目录

在当今瞬息万变的世界中,安全性和可持续性不再是可选项,而是必不可少。随着我们的建筑、交通系统和数据基础设施日益先进和互联互通,支撑它们的材料也必须随之升级,以满足现代需求。过去,电线导管系统仅因其机械强度或安装便利性而被选中,而如今,评估其性能时,必须考虑防火安全、有毒物质排放和环境影响等因素。.

这种优先事项的转变使低烟无卤 (LSZH) 导管成为关注焦点。LSZH 导管旨在最大限度地减少火灾中的危害并减少有毒气体的释放,体现了设计领域向更智能、更安全、更负责任的方向发展的趋势。随着安全规范的日益严格和绿色建筑实践的蓬勃发展,了解 LSZH 导管的作用比以往任何时候都更加重要——对于工程师、建筑师和设施管理人员而言皆是如此。.

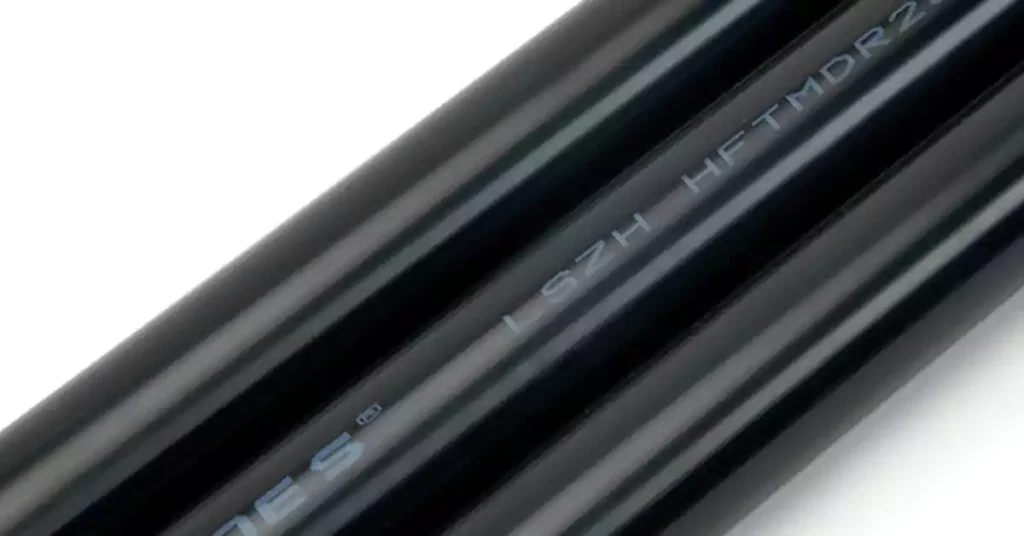

低烟无卤导管 低烟无卤(LSZH)电线导管是指由特殊工程材料制成的一种电线导管,这种导管燃烧时不会释放卤代气体,并且产生的烟雾也显著减少。与燃烧时会释放浓稠、有毒且腐蚀性烟雾的传统材料(例如PVC)不同,LSZH导管的设计兼顾了安全性和环境保护。.

低烟无卤(LSZH)材料的概念起源于电缆行业,最早由Raychem公司的Richard Skipper于1979年开发。这类材料通常由热塑性或热固性化合物制成,并填充有无卤阻燃剂——最常见的是三水合铝(ALTH)。当暴露于高温下时,ALTH会发生化学反应,释放蒸汽、吸收热量,并有助于形成保护性炭层,从而减少火焰蔓延和有害气体的释放。.

低烟无卤(LSZH)导管因其在火灾中能够释放低密度、无毒烟雾而备受青睐,这使得人员疏散更加便捷,也让消防员的作业更加安全。由于它们不会释放氯或氟等腐蚀性卤素,因此还能帮助保护电子设备免受损坏。.

低烟无卤管道的定义在于其具备以下能力:

- 尽量减少火灾期间的烟雾排放

- 消除卤素气体释放

- 减少健康和环境危害

- 保护关键系统免受腐蚀性损害

- 支持遵守更严格的现代安全规范

随着人们越来越重视居住者安全、系统弹性和可持续设计,低烟无卤管道正日益成为那些将火灾风险、空气质量和环境影响作为首要考虑因素的应用的首选。.

低烟无卤 (LSZH) 导管具有一系列全面的优势,超越了人们对电气保护的传统预期。.

由于采用了特殊的材料配方,LSZH导管比传统的PVC导管轻得多。对于壁厚相同的导管,LSZH导管通常轻30%以上——这在大型安装项目中是一项重大优势,因为易于搬运可以降低劳动强度并加快项目进度。尽管重量更轻,LSZH导管仍保持了优异的机械强度(比PVC导管高15%-20%),在不增加体积的情况下,提供更强的机械保护和更长的使用寿命。.

