目录

电气导管 plays a fundamental role in the safe and reliable operation of health care facilities. Whether it’s a large hospital, an intermediate care facility, or a community medical center, properly installed conduit ensures that electrical wiring is protected, organized, and compliant with code requirements.

In these environments, the electrical system supports everything from lighting and life-support equipment to data networks and HVAC controls. Electrical conduit, especially types like PVC electrical conduit that helps shield these systems from physical damage, moisture, and interference, while also allowing for efficient installation and maintenance.

This article will explore the importance of electrical conduit in health care settings, common types used, considerations for installation, and how conduit systems support the work of electrical and mechanical engineers, contractors, and facility managers alike.

After reading this article, you’ll know:

- What is electrical conduit and the types for health care facilities

- What is health care facilities and types

- Codes requirements for electrical conduit in health care facilities

- Installation and maintenance of electrical conduit in health care facilities

什么是电气导管?

An electrical conduit is a protective tubing system used to route and safeguard electrical wiring in buildings and structures. It serves two main purposes: mechanical protection of the wires and compliance with safety regulations. Conduits are typically installed in walls, ceilings, floors, or underground to contain insulated conductors, prevent accidental damage, and maintain an organized, code-compliant electrical system.

In health care settings, electrical conduit systems are essential for safely distributing power to critical equipment, emergency lighting, HVAC systems, and mechanical equipment. They also help meet the rigorous code requirements related to fire protection, patient safety, and continuity of service.

A well-designed conduit system in a hospital or clinic ensures the electrical infrastructure remains safe, accessible, and adaptable, which are the factors that especially important in facilities where even minor electrical failures can affect patient care.

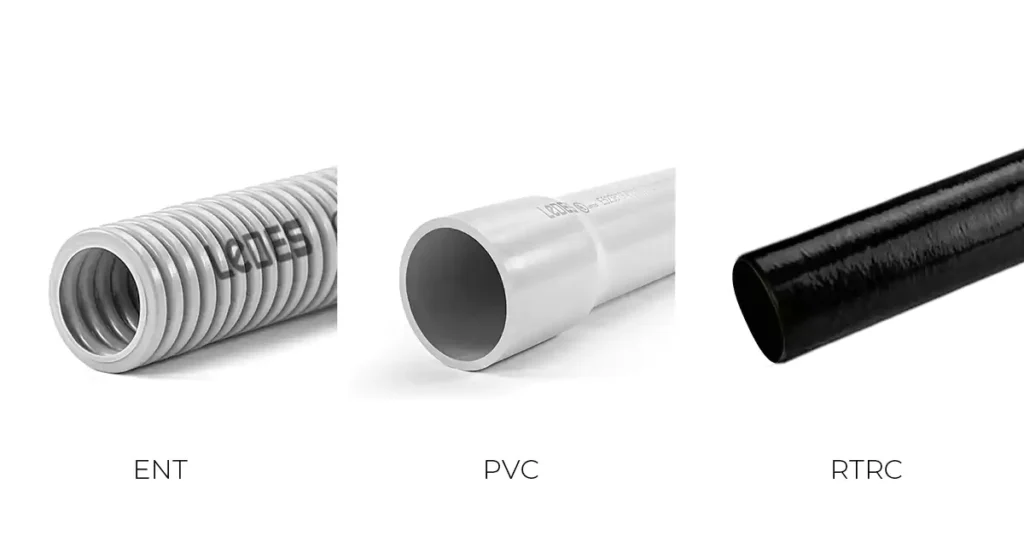

7 Common Conduit Types Used in Health Care Facilities

In health care facilities, electrical conduit systems must meet strict safety, hygiene, and reliability standards. Selection is based not just on location and environment, but also on compliance with the National Electrical Code (NEC) Article 517, which governs wiring in patient care areas, critical branches, life safety systems, and essential electrical systems.

Conduit types used are broadly categorized into metallic and non-metallic, and their selection depends on mechanical protection needs, grounding requirements, fire ratings, moisture exposure, and ease of future maintenance.

Metallic Conduit Types

Metallic conduit systems are commonly used in patient care spaces, mechanical rooms, and fire-rated assemblies, primarily due to their grounding continuity, mechanical strength, and fire resistance.

• EMT (Electrical Metallic Tubing)

Widely used in indoor health care applications, including patient rooms, procedure rooms, and general hospital corridors.

EMT is permitted in patient care areas when properly bonded and secured.

