涵盖数百页内容和众多规则,但一些核心章节几乎涵盖所有项目或安装类型。了解这些关键条款,为遵守规范和安全的电气设计奠定坚实的基础。

第一章 - 电气装置的一般要求

《国家电气规范》(NEC)第1章构成了整个规范的结构和定义支柱。该章包含第100条和第110条,定义了关键术语并规定了所有电气系统的基本安装要求。这些一般规定适用于住宅、商业、工业和特殊用途的安装。

第110条规定了所有电气设备和安装条件的一般要求。该要求涵盖机械完整性、额定电压、环境适用性、可及性和间隙等关键领域。一些关键要点包括:

修改和可用故障电流

其中最重要的更新来自 第 110.24(B) 条,直接解决系统修改:

如果对电气装置进行的更改影响了服务中可用的故障电流,则需要执行以下操作:

- 必须验证或重新计算可用的故障电流。

- 服务设备必须具有适当的额定值,以处理其线路端子上更新的故障电流。

- 必须更新现场标记以反映新的可用故障电流(某些情况下不需要,请查看第 110.24 条)。

这是一项安全关键规则,旨在确保设备额定值与不断变化的负载和故障条件保持一致。如果系统短路电流增加,而配电盘未更新或重新贴标,则发生灾难性故障的风险会增加。

间隙和工作空间

该规范规定了配电盘和设备周围的最小工作空间尺寸:

- 面板前方至少需要 3 英尺的深度(取决于电压)。

- 工作空间必须整洁、方便、且光线充足。

- 任何管道或外来系统不得侵入该区域。

这些间隙确保人员的安全操作和维护。

标签和识别

断开装置必须有清晰的标记。

设备必须带有标明其电压、电流、瓦数或其他额定值的标记。

必要时,现场应用的危险标记必须耐用、可见且永久。

环境评级

设备必须适合其安装环境。例如:

室内设备不能安装在室外,除非它符合 NEMA 室外使用标准。

在潮湿的地方,必须使用防风雨外壳和导管配件。

根据位置不同,导管和配件应具有耐腐蚀、耐紫外线辐射和耐温度变化的能力。

第 2 章 - 接线和保护

美国国家电气规范 (NEC) 第 2 章是电气安全领域最重要的章节之一。它全面阐述了正确识别、布置和保护电导体和电路的要求。本章的主要目标是确保所有布线系统不仅能够正常使用,还能避免触电、过热、火灾和短路等危险。

关于分支电路

第210条 - 交流电不超过1000伏,直流电不超过1500伏的电路

电压和导体识别的一般规则: 对于 60 伏以上的直流分支电路,必须使用经批准的方式(例如红色或黑色外饰面或永久性标签)清楚地标记导体的极性。

GFCI保护要求: 许多易受潮或与水接触的场所的插座必须配备 GFCI(接地故障断路器)保护。这些场所包括厨房、浴室、屋顶、地下室、洗衣区和工业水生环境。此外,也列出了一些特殊情况的例外情况,例如工业实验室、融雪系统或医疗保健设施。

直流系统的分支电路: 导体必须在所有端接、连接和接头处进行标记,并特别考虑尺寸(4 AWG 以上或以下)和极性标记。

第235条 — 1000伏以上分支电路

第235条是对第210条的补充,适用于交流电超过1000伏或直流电超过1500伏的电路。与第210.3条类似,第235条包含一个表235.3,其中列出了适用附加保护要求的特定设备(例如,电机、母线槽、暖通空调系统)。

监督安装

在高压环境中,分支电路导体的尺寸可在工程专业人员的指导下确定。监督安装必须满足以下两项要求:

- 在工程监督下进行设计和安装。

- 维护和服务由经过培训并具有高压系统经验的人员执行。

这项规定有助于简化先进系统,同时确保只有合格的专业人员负责其设计和维护。

过流保护

过流保护对于防止过载、短路和接地故障造成的损坏至关重要。NEC 第 240 条概述了详细的规定,包括:

保护装置和可访问性

断路器和熔断器开关必须易于接近,手柄高度不得超过 2.0 米(6 英尺 7 英寸),除非有特殊例外情况(例如,母线槽、危险外壳或允许便携式接近的地方)。

多线分支电路

对于服务于单相、线对中性负载的多线电路,允许使用带有手柄的单独单极断路器来保护每个未接地的导体,确保同时断开。

抽头导体

无限长度的外部分接头 (240.21(B)(5)):NEC 允许无限长度的外部分接头导体,前提是它们满足严格的条件,包括防止物理损坏、终止于单个过流装置以及将断开装置放置在最靠近导体入口的易于接近的位置。

不可互换的保险丝

S 型保险丝的设计旨在防止与额定值较低的保险丝互换,通过确保仅安装额定值适当的保险丝来提高系统安全性。

变压器二次导体保护

变压器次级导体的过流保护取决于变压器的配置。某些配置,例如单相两线或三线三角形接线,可以通过一次侧过流保护器 (OCPD) 进行保护,前提是满足 450.3 中的条件和载流量限制。

翻新设备

特定的过流保护装置(例如低压电源断路器和机电继电器)可以进行翻新,但必须将其列为翻新装置并进行相应标记,以符合 110.21(A)(2) 的规定。

过压保护

过压保护对于保护电气系统免受瞬态电压浪涌(例如雷击、公用设施切换或内部系统故障引起的电压浪涌)的影响至关重要。NEC 第 2 章第 242 条对过压保护进行了规定,其中规定了浪涌保护装置 (SPD) 和浪涌保护器的一般要求和安装要求。

第 242 条涵盖低压和高压电涌保护:

- 第二部分规定了永久安装在不超过 1000 伏(标称)的场所布线系统中的 SPD。

- 第三部分讨论了安装在超过 1000 伏(标称)的场所系统上的浪涌保护器。

SPD 和浪涌保护器的要求

不允许修复(242.2): 为确保可靠性和安全性,SPD 和浪涌保护器不允许进行翻新。必须始终按照原始制造和列出的标准使用。

接地要求(242.32): SPD 接地连接必须符合第 250 条第 III 部分的规定,确保与接地电极系统正确连接。接地电极导体在金属外壳内运行时,必须符合 250.64(E) 中概述的具体条件,例如正确连接和防止物理损坏。

组件 SPD 的制造商安装 (242.18): 4 类 SPD 和其他组件型浪涌保护器不适用于现场安装。它们必须由原始设备制造商安装,因为这些设备集成在设备中,而非独立的现场安装产品。

