目录

直埋管道 指一种设计和安装于地下、无需额外保护或包裹的管道或导管系统。它通常用于需要将电缆或电线铺设于地下的电力、电信或数据通信应用。

直埋导管通常由高密度聚乙烯 (HDPE) 或硬质聚氯乙烯 (PVC) 等耐用材料制成,可有效抵御潮湿、土壤酸化和其他环境因素的影响。导管设计具有抗腐蚀、抗冲击和抗挤压等特点,确保其所容纳的电缆或电线的完整性。

名称中的“DB”代表“直埋”,表明其适合地下安装,无需额外的混凝土包覆。这使得它成为各种地下电气应用的经济高效且用途广泛的选择。

地下埋管 (DB) 有多种类型,每种都有各自的规格和优势。以下是美国和加拿大最常用的一些地下埋管。

笔记: 详细了解 PVC 导管的 UL 651 标准要求 如果您对此部分感兴趣,请参阅我们上一篇文章。

DB60导管 是一种专为电信和数据网络应用中的电缆和电线而设计的导管。“DB60”标识指的是其尺寸,标准尺寸为高和宽均为 60 毫米。但需要注意的是,我们也可能提供其他尺寸和型号,以满足特定的安装需求。

- 轻松安装:告别厚重的混凝土外壳。DB60 的直埋功能可节省您的时间和成本,让安装变得轻而易举。

- 卓越的强度:DB60 可承受地下土壤的压力和运动的压力,确保您的电缆安全。

- 经济实惠的选择:与传统金属导管相比,DB60 由于易于安装且重量更轻,可显著节省成本。

根据导管类型和位置确定最小埋深的一般准则(有关具体要求,请参阅国家电气规范 (NEC) 和其他行业标准):

- 住宅区:18英寸(45厘米)

- 商业和工业领域:24英寸(60厘米)

- 道路交叉口:36英寸(90厘米)

DB100导管 是一种专为直埋设计的 PVC(聚氯乙烯)导管。它主要用于保护地下电缆,无需像混凝土那样进行额外的包裹。与 DB120 等较重的导管相比,DB100 是一种更轻型的导管,通常用于住宅、轻型商业和通信电缆应用。

经济高效:

DB100 比 DB120 等额定重量更大的导管更经济实惠,因此对于不需要极端机械强度的项目来说,它是一个实用的选择。

重量轻且易于安装:

更薄的壁和更轻的重量使 DB100 更易于操作和更快安装,有助于减少劳动时间和成本。

可直接埋葬:

它专为地下安装而制造,无需额外保护,简化了开沟和电缆铺设。

耐腐蚀、防潮:

DB100 是一种 PVC 材料,不会像金属导管那样腐蚀,并且具有出色的抗湿气和土壤中多种化学物质的能力。

光滑的内部:

光滑的内表面减少了拉动电缆时的摩擦,有助于防止安装过程中电缆损坏。

虽然具体要求可能因当地规范和项目条件而异,但对于低压和通信线路,常见的指导原则是从导管顶部到地面的距离为 18 至 24 英寸(45-60 厘米)。

如果安装在车道、道路或重型设备可能穿过的地方,可能需要更深的埋置(通常为 24 至 36 英寸,有时还需要混凝土包裹等额外保护)。

DB120导管 是一种广泛用于保护和整理电线电缆的电气导管。它由优质耐用的材料制成,例如聚氯乙烯 (PVC) 或聚乙烯 (PE),这些材料具有出色的抗腐蚀、防潮、耐化学腐蚀和抗紫外线性能。“DB120”指的是 PVC 的特定等级,表明其壁厚和强度。

- 耐用性:DB120 导管耐腐蚀、耐化学品和耐风化,非常适合长期地下使用。

- 抗冲击性:DB120 导管的厚壁可以承受显著的冲击,保护内部的电线免受损坏。

- 重量轻:与混凝土或金属导管相比,DB120 重量轻得多,因此更易于处理和安装。

- 灵活性:DB120 导管具有多种长度和直径,可轻松适应不同的项目需求。

- 经济高效:与其他类型的地下导管相比,DB120 导管是一种相对经济实惠的选择。

- 住宅区:12英寸(30厘米)

- 商业和工业领域:18英寸(45厘米)

- 道路交叉口:36英寸(90厘米)

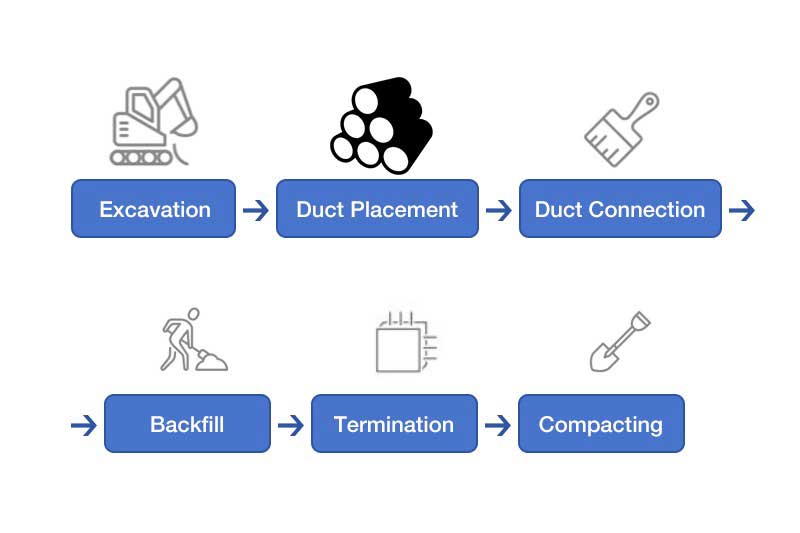

安装DB120导管的过程相对简单。基本步骤如下:

- 开挖沟槽:沟槽应足够深,以满足当地对电力和通信线路的埋深要求。

- 铺设导管:将导管放入沟槽中,确保其水平且无杂物。

- 连接导管部分:使用溶剂胶或机械联轴器将导管部分连接在一起。

- 拉电线:将电线或通讯线拉过导管。

- 回填沟渠:用泥土回填沟渠,并将其夯实以消除气穴。

DB120 导管用途广泛,包括:

- 住宅和商业地下电线

- 交通信号和街道照明系统

- 电信和数据电缆

这些导管采用坚固的PVC(聚氯乙烯)制成,专为埋入混凝土而设计。这意味着它们将成为地下基础设施不可或缺的一部分,保护敏感电缆免受地下生活环境的严酷影响。

- 卓越强度:“EB”标识代表其卓越的抗冲击性能,能够承受土壤移动和意外冲击的压力。它们如同默默守护者,保障您的电流不间断流动。

- 卓越的耐用性:这些管道被包裹在混凝土中,形成坚固稳定的网络,最大限度地降低了地面运动造成损坏的风险并确保了持久的性能。

- 重量轻:与金属导管相比,EB20/35 导管重量轻,更易于处理和安装,从而节省时间和人工成本。

- 兼容性:这些导管具有多种直径和长度,可以根据不同的项目需求进行定制,从小型住宅设施到大型商业综合体。

安装 EB20/35 导管遵循一个简单的过程:

- 堑壕战:挖一条足够深的沟渠,以满足当地的埋葬深度要求,为其中的电气动脉提供充足的保护。

- 混凝土支架:准备一层坚固的混凝土作为导管的支撑和保护外壳。

- 奠定基础:小心地将导管部分放入沟槽中,确保正确对齐和连接。

- 连接力:使用溶剂胶或机械接头来创建无缝、防漏的管道网络。

- 混凝土斗篷:用准备好的混凝土覆盖管道,形成统一且坚不可摧的屏障。

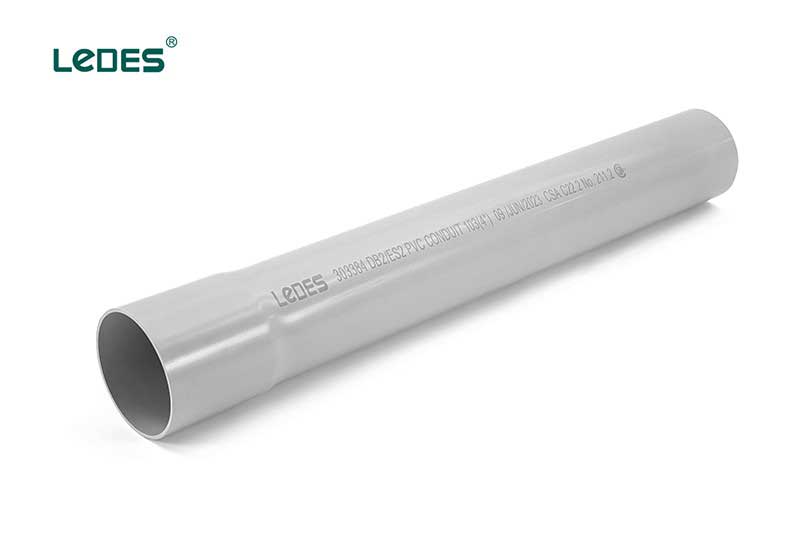

DB2/ES2 导管 指用于通信目的的特定类型的管道。它通常是一种非金属管道,用于容纳和保护通信电缆,例如光纤电缆或以太网电缆。Ledes DB2 管道由 PVC 制成,经 CSA C22.2 No.211.1 认证,常用于电信、网络和数据中心等各行各业,为高效有序的通信电缆安装提供管道。

- 耐腐蚀:DB2/ES2 PVC 线管采用高 PVC 材质制成,非金属材质,即使暴露于自然腐蚀环境中也不会生锈。确保在地下环境中长期稳定运行,为布线系统提供安全可靠的保护。

- 重量轻:重量轻,使搬运和安装更容易,大大节省时间和人工成本。

- 直接埋葬:适用于直接埋葬应用,按照加拿大电气规范 (CEC) 安装时不需要额外保护。

- 轻松拉线:DB2/ES2 具有光滑的内表面,可减少长距离拉电线和电缆时的摩擦。

DB2/ES2 PVC 管道可用钢锯轻松切割,或使用 PVC 切割机切割小尺寸管道。

要连接不同长度的管道或配件,只需使用溶剂型胶粘剂即可。PVC溶剂型胶粘剂可以使接头牢固防漏。操作简便,节省时间。

- 沟底:挖一条足够深的沟渠,以满足当地的埋深要求,保护其中的电线。

- 奠定基础:小心地将 DB2 管道部分放置在沟槽中,确保使用溶剂胶或机械联轴器正确对齐和连接。

- 回填:一旦导管固定好,用土回填沟槽,确保适当压实以消除气穴。

DB 管道的埋置深度可能因多种因素而异,包括当地法规、具体项目要求以及安装类型。不过,有一些通用的准则需要考虑:

当地法规: 查看您所在地区的当地建筑规范和法规。这些规范和法规通常会规定不同类型的管道和公用设施的最小埋置深度。

环境因素: 考虑霜冻深度、土壤类型和地面条件等因素。这些因素会影响管道的稳定性和保护性。在冰冻温度地区,通常将管道埋设在霜冻线以下以防止损坏。

保护和可访问性: 管道埋设深度应足以抵御外部因素(例如挖掘、交通和环境因素)的影响。此外,管道埋设深度还应便于维护和必要时的检修。

作为一般准则,非金属通信管道(如 DB 管道)通常埋设在 18至24英寸 (45至60厘米)。但是,务必咨询当地政府部门以及熟悉具体项目和当地法规的专业人士,以确定您所在位置DB管道的适当埋设深度。

在为地下项目选择DB导管之前,务必了解其设计、材料和性能的标准。这些标准确保导管满足最低的安全性、耐用性和质量基准——在基础设施可靠性至关重要的情况下,这一点至关重要。

在美国, 主要标准有:

- ASTM F512-19: 地下安装用光滑壁聚氯乙烯(PVC)导管和配件的标准规范。

- NEMA TC 6 和 8: 适用于地下安装的聚氯乙烯 (PVC) 塑料公用设施管道。

在加拿大,关键标准是:

- CSA C22.2 第 211.1 号: 刚性类型 EB1 和 DB2/ES2 PVC 导管。

专业提示: 想要了解更多 CSA CC22.2 标准的详细信息?点击链接阅读我们的上一篇文章。

美国地下电气管道最重要的标准之一是 ASTM F512-19。该规范定义了用于地下安装通信和电力电缆的光滑壁聚氯乙烯 (PVC) 管道和配件的材料、结构和性能要求。

该标准根据导管的刚度和预期用途将导管分为五种类型:

EB-20型 — 混凝土外壳(刚度较低)

EB-35型 — 混凝土外壳(刚度更高)

DB-60型 — 直接埋设(刚度较低)

DB-100型 — Direct burial (higher stiffness)

Type DB-120 — Direct burial (very high stiffness)

EB types are mainly intended for installation within concrete encasement, while DB types are specifically built for burial directly in the soil, where higher strength and durability are essential.

To comply with ASTM F512-19, conduits must pass several critical tests that assess their durability and performance under underground conditions:

Conduits must be made from virgin or reworked PVC compound that meets detailed material properties such as strength, impact resistance, and chemical resistance.

The PVC material must meet specific cell classifications as defined in ASTM D1784, including:

- 12254

- 12164 (requiring a minimum tensile strength of 4000 psi or 28 MPa)

- 12264 (requiring a minimum tensile modulus of 500,000 psi)

Molded fittings must be made from PVC compounds with cell classifications of:

- 12234, or

- 13343,

also as defined under ASTM D1784.

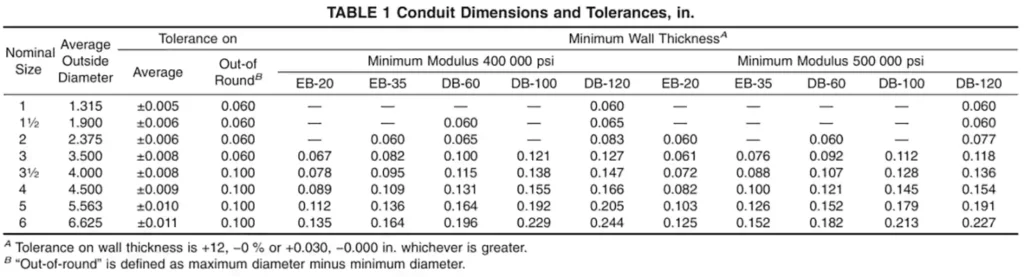

Outside diameters, wall thicknesses, and lengths must fall within tight tolerances to ensure consistent quality and compatibility with fittings.

Special dimensional requirements are defined separately for EB and DB types due to their different burial conditions.

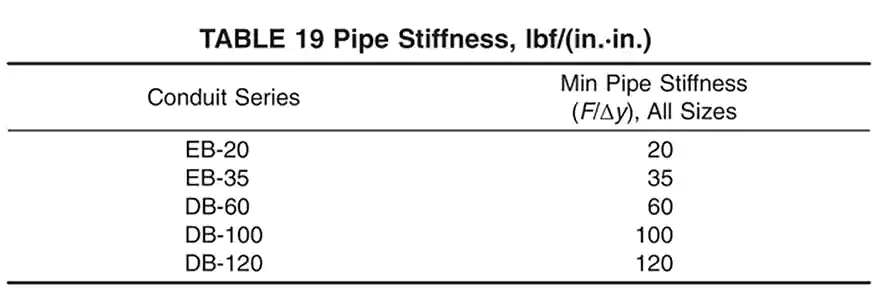

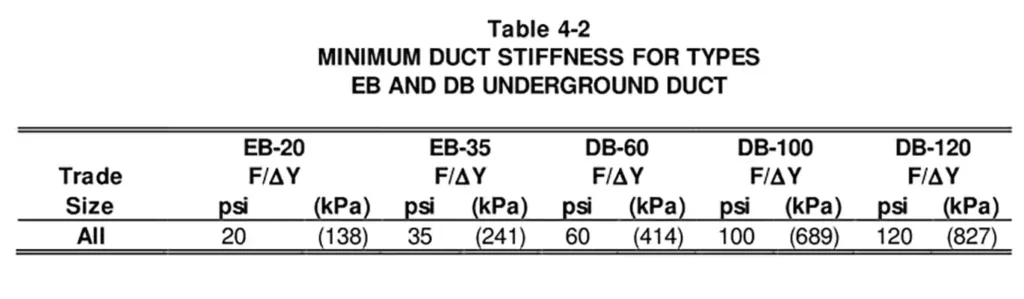

Pipe stiffness is a critical performance characteristic for underground conduits, particularly those intended for direct burial where soil loads and external pressures are a concern.