优点:

Lightweight and easy to bend

Provides a continuous grounding path

Fire-resistant

限制:

Must be used with listed fittings and bushings

Not recommended for corrosive or wet environments without extra protection

• IMC (Intermediate Metal Conduit)

Applied in areas requiring higher impact resistance than EMT, such as service entrances or exposed mechanical spaces.

优点:

Thicker wall than EMT

Approved for indoor and outdoor installations

Can be used in place of RMC to reduce cost and weight

限制:

Heavier and more rigid than EMT

Requires threading tools if not pre-threaded

• RMC (Rigid Metal Conduit)

Essential in critical areas exposed to mechanical stress or moisture, including generator rooms, rooftop installations, and underground raceways.

RMC is permits in all health care settings; it provides the highest level of physical protection.

优点:

Maximum durability

Excellent for grounding

Corrosion resistance (when galvanized)

限制:

Heavy and more labor-intensive

Requires threading and specialized tools

• LFMC (Liquid-tight Flexible Metal Conduit)

Used to connect vibrating or movable equipment like HVAC units, motors, or pumps in mechanical rooms.

Not generally used as a primary raceway in patient care areas. Limited use permitted where flexibility is essential.

优点:

Waterproof jacket

Flexible routing

限制:

Short runs only

Must be bonded and terminated properly

Non-Metallic Conduit Types

Non-metallic conduits are used more selectively in health care environments, typically in non-patient areas, underground runs, or locations where corrosion is a major concern. Their usage is more restricted inside patient care spaces due to grounding requirements under NEC.

• PVC Conduit (Rigid Nonmetallic Conduit – RNC)

PVC conduit (RNC) commonly used for underground feeder conduits, outdoor lighting, and utility services outside the building envelope.

Not allowed in patient care spaces unless installed in listed metal raceways or systems that provide redundant ground paths.

优点:

Lightweight and corrosion-resistant

Cost-effective

Easy to cut and solvent weld

限制:

Requires proper solvent welding and curing

Not suitable for plenum spaces or critical branch circuits without additional protection

• ENT (Electrical Nonmetallic Tubing)

Used behind walls or ceilings in non-patient care areas, such as administration, offices, or residential quarters.

耳鼻喉科导管 is not permitted in patient care areas per NEC 517.13 due to lack of a continuous grounding path.

优点:

Very flexible and fast to install

Uses snap-lock fittings

限制:

Limited to dry, concealed areas

Cannot be used in fire-rated assemblies unless specifically listed

• RTRC (Reinforced Thermosetting Resin Conduit – Fiberglass)

Rare but valuable in chemical or corrosive environments, such as certain labs or sterilization rooms.

优点:

High corrosion and temperature resistance

非导电

限制:

Higher cost

Requires special adhesive joining and supports

Summary Table:

Here are 7 types of electrical conduit used for Health Care Facilities summary list.

导管类型 | 优点 | 限制 | NEC 参考 | CEC Reference |

紧急医疗救护 | Lightweight, easy to bend; provides continuous grounding; fire-resistant | Not for wet/corrosive areas unless protected; needs listed fittings | Article 358 | Rule 12-1400 to 12-1414 |

整合营销传播 | Thicker wall than EMT; cost-effective vs. RMC; indoor/outdoor use | Heavier than EMT; threading needed | Article 342 | Rule 12-1000 to 12-1014 |

再生材料公司 | Highest durability; corrosion resistant; excellent grounding | Heaviest; labor-intensive; threading required | Article 344 | Rule 12-1000 to 12-1014 |

低频磁共振 | Waterproof; flexible routing | Not for long runs; not primary raceway in patient care; proper termination needed | Article 350 | Rule 12-1300 to 12-1308 |

PVC | Lightweight, corrosion-resistant; easy installation; low cost | Not allowed in patient areas; no inherent grounding; solvent welding needed | Article 352 | Rule 12-1100 to 12-1124 |

耳鼻喉 | Very flexible; fast install; snap-fit fittings | Dry, concealed areas only; no fire rating unless listed; not for patient care | Article 362 | Rule 12-1500 to 12-1514 |

RTRC | High corrosion/temperature resistance; non-conductive | Expensive; special adhesives & supports required | Article 355 | Rule 12-1200 to 12-1220 |

Understanding Health Care Facilities

Health care facilities encompass a wide range of building types, each with distinct functions, patient care needs, and infrastructure requirements. Electrical conduit design within these facilities is not one-size-fits-all, it must be tailored to the specific operational and safety needs of the environment.