接地和接合

接地和连接是电气系统安全可靠运行的基础。NEC 第 2 章(特别是第 250 条)规定了性能和规范要求,以确保电气系统的接地和连接能够保护人员和财产免受触电、火灾和设备损坏。

目的和一般要求

接地和接合的总体目标是:

限制电压 因雷击、线路浪涌或意外接触高压线路而造成的电压波动。

稳定电压 正常运行期间接地。

建立低阻抗路径 以便于接地故障时过流保护装置的操作。

五大绩效要求

- 电气系统接地: 接地系统必须以限制电压浪涌并稳定电压的方式连接到地面。NEC 强调尽量缩短接地电极导体的长度,并避免不必要的弯曲或环路。

- 电气设备接地: 非载流导电部件(例如金属外壳)必须接地以限制这些材料上的电压。

- 电气设备粘合: 所有包含导体的导电部件必须连接在一起并连接到供电系统接地,以形成连续、有效的故障电流路径。

- 导电材料与其他设备的粘合: 可能带电的导电材料(例如管道、结构钢)必须与接地系统连接。

- 有效接地故障电流路径: 接地导体和连接导体必须形成连续的低阻抗电路,才能安全承载故障电流。需要注意的是,大地并非有效的接地故障电流路径。

交流电系统的接地要求

根据系统电压和配置,大多数交流电系统都需要接地:

低于50V的系统 如果出现以下情况,必须接地:

由一次系统对地电压超过 150V 的变压器供电。

系统未接地。

作为架空导线安装在室外。

50V至1000V之间的系统 如果出现以下情况,必须接地:

任何导体对地电压超过150V。

该系统为三相四线星形连接系统,使用中性线作为电路导体。

该系统为三相四线三角形连接,以中点作为电路导体。

不符合这些条件的系统可能被允许不接地运行,但仍必须符合相关的 NEC 安全和维护标准。

特殊接地注意事项

阻抗接地系统: 这些必须遵循 250.36 或 250.187 中的具体要求,使用电阻器或电抗器限制故障电流。

户外变压器: 当变压器位于室外时,变压器或另一个室外位置至少需要一个额外的接地电极连接 - 阻抗接地系统除外。

单独派生系统: 这些系统(例如变压器)需要自己的接地电极连接,并且必须遵循有关接地和导体尺寸的详细规则。

接地电极系统: 所有现有的接地电极必须粘合在一起以形成接地电极系统,包括棒、板、混凝土包裹电极和建筑钢材。

服务担保: 服务导体的金属外壳和线槽必须粘合在一起,以提供返回电源的连续路径。

第 3 章 - 接线方法和材料

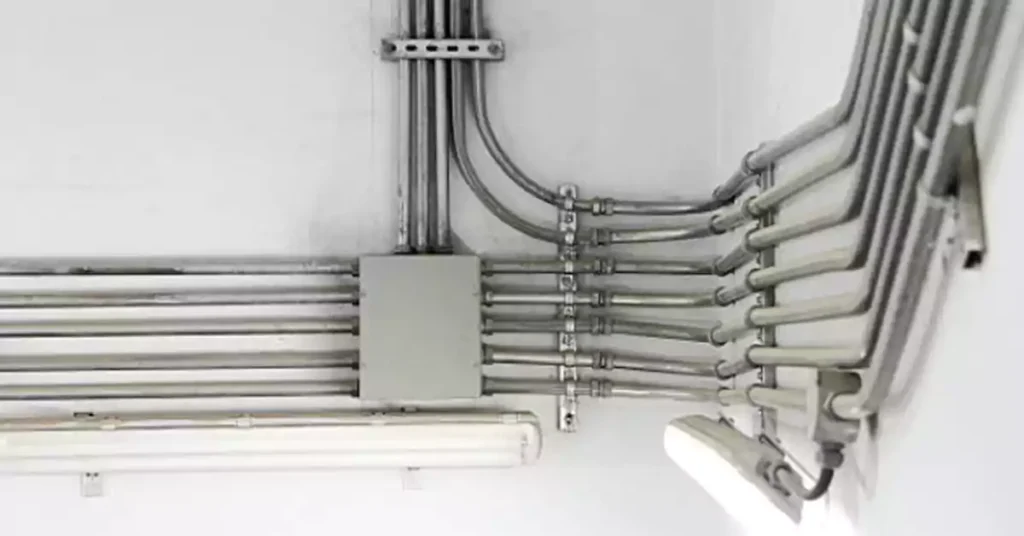

NEC 第 3 章阐述了如何布线、支撑和保护电导体,以及在不同条件下允许使用哪些类型的电缆、线槽和外壳。该章根据电压等级、位置(室内或室外)、环境暴露、机械防护等因素,为布线系统设定了技术和安装标准。

第300条为NEC中的所有布线方法提供了基本规则,除非另有更具体的条款进行修改。该条款适用于线槽、电缆组件、外壳、接线盒和导线安装。本条款强调安全性、可达性、耐用性以及与其他系统的适当隔离。以下是本章的一些关键方面:

主要条款

- 机械保护: 必须保护导线和电缆免受物理损坏。例如,当导线和电缆穿过金属螺柱或框架时,必须使用套管或护环。

- 与其他系统的间距: 电气管道不能包含其他类型的系统(例如,水管、煤气管道)。

- 工作空间和通道: 插座和接线盒处必须有足够长度的导线(至少 6 英寸)用于连接或端接。

- 腐蚀性和潮湿环境: 必须列出在潮湿或腐蚀性场所使用的接线方法(例如,带有耐腐蚀配件的 PVC 导管)。

- 滚道填充和弯曲半径: 禁止过度填充线槽,并且导体必须具有足够的弯曲空间以避免绝缘损坏。

- 防火分隔: 穿过防火组件的管道或电缆周围的开口必须防火,以防止火势蔓延。

专业提示: 想知道两种常见的接线方法吗?在上一篇文章中,我们详细讲解了 隐蔽管道布线 和 地面导管布线您可以点击上面的文字来了解它们的优缺点,以及安装方法。

通用布线导体

第 310 条规定了住宅、商业和工业系统中大多数布线装置所用的电导体的类型、特性和额定值。

它涵盖:

- 导体类型: 允许使用实心或绞合铜、铝或铜包铝导体。

- 绝缘类型: 常见的绝缘类型包括:

THHN/THWN-2: 干燥和潮湿的地方,最高温度可达 90°C

XHHW/XHHW-2: 防潮、耐热

USE-2/RHH/RHW-2: 地下和服务入口使用

- 载流量: 导体载流量(载流量)的定义基于:

导体尺寸

绝缘温度等级

环境温度

管道内载流导体的数量

- 额定电压: 导体按其最大电压列出(例如,600V、1kV)。

- 平行导体: 对于大导体(1/0 AWG 或更大),允许并联多个导体以实现更高的载流量。

第 342 至 362 条 – 导管和管材类型

NEC 根据材料、结构和应用,为每种线槽系统提供了单独的条款。这些线槽用于物理保护导体、支持接地连续性,并允许导体布线符合第 300 条的规定。

NEC 代码中列出了 7 种类型的导管:

中间金属导管 (IMC)

IMC 是一种钢制导管,其管壁比硬质金属导管 (RMC) 更薄,但机械防护性能相当。它采用镀锌处理,具有耐腐蚀性能,并获准用于暴露、隐蔽和危险场所。对于需要强度但又兼顾重量和成本的户外或工业环境,IMC 是理想的选择。

刚性金属导管 (RMC)

RMC 是最重、最坚固的金属导管,由镀锌钢或不锈钢制成。它旨在提供最大程度的物理保护,可安装在所有环境中,包括露天和地下位置。RMC 通常用于高风险区域,例如关键基础设施、石化工厂或易受机械磨损或严重腐蚀的区域。

硬质聚氯乙烯导管(PVC)

硬质PVC导管 是一种由塑料制成的非金属管道,耐潮湿和腐蚀。它重量轻,易于切割,是地下安装、潮湿环境以及污水处理厂或沿海地区等腐蚀性环境的理想选择。PVC 导管在暴露于温度变化时必须与膨胀接头一起使用,并且通常使用溶剂型胶粘剂进行连接。

高密度聚乙烯导管(HDPE)

HDPE 导管是一种柔性非金属导管,具有优异的抗冲击性和柔韧性。它通常用于地下电力和通信系统,包括定向钻孔安装。HDPE 导管能够以较长的连续长度进行安装,且接头较少,因此非常适合大型公用事业和基础设施项目。

电气金属管(EMT)

EMT 导管通常被称为“薄壁”导管,由镀锌钢或铝制成,比 IMC 和 RMC 更轻。它广泛应用于商业建筑,尤其适用于中等防护即可满足需求的室内墙体和天花板。EMT 导管必须采用机械固定,并使用压缩或紧定螺钉接头连接。未经额外防护,EMT 导管不适用于直埋或腐蚀性环境。

柔性金属管(FMT)

FMT 由螺旋缠绕金属管组成,可为短而复杂的布线提供灵活性。它适用于因振动、移动或空间限制而无法使用刚性导管的情况。典型应用包括灯具线缆、电机连接和密封外壳。除非另有说明,否则不适用于潮湿或危险场所。

电气非金属管 (ENT)

耳鼻喉 ENT 是一种波纹柔性塑料管,适用于注重快速安装的室内应用。它重量轻,不含金属,可手动弯曲,非常适合用于住宅或商业建筑的墙壁、地板和天花板。ENT 通常与合适的配件和接线盒搭配使用,用于防火建筑,并简化了楼板或浇筑混凝土结构的安装。

导管安装的一般要求:

必须以特定的间隔牢固支撑和固定。

必须使用适当的套管或配件来保护导体。

导管必须没有锋利的边缘,并在需要的地方密封,以防止湿气或气体进入。

在受温度变化影响的长距离室外运行中需要使用膨胀配件(例如 PVC 导管)。

每种导管类型均受 NEC 中特定安装规则的约束,以确保布线系统受到保护、安全且符合规范。选择正确的导管类型不仅可以保持电气系统的完整性,还可以确保在各种环境条件下的安全。

笔记: 想了解 PVC 导管安装的细节?您可以 单击此处获取有关 PVC 导管安装的专业提示。

第 392 条 - 电缆桥架

电缆托架是用于工业和商业环境中布线和支撑电缆的结构支撑系统。第392条涵盖了电缆托架系统的设计、安装和使用,这些系统包括梯式托架、通风槽式托架、实心底部托架和金属丝网托架。

电缆桥架的类型

梯子托盘: 开放式横档有利于空气流通,方便电缆进出。

通风槽: 部分封闭,提供中等支撑和气流。

实心底托盘: 完全封闭,用于机械保护至关重要的情况。

金属丝网/篮子托盘: 重量轻、安装快捷,适用于控制和数据电缆。

NEC对电缆桥架的要求

载流量调整: 安装在托盘中的电缆可能需要根据填充和通风情况降低载流量。

填充计算: 托盘填充限制取决于电缆类型和尺寸——过度填充会减少散热。

接地: 如果列出并正确粘合,金属托盘可用作设备接地导体 (EGC)。

支撑间距: 必须定期支撑托盘以防止下垂或损坏。

专业提示: 还在为选择 Conduit 还是 Trunking 而困惑吗?别担心,您可以阅读这篇文章,快速了解 了解导管和线槽之间的区别,以及它们的优缺点,以帮助您选择正确的。

第五章 特殊占用

美国国家电气规范 (NEC) 第 5 章重点关注特殊用途——由于其功能、内容或环境而面临特殊电气安装挑战的场所和结构。第 5 章对通用规则进行了修改,以满足危险、医疗、农业、移动和娱乐等用途的特殊需求。

危险(分类)场所

危险场所是指可能存在足够数量的易燃气体、蒸汽、粉尘或纤维,从而可能造成火灾或爆炸风险的区域。NEC 根据危险类型,使用等级、分区、组别系统或区域系统对这些区域进行分类。