According to ASTM F512-19:

Minimum Pipe Stiffness Values are as follow:

测试方法

The stiffness of the conduit is determined by a standardized parallel-plate loading test, following the procedures outlined in ASTM D2412. Here’s how the method works:

- A short length of pipe is placed horizontally between two rigid, parallel flat plates.

- The plates are brought together at a controlled rate of 0.50 ± 0.02 inches (12.5 ± 0.5 mm) per minute.

• During loading, load versus deflection (diameter change) data are recorded. - If cracking, crazing, delamination, or rupture occurs during the test, the corresponding load and deflection at the moment of failure are documented.

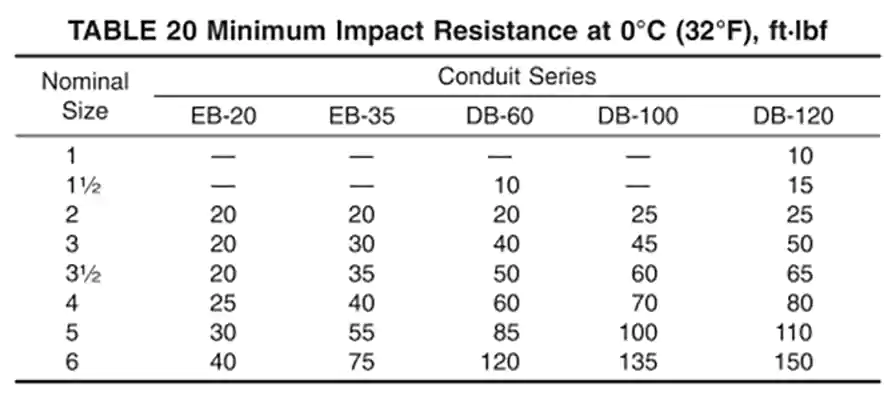

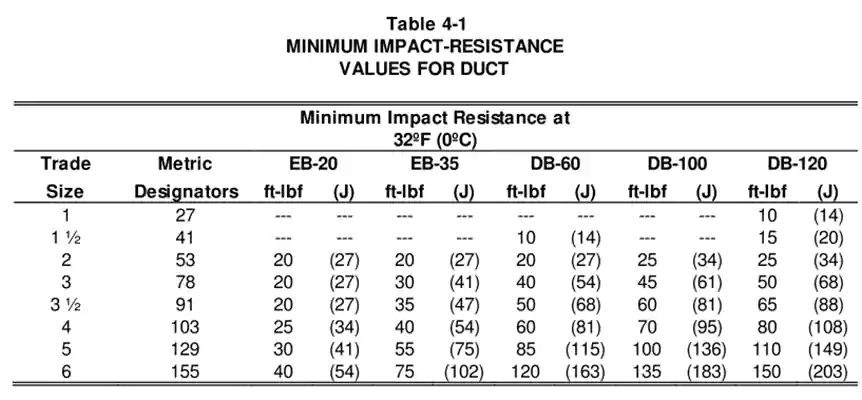

Impact resistance is another critical performance factor for underground PVC conduits. This is a quality control test that must be conducted at the time of manufacture to ensure consistent product reliability.

According to ASTM F512-19:

Minimum Requirements:

测试方法:

Impact testing is performed according to ASTM D2444, a 20-lb (9.1 kg) Tup B and a flat plate holder (Holder B) are used to apply the impact force.

温度考虑因素:

If the test is performed at temperatures above 0°C (32°F), the specimen must be tested within 15 seconds after removal from the conditioning environment to maintain accuracy.

This impact test ensures that DB conduits can resist sudden, heavy loads without cracking or breaking, maintaining their structural integrity underground.

Ensuring a watertight connection between conduit sections is essential for underground installations, especially to prevent infiltration of moisture or soil into the electrical or communication pathways.

According to ASTM F512-19:

要求:

Conduit joints must not leak when subjected to pressure testing.

测试方法:

- A section of conduit is cemented to a bell (socket) following the manufacturer’s instructions, or, if no instructions are available, by using the method described in ASTM Practice D2855.

- The assembled joint must stand undisturbed for at least 6 hours to allow the solvent cement to properly cure.

- After curing, the joint is subjected to an internal water pressure of at least 25 psi (170 kPa) and maintained at this pressure for at least 1 hour.

Passing Criteria:

During the test, no leakage of water is permitted.

Bond:

A probe or point of a knife blade is used to separate the concentric layers.

It shall not be possible to separate any two layers using a probe or the point of a knife blade in such a way that the layers come apart cleanly or that the probe or blade can move freely between them.

ASTM F512-19 requires conduit products to carry clear and standardized markings to ensure easy identification, traceability, and compliance with quality expectations. Key requirements include:

制造商名称或商标

PVC Cell Classification

Nominal Size and Type of Conduit

Minimum Wall Thickness

Control or Code Number

Standard Designation must be marked:

“ASTM F512” for single extrusion conduit

“ASTM F512 COEX” for coextruded conduit

Marking Frequency: At intervals not exceeding 5 feet (1.5 meters) along the conduit length.