To support this, the National Electrical Code (NEC) Article 517 – Health Care Facilities provides detailed rules for electrical systems in medical environments, including specifications for wiring methods, grounding, essential systems, and patient protection.

What Is a Health Care Facility?

A health care facility is any building or part of a building where medical, dental, psychiatric, nursing, or surgical care is provided to individuals. This includes treatment areas where patients may be examined, diagnosed, or cared for, whether for routine outpatient visits or for life-sustaining procedures.

NEC defines patient care spaces as areas intended to be used for treatment or care of patients. These spaces require enhanced electrical protection, including strict conduit and grounding rules, to prevent electrical shock, interference, or failure during critical operations.

6 Common Types of Health Care Facilities

Understanding the facility type helps determine conduit system requirements, particularly in patient care zones. Below are the most common categories:

1. Hospitals

Hospitals are large, complex institutions that provide comprehensive medical services, including emergency care, inpatient treatment, surgery, critical care, diagnostics, and specialty care. They operate 24/7 and must support life-saving interventions, continuous patient monitoring, and rapid response capabilities.

Hospitals typically include:

Emergency departments

Intensive care units (ICUs)

Operating theaters

Patient wards

Diagnostic imaging departments

Laboratories

Pharmacy and sterile processing

Mechanical/electrical service areas

2. Ambulatory Health Care Centers

These facilities offer same-day medical services without requiring overnight stays. They are designed to increase access to care while reducing the strain on hospitals.

Common types include:

Urgent care centers

Dialysis clinics

Day surgery centers

Imaging and diagnostic labs

Outpatient therapy and rehabilitation centers

These facilities prioritize patient flow, efficiency, and quick service delivery in a clean, well-controlled environment.

3. Community Health Clinics and Medical Offices

Serving as the front line of preventive care, these facilities are typically located in neighborhoods or rural areas to provide accessible medical services. They focus on routine health checks, vaccinations, chronic disease management, and family medicine.

4. Skilled Nursing Facilities (SNFs)

SNFs offer round-the-clock care for patients recovering from surgery, illness, or injury who require nursing and rehabilitation services. These facilities bridge the gap between hospital discharge and return to home.

5. Assisted Living and Long-Term Care Facilities

These facilities provide housing and limited medical assistance to elderly individuals or those with chronic health conditions who do not require intensive nursing care. Emphasis is placed on safety, mobility, and dignity, with spaces designed to feel more residential.

Common features include:

Private or semi-private rooms

Communal dining and activity areas

Support for medication, hygiene, and mobility

Emergency alert systems in resident rooms

6. Intermediate Care Facilities (ICFs)

ICFs provide long-term care and health-related services to individuals with intellectual or developmental disabilities. These facilities emphasize both medical oversight and support for independent living skills.

Services typically include:

Basic medical monitoring

Behavioral and occupational therapy

Educational and social programming

Residential accommodations

Each of these facility types has specific infrastructure needs shaped by its clinical functions, resident populations, and operational scale. As the article progresses, we will explore how electrical conduit systems are planned and implemented to support these environments safely, efficiently, and in full compliance with applicable standards.

Why Electrical Conduit Matters in Health Care Facilities

Health care environments demand exceptional electrical reliability. From advanced imaging systems to life-sustaining devices and facility-wide HVAC operations, nearly every aspect of a modern medical center relies on uninterrupted electrical power. In this high-stakes setting, electrical conduit is more than just a protective channel for wires, it is an essential infrastructure component that supports safety, continuity, and adaptability across all departments and systems.

1. Protecting Vital Medical and Support Systems

Modern health care facilities are powered by a wide spectrum of critical equipment:

- Life-support machines and surgical devices

- Imaging and diagnostics systems (e.g., MRI, CT, lab automation)

- Sterilization units and water purification systems

- HVAC systems controlling temperature, pressure, and infection control

These systems operate continuously and must be shielded from mechanical impact, chemical exposure, and environmental stress. Electrical conduit provides this protection, ensuring that cables remain undamaged, dry, and stable under various conditions.

Beyond patient-facing tools, supporting infrastructure like HVAC and water treatment also play a vital role in patient safety. A ventilation failure, for example, could compromise air quality in operating rooms, while an electrical fault in a water system could trigger pressure changes that release biofilms or contaminants.

2. Mitigating Electrical Hazards

Electrical hazards in health care settings are uniquely dangerous due to:

The density of electrical devices

Continuous human occupancy

The vulnerability of patients with limited mobility or awareness

Risks include electrical fires, shock, system malfunctions, and equipment downtime. Conduit mitigates these hazards by:

Physically shielding conductors from damage

Preventing wire exposure in high-traffic or wet environments

Controlling EMI (electromagnetic interference) near sensitive devices

In environments where even a brief outage can result in medical delays or life-threatening interruptions, proper conduit installation becomes a critical first line of defense against electrical failure.