- 常见的环境包括化工厂、燃料储存区、面粉厂和喷涂区。

- 认可的接线方法包括防爆外壳、密封以及使用带有特殊配件的特定导管系统,例如 RMC、IMC 和 PVC 型。

- 设备必须列出并贴上环境标签,安装技术必须限制危险物质进入布线系统。

医疗保健设施

医疗保健设施对电力可靠性和患者安全提出了至关重要的要求。第517条涵盖医院、疗养院、诊所及类似环境。

- 它介绍了基本电气系统,包括生命安全、关键和设备分支,每个分支都有特定的安装和分离要求。

- 布线必须降低电气故障、医疗设备干扰和火灾危险的风险。

- 精确定义接地、冗余、独立电源系统和导管类型的要求,以保持性能和合规性。

农业建筑

第 547 条规定了农业和畜牧业环境中的电气系统,在这些环境中,高湿度、灰尘和氨等腐蚀剂会损坏典型的电线。

- 必须使用耐腐蚀导管和配件(例如 PVC 涂层或非金属材料)保护电线免受物理损坏和腐蚀。

- 接地系统必须尽量减少可能对牲畜造成伤害的电压梯度。

- 本文还讨论了动物圈养区和农作物生产空间的照明、插座和设备控制的安装。

预制建筑和移动房屋

这些文章涵盖了工厂建造结构的电气要求,例如制造房屋、移动房屋、模块化建筑和移动房屋公园。

电气系统必须允许安全且标准化地连接到公用设施服务。

要求包括过流保护、正确接地和使用认可的柔性连接。

公园和停车场必须提供耐天气影响且易于使用的服务设备,确保安全的使用过渡。

休闲车和公园

这些部分为休闲车(RV)及其服务设施提供了指导方针。

房车内的线路必须紧凑、安全,并能防止振动和移动。

房车公园必须提供带有列出的电源插座、过流保护和适合移动连接的接地的配电系统。

所有组件在室外安装时必须防风雨、防篡改。

第5章在确保电气装置在非标准环境中保持安全、符合规范和正常运行方面发挥着关键作用,以上只是其中一部分。它认识到某些场所存在较高的风险,例如爆炸、设备故障或生命安全威胁——这些风险需要专门的材料、安装方法和防护措施。

第六章 特殊装备

美国国家电气规范 (NEC) 第 6 章专门针对特殊设备,该章节至关重要,它规定了新兴技术和专用系统的安全和安装标准。随着电动汽车、可再生能源和模块化数据中心的快速发展,这一章节比以往任何时候都更加重要。以下是第 6 章中四条重要条款的介绍:

第625条 - 电动汽车电力传输系统

第625条涵盖电动汽车(EV)充电系统的安装和安全要求,包括传导式、感应式和无线电力传输方式。该条款涉及电动汽车供电设备(EVSE)、连接器和相关线路等设备。主要条款包括:

范围: 适用于将电动汽车连接到房屋布线以进行充电、电力输出或双向电流流动的电导体和设备。

设备要求: EVSE 必须在应用程序中列出或标记。

过流保护: 充电设备被视为连续负载;过流保护必须相应调整。

人员保护: 人员保护系统的要求,例如接地故障断路器 (GFCI) 保护。

安装指南: 电线和电缆组件的规格,包括长度和结构。

位置考虑: 室内和室外位置的安装指南,考虑通风和可达性等因素。

笔记: 想了解更多关于电动汽车充电系统规范的信息吗?我们列出了 电动汽车充电站的四项国际标准 在我们之前的帖子中,您可以点击上面的文字阅读。

第 646 条 – 模块化数据中心

第646条规定了模块化数据中心(MDC)的要求。MDC是预制单元,用于容纳信息技术设备和支持系统。这些单元的额定电压不超过600伏,并包含配电设备和暖通空调系统等组件。关键考虑因素包括:

定义: MDC 是预制单元,由容纳多个 IT 设备机架或机柜以及各种支持设备的外壳组成。

列出并贴标签: MDC 必须列出并标明其预期用途。

工作空间: 遵守工作空间要求,确保维护和操作期间的安全。

接线和接地: 遵守适合这些设施模块化特性的布线方法和接地规范。

专业提示: 想了解更多关于电气导管的类型及其在数据中心的应用吗?我们已经详细讲解了 电气导管的重要性及其在数据中心的应用 在我们上一篇文章中。您可以点击上方文字阅读更多内容。

第690条 - 太阳能光伏(PV)系统

第690条规定了太阳能光伏 (PV) 系统的安装要求,但不包括大型公用事业光伏系统(第691条涵盖)。该条款管辖光伏阵列电路、逆变器、控制器、断路器、接地和互连——无论是独立运行、与其他电源互动运行还是混合运行——用于产生交流或直流电力。

主要亮点包括:

范围和适用性: 涵盖住宅、商业和工业光伏系统(不包括公用事业规模的电站)。允许在单个建筑物上安装多个光伏系统,并配备相应的标签和目录。

设备要求: 必须列出或评估光伏组件(例如逆变器、模块、汇流箱、快速关闭系统)以用于特定的光伏应用。

电路和电压要求: 将直流电压限制为 1000V(单户和双户住宅为 600V);必须仔细计算导体载流量和最大电路电流;双极电路和多电压系统有特殊规定。

电弧故障和接地故障保护: 80V 以上的直流电路必须具有电弧故障保护;除非获得豁免,否则 30V 或 8A 以上的系统需要接地故障保护 (GFDI)。

快速关机: 建筑物上或建筑物内的光伏电路必须安装,以确保消防员的安全——地面安装和非封闭结构(如车棚)除外。

断开方式: 光伏系统必须具有清晰标记且易于访问的与其他电力和存储系统断开的方式。

接线方法和可访问性: 可触及的 30V 以上的光伏导线必须封闭(例如,MC 电缆或线槽);如果有可触及的断开装置,则可以在屋顶上安装电源转换器。

浮动光伏系统: 必须适合增加的机械应力、腐蚀和湿度,并允许在水面上进行预期的运动。

接地和接合: 允许功能接地、非接地和直接接地的直流电路配置,并具有详细的安全接地要求。

专业提示: 等等,除了 NEC 之外,还有其他电气规范需要遵守吗?在上一篇文章中,我们详细解释了 太阳能管道的类型和规范合规性。您可以点击上面的文字阅读更多内容。

第694条 – 风力发电系统

《国家电气规范》第694条规定了风电系统的要求,包括一台或多台风力涡轮机以及发电机、逆变器、控制器和储能系统等相关设备。这些系统可以独立运行,也可以与其他电源相互作用,并可产生交流或直流输出。

主要条款包括:

合格人员: 安装、接线和维护必须由合格人员进行。

设备清单: 风力涡轮机和相关部件必须列出、贴上现场标签或接受监督评估。

过压和超速保护: 使用引水负荷控制器的系统必须包含可靠的辅助措施,以防止涡轮机超速。需要配备浪涌保护装置。

容器: 维护插座必须包括 GFCI 保护和过流保护。

电路要求: 输出电路被视为连续负载,在住宅环境中具有电压和接入限制。

关机并断开连接: 系统必须包括涡轮机关闭和断开的装置。

接线和接地: 所有接线方法和连接必须符合 NEC 的安全性和系统稳定性要求。

第七章——特殊情况

美国国家电气规范 (NEC) 第 7 章探讨了特殊情况——那些支持生命安全、在异常情况下运行或涉及新兴技术的电气系统。本章对于需要持续电源、备用电源或替代电源的系统以及用于监控或信号传输的系统至关重要。

从应急系统和法律要求的备用电源到储能和火灾报警,第 7 章提供了明确的安装要求,以确保可靠性、安全性和符合规范。

第700条-应急系统

应急系统是法律规定的电力系统,在断电情况下必须继续运行,以保护人身安全。这些系统包括为出口标志、应急照明、火灾探测和警报、公共安全通信以及关键通风系统供电的系统。

主要要求包括:

转乘时间: 自动转换开关确保断电后 10 秒内恢复供电。

电路分离: 紧急接线必须与所有其他接线系统物理隔离,除非位于单独的隔间中。

使用 上市 以及发电机或电池系统等可靠能源。

遵守 制定测试、维护和识别标准,以确保紧急情况下的可用性。

第701条 - 法律要求的备用系统

法定备用系统是指地方或国家法律强制要求在停电期间维持某些功能的系统,但它们的重要性不如应急系统。这些系统可能支持大型建筑中的电梯、暖通空调系统和污水泵等系统。

亮点:

电力恢复必须在公用电源断电后 60 秒内进行。

必须单独识别和安装这些系统。

燃料供应、通风和控制系统必须满足特定的运行时间和可靠性标准。

第706条 - 储能系统(ESS)

随着可再生能源的兴起和电网弹性建设的推进,电池组、飞轮和超级电容器等储能系统 (ESS) 已成为现代设施的重要组成部分。NEC 第 706 条是新增加的条款,涵盖了储能系统的安装、保护和标签。

要点包括:

安装: 必须按照制造商的说明和第 706 章规定安装 ESS。

电池类型: 要求因化学而异:

锂离子: 必须包括热失控预防和防火外壳。

铅酸电池: 需要通风和控制溢出。

位置限制: ESS 必须安装在经批准的房间或柜子中,并具有所需的间隙和通风。

关机协议: 系统必须具有标记清晰、可访问的紧急关闭机制。

专业提示: 您的业务涉及储能系统 (ESS) 行业吗?在上一篇文章中,我们列出了 四项国际标准及七项遵守技巧。您可以点击上面的文字来了解更多。

第760条-火灾报警系统

火灾报警系统是保障生命安全所必需的,用于在烟雾或火灾事件发生时向居住者和应急人员发出警报。第760条概述了限功率和非限功率火灾报警电路的接线和安装规则。

主要亮点包括:

电路类型: 分为:

限功率火灾报警(PLFA): 较低电压;使用特定电缆类型(例如,FPL、FPLP、FPLR)。

非功率限制火灾报警(NPLFA): 更高的功率要求;必须遵循一般接线规则。

电缆保护: 火灾报警电缆必须:

列出防火要求并进行路由以避免物理损坏。

除非使用屏障,否则应与其他系统隔离。

电源供应: 必须具有主电源和辅助(备用)电源,通常电池能够待机 24 小时并保持 5 分钟的警报操作。

标记: 接线盒和导管必须标有“火警电路”。

第 770 条 - 光纤电缆和管道

光纤电缆虽然并非传统的电力系统,但对于现代通信和控制系统至关重要。第770条详细说明了非导电和导电光纤电缆的安装要求。

涵盖防火电缆类型(OFNR、OFNP)。

包括管道、弯头、支撑间距和机械保护的规则。

强调在高性能网络中保持信号完整性并最大限度地降低损坏风险。

特殊情况的额外最佳实践

虽然第 7 章中的每一篇文章都包含非常具体的要求,但一些通用的最佳实践包括:

- 文档和标签:

清晰地标记所有系统,特别是涉及生命安全或待机操作的系统。

按照 NFPA 70 和当地 AHJ(管辖当局)的要求保存安装记录、图纸和测试结果。

- 环境考虑:

位于潮湿、腐蚀性或爆炸性环境(如与第 5 章结合的环境)中的系统必须使用列出的外壳、耐腐蚀材料和 NEMA 额定设备。

- 与其他规范的协调:

火灾报警和应急系统不仅必须符合 NEC,还必须符合 NFPA 72(国家火灾报警和信号规范)和 NFPA 110(应急和备用电源系统标准)。

- 维护和测试:

第七章系统需要持续检查和测试,有时每月一次,以确保符合规定。紧急情况下系统故障通常源于缺乏维护。

第 8 章 - 通信系统

NEC 第 8 章规定了通信电路的规则和要求,包括电话系统、电视和无线电分配、互联网/数据布线、对讲机以及网络控制系统。与之前章节中规定的电力电路不同,第 8 章专门针对用于传输信息而非电力的低压系统。

第800条 - 通信系统的一般要求

本文概述了安装通信电缆和相关硬件的一般规则,包括:

- 电缆类型和额定值:

通信电缆包括 CM、CMR、CMP 和 CAT5e/CAT6/CAT6A 等数据类型。

防火等级很重要:出于防火安全考虑,管道或静压箱空间内需要使用 CMP 电缆(静压等级)。

- 与电源线分离:

通信电缆必须与电源和照明导体分开,以避免电气干扰和感应电压。

与电源电路并行运行时,通常需要专用管道、屏障或间距。

- 接地和接合:

所有通信系统必须在服务入口或建筑物入口处接地,以限制电压浪涌并确保人身安全。

必须使用列出的硬件进行粘合,并且必须符合第 800 条和第 250 条的规定。

- 防止物理损坏:

必须在电缆容易受损的地方进行保护,例如暴露的位置或穿过墙壁或地板的穿透点。

笔记: 想知道美国、加拿大和澳大利亚之间的通信管道差异吗?在上一篇文章中,我们列出了 美国和澳大利亚通信管道的类型和规范合规性。您可以点击上面的文字来了解更多。

第820条 - 社区天线电视和广播分配系统(CATV)

第 820 条涵盖提供电视、卫星或射频信号分配的同轴电缆系统。

主要要求包括:

- 接地要求:

同轴电缆的屏蔽层必须尽可能靠近电缆入口点接地,通常使用接地块。

- 电涌保护:

CATV 系统必须包括电涌保护器或列出的天线和分离器,旨在减轻雷击或瞬态电压。

- 权力分离:

与其他通信系统一样,CATV 电缆必须与电源线保持足够的距离,尤其是在进入建筑物或共用线槽时。

常见应用

NEC 第 8 章系统常见于:

商业建筑 – 结构化布线、对讲机、闭路电视

住宅 – 电话线、同轴电视电缆、互联网线路

医院和学校 – 护士呼叫系统、寻呼机、数据网络

智能建筑 – 通过数据网络集成照明和 HVAC 控制

导管适合通信系统安装

为了实现物理保护、布线和规范合规,通信电缆通常安装在非金属导管中,尤其是在地下或暴露区域。第 8 章应用中一些最常用的导管类型包括:

DB 导管(直埋导管)

DB-60 和 DB-120 PVC导管 广泛应用于地下电信线路。

这些导管专门用于埋设,无需额外包装,具有出色的抗土壤腐蚀、抗冲击和抗潮性能。

DB 导管非常适合从服务基座到建筑物铺设光纤和 CATV 线路,尤其是在校园或住宅区。

HDPE导管(高密度聚乙烯)

柔韧、耐腐蚀,适用于长距离地下通信电缆牵引。

通常与光纤电缆和微管系统结合使用。

在数据中心主干网、公用设施走廊和电信提供商网络中很常见。

波纹管

重量轻、灵活,易于安装在墙壁空腔或架空地板上。

常用于低压降,例如从墙盒到数据端口或访问控制单元。

可用 无卤选项 适用于火灾敏感区域。

关键考虑因素

- 标签和识别:

通信电缆应有清晰的标签以便识别,尤其是当多个系统一起安装时。

- 代码协调:

虽然 NEC 负责安全管理,但 TIA/EIA-568、IEEE 和 BICSI 等其他标准也指导着性能和设计。同时遵守 NEC 安全规范和 IT 标准,可确保最佳安装效果。

- 避免信号干扰:

保持适当的分离和屏蔽以避免电磁干扰(EMI),特别是在高噪声环境或附近有高功率设备的地方。

- 防火要求:

当通信电缆穿过防火墙或地板时,必须使用列出的防火系统来保持屏障的耐火等级。

遵循 NEC 合规性 - 分步指南

符合 NEC 标准意味着确保电气装置的每个部分都安全、符合规范,并能够在实际条件下长期运行。无论您是在进行住宅升级改造、商业建筑施工,还是工业规模的系统工程,遵循国家电气规范 (NEC) 的系统方法都至关重要。

以下是向 NEC 投诉时需要了解的一些因素:

定义应用程序类型

首先确定占用类型和所涉及的具体系统。NEC 的许多规则都是围绕建筑物或系统的性质制定的:

住宅、商业或工业

危险场所(例如,石化工厂)

医疗保健、农业、数据中心或电动汽车基础设施等特殊领域

它是否包括火灾报警、应急电源或通信电缆等系统。

识别正确的代码版本和本地修订

务必核实您所在地区采用的 NEC 版本。虽然 NEC 每三年更新一次,但并非所有州或司法管辖区都会立即采用最新版本。此外,许多市政当局会添加地方修正案,以取代或补充 NEC 规则。

为了保持合规:

确认当地采用的 NEC 版本(例如 2020、2023)

审查任何特定于州的电气规范。

在设计阶段早期与具有管辖权的机构 (AHJ) 进行协调。

评估安装环境

选择电气材料和方法时,必须考虑现场条件。NEC 强调适用性,其依据如下:

环境温度: 在高温区域(例如阁楼、屋顶)安装导线时,必须降低额定值。请参阅 NEC 310.15(B)。

潮湿和腐蚀: 在潮湿的地方(例如室外、地下)使用防水、耐腐蚀的外壳和管道。

暴露在阳光下: 安装在阳光直射处的材料必须具有抗紫外线功能。

物理损坏潜力: 在受到冲击或移动的区域,滚道必须承受重载或受到机械保护。

选择符合 NEC 标准的布线方法和材料

请参阅第 3 章,了解根据项目环境和 NEC 范围可接受的布线方法。选择时必须考虑以下因素:

导体类型和绝缘 (例如,THHN、XHHW-2、MTW)

管道系统 (例如,EMT、RMC、PVC、ENT)

电缆组件 (例如,NM、MC、AC电缆)

盒子、配件、连接器和支架

所有材料必须由公认的第三方测试机构(例如 UL、CSA)列出并贴上标签,并按照其列表使用。

特殊用途和设备

如果您的项目包含特殊用途或特殊设备,请遵循超出一般布线规范的具体规则。例如:

卫生保健: 需要隔离接地、冗余电路和必要的系统分离。

危险场所: 强制使用防爆配件和密封管道系统。

农业建筑: 需要耐腐蚀和防尘外壳。

火灾警报: 必须满足生存能力和分离要求。

NEC 还定义了对安全和检查至关重要的间隙、电路分离和系统标签规则。

确保接地和接合完整性

有关正确的接地和连接,请参阅 NEC 第 250 条,包括:

接地电极系统 (例如接地棒、建筑钢材)

Main and supplemental bonding jumpers

Equipment grounding conductors sized according to NEC Table 250.122

Improper grounding is one of the most common causes of NEC violations and electrical hazards.

Calculate Conduit Fill, Ampacity, and Voltage Drop

Proper wire sizing must consider:

Ampacity derating: Based on ambient temperature and number of conductors.

Conduit fill: Overfilling leads to overheating.

Voltage drop (recommended max 3% for branch circuits): Especially critical for long runs and energy-efficient designs.

Schedule Inspections

Coordinate with the AHJ for inspection stages, such as:

Rough-in inspections: Check wiring, supports, and boxes before finishes are applied.

Final inspections: Ensure proper device installation, labeling, grounding, and safety clearances.

Additionally, perform system tests like:

Continuity and insulation resistance

Polarity and GFCI/AFCI verification

Load balancing and voltage readings

For commercial and industrial systems, commissioning and third-party validation may be required.

The NEC provides a consistent framework for safe, functional electrical installations, but true compliance requires more than just code references. Professionals must consider installation environments, equipment ratings, material compatibility, and local rules every step of the way.