Additional markings are allowed if the manufacturer deems them useful.

In addition to ASTM standards, another important reference for underground PVC conduit manufacturing in North America is the NEMA TC 6 & 8 standard.

This standard is published by the National Electrical Manufacturers Association (NEMA) and plays a critical role in defining the performance and quality requirements for polyvinyl chloride (PVC) conduit used in both direct burial and concrete encasement applications.

Key Points and Testing Requirements:

Conduits and fittings must be made from high-quality PVC compounds that meet minimum performance standards for strength, chemical resistance, and durability. Similar as ASTM F512-19 requirements.

Precise tolerances are set for conduit diameter, wall thickness, and socket dimensions to ensure proper fit and function in the field.

Testing procedure and requirements are the same referenced in ASTM F512-19. Measurements are take at 5% vertical deflection of the conduit’s inside diameter.

The testing method and requirements are the same with ASTM F512-19, but NAME TC 6&8 explicitly warns that UV exposure reduces impact resistance; values only valid at time of manufacture.

Same requirements as ASTM F512-19.

制造商名称或商标

Standard Size Designation and Type of Conduit

PVC Cell Classification

Standard designation

Marking Frequency: Markings must be repeated at uniform intervals and appear at least every 10 feet (3.05 meters).

Additional markings that manufacturer considers necessary.

In addition to ASTM and NEMA standards, CSA C22.2 No. 211.1 is an important specification covering polyvinyl chloride (PVC) conduit intended for underground installations in Canada. CSA (Canadian Standards Association) standards ensure products meet strict safety and performance requirements suitable for Canadian environments, including extreme cold.

This standard sets the materials, construction and performance requirements for:

- 硬质 PVC 导管:

EB1 类型: Intended for encasement in concrete or masonry.

类型 DB2/ES2: Intended for direct burial in the ground or encasement in concrete or masonry.

- Associated Fittings:

Including straight couplings, 5° angle couplings, caps, plugs, bell-end terminators, bends, and adapters.

The conduit must be manufactured from PVC compounds that meet minimum requirements for physical and chemical properties such as tensile strength, impact resistance, and resistance to sunlight (for exposed sections). And have an ASTM D1784 cell classification of 12224.

The standards specifies the minimum wall thickness and outside diameters for different trade sizes. The requirements are different to ASTM and NEMA standards since they are different types and used in different regions.

This test verifies the toughness of the conduit material – especially under handling and installation conditions at both normal and cold temperatures.

测试方法:

A falling weight impacts the conduit placed on a specially prepared support bed.

Impact Energy and Temperatures

- At room temperature (23 °C): The impact energy applied must be 61 joules.

- At cold temperature (–18 °C): The impact energy applied must be 34 joules.

The crush resistance test evaluates the ability of PVC conduit to maintain its shape under compressive loading. This test ensures that the conduit can withstand burial or encasement pressures without permanent deformation.

测试程序:

- Test is performed at 23 ± 2°C (standard room temperature).

- Before loading, the vertical inside diameter of each specimen is measured and recorded.

- Each specimen is placed horizontally between two flat steel platens on a static load test bed (according to Figure 2 of CSA C22.2 No. 211.0).

The conduit is positioned so that the vertical axis (direction of measurement) is under compression. - A test mass of 90 kg, including the mass of the upper platen, is applied gradually onto the specimen. The load is maintained for 60 ± 5 seconds.

- After 60 seconds under load, remeasure the vertical inside diameter. And after 300 ± 20 seconds (5 minutes), measure the vertical inside diameter again to assess recovery.

通过标准:

- During Load:

The average percentage decrease in vertical diameter shall not exceed:

12% for Type EB1 conduit

10% for Type DB2/ES2 conduit

- After Recovery:

The average percentage decrease shall not exceed 5% for both types.

The test method is same as ASTM and NEMA standards, which is performed in accordance with ASTM D2412.

要求:

- Type EB1 conduit must have a minimum pipe stiffness of 200 kPa at 5% deflection.

- Type DB2/ES2 conduit must have a minimum pipe stiffness of 300 kPa at 5% deflection.

测试程序:

- Two pieces of conduit, each 1 ± 0.1 meters long, are solvent-cemented into a standard coupling.

- After assembly, the joint must be cured for 24 hours at room temperature to ensure proper bonding.

- The entire assembly is completely filled with water, ensuring no trapped air inside.

- A gauge pressure of 35 kPa (around 5 psi) is applied inside the filled assembly.

- The pressure must be maintained continuously for 4 hours.

验收标准:

- Throughout the 4-hour period, the joint must withstand the pressure without any rupture or leakage.

- Visual inspection is performed after the test to ensure no signs of leaking or joint separation.

粘合强度:

- Choose eight points spaced equally around the circumference (every 45 degrees approximately).

- At each valley point, use a sharp probe or knife point. Attempt to separate the inner and outer walls manually by prying or picking.

- The conduit cannot cleanly separate the inner and outer walls at any of the eight points.

The chemical resistance requirements ensure that rigid PVC conduits maintain their mechanical and physical properties when exposed to aggressive chemical environments.

About Test:

The conduits are immersed for 7 days in the selected chemical solutions.

After immersion, the specimens must not exhibit a mass change greater then 2%.

After removing the samples from the chemical solutions, the specimens are subjected to a tensile strength at a crosshead speed of 12.7 mm/min ± 25% within 1 hour.