3. Ensuring Operational Resilience

Hospitals and clinics cannot afford downtime. Separate, independent electrical systems are required, such as:

Life safety branch (emergency egress lighting, fire alarms)

Critical branch (patient monitors, ventilators)

Equipment branch (elevators, imaging equipment)

These systems must switch over to emergency power within seconds of a grid outage. Electrical conduit, especially when designed for redundancy and fire resistance, ensures that emergency feeders and backup systems remain intact and functional even under adverse conditions.

4. Adapting to Evolving Medical Technologies

The health care sector is continually evolving. Facilities must be able to accommodate:

New medical equipment (robotic surgery, AI diagnostics)

Infrastructure expansion (new wings, labs, or exam rooms)

Technological upgrades (IoT networks, EV charging for ambulances)

Power demand increases due to digital systems

Conduit systems that are properly planned and enable smooth retrofitting, expansions, and technology rollouts, without needing full system rework. This supports long-term operational flexibility and capital efficiency.

Code Compliance for Electrical Conduit in Medical Centers

In health care environments, electrical conduit systems are not just about protection and routing, they are part of a strict regulatory framework designed to ensure patient safety, system reliability, and facility integrity. Electrical engineers, designers, and contractors must follow national and regional codes that dictate what types of conduit are allowed, how systems must be grounded, and how circuits are to be isolated and protected.

The most relevant standards globally include:

- NEC (NFPA 70, U.S.) – Article 517

- CEC (Canadian Electrical Code) – Section 24

- AS/NZS 3000 / AS/NZS 3003

Below is an overview of these key code requirements:

专业提示: Want to know more about PVC conduit, electrical code compliance expert insights? You can click the link below to read the electrical code compliance in your country.

NEC Code Compliance Tips (NFPA 70, USA)

Canadian Electrical Code Expert Insights (CSA Group, Canada)

National Electrical Code (NEC) – Article 517

The National Electrical Code (NEC), Article 517 is the primary authority governing electrical systems in U.S. health care facilities. It sets detailed installation criteria for hospitals, outpatient clinics, nursing homes, limited care facilities, and other settings that provide medical services to human beings.

Electrical conduit systems play a crucial role in fulfilling NEC’s aims: minimizing shock hazards, ensuring continuity of critical operations, and maintaining system grounding integrity.

Here’s a focused overview of the most important conduit-related provisions:

1. Approved Wiring Methods and Conduit Types

Metallic conduit systems (e.g., EMT, IMC, RMC) are required for branch circuits in patient care areas.

Nonmetallic conduit (e.g., PVC) cannot be used in these spaces unless encased in concrete and paired with an insulated equipment grounding conductor.

Flexible metallic conduit (FMC) may be used in limited cases, such as short connections to movable equipment.

2. Mandatory Redundant Grounding

To reduce voltage differences that can cause electric shock:

- All branch circuits must include an effective ground-fault path via the metal conduit or metallic cable armor that qualifies as an EGC.

- Additionally, an insulated copper equipment grounding conductor (EGC) must be installed with the circuit conductors.

- This dual-path requirement ensures redundant, low-impedance grounding and is mandatory for all receptacles, metal boxes, and fixed equipment in patient care areas.

笔记: PVC conduit alone does not meet the dual grounding requirement and should not be used in patient care spaces unless it meets exception criteria (e.g., concrete-encased runs outside patient areas).

3. Ground-Fault Protection Requirements

Critical care hospitals and facilities with life-support systems must install ground-fault protection on main service and feeder disconnects to reduce arc flash and fire risk.

4. Receptacles at Patient Bed Locations

Minimum receptacles: 8 for general care; 14 for critical care areas per patient bed location.

Must include devices on both normal power and critical branch circuits.

Receptacles must be:

Hospital-grade

Individually grounded via insulated copper EGC

Clearly marked to show panel and circuit origin

5. Essential Electrical System (EES)

Healthcare facilities are required to maintain a multi-branch emergency electrical system, designed to operate during power outages. This is essential for life safety and to prevent disruption to critical operations.

The code requires three separate branches:

Life Safety Branch: Egress lighting, fire alarms, communication.

Critical Branch: Equipment directly supporting patient care (monitors, ventilators).