By following this structured guide and aligning each phase of your installation to NEC provisions, you can deliver systems that are safe, efficient, and future-proof.

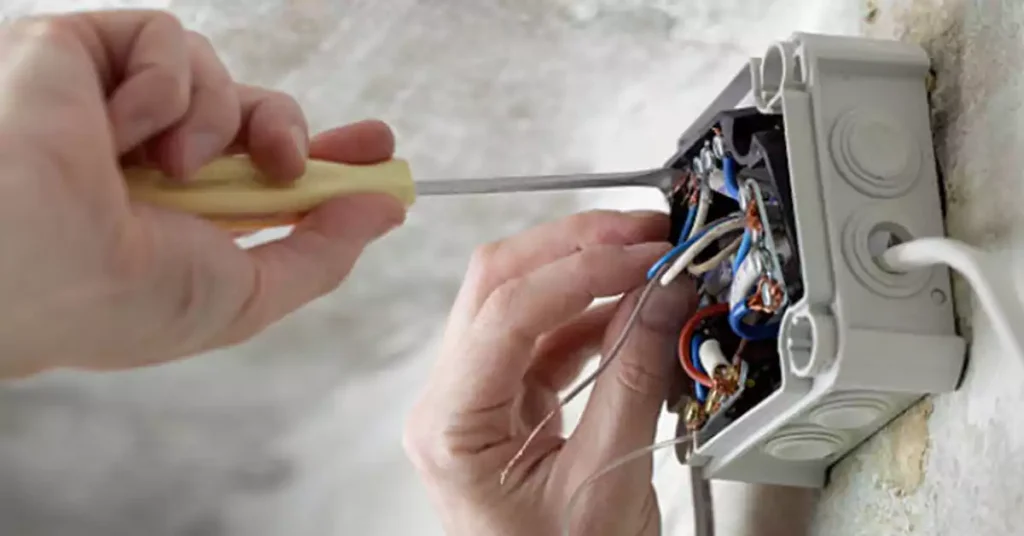

10 Commons NEC Violations and How to Avoid Them

Even skilled electricians and experienced contractors can encounter National Electrical Code (NEC) violations, many of which are surprisingly avoidable. These missteps can delay project approvals, create safety hazards, or lead to costly rework. Understanding the most common pitfalls and how to prevent them is key to maintaining both compliance and safety.

Here are several frequently encountered NEC violations, along with practical advice on how to avoid them.

Inadequate Grounding and Bonding

One of the most frequent issues in electrical installations is poor or missing grounding and bonding. This can lead to equipment damage, shock hazards, or unreliable system performance.

How to avoid it:

Ensure all metal components and systems are properly bonded and connected to an effective ground. Use appropriate connectors and follow correct installation practices for grounding electrodes and conductors. Never rely on flexible metal conduits or enclosures as the sole path to ground.

Overfilled Junction or Outlet Boxes

Stuffing too many wires into a single electrical box without accounting for space requirements can lead to overheating or damaged insulation.

How to avoid it:

Always size electrical boxes according to the number and size of wires, devices, and clamps inside. Use larger boxes or box extensions when needed. Plan box fill before pulling conductors to avoid overfilling during installation.

Conduit Overfill and Poor Bending Practices

Running too many wires through a single conduit or using sharp, cramped bends can make maintenance difficult and lead to wire damage.

How to avoid it:

Limit the number of wires in each conduit to prevent excessive heat buildup. Maintain proper bending radii to ensure easy wire pulling and avoid stress on the insulation. Choose conduit sizes that allow for future wiring adjustments.

Missing GFCI or AFCI Protection

Omitting required safety protection, such as Ground-Fault Circuit Interrupters (GFCIs) or Arc-Fault Circuit Interrupters (AFCIs), is a common oversight—especially in kitchens, bathrooms, outdoor spaces, or bedrooms.

How to avoid it:

Know where these devices are required and include them in both design and installation phases. Use labeled GFCI/AFCI receptacles or breakers, and test them after installation.

Loose or Unsupported Cables and Conduits

Failing to secure cables or conduits can cause sagging, mechanical damage, or even failure under stress or vibration.

How to avoid it:

Support all wiring methods securely with proper fasteners at regular intervals. Avoid over-tightening straps, and use approved supports compatible with the conduit or cable type.

Using Incorrect Connectors or Fittings

Improvised or incompatible fittings can result in poor electrical continuity, mechanical weakness, or moisture intrusion.

How to avoid it:

Only use listed connectors and fittings that match the type and size of conduit or cable being used. Avoid mixing metal and plastic components unless specifically approved.

Ignoring Temperature Ratings or Ampacity Adjustments

Neglecting to consider high ambient temperatures, insulation type, or bundled conductors can lead to overheating and premature equipment failure.

How to avoid it:

Use wire types with insulation suitable for the environment, and adjust ampacity when cables are bundled or installed in hot areas like attics or near heating systems. Select conduit materials that perform well in those temperatures.

Poor Identification of Conductors

Using the wrong color or failing to label wires clearly can confuse maintenance personnel or lead to unsafe connections.

How to avoid it:

Follow consistent wire color conventions: black or red for hot wires, white or gray for neutrals, and green or bare copper for grounding. When color is unclear, label conductors clearly at both ends.

Insufficient Working Space Around Panels

Installing panels in cramped or obstructed areas makes safe operation and maintenance difficult—and can lead to code violations during inspection.

How to avoid it:

Ensure that electrical panels and service equipment have clear, unobstructed access with adequate working space in front and around them. Avoid placing panels in closets, bathrooms, or storage spaces.

Lack of Weatherproofing in Outdoor Installations

Failing to use weather-resistant materials outdoors or in wet locations can lead to corrosion, water damage, and dangerous short circuits.

How to avoid it:

Use weatherproof boxes, covers, fittings, and conduit suitable for wet or damp environments. Seal all connections carefully and install covers that protect outlets even while in use.

Staying Updated with the NEC - 3 Tips

The National Electrical Code (NEC) is not a static document—it is revised 每三年 to reflect changes in technology, safety practices, and the evolving needs of the electrical industry. Staying updated is not just recommended—it’s essential for compliance, performance, and safety.

Here are some points you can follow to ensure remain NEC-compliant and up to date.

Staying Compliant Through Education and Training

Continuing Education

Licensing authorities in many jurisdictions require electricians, engineers, and contractors to complete continuing education to renew their licenses. These courses typically cover updates in the latest NEC edition, with a focus on changes in definitions, requirements, and safety standards.

