目录

全球电动汽车 (EV) 的普及正在加速,对可靠、高效、安全的电动汽车充电基础设施的需求也日益增长。每个高性能充电站的背后都有一个经常被忽视却又至关重要的部件——电线导管。合适的电线导管作为电缆的保护通道,不仅可以保护线路免受物理损坏、天气和紫外线照射的影响,还能确保符合电气规范和标准。

对于电动汽车充电站而言,导管的选择不仅仅是选择合适的管道,还需要考虑性能、安全性、法规要求和长期适应性之间的平衡。使用错误的导管类型可能会导致昂贵的维修、违反法规或降低充电效率。

本文将向您介绍电动汽车充电应用电线管选择的基本知识。无论您是承包商、设施经理还是电动汽车基础设施规划人员,您都将了解:

- 为什么导管对充电站的可靠性和安全性起着至关重要的作用

- 电动汽车充电管道要求与标准住宅电气安装有何不同

- 最适合各种电动汽车充电水平的导管类型

- 如何根据环境、负载和未来可扩展性做出明智的选择

- 延长系统寿命的实用安装和维护技巧

了解电动汽车充电

什么是电动汽车充电?

电动汽车充电是将电能从电源传输到电动汽车电池以补充其储存能量的过程。

这是通过电动汽车供电设备(EVSE)实现的——通常称为充电站,它提供:

- 安全电气连接 电网和电动汽车之间。

- 控制和监控功能 来规范充电。

- 保护功能 例如过流保护、接地故障检测以及与车载系统的通信。

电动汽车充电可以使用交流电 (AC) 或直流电 (DC) 电源:

- 交流充电 (1 级和 2 级)使用电动汽车的车载充电器将电网的交流电转换为直流电以供电池存储。

- 直流快速充电 使用车外充电器将直流电直接输送至电池,绕过车辆的车载充电器,实现更快的充电速度。

北美电动汽车充电水平

电动汽车充电标准化为三个主要级别,每个级别具有不同的电压、电流和充电速度特性。

充电水平 | 电压 | 典型电流 | 功率输出 | 充电速度 | 常见用例 |

1级(AC) | 120V(单相) | 12–16 上午 | 约1.4–1.9千瓦 | 每小时约 2-5 英里 | 使用标准插座进行家庭充电;夜间充电速度慢 |

2级(AC) | 208–240 V(单相) | 16–80 安 | 约2.5–19.2千瓦 | 每小时约 12-80 英里 | 住宅、工作场所、商业停车场、车队仓库 |

直流快速充电(DCFC) | 400–1000 V 直流 | 50–500 A(取决于地点) | ~50–350+ 千瓦 | 20-40分钟内行驶约60-200英里 | 高速公路走廊、高流量零售、车队运营、公共 |

笔记: 充电速度取决于车辆电池容量、接受率以及充电状态,实际结果会有所不同。

电动汽车充电与标准住宅用电有何不同

电动汽车充电,尤其是 2 级和 DCFC 充电与普通家用电气负载有显著不同:

1.持续高负荷

根据国家电气规范 (NEC) 的定义,电动汽车充电设备 (EVSE) 通常被视为连续负载,这意味着其预计运行时间超过 3 小时。这会影响导线尺寸、降额和导管填充的考虑。

2. 更大的导体和线槽尺寸

2 级和 DCFC 通常需要更粗的导线(例如 #6 AWG 及更大),有时需要多条并联导线,这直接影响导管直径和弯曲半径

3. 户外及恶劣环境

许多站点位于户外,暴露于紫外线、雨水、雪、除冰盐、油和机械损坏,需要防风雨和耐腐蚀的导管材料。

4. 复杂通路

安装可能涉及挖沟、停车场穿越或地下运行,引入埋深要求和特殊配件。

5. 数据与电源分离

现代 EVSE 包括网络和控制电缆,可能需要与电力导体分开的导管以符合要求并减少干扰。

6. 未来的可扩展性

与大多数家庭布线不同,电动汽车充电基础设施通常会随着时间的推移而扩展——从一开始就规划备用管道容量可以节省大量的未来成本。

电动汽车充电导管的用途

在电动汽车充电站中,导管作为电源线和数据线的保护和组织通道,确保:

- 机械保护 免受车辆、行人和环境危害。

- 环境抵抗力 抵御紫外线、腐蚀、潮湿和极端温度。

- 守则合规性 用于导体填充、弯曲半径、埋设深度和列表/标记。

- 可维护性 – 允许在不干扰安装的情况下更换或升级电线。

- 隔离 高压电源和低压通信电路。

- 面向未来 通过为额外或更大的导体提供空间。

为什么导管选择对于电动汽车充电站如此重要

- 热管理: 更大、连续加载的导体会产生更多的热量,材料类型、尺寸和安装方法会影响冷却。

- 耐用性: 户外环境需要抗紫外线、防腐蚀和抗冲击的导管。

- 安装效率: 正确的尺寸和弯曲配置可减少劳动时间和拉动难度。

- 可扩展性: 超大尺寸或备用导管支持未来升级,无需新开挖沟槽。

- 监管部门批准: 使用正确列出和标记的导管可简化检查和批准。

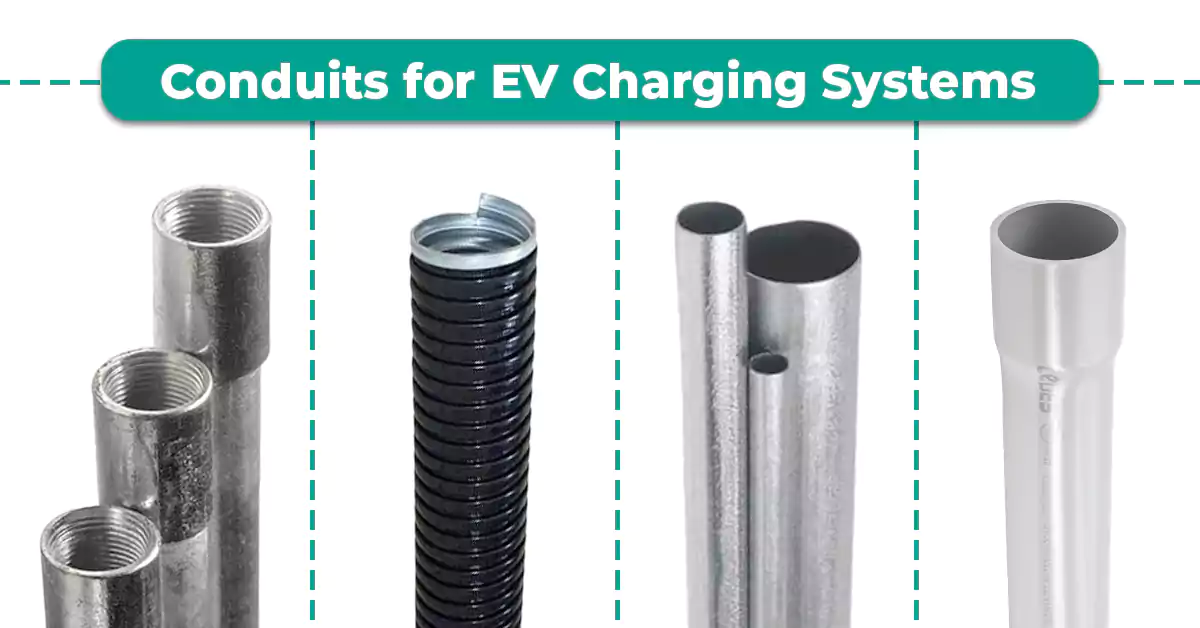

电动汽车充电站的 4 种常见导管类型

选择合适的导管首先要了解可用的材料及其在电动汽车充电应用中的性能。每种类型的导管都有其独特的优势和局限性,具体取决于安装地点是室内、室外、地下还是暴露在恶劣条件下。以下是电动汽车充电基础设施中最常用的导管选项。

1. PVC 导管(硬质 PVC/Schedule 40 和 Schedule 80)

由聚氯乙烯 (PVC) 制成的轻质、非金属、耐腐蚀导管。

优势:

优异的耐腐蚀和耐化学性。

提供适合户外暴露的抗紫外线版本。

重量轻,易于切割和安装。

性价比高。

限制:

抗冲击性比钢低。

在户外运行时必须控制热膨胀。

最适合电动汽车充电:

地下运行、室外基座安装以及耐腐蚀性至关重要的环境。

80号PVC管 建议在需要机械保护的区域(例如,车道附近的地面上)使用。

2. EMT(电气金属管)

薄壁钢导管,通常镀锌以防腐蚀。

优势:

提供良好的物理保护,防止撞击。

使用标准工具即可轻松弯曲。

具有导电性,因此可以作为设备接地导体(EGC)。

限制:

除非经过适当的涂层或处理,否则在室外/潮湿环境中容易腐蚀。

比 PVC 重,安装需要更多劳动力。

最适合电动汽车充电:

室内车库、有遮蔽的充电站以及湿度较低的地方。

3. RMC(刚性金属导管)和IMC(中间金属导管)

厚壁(RMC)或中厚壁(IMC)重型钢导管。

优势:

最大程度的机械保护。

对于暴露和人流量大的区域具有高度耐用性。

优良的接地导体。

限制:

安装成本高且费力。

重量级。

如果没有保护涂层,在恶劣的户外环境中会随着时间的推移而腐蚀。

最适合电动汽车充电:

物理损坏风险较高的区域(例如公共停车场、车队仓库)。

需要增加安全性和稳健性的站点。

4. 液密柔性导管(LFMC / LFNC)

柔性导管有金属(LFMC)和非金属(LFNC)版本,采用防水外套设计。

优势:

防水、防油、防化学品。

灵活适用于短距离运行、连接或设备端接。

适用于易发生振动的安装。

限制:

不建议长距离运行(更昂贵且更难拉导线)。

除非另有说明,某些类型的抗紫外线能力有限。

最适合电动汽车充电:

刚性导管和充电设备之间的短连接,特别是在室外或潮湿环境中。

管道汇总表

导管类型 | 材料 | 优势 | 限制 | Best Applications in EV Charging |

PVC | 硬质 PVC | Corrosion-resistant, lightweight, cost-effective, UV-rated options | Thermal expansion, less impact-resistant | Underground runs, outdoor pedestals, Schedule 80 for exposed areas |

RMC / IMC | Thick steel | Maximum strength, security, grounding | Costly, labor-intensive, corrosion risk | Public/high-traffic areas, fleet depots |

紧急医疗救护 | Thin-walled steel | Good impact protection, easy bends, grounding | Corrosion in outdoor use, heavier install | Indoor garages, sheltered charging |

LFMC / LFNC | Flexible metallic/nonmetallic | Waterproof, chemical resistant, flexible for terminations | Not for long runs, limited UV resistance | Equipment connections, outdoor short runs |

How to Choose the Right Conduit for EV Charging Stations

Selecting the right conduit for an EV charging project isn’t about picking the strongest or cheapest option, it’s about matching the conduit type to the project’s electrical demands, environment, and future needs. Below are the critical factors to consider when making the decision.

1. Electrical Load & Heat Management

High-power chargers, especially Level 2 and DC fast chargers, carry large currents that generate significant heat. Conduits must allow heat dissipation and prevent overheating.

Metallic conduits (RMC/IMC): Excellent thermal conductivity, helping to dissipate heat and provide fire resistance in high-load installations.

Nonmetallic conduits (PVC/HDPE): Adequate for moderate loads but must be properly sized to avoid overheating and ensure safe ampacity.

2. Environmental Exposure

EV charging conduits are often installed outdoors, where they face moisture, UV radiation, and corrosive environments.

Rigid PVC (UV-rated): Excellent for moisture and sunlight resistance, common in outdoor and underground use.

Fiberglass or HDPE: Preferred in marine or chemically aggressive areas, where corrosion is a concern.

Bare steel: Should be avoided in corrosive environments unless properly coated.

3. Physical Protection Against Damage

Charging stations are often located in parking lots and public spaces, which increases risk of physical damage.

Schedule 80 PVC or RMC: Recommended in exposed areas with vehicle traffic or mechanical impact risk.

Underground installations: NEC 352.10 requires a minimum burial depth. Schedule 80 PVC or concrete-encased metallic conduit is commonly used to resist soil pressure and traffic loads.

4. Installation Constraints

Not every site allows for straight conduit runs. Tight spaces, walls, and complex layouts often require more flexible solutions.

急救人员: Easily bent onsite, making it suitable for garages and indoor runs.

LFMC (Liquidtight Flexible Metal Conduit) and LFNC (Liquidtight Flexible Nonmetallic Conduit): Provide flexibility for final connections, vibration-prone equipment, or areas requiring frequent adjustments.

5. Cost vs. Performance Balance

Over-specifying conduit (e.g., using RMC everywhere) drives costs up, while under-specifying risks premature failure.

Key Considerations:

PVC is generally most economical for underground and outdoor runs.

Metal conduits are more expensive but may be necessary in certain jurisdictions or environments.

Flexible conduits should be limited to short connections due to cost and pulling difficulty.