Equipment Branch: HVAC, imaging, pumps.

Each branch must:

Be powered by separate panelboards and transfer switches.

Use dedicated conduit and raceways, no mixing of circuits.

Be mechanically protected and comply with 517.13 grounding rules in patient spaces.

6. Wet Procedure Locations

Requires shock protection in wet procedure locations (e.g., ORs with washdown), using either:

Isolated power systems or leakage interruption systems.

7. Bonding, Junctions, and Connections

517.13 and 517.19(E) specify approved methods for bonding metal raceways:

- Grounding bushings

- Threaded hubs

- Bonding-type locknuts or bushings

Ensures continuity of the EGC across all junction points.

8. Special Locations (Anesthesia, X-ray, Data, and Fire Alarms)

Article 517 classifies flammable anesthetizing locations as Class I, Division 1 hazardous.

And for Low-voltage systems (e.g., nurse call, fire alarms, signaling) in patient care areas, requiring equivalent insulation and separation but are exempt from full conduit/grounding mandates unless otherwise noted.

NEC Article 517 is one of the most comprehensive and stringent sections of the Code. Its goal is not just to protect systems, but to protect lives – patients, clinicians, and staff, by ensuring electrical integrity in the most sensitive environments. Electrical conduit is at the heart of this strategy, providing both mechanical protection and grounding infrastructure for critical health care circuits.

Canadian Electrical Code (CEC) – Section 24

In Canada, electrical installations in health care settings are regulated by the Canadian Electrical Code (CEC), Section 24: Patient Care Areas. This section outlines specific safety and performance standards for hospitals, clinics, long-term care facilities, and other medical environments where patients may be examined, diagnosed, or treated.

Section 24 imposes special rules beyond general electrical practices, focusing on branch circuit design, grounding and bonding, essential electrical systems, and isolation techniques. These rules aim to reduce the risk of electrical shock, ensure system reliability during emergencies, and protect both patients and healthcare personnel.

1. Designation of Care Areas

CEC Section 24 applies to three types of patient care areas:

- Basic Care Areas (e.g., general treatment rooms)

- Intermediate Care Areas (e.g., intensive monitoring wards)

- Critical Care Areas (e.g., ICUs, operating rooms)

These categories determine the stringency of electrical protection and conduit requirements.

2. Branch Circuit Requirements in Patient Care Environments

- All branch circuits must use copper conductors, not smaller than No. 12 AWG.

- Circuits must originate from a grounded distribution system, or in some cases (critical/intermediate care), from isolated power systems.

- Circuits supplying receptacles or equipment in a patient care environment must not serve loads outside that space, except for adjacent rooms, with proper restrictions.

- Circuits must be limited to 150 V to ground, unless supplying specialized medical equipment like mobile X-ray units.

3. Bonding and Grounding in Patient Care Areas

Proper bonding to ground is mandatory to ensure all accessible conductive surfaces are at the same potential, minimizing shock hazard.

Key conduit and wiring requirements include:

- Insulated bonding conductors must be used, except when in non-metallic conduit or appropriate cable assemblies.

- Every branch circuit must include a dedicated equipment bonding conductor, even in multi-wire arrangements.

- Bonding conductors must run with the circuit conductors inside the same raceway or cable.

- Panelboards serving these circuits must be bonded using copper conductors sized per CEC Table 16, and not smaller than No. 6 AWG when bonding between multiple panels.

- Three-phase equipment and exposed conductive parts of medical/non-medical systems must be bonded with individual conductors.

Conduit systems (metallic or non-metallic) play a vital role in mechanically protecting bonding paths and maintaining proper separation between grounded and isolated systems.

4. Receptacle Requirements

All 15 A and 20 A non-locking receptacles must be hospital grade (except for housekeeping use).

Receptacles powered by essential electrical systems must be red-colored for identification.

Isolated ground receptacles are not permitted in any patient care area.

In areas cleaned with liquids or subject to flooding, receptacles must be:

At least 300 mm above floor level, and

GFCI-protected or supplied from an isolated system.

5. Essential Electrical Systems (EES)

CEC mandates that healthcare facilities have an essential electrical system that continues to function during a utility power outage. It ensures that life safety, critical medical equipment, and facility operations are not interrupted.

Key components include:

Vital Branch: Supplies life-support and patient-care equipment.

Delayed Vital Branch: Supports loads that can be reconnected with a short delay.

Conditional Branch: Supplies other important, but not life-critical, loads.

Conduit and wiring for EES must:

Be physically separated from all non-essential systems.