The average tensile strength of the chemical-exposed specimens must not differ from the average tensile strength of the control (unexposed) specimens by more than 15%.

Manufacturer’s name, trademark

Conduit type, such as DB2/ES2 PVC Conduit

交易规模

The date of manufacture

Standard: CSA C22.2 No.211.1

Item | ASTM F512-19 | NEMA TC 6 和 8 | CSA C22.2 第 211.1 号 |

地区 | U.S. | U.S. | 加拿大 |

导管类型 | EB20, EB35, DB60, DB100, DB120 | EB20, EB35, DB60, DB100, DB120 | EB1, DB2/ES2 |

抗冲击性 | 20 ft-lbf at 0 °C | 20 ft-lbf at 0 °C | 61 J at 23 °C, 34 J at -18 °C |

抗压强度 | 未指定 | 未指定 | 90 kg load for 60s, avg. Deformation: EB1≤12%, DB2≤10%, recovery≤5% |

刚性 | ASTM D2412: specify min. Stiffness for each conduit type at 5% deflection | Same as ASTM F512-19 | ASTM D2412: EB1≥200 kPa, DB2≥300 kPa at 5% deflection |

关节紧张 | Water medium, 25 psi (172 kPa) pressure for 1 hour | Water medium, 25 psi (172 kPa) pressure for 1 hour | Water medium, 35 kPa (5 psi) pressure for 4 hours |

粘结强度 | No layer separation under probe or blade | 未指定 | No clean separation allowed using knife at 8 points around circumference |

耐化学性 | 未指定 | 未指定 | <2& mass change; tensile strength change <15% after 7-day immersion |

When selecting the right conduit for an electrical installation, one of the most important considerations is whether the conduit is intended for underground or above-ground applications. Two of the most common types are DB conduit (specifically DB2/ES2 for Canada or DB120 in the U.S.) and Schedule 40 PVC conduit.

While both are made from polyvinyl chloride (PVC), their designs, wall thicknesses, performance characteristics, and application scenarios differ significantly.

特征 | DB Conduit (DB2/ES2, DB120) | 40 号 PVC 导管 |

主要用途 | Underground installations (direct burial or concrete encasement) | Above ground installations or embedded in walls/ floors |

标准 | CSA C22.2 No.211.1 (Canada), NEMA TC 6&8 (U.S.) | UL651, NEMA TC2 |

壁厚 | Thinner than Schedule 40 | Thicker wall for higher mechanical protection |

灵活性 | More flexible for easier trench installation | More rigid |

Installation Method | Buried directly or encased in concrete | Surface-mounted or embedded in structures |

抗压强度 | Designed for buried loads | Higher crush resistance due to thicker wall |

抗紫外线 | Not always UV resistant (buried) | Typically UV resistant for outdoor exposure |

Impact resistant | 缓和 | 更高 |

刚性 | 缓和 | 更高 |

成本 | 更具成本效益 | More expensive |

Understanding their differences can better help you to choose the right conduit type for your project, whether to choose DB conduit or above ground use conduit.

Choosing the right underground conduit starts with understanding your installation environment and matching it with the appropriate conduit type and standard. In the U.S., popular underground conduit types include EB20, EB35, DB60, DB100, DB120, Schedule 40, and Schedule 80. Each has specific strengths designed for different applications.

For concrete encased underground installations, choose the EB types.

For light-duty direct burial underground installations, such as garden lighting or residential landscape wiring, DB60 or DB100 can offer a budget-friendly solution with adequate protection. However, for most utility-grade and code-compliant electrical work, DB120 is considered the standard. It offers a balance of crush resistance, flexibility, and durability, making it suitable for use under driveways, sidewalks, or landscaped areas.

If your project requires conduits to run both underground and above ground (e.g., from underground into a building or panel), you may need to use to Schedule 40 or even Schedule 80 conduit. These rigid PVC conduits can used both underground and above-ground, and are thicker-walled, provide better UV resistance and impact protection when exposed. However, Schedule 40/80 are generally more rigid and may be harder to install in tight bends or curved runs, unlike DB conduit, which is easier to work with in trench applications.

Not all suppliers are created equal. Beyond just selling conduit, a dependable supplier should provide verified compliance with standards like CSA C22.2 No. 211.1, ASTM F512, or NEMA TC6 & 8. Look for evidence of product testing, such as impact resistance, joint tightness, stiffness, and bond integrity. Ask for certifications or test reports when necessary.

It’s also beneficial to work with a supplier that offers a complete system—conduits along with compatible fittings, adapters, elbows, and accessories—to ensure ease of assembly and reduce compatibility issues. Consider the supplier’s track record in your industry, their availability of technical support, and their responsiveness to project-specific needs. Local warehousing, fast delivery, and customization options are also key indicators of a reliable partner.

Ultimately, the best supplier is one that not only delivers high-quality products but also stands behind them with technical knowledge, compliance documentation, and after-sales support. Making the right choice will help your underground installation go smoothly and perform reliably for years to come.

When choosing between direct burial (DB) conduit and above-ground conduit systems, understanding the full cost-benefit profile is essential.

Upfront Cost: DB conduit typically has a lower initial cost than above-ground use conduit, such as Schedule 40 rigid PVC conduit

安装费用: DB conduit is easier to install due it’s lighter weight, making the labor costs lower. While Schedule 40 is heavier and potentially increases the installation costs.

Long – Term Costs: While DB conduit is less expensive upfront, it may require more frequent maintenance or replacements due to lower durability. Schedule 40, with its greater durability, can lead to lower long-term maintenance and replacement costs.