6. Code Compliance & Listings

Why it matters: EVSE installations are inspected, and failing to meet code can mean costly rework.

Key Considerations:

NEC Article 625 (EVSE) + Chapter 3 (Wiring Methods) requirements.

UL 651 (PVC), UL 514 (fittings), UL 797 (EMT), UL 6 (RMC), etc.

Always use UL-listed or equivalent certified conduit.

Verify markings match installation conditions.

Markings for “Sunlight Resistant,” “Wet Location,” or “Direct Burial” when required.

笔记: If you are an electrical engineer and would like to learn more about the performance requirements of UL 651 for PVC conduit, you can view our expert guide by clicking the link above.

7. Future-Proofing

EV charging infrastructure must consider not just today’s needs but also future expansion.

Oversizing conduits (e.g., installing 2″ or 3″ conduits even if current wiring requires only 1″) can save significant costs later by avoiding retrenching or rebuilding.

Planning for additional conduit exits during underground installations makes expansion easier.

Code & Compliance for EV Charging Conduits

Building EV charging infrastructure isn’t just about choosing durable conduit or installing it neatly — it must be designed, installed, and inspected in compliance with recognized electrical codes and safety standards. These codes ensure that EV charging stations operate safely under high and continuous electrical loads, resist environmental challenges, and provide long-term reliability.

For contractors, engineers, and facility managers, navigating these standards is essential not only to pass inspection but also to protect users, equipment, and investment. Below are the most relevant standards and codes governing EV charging conduit installations in North America and globally.

专业提示: Still don’t know the 4 most important codes for EV Charging Stations in the world? No problem, click the link above to learn now and become an industry expert!

United States: National Electrical Code (NEC)

The National Electrical Code (NEC), published by the NFPA (National Fire Protection Association), provides the foundation for EVSE (Electric Vehicle Supply Equipment) installations in the U.S. Several articles are particularly important:

NEC Article 300 – Wiring Methods

Article 300 establishes the fundamental rules that apply to wiring methods and materials used in all electrical installations, including EV charging stations. It covers provisions for conductor routing, protection against physical damage, burial depths, raceway requirements, spacing between conductors, and protection from environmental conditions. For EV infrastructure, compliance with Article 300 ensures that feeders and branch circuits supplying charging equipment are properly installed, adequately protected, and suitable for the environment in which they are placed (indoor, outdoor, underground, or embedded in concrete).

Key considerations from Article 300 for EV charging projects include:

Conductor Protection: Ensuring wiring is guarded against mechanical damage, moisture, and chemical exposure.

Raceways and Conduits: Requirements for installation methods such as EMT, PVC, or rigid metal conduit, depending on site conditions.

Separation of Circuits: Preventing interference and hazards by maintaining proper spacing between different classes of conductors.

地下设施: Minimum burial depths and protection from corrosion and water intrusion.

By establishing these foundational requirements, Article 300 provides the structural and safety framework that supports the more specialized requirements of Article 625.

Conduit-Specific Articles

Article 342 – Intermediate Metal Conduit (IMC): Lighter than RMC but still suitable for burial and concrete encasement.

Article 344 – Rigid Metal Conduit (RMC): Maximum strength; allowed in exposed, concealed, wet, or direct-burial locations.

Article 350 – Liquidtight Flexible Metal Conduit (LFMC): For wet, buried, or exposed installations needing flexibility.

Article 352 – Rigid PVC Conduit (PVC): Corrosion-resistant; allowed underground, in concrete, and exposed (if sunlight resistant). Restricted in high-heat or severe physical damage areas.

Article 358 – Electrical Metallic Tubing (EMT): Easy to bend and lightweight; approved indoors/outdoors but not direct-buried.

Article 356 – Liquidtight Flexible Nonmetallic Conduit (LFNC): Similar to LFMC but nonmetallic; listed for burial or outdoor use.

NEC Article 250 – Grounding & Bonding

Establishes rules for grounding and bonding electrical systems.

Metallic Conduits (RMC, IMC, EMT, LFMC): Can serve as an Equipment Grounding Conductor (EGC) if installed with approved fittings.

Nonmetallic Conduits (PVC, LFNC): Require a separate grounding conductor.

Provides sizing rules for grounding electrode conductors and bonding jumpers.

NEC Article 625 – Electric Vehicle Charging Systems

Article 625 specifically governs the installation and operation of electric vehicle charging systems. It expands on the general rules of Article 300 and applies them to the unique characteristics and risks of EV charging equipment. The scope of Article 625 includes conductors, connectors, couplers, inlets, supply equipment, and associated devices used to transfer energy between the premises wiring system and an electric vehicle.