Be installed in dedicated raceways, boxes, and cabinets, with exceptions only for transfer switches or dual-fed emergency lights.

Include automatic or manual transfer switches, which must comply with CSA standards.

Emergency power must be provided by:

On-site generator sets.

Installed in a service room or enclosure compliant with fire and mechanical codes.

6. Isolated Power Systems in Critical and Wet Areas

For certain critical care or wet procedure locations, isolated power systems are required to:

Limit the current-to-ground during a first fault.

Avoid circuit tripping and allow continuous equipment operation while maintaining safety.

Core requirements:

Supplied by isolating transformers, motor-generators, or battery inverters.

Include line isolation monitors with visible alarms.

Conductor insulation must be color-coded (e.g., orange and brown) and meet specific dielectric performance standards.

Only single or adjacent rooms may be supplied per isolated circuit to maintain fault identification.

笔记: Grounded and isolated circuits must not share the same conduit, even if separated internally.

AS/NZS 3000 and AS/NZS 3003

In Australia and New Zealand, electrical installations in health care facilities are governed by a two-tiered framework consisting of AS/NZS 3000:2018 and AS/NZS 3003:2018:

- AS/NZS 3000(接线规则) establishes general requirements for safe electrical installations across all types of buildings and occupancies.

- AS/NZS 3003: Electrical installations—Patient areas supplements these rules with specific provisions for electrical installations in patient areas of healthcare facilities, where safety is paramount due to direct patient interaction with electrical medical equipment.

AS/NZS 3000: General Wiring Rules

AS/NZS 3000 is the base document for all low-voltage electrical installations in Australia and New Zealand. Although it is not healthcare-specific, it forms the legal and technical foundation for:

- Selection of wiring systems and conduit types,

- Installation methods and clearances,

- Earthing, bonding, and circuit protection,

- Segregation of services (power, control, communication),

- Protection against electric shock, fire, mechanical damage, and undervoltage, and

- Inspection and testing requirements.

AS/NZS 3003: Patient Areas

AS/NZS 3003 applies specifically to “patient areas”, defined as spaces where electrical equipment may be used in contact with patients during diagnosis, monitoring, or treatment. This includes:

General medical/surgical wards,

Emergency departments,

Intensive care units (ICUs),

Operating theatres,

Recovery rooms,

Dialysis and oncology treatment zones,

Cardiac catheter labs, and

Aged care rooms with medical support.

AS/NZS 3003 distinguishes two protection categories:

- Body-protected areas: where electrical contact with the body is possible (e.g., general wards).

- Cardiac-protected areas: where equipment may affect heart function or pose life-critical risks (e.g., ICUs, theatres).

Key Requirements of AS/NZS 3003 Code:

Wiring and Distribution

No looping: Each socket-outlet must be wired on a dedicated final subcircuit—no daisy-chaining.

Circuits must originate from the same distribution board serving that patient area.

Circuit protection must avoid shared neutrals in patient areas to prevent shock risks and ensure isolation.

Colour coding is required for medical socket-outlets (e.g., red or green) to denote function and supply.

Socket-Outlets (Receptacles)

Only hospital-grade socket-outlets may be used.

Isolated-ground (IG) outlets are not permitted in patient areas due to the increased risk of electric shock under certain fault conditions.

All socket-outlets must be clearly labeled and traceable to the supplying circuit and protection device.

Equipotential Bonding and Earth Reference

Supplementary equipotential bonding is required in both body- and cardiac-protected areas.

Bonding conductors must connect all exposed conductive parts, such as medical equipment housings, patient bed rails, metallic pipes, and gas outlets, to a common earth reference bar (ERB).

Bonding is crucial for minimizing touch voltages and preventing dangerous potential differences during faults or leakage.

Isolated Power Systems (IPS)

In cardiac-protected areas, an Isolated Power Supply (IPS) is typically required to limit fault current and maintain continuity of supply during a single fault condition.

The IPS must include:

Line Isolation Monitor (LIM) that alerts staff to insulation faults,

Separate supply via isolating transformers, and

Insulation monitoring that complies with Class 1 equipment use.

IPS circuits must be single-phase, 2-wire, and identified with orange and brown conductors.

Protection Devices and Residual Current Devices (RCDs)

RCDs are required for general-purpose socket-outlets but must not be used where they could interrupt power to life-support equipment without medical approval.

Special consideration is required for selective coordination and time-delay RCDs in essential circuits.

RCD protection may be omitted in certain IPS or isolated medical systems.