Direct Burial (DB) conduit plays a vital role in today’s underground electrical infrastructure, offering a reliable, durable, and code-compliant solution for protecting cables in harsh below-ground environments. Whether used in residential power distribution, commercial utilities, or infrastructure projects like EV charging stations and data centers, DB conduit stands out for its moisture resistance, long-term performance, and ability to meet stringent testing standards such as CSA C22.2 No. 211.1, ASTM F512, and NEMA TC6 & 8.

In this guide, we’ve explored the key differences between DB conduit and above-ground options like Schedule 40, breaking down everything from crush resistance and joint integrity to bond strength, chemical resistance, and cost-effectiveness. We’ve also discussed how to choose the right type of conduit and the importance of selecting a trustworthy supplier to ensure both compliance and performance.

Ultimately, DB conduit offers more than just buried protection – it delivers peace of mind. For those planning underground installations where safety, longevity, and minimal maintenance are priorities, DB conduit is a forward-thinking and cost-efficient choice.

signed for direct burial and concrete encasement, are the ideal choice for underground electrical installations. For more product information, please send us a request form 或者 email us directly. Ledes’ professional team will help you with your questions and projects need.

我可以使用不带导管的直埋电缆吗?

Yes, you can use direct burial cables without a conduit—but only if the cable is specifically rated for direct burial use. These cables are designed with robust insulation and jackets that can withstand underground conditions, including moisture, soil pressure, and temperature changes.

However, using conduit, especially DB type conduit, can provide extra mechanical protection for cables against rocks, shifting soil, and accidental digging.

从国际上采购直接埋葬产品有哪些风险?

Sourcing direct burial (DB) conduit products internationally can offer cost advantages, but it also comes with notable risks. Here are the key concerns:

- Product Quality

Not all direct burial conduits can meet the industry safety and performance requirements, when selecting the conduit manufacturer, make sure their products comply with the required standards and provide relevant test reports or certifications. If the conduit can’t meet the requirements, can result in costly failure and pose safety risks.

- Lead Time and Logistics

Shipping products from overseas can lead to longer lead times, especially in peak construction seasons. Unpredictable customs delays or disruptions due to geopolitical issues or port congestion. And need to pay increased freight costs.

尖端: Plan procurement schedules in advance and ensure suppliers have reliable logistics partners. Always factor in buffer stock for urgent needs.

- Communication Barriers and After-Sales Support

Cross-time zone collaboration and language differences can lead to misinterpretations or delays in communication. Technical requirements may not be fully understood, and important issues might not be addressed in a timely manner. This can become especially problematic during installation or in the event of product failure, where quick access to technical support or replacement parts is critical. In some cases, after-sales service from international suppliers may be slow, unresponsive, or not aligned with local expectations.

尖端: Choose suppliers with bilingual technical teams, clear communication channels, and a local or regional support network. Always confirm their responsiveness and support capabilities before committing to large-scale procurement.

直接埋葬安装是否需要考虑环境因素?

Yes. Direct burial conduit systems must be designed with environmental factors in mind to ensure long-term reliability and safety. One of the primary concerns is soil composition—certain soils can be highly acidic or alkaline, which may degrade materials over time. In addition, microbial activity in the soil can contribute to corrosion, particularly in metallic components.

To mitigate these risks, conduits used for direct burial—such as PVC DB2 or HDPE conduit—are typically engineered to resist chemical attack and biological degradation. These materials are non-reactive, corrosion-resistant, and well-suited for harsh subsurface environments.

我应该寻找直埋产品哪些认证?

In the United States and Canada, products are expected to meet standards set by organizations like UL (Underwriters Laboratories), CSA (Canadian Standards Association), ASTM (American Society for Testing and Materials), and NEMA (National Electrical Manufacturers Association). These certifications confirm that the conduit has been rigorously tested for factors such as structural integrity, stiffness, chemical resistance, and joint tightness—qualities especially important in underground environments where long-term durability is critical.

For example, CSA C22.2 No. 211.1 covers direct burial PVC conduit in Canada, including DB2 and EB1 types, and mandates performance under various physical and chemical tests. Similarly, ASTM F512 addresses the requirements for coextruded pipe, such as uniform bond strength and resistance to layer separation. Products certified under UL standards may also carry additional marks for fire resistance or impact performance. Ensuring that your direct burial conduit carries these recognized certifications helps protect your installation from failure, reduces liability, and guarantees that you’re using a product suited for its intended underground application.

地下电缆的缺点是什么?

While underground cables offer several advantages, there are also some disadvantages associated with their use. Here are some common disadvantages of underground cables:

- 安装成本较高: One of the primary drawbacks of underground cables is the higher installation cost compared to overhead cables. Excavation, trenching, and specialized equipment are required for laying the cables underground. These additional expenses can make the initial installation significantly more expensive, especially in areas with complex geographical features or urban environments where extensive underground infrastructure already exists.

- Increased Maintenance and Repair Difficulty: Maintaining and repairing underground cables is more challenging and time-consuming compared to overhead cables. Locating faults in underground cables requires specialized equipment and expertise, and accessing the cables buried beneath the ground can be cumbersome. This difficulty in fault detection and repair can lead to longer downtime and higher maintenance costs.

- 受限访问: Underground cables are less accessible for maintenance and repairs. In densely populated areas or urban environments, accessing underground cables can be particularly challenging due to the presence of buildings, roads, and other infrastructure. This limited accessibility can result in delays and disruptions during maintenance and repair work, further increasing costs and causing inconvenience to service providers and customers.