Some major provisions of Article 625 include:

Voltage Ratings: Charging systems are permitted to operate up to 600 volts AC or DC unless otherwise specified.

Listing Requirements: All materials and equipment used must be listed (UL-certified or equivalent) for their intended purpose.

Equipment Construction: Requirements for EV couplers, cord lengths, cable management, interlocks, automatic de-energization, and personnel protection systems to prevent electric shock.

过流保护: Branch circuits and feeders supplying EVSE must be rated for continuous duty at no less than 125% of the maximum load.

断开方式: Equipment rated above 60A or 150V to ground must have a readily accessible disconnect, lockable in the open position.

Connection Methods: Allows cord-and-plug connection for lower-rated EVSE, while higher-rated equipment must be permanently wired.

Interactive Systems: Addresses bidirectional energy transfer, such as vehicle-to-grid (V2G) applications, linking to Articles 702 (optional standby systems) and 705 (power production sources).

Location and Ventilation: Establishes minimum installation heights, placement requirements, and ventilation needs where battery off-gassing may occur.

In essence, Article 625 ensures that EV charging systems are not only electrically safe but also designed to prevent hazards such as electric shock, fire, and mechanical failure. It bridges the general electrical installation rules of Article 300 with the specific demands of modern electric mobility infrastructure.

Canada: Canadian Electrical Code (CEC)

While the National Electrical Code (NEC) governs EV charging installations in the United States, the Canadian Electrical Code, Part I (CEC), Section 86 provides the framework for installations across Canada. Section 86 is dedicated exclusively to electric vehicle charging systems, supplementing the general requirements of the CEC to address the unique demands of EV infrastructure.

Key Provisions of CEC Section 86:

危险场所

When EV charging equipment is installed in hazardous areas (as defined in Sections 18 and 20 of the CEC), the installation must comply with additional requirements for explosion-proof and flame-proof design. This is particularly relevant for commercial garages, fuel stations, and industrial sites.

Voltage Limitations

The CEC permits nominal AC system voltages up to 750 V for EV charging equipment. This aligns with typical Level 2 and DC fast charging infrastructure while limiting risks in higher-voltage applications.

Receptacles

Standard receptacles for EV charging must be clearly labeled and dedicated for EV use.

A common configuration is a CSA 5-20R single receptacle supplied by a 125 V, 20 A branch circuit.

Outdoor receptacles within 2.5 m of grade must include Class A GFCI protection, ensuring enhanced safety in damp conditions.

Branch Circuits

Each EVSE must be supplied by a separate branch circuit with no other loads permitted, except ventilation equipment directly associated with the EVSE.

Continuous Load Classification

EV charging loads are considered continuous, requiring conductor and overcurrent protection sizing at 125% of the rated current (similar to NEC requirements).

Disconnecting Means

A dedicated disconnect is required for EVSE rated 60 A or more or over 150 V to ground.

This disconnect must be located within sight of and accessible to the EVSE, and must be lockable in the open position.

Bidirectional Power and Energy Export

The CEC explicitly addresses vehicle-to-grid (V2G) and vehicle-to-building (V2B) applications:

Only EVSE that is specifically approved and marked for bidirectional power may be used in such systems.

Installations must also comply with Section 84 (Interconnection of Electric Power Production Sources), ensuring safe integration with premises wiring and the utility grid.

Additional restrictions apply in commercial garages and fuel-dispensing facilities, where EVSE must be located outside hazardous areas.

Location Requirements

Indoor Sites: Includes garages, underground parking structures, and agricultural buildings. Where ventilation is required (e.g., for battery off-gassing), the EVSE must be interlocked with the ventilation system to prevent operation if ventilation is disabled.

Outdoor Sites: Includes residential driveways, carports, curbsides, and parking lots. Outdoor EVSE must be rated for weather exposure and installed to withstand environmental conditions.

Height Requirements: EVSE must be installed at a mounting height between 450 mm and 1.2 m above finished floor or grade, ensuring accessibility and protection from physical damage.

International Standards (IEC / ISO / AS/NZS)

IEC 61851:

Global standard for EV conductive charging systems, covering safety, performance, and installation.

IEC 60364-7-722:

Wiring rules for EV charging installations, requiring dedicated circuits and consideration for load management.