Inspection and Testing

AS/NZS 3003 outlines detailed initial verification and periodic testing protocols, including:

Earth fault loop impedance,

Insulation resistance,

Polarity,

Operation of RCDs and LIMs,

Continuity of protective earth and bonding systems.

Testing must be documented and repeated periodically to ensure ongoing safety and compliance.

Conduit and Cabling

Metallic and non-metallic conduit systems must provide mechanical protection and support fault loop impedance requirements.

Segregation is mandatory between different systems (e.g., power, data, nurse call, and emergency lighting).

All cables must be low-smoke and halogen-free where required by local fire codes or healthcare policy.

Installation & Maintenance of Electrical Conduit in Health Care Facilities

Proper installation and diligent maintenance of electrical conduit systems are fundamental to ensuring electrical safety, reliability, and compliance within health care environments. Given the unique risks present in patient care areas, such as critical equipment loads, life support systems, and restricted evacuation capabilities, conduit systems must be installed to the highest standard, with ongoing maintenance tailored to prevent faults and downtime.

This section explores best practices and key considerations for installing and maintaining conduit systems in hospitals, clinics, nursing homes, and other medical facilities.

Installation Best Practices

1. Material Selection by Zone

Health care facilities contain a wide variety of spaces, each with specific electrical and environmental requirements. Conduit material should be selected based on:

Patient care areas (basic, intermediate, critical): Often require metallic conduit (e.g., EMT, RMC) for effective grounding.

MRI or imaging suites: Prefer non-metallic conduit (e.g., PVC or fiberglass) to avoid electromagnetic interference.

手术室和湿式操作区域: 由于需要增强密封性、耐腐蚀性和机械强度,因此通常使用PVC涂层钢导管。.

2. 种族隔离和赛车场

根据规范要求:

重要系统导管(生命安全、重症监护)必须与非重要线路分开安装。.

避免在不同的电气系统中共用线槽、接线盒或配电盘。.

使用颜色编码的导管或标签来区分正常、关键和应急电源电路。.

3. 接地和连接

接地对于患者安全至关重要,并受到严格监管。导管系统必须:

确保电气系统的持续连通性(尤其是在金属系统中)。.

必要时应安装设备接地导体(EGC),尤其是在病人护理区域。.

遵循特定的连接要求,包括最小导体尺寸和专用连接点。.

4. 密封和感染控制

墙壁和天花板上的导管穿孔应:

使用经批准可用于电气穿孔的防火材料进行正确密封。.

旨在防止手术室或潮湿环境中液体渗入。.

安装方式可最大限度减少灰尘积聚,并有助于保持表面卫生。.

5. 支持和无障碍

所有导管布线必须:

定期进行牢固支撑,防止下垂或移位。.

安装此装置是为了方便检修和更换电缆,以便检修接线点和拉线点。.

布线应避开上方障碍物、医用气体管道或病人床区域(除非有防护措施)。.

维护和检查要求

1. 例行目视检查

设施工程师或电气承包商应进行例行目视检查,理想情况下每半年或每年一次,以检查以下方面:

导管损坏(裂缝、腐蚀、凹痕)

脱落的配件或松动的支架

水或液体渗入箱体或线槽

过时的标记或缺失的标识

2. 接地和连接测试

定期检查粘合完整性至关重要:

测量患者护理空间内设备接地导体与连接点之间的连通性。.

确认金属线槽仍然能够提供有效的故障电流通路。.

检查插座和配电盘的接地情况,尤其是在系统升级之后。.

3. 环境监测

在恶劣环境(例如,暖通空调屋顶、锅炉房、消毒区)中,管道系统必须检查以下方面:

紫外线对塑料导管的降解作用

金属导管系统的腐蚀

振动或冲击造成的机械磨损

4. 升级和改造

当引入新的医疗设备时,导管系统可能需要:

重新布线或加大尺寸以满足载流量和弯曲半径要求。.

重新连接以维持接地故障保护。.

区域重新分类(例如,从普通病房到重症监护病房),需要升级管道以满足更严格的安装标准。.

5. 记录保存和合规性审计

准确的文档记录有助于确保代码合规性和运营连续性:

维护竣工后的导管布置图和电路图。.

记录检查日期、缺陷、维修和测试结果。.

确保设施已做好准备,接受当地电力管理部门或认证机构的合规性审核。.

笔记: 想知道 安装电线导管的详细步骤和专家提示是什么? 您可以点击上面的链接阅读我们上一篇文章。.