不使用导管埋设地下电缆有哪些风险?

Burying underground cables without conduit can pose several risks and disadvantages. Here are some of the potential risks associated with not using conduit for underground cable installations:

- 物理伤害: Without conduit protection, underground cables are more susceptible to physical damage from external factors such as rocks, tree roots, construction activities, or accidental digging. Without a protective barrier, the cables are more exposed and vulnerable to potential impacts or compression, which can result in cable insulation damage or conductor breakage.

- Moisture and Water Ingress: Underground environments can be prone to moisture and water infiltration. Without conduit, there is a higher risk of water seepage into the cable system, which can cause insulation degradation, short circuits, and corrosion of conductors or connectors. Moisture ingress can significantly affect the performance and longevity of the cables, leading to service disruptions and costly repairs.

- 化学品暴露: Underground locations may contain chemicals or substances that can adversely affect cable integrity and performance. Without conduit, the cables are more exposed to potential chemical exposure from soil contaminants, industrial activities, or accidental spills. Chemical interactions can result in cable degradation, insulation breakdown, and overall system failure.

- Difficulty in Cable Replacement or Upgrades: Without conduit, replacing or upgrading underground cables becomes more challenging. The absence of a dedicated pathway can make it difficult to remove and install new cables or make modifications to the existing infrastructure. This limitation can increase the complexity, time, and cost associated with future cable replacements or system upgrades.

- Lack of Cable Identification and Organization: Conduit provides a structured and organized pathway for cables, allowing for easier identification and management. Without conduit, the cables may become tangled or disorganized, making it harder to locate specific cables for maintenance, repairs, or expansions. This can lead to increased downtime and inefficiencies during troubleshooting or system upgrades.

直埋电缆需要导管吗?

Direct burial cables do not require a conduit for installation. They are specifically designed to be buried directly in the ground without additional protection. These cables have insulation and jackets that provide resistance to moisture, temperature variations, and physical damage. However, local electrical codes and regulations may have specific requirements, so it’s important to consult them.

While direct burial cables can be installed without conduit, using a conduit may offer additional benefits depending on the specific requirements of the project. Conduit can provide extra physical protection and make cable replacement or maintenance easier. It can also be helpful in challenging environmental conditions or for locating the cable. However, installing a conduit adds cost and complexity to the project.

Ultimately, the decision to use a conduit with direct burial cables depends on factors such as soil conditions, project requirements, and local regulations. Evaluating these aspects and consulting with a professional electrician can help determine the best approach for your specific circumstances.

最适合直接埋葬的管道是什么?

The best conduit for direct burial is commonly recommended to be PVC (Polyvinyl Chloride) due to its durability, stability, and proven performance. PVC conduits have been extensively used and tested for underground installations. They offer several advantages, including:

Sturdiness: PVC conduits are known for their strength and ability to withstand external pressures and impacts. They provide reliable protection for the cables against physical damage from rocks, soil shifting, or other potential hazards.

Moisture Resistance: PVC is highly resistant to moisture and water ingress, making it an ideal choice for underground applications. It helps prevent water from reaching the cables, which can cause insulation degradation or short circuits.

Size Options: PVC conduits are available in various sizes, allowing for flexibility in accommodating different cable diameters or multiple cables within a single conduit. This versatility makes PVC conduits suitable for a wide range of direct burial cable installations.

Cost-Effectiveness: PVC conduits are generally more cost-effective compared to other options like metal conduits. They are less expensive to purchase and install, contributing to overall cost savings for the project.

Additionally, Fiberglass Reinforced Plastic (FRP) conduits are another option for direct burial applications. FRP conduits offer excellent durability, corrosion resistance, and high tensile strength. They are known for their non-conductive properties, making them suitable for installations where electrical grounding is a concern. FRP conduits are particularly useful in corrosive environments or areas with high moisture content.

PVC 导管适合直埋吗?

根据 NEC 规范 352.10“允许用途”,PVC 导管适用于直埋和地下混凝土埋设。这意味着,只要符合 NEC 300.5 和 305.15 部分规定的要求,PVC 导管可以直接埋入地下,无需额外保护。这些部分为地下应用(包括直埋)中的导管安装提供了指导。因此,根据 NEC 规范,PVC 导管被认为是直埋安装的理想选择。

电线应埋多深?

The depth at which electrical lines should be buried can vary depending on several factors, including the type of electrical line, local building codes, and regulations. Here are some general guidelines:

- Residential Power Lines: In most residential applications, electrical lines, such as service entrance cables or underground feeders, are typically buried at a depth of 18 to 24 inches (45 to 60 cm). However, local codes may require deeper burial depths, so it’s essential to consult the specific regulations in your area.

- Commercial and Industrial Power Lines: For commercial or industrial installations, the burial depth of electrical lines is often greater than in residential settings. Depths can range from 24 to 36 inches (60 to 90 cm) or even deeper, depending on the type of electrical line, voltage, and local codes.

- Direct Burial Cables: Direct burial cables, designed for underground installations without conduit, generally have specific burial depth requirements specified by the manufacturer. It’s crucial to follow the manufacturer’s guidelines to ensure proper installation and performance of the cable.

- Other Factors: Besides burial depth, it’s important to consider factors such as soil type, environmental conditions, and the presence of other utilities. Some local codes may require additional depth or clearance requirements to protect electrical lines from damage caused by external factors or future excavation.