AS/NZS 3000 (Australia/New Zealand Wiring Rules):

Governs wiring installations, including EVSE. Requires proper mechanical protection for underground conduits, corrosion resistance, and compliance with ambient temperature ratings.

Why Choose Ledes PVC Conduit for EV Charging Stations

Selecting the right conduit brand is just as important as choosing the correct type of conduit. A high-quality conduit ensures long-term performance, safety, and compliance for demanding EV charging infrastructure. Ledes PVC conduit has become a trusted choice for many EV projects worldwide due to its proven durability, strict quality standards, and specialized solutions for solar and EV applications.

笔记: If you want to learn about the 4 Types of Electrical Conduits and their applications for an EV Charging Station, you can click on the link above.

Key Reasons to Choose Ledes PVC Conduit

1. Engineered for Harsh Outdoor Environments

EV charging stations are often exposed to sunlight, rain, snow, and wide temperature fluctuations. Ledes PVC conduits are UV-resistant, weatherproof, and maintain their integrity under prolonged outdoor exposure, ensuring reliable protection of cables in all climates.

2. Superior Electrical Safety

Safety is paramount in EV charging systems where high voltages and currents are involved. Ledes PVC conduits are flame-retardant, with excellent mechanical strength, and sunlight resistance options are available, significantly increasing the safety of EV charging systems.

3. Wide Range of Standards Compliance

Ledes offers conduits tested and certified to meet major international standards, such as UL, CSA, and AS/NZS 2053, ensuring compliance with NEC and other local electrical codes. This makes them suitable for EV charging projects in North America, Australia, and beyond.

4. Complete System of Conduits and Fittings

One challenge in EV installations is achieving a seamless conduit system with compatible fittings. Ledes provides a full range of rigid and corrugated conduits, elbows, couplings, adaptors, junction boxes, and accessories, allowing installers to source everything from one reliable manufacturer.

5. Cost-Effective without Compromising Quality

Compared with metallic conduits, Ledes PVC conduits are lightweight, easier to handle, and significantly reduce labor and transportation costs. They offer a balance of affordability and long-term reliability, making them an efficient choice for large-scale EV charging rollouts.

Installation Tips and Best Practices for EV Charging Conduit

Choosing the right conduit is only half the job, how it’s installed is equally critical for ensuring safety, compliance, and system longevity. Proper installation practices protect against environmental damage, reduce maintenance costs, and ensure compliance with NEC/CEC standards. Below are key best practices:

专业提示: Best practices for conduit installation are code compliance. We’ve described the Conduit Bending and Support, Grounding, and Bonding Requirements in the last post, and the data sheets attached. Click the links above for quick access to relevant information.

1. Proper Sealing for Moisture Protection

Outdoor and underground runs are highly susceptible to water ingress, which can corrode wires, trip breakers, and cause failures.

For PVC conduit, use solvent cement rated for watertight joints (UV-resistant for outdoor use).

For metallic conduit (RMC/IMC), apply thread sealants, rubber gaskets, or O-rings at joints to block moisture.

Use watertight connectors at junction boxes to prevent leaks.

In indoor garages, condensation barriers help mitigate moisture buildup from temperature swings.

Always inspect seals regularly and replace deteriorated gaskets to maintain system integrity.

2. Temperature and Heat Management

EV chargers, particularly Level 2 and DC fast chargers, generate substantial heat.

Use conduit materials rated for the ambient environment and cable load.

Larger conduit sizes not only ease wire pulling but also promote heat dissipation, reducing risk of overheating.

3. Conduit Support and Spacing

Follow NEC/CEC requirements for support intervals (e.g., every 3–5 feet for PVC, closer for heavy or vertical runs).

Use vibration-resistant clamps on outdoor poles, wall mounts, or island pedestals to prevent loosening over time.

Proper securing prevents sagging, strain, and mechanical damage.

4. Burial Depth and Underground Runs

For underground feeders, NEC/CEC generally requires 18–24 inches of cover for PVC conduit.

Use Schedule 80 PVC or concrete-encased metallic conduit where extra mechanical protection is needed, such as under driveways or high-traffic areas.

Ensure watertight joints and plan for future expansion exits when trenching.

5. Minimizing Bends and Pull Points

Avoid more than four 90° bends per conduit run, as excessive bends make pulling conductors difficult and increase insulation damage risk.

For long runs, install pull boxes or junctions to reduce stress during wire pulling and simplify future upgrades.

Always maintain the NEC-required minimum bend radius to protect conductor insulation.

6. Expansion and Thermal Movement

Conduit, particularly PVC, expands and contracts with temperature changes.