结论

在医疗保健环境中,电气可靠性与患者安全密不可分,导管系统远非被动的基础设施,而是生命攸关生态系统的重要组成部分。从支撑关键设备和应急系统,到满足美国(NEC)、加拿大(CEC)以及澳大利亚/新西兰(AS/NZS)的严格规范要求,导管在保护电路、预防危险和增强运行韧性方面发挥着基础性作用。.

总而言之,电气导管在医疗保健领域的作用远不止于隔离。它是安全、性能和可靠性的无声守护者,构成了电气系统的脊梁,尤其是在那些容不得丝毫故障的环境中。.

常见问题解答:

医疗机构中电线导管的主要用途是什么?

电线导管保护线路系统免受物理损坏,为电力、照明、医疗设备和通信等重要服务提供支持,并有助于确保生命攸关系统的不间断运行。它还能实现正确的接地、隔离和防火,这在有脆弱患者和精密电子设备的场所至关重要。.

为什么医疗环境中的电气安全标准如此严格?

患者安全至关重要。在医疗环境中,即使是轻微的电气故障也可能导致人身伤害、设备故障甚至死亡。严格的标准能够最大限度地降低触电、火灾、电磁干扰和系统故障的风险,尤其是在生命维持设备和患者护理区域附近。.

医疗机构通常允许使用哪些类型的电线导管?

允许使用的导管类型包括:

金属线槽(EMT、RMC、IMC)——用于病人护理区域,以确保接地完整性。.

柔性金属导管(FMC)——用于设备连接,但存在一些局限性。.

非金属导管(例如 PVC)——可在病人护理区域外使用,或进行适当的接地和保护。.

医疗机构中常见的电气危害有哪些,坚固的导管有助于缓解这些危害?

患者护理场所发生电击

短路和电弧

过热和电线损坏

生命维持设备断电

敏感设备中的交叉干扰

电缆线路中的火灾蔓延

电气中的 EES 是什么意思?

EES 是“基本电力系统”的缩写,是医疗机构电力基础设施的专用部分,旨在在电力中断期间运行。它确保在紧急情况下患者护理和安全关键系统的连续性。

EES有哪些不同类型?

在医院中,基本电气系统(EES)通常包括:

生命安全部门 – 应急照明、火灾报警器和疏散系统。.

关键分支 – 用于病人生命维持、医疗设备和关键手术的电路。.

装备分部 – 运行所必需的暖通空调、水泵和建筑系统。.

医院的接地系统是什么?

医院采用稳健的等电位接地和连接系统,以维持低阻抗路径并最大限度地减少患者护理区域的电压差。该系统包括:

接地配电系统

设备接地导体

特定区域的孤立地面网络

集中式接地点(例如,患者设备接地端子)

澳大利亚/新西兰的医疗机构是否强制安装剩余电流保护装置(RCD)?

是的,潮湿区域或地面液体可能造成触电危险的地方必须安装剩余电流动作保护装置(RCD)。AS/NZS 3003 标准强制要求在这些高风险场所使用 RCD 保护或隔离式电源系统(配备线路隔离监测器),以防止触电并确保持续运行。.

医疗机构的消防安全要求是什么?

消防措施包括:

用于控制电气火灾的金属导管

医院级防火封堵穿透部位

用于疏散照明和警报的冗余 EES

采用低烟无卤电缆和导管以减少有毒烟雾

医院发生火灾最常见的原因是什么?

电气故障(短路、电弧、过载电路)是医院火灾的主要原因之一,尤其是在高负荷设备和老旧基础设施附近。.

我可以在医疗机构的安装中使用PVC导管吗?

是的,PVC导管可以用于患者护理区域以外的非关键区域,或用于地下线路和馈线敷设。但是,除非配备单独的绝缘接地导体并符合NEC 517的规定,否则不得在患者护理区域内使用PVC导管。.

医院的管道需要接地吗?

当然。患者护理区域的所有导管系统都必须确保设备有效接地。金属导管通常用作接地路径;如果使用非金属导管,则需要单独的绝缘铜接地线。.

医院可以使用软管吗?

是的,但有一些限制。柔性金属导管 (FMC) 或液密柔性金属导管 (LFMC) 可用于设备的最终连接,但必须符合 NEC/CEC/AS/NZS 安装规范,且不得用作患者区域的主要布线方式。.

医院的火灾报警和应急照明是否需要导管?

是的。医疗机构中的火灾报警和应急照明电路被视为生命安全系统,通常必须敷设在金属导管(EMT/RMC)或防火组件中,以确保耐用性、隔离性和符合规范。.