Manufacturer and Industry Training

Many conduit, wiring, and equipment manufacturers offer product-specific training aligned with NEC updates. These sessions help professionals apply code requirements to real-world products and systems, especially in emerging fields like EV charging infrastructure and solar energy.

On-the-Job Experience and Mentoring

For apprentices and journeymen, learning on-site under the guidance of a master electrician is one of the most practical ways to build NEC knowledge. Experienced professionals often share field-proven practices that align with code requirements while improving installation efficiency and quality.

The Role of Inspections and Permits

Electrical Permits Ensure Compliance Before Work Begins

Before most electrical work can begin, contractors must apply for a permit. This process ensures that the design and scope of work meet NEC standards and local amendments.

Inspections Catch Mistakes and Improve Safety

Inspections are conducted at critical phases of a project—often before walls are closed and again after completion. Inspectors act as an essential line of defense, verifying installations are safe, code-compliant, and professionally executed.

Working With Inspectors, Not Against Them

Professionals who view inspectors as allies—not obstacles—tend to deliver better projects. A good relationship with local authorities can streamline approvals and improve understanding of evolving code interpretations.

Essential Resources for NEC Compliance

NFPA 70: National Electrical Code Handbook

The NEC Handbook, published by the National Fire Protection Association (NFPA), provides the full text of the Code with expert commentary, illustrations, and real-world application notes. It’s an indispensable tool for in-depth learning and design reference.

NEC Mobile App and Digital Access

NFPA also offers the NEC in a mobile app, making it easy to search, bookmark, and reference sections in the field. Many professionals use the app as a fast and reliable way to find answers on-site.

Local Code Amendments

Each city or state may adopt the NEC with additions or modifications. Always check with your local Authority Having Jurisdiction (AHJ) to confirm which edition is in force and whether any unique rules apply to your project.

Trade Associations and Online Communities

Organizations like IAEI (International Association of Electrical Inspectors), NECA (National Electrical Contractors Association), and IEC (Independent Electrical Contractors) provide access to training, publications, and forums where professionals can discuss code questions and stay updated on industry trends.

结论

The National Electrical Code (NEC) is more than just a rulebook—it’s the foundation of electrical safety across the United States and beyond. It represents decades of industry experience, real-world lessons, and engineering standards that aim to protect people, property, and electrical systems.

One of the most critical aspects of NEC compliance is choosing the right electrical conduit. Whether it’s PVC for underground runs, EMT for commercial interiors, or specialized low-smoke halogen-free solutions for sensitive environments, conduit selection directly affects safety, performance, and code adherence. Using properly rated conduits not only ensures regulatory compliance but also contributes to long-term system durability and resilience.

Ultimately, following the NEC leads to safer electrical installations, reduced fire and shock hazards, and fewer costly reworks or legal issues. For electrical professionals, contractors, inspectors, and engineers, understanding and applying the NEC is not just a requirement—it’s a commitment to quality and safety in every project.

常见问题解答

什么是国家电气规范 (NEC)?

美国国家电气规范 (NEC) 是由美国国家消防协会 (NFPA) 为美国电线和设备安全安装而制定的一套标准化指南。NEC 每三年更新一次,旨在保护人员和财产免受触电、火灾和电弧闪光等电气危害。它涵盖了从布线方法和导管类型到接地、特殊用途和可再生能源系统的方方面面。

国家电气规范是法律吗?

从技术上讲,NEC 本身并非法律,但一旦被州或地方司法管辖区采纳为建筑规范的一部分,便具有法律效力。美国大多数州和地区都采用 NEC(通常会进行修订),使其成为这些地区事实上的法律要求。合规性通常由当地电气检查员强制执行。

所有国家都有国家电气规范吗?

No, not all countries have a version of the NEC. The NEC is primarily used in the United States, although some other countries, especially in Latin America and the Caribbean, may use it or base their standards on it. Other countries typically have their own national electrical standards, such as:

IEC 标准 (International Electrotechnical Commission) used in Europe and many parts of Asia and Africa

加拿大电气规范 (CEC) in Canada

AS/NZS 3000 (Wiring Rules) in Australia and New Zealand

使用 PVC 管作为电线导管不好吗?

Yes. Only specific types of PVC conduit are approved for electrical use—you cannot use regular plumbing PVC (typically white Schedule 40 or 80) as an electrical conduit.

For electrical installations, you must use electrical-grade PVC conduit such as:•

- Rigid Polyvinyl Chloride Conduit (PVC Schedule 40 or 80) — marked and listed for electrical use

- 电气非金属管 (ENT) — also made of PVC, flexible, and used in certain wall or ceiling applications

These conduits:

- Are listed and labeled for electrical safety

- Provide protection against corrosion and moisture

- Must be installed following NEC requirements regarding bends, supports, burial depth, and temperature ratings

Using plumbing-grade PVC for electrical wiring is unsafe and non-compliant, as it may not have flame resistance, UV protection, or dimensional consistency required for pulling conductors.

我可以沿着导管外面铺设接地线吗?

No, running a ground wire along the outside of a conduit is not compliant with the NEC. Grounding conductors must be:

- Inside the raceway or cable assembly

- Protected from physical damage

- Installed in a way that ensures electrical continuity and conductivity

Exposed grounding conductors are susceptible to mechanical damage and corrosion, which can compromise safety.

根据 NEC,电源插座是什么?

根据国家电气规范 (NEC) 的定义,电源插座是指布线系统上用于将电流输送给用电设备的点。实际上,它通常指用于连接电器或设备的插座。然而,根据具体情况,该术语也可能适用于其他插座,例如照明插座、电机插座或设备插座。

国家电气规范 (NEC) 的最新版本是什么?

最新版本是2023 NEC,由美国国家消防协会(NFPA)发布。该版本每三年更新一次。

哪些法规涵盖电气装置?

美国的电气安装主要受 NEC (NFPA 70) 管辖。地方司法管辖区可能会采用 NEC 进行修订或不修订,并且可能制定自己的建筑或能源规范。加拿大主要受 CEC(加拿大电气规范)管辖,不同地区可能各自有自己的地方规范。

在美国自己做电气工作合法吗?

是的,但这取决于州和地方的管辖范围。在许多地区,如果房主获得适当的许可并通过检查,他们可以在自己的房屋上进行某些电气工作。但是,商业工作或高压系统通常需要持证电工。

参考