Install expansion couplings in long outdoor runs exposed to direct sunlight or temperature fluctuations.

Leave space where conduit penetrates walls or slabs to prevent stress cracking.

7. Derating, Fill, and Overcurrent Protection

Follow the NEC 40% fill rule to avoid overheating in conduit runs.

Apply ampacity derating when grouping multiple EV chargers in one conduit.

Ensure GFCI protection in wet or outdoor locations, and AFCI protection where required.

Metallic conduits must be properly grounded to ensure fault protection.

8. Professional Installation is Non-Negotiable

The NEC requires that EVSE be installed by a qualified person.

Licensed electricians ensure correct wire sizing, breaker selection, grounding, and permitting.

Professional installation prevents costly mistakes such as undersized conductors, improper bonding, or code violations.

Future-Proofing Your EV Charging Conduit Infrastructure

The electric vehicle industry is evolving rapidly, and charging infrastructure must be designed with tomorrow’s needs in mind—not just today’s. Future-proofing conduit installations ensures that your EV charging stations remain safe, efficient, and adaptable as demand grows and technologies advance. Conduits are not just protective channels for wiring; they form the backbone of your electrical infrastructure, and planning ahead can save significant costs and effort in the long run.

1. Plan for Higher Charging Capacity

While many installations today serve Level 2 chargers, demand for DC fast charging (Level 3) is increasing. Installing conduits that can accommodate larger conductor sizes ensures that you won’t need to excavate or redo the conduit system when upgrading to higher power chargers. Choosing larger diameter conduits or leaving spare conduits in place allows for scalability.

2. Allow for Smart and Connected Infrastructure

Future charging systems will integrate with smart grids, load management systems, and even vehicle-to-grid (V2G) technologies. Conduits should be sized and routed to handle not only power cables but also communication and data cables. Using separate conduits for signal and control wiring helps prevent interference and supports long-term reliability.

3. Consider Renewable Energy Integration

Many EV charging stations are being paired with solar power, battery storage, and energy management systems. Future-ready conduit planning should allow for routing additional wiring to connect renewable sources, inverters, and monitoring equipment without disrupting existing infrastructure.

4. Comply with Evolving Standards and Safety Requirements

Electrical codes and standards for EV charging are continuously updated. By selecting conduits that already meet or exceed the latest UL, NEC, and local code requirements, you reduce the risk of needing premature replacements. Choosing nonmetallic conduits that are fire-resistant, UV-stabilized, and corrosion-resistant can extend service life in both indoor and outdoor applications.

5. Design for Accessibility and Maintenance

Future-proofed conduit systems should allow easy access for inspection, cable replacement, and upgrades. Using sweep bends instead of sharp elbows, planning access points, and avoiding overly complex routing will make future work less costly and time-consuming.

6. Build with Sustainability in Mind

As EV adoption grows, sustainability is becoming a driving factor. Low-smoke halogen-free (LSZH) conduits or recyclable PVC options help reduce environmental impact while maintaining performance. Considering eco-friendly materials now aligns your infrastructure with future sustainability regulations.

结论

Selecting the right conduit for EV charging infrastructure is far more than a matter of routing wires—it is a critical step in ensuring safety, compliance, and long-term reliability. From understanding the EV charging systems, suitable conduit types, to adhering to NEC and CEC requirements, each decision impacts both performance and regulatory compliance.

Looking forward, future-proofing your conduit infrastructure is essential to accommodate evolving EV technologies, higher charging capacities, smart grid integration, and renewable energy solutions. Thoughtful planning today reduces costly retrofits tomorrow and ensures your EV charging network remains reliable, safe, and adaptable for decades.

By combining high-quality materials, adherence to electrical codes, meticulous installation, and forward-looking design, you can create EV charging infrastructure that not only meets current needs but is ready to handle the challenges of the rapidly advancing electric vehicle landscape.

常见问题解答

What are the different EV charging levels, and how do they affect conduit choice?

There are three main charging levels:

Level 1 (120V AC, ~12–16A): Slow charging, typically for home use.

Level 2 (208–240V AC, 16–80A): Common for residential, workplace, and public charging.

DC Fast Charging (DCFC) (400–1000V DC, up to 350kW): Primarily for commercial/public sites.

As charging power increases, conductors generate more heat, requiring larger wire gauges and, often, larger conduit diameters to ensure safe heat dissipation and compliance with code.

Why is conduit important for EV charging stations?

Conduit serves as the protective pathway for conductors, shielding them from physical damage, moisture, UV exposure, soil chemicals, and corrosion. Proper conduit selection not only enhances durability but also ensures electrical safety, reduces fire risks, and extends the life of the EV charging system.

What environmental factors should I consider for outdoor or underground conduit installations?

For outdoor applications, key considerations include:

UV resistance to prevent degradation in sunlight.

Moisture resistance against rain, snow, and humidity.

Temperature stability for extreme heat or cold.

For underground installations, conduits must resist soil pressure, chemical exposure, and constant wet conditions. Schedule 80 PVC or encased metallic conduits are often required for durability.

How does the National Electrical Code (NEC) influence conduit selection?

The NEC provides strict safety standards:

Article 625: Covers EV power transfer systems, continuous load requirements (125% sizing), GFCI protection, and dedicated circuits.

Article 300: General wiring requirements, including wet location rules, bend limitations, and burial depths.

Conduit-specific Articles (344, 352, 358, etc.): Define permitted uses and restrictions for each conduit type.

Article 250: Grounding and bonding requirements, especially when using non-metallic conduit.

Compliance is not optional — it is mandatory for safety and inspection approval.

How do I size conduit and wire correctly for an EV charger?

Wire gauge depends on the charger’s amperage and circuit length. For example:

A 40A EVSE typically requires 8 AWG copper,

A 48A EVSE often requires 6 AWG copper (4 AWG for long runs).

Circuit breakers must be sized at 125% of the charger’s continuous load. Conduit fill must not exceed 40% of its internal area, and derating factors apply when bundling multiple circuits. Always verify sizing against NEC tables.

When should I use metal conduits instead of non-metallic ones?

刚性金属导管(RMC): Maximum protection against impact, ideal for commercial/industrial and high-traffic areas.

中间金属导管 (IMC): Strong yet lighter than RMC; suitable for cost-effective commercial use.

电气金属管(EMT): Lightweight, cost-effective, and suitable for indoor/protected runs.

Metal conduits are also advantageous when an Equipment Grounding Conductor (EGC) is desired through the conduit body itself.

Can I use PVC conduit for EV charger?

Yes. PVC conduit (Schedule 40 or Schedule 80) is widely used for EV charger installations, especially underground or outdoor runs, because it is non-corrosive, lightweight, and cost-effective. Schedule 80 is required where the conduit is exposed to physical damage. For indoor runs, EMT or ENT may also be used.

What are common installation mistakes to avoid?

Using undersized wire or breakers for the charger’s load.

Overfilling conduits beyond NEC’s 40% limit.

Skipping required pull boxes for long runs or multiple bends.

Poor sealing of joints, leading to water ingress.

Neglecting grounding and bonding requirements.

Attempting DIY installation without permits or inspection.

Such mistakes can cause overheating, premature failure, or failed inspections.

What size conduit for Tesla charger?

The Tesla Wall Connector typically uses 3/4 inch (21 mm) conduit as the default size, but it can also accommodate 1 inch (27 mm) conduit. A 1-inch conduit is recommended for easier wire pulling, especially for the back entry point.

Do EV chargers need an earth rod?

In most residential installations, a separate earth rod is not required if the home already has a compliant grounding electrode system. However, in some regions or commercial installations, additional grounding electrodes may be required. Always follow NEC and local codes.

What are the electrical requirements for EV charging?

Dedicated circuit (no shared loads).

Correct breaker size.

240V supply for Level 2.

Proper conduit and conductor sizing per NEC.

Grounding and bonding per NEC 250.

GFCI protection may be required depending on installation.

Can EV charge without earthing?

No. Proper grounding is critical for EV safety. Without grounding, there is a risk of shock or equipment damage. NEC requires that EVSE (Electric Vehicle Supply Equipment) be grounded. Some chargers also have built-in ground monitoring that will prevent charging if grounding is inadequate.

What is the 80% rule for EV charging?

The NEC requires continuous loads (running for 3+ hours) not to exceed 80% of the breaker rating. EV charging is considered a continuous load.

Example: A 40A breaker can only supply 32A continuous charging load.

This is why many Level 2 chargers rated at 32A require a 40A breaker.

What type of outlet is best for EV charging station?

NEMA 14-50 outlet (240V, 50A): Most common for Level 2 portable chargers.

Hardwired wall-mounted EVSE: Preferred for permanent installations (safer, no outlet wear).

For Tesla, a Wall Connector is recommended for higher charging speeds.