发生火灾时,能见度和空气质量可能决定生死。低烟无卤(LSZH)管道经过特殊设计,能够以较低的速率释放低光学密度的烟雾,从而为人员提供更洁净的空气和更清晰的逃生路径。该特性已通过ASTM E662等权威标准的测试和验证,该标准可测量明火和非明火条件下的烟雾密度。低烟雾产生量也有助于保障救援人员的安全,并降低烟雾颗粒引发二次火灾蔓延的可能性。.

与可能释放腐蚀性或有毒卤代气体(例如氯化氢)的传统导管材料不同,低烟无卤导管不含卤素。因此,对于涉及人体健康、精密电子设备或通风系统的场所,低烟无卤导管是更佳的选择。符合IEC 60754标准可确保低烟无卤材料释放的有毒和腐蚀性气体极少,从而保护室内空气质量,并在发生火灾时减少对附近系统的长期损害。.

低烟无卤(LSZH)导管的配方符合IEC 61386、UL1685、UL94等严格的阻燃标准,确保其具有良好的抗燃性和阻隔火势蔓延的能力。其配方通常包含矿物基阻燃添加剂,例如三水合铝,这些添加剂在高温下会释放水蒸气,吸收热量并形成一层保护性的炭化层。这不仅能减缓火势蔓延,还有助于在紧急情况下保持结构完整性。.

虽然低烟无卤导管的前期成本可能比标准PVC导管高出10-15%,但其长期经济优势是显著的:

- 根据 20–30% 降低的保险费 伦敦劳合社(2022), 由于火灾风险降低。.

- 由于其具有很高的耐火性和更长的使用寿命,因此维护和更换成本更低。.

- 降低医院、隧道、数据中心等人员密集场所的责任和诉讼风险。.

- 在服务连续性至关重要的关键应用中,最大限度地减少停机时间。.

保护生命安全是低烟无卤(LSZH)技术发展的首要目标。在火灾紧急情况下,如果能最大限度地减少烟雾并避免有毒气体的释放,人员安全逃生的可能性将大大提高。低烟无卤管道在改善建筑物疏散策略、提高室内空气质量以及改善应急人员的工作条件方面发挥着直接作用。.

随着可持续发展成为建筑和电气行业的关键驱动因素,低烟无卤(LSZH)导管助力实现更环保的项目目标。其无卤特性确保在使用过程中以及发生火灾时,最大限度地减少有毒副产物向环境的释放。许多LSZH配方还可回收利用,并在严格的环境控制下生产,符合LEED和其他绿色建筑认证体系的要求。.

低烟无卤导管的性能和安全性得到了众多成熟的国际和地区标准的保障。这些标准评估了阻燃性、烟雾密度、毒性和结构性能等关键特性,确保低烟无卤导管满足现代基础设施和高风险环境的严苛要求。.

一些最相关且应用最广泛的标准包括:

IEC 61386 – 规定导管系统的机械和电气性能。.

IEC 60754 – 涵盖电缆材料燃烧过程中产生的卤素气体排放。.

IEC 61034 – 测量电缆燃烧过程中的烟雾浓度。.

ASTM E662 – 在受控条件下评估烟雾产生情况。.

UL 1685 / UL 94 – 评估电气导管系统的垂直火焰蔓延和耐火性能。.

NFPA 130 固定轨道交通和客运铁路系统的消防标准

AS/NZS 2053 – 适用于澳大利亚和新西兰地区的导管系统。.

这些标准共同确保低烟无卤管道不仅能最大限度地减少有毒气体和烟雾的产生,而且能在极端条件下提供长期的结构可靠性。.

想要更深入了解这些低烟无卤标准及其在导管系统中的应用,请查看我们上一篇关于此主题的文章。 无卤导管的规范符合性。.

在选择电气安装导管材料时,了解低烟无卤 (LSZH) 导管和聚氯乙烯 (PVC) 导管之间的区别至关重要。以下是重点介绍关键性能指标的对比分析:

指标 | 低烟无卤导管 | PVC 导管 |

烟雾浓度 | 低(通常≤60Ds) | 高(最高可达 600 度) |

卤素含量 | 无卤素 | 含有卤素 |

有毒气体排放 | 有毒气体排放量极低 | 燃烧时会释放有毒气体 |

阻燃性 | 优良(例如,UL94 V-0,5VA) | 符合基本标准要求 |

重量 | 大约 30% 打火机 | 更重 |

机械强度 | 高的 | 高,尤其是第 80 号附表 |

极端温度 | 在高海拔和寒冷环境中表现出色 | 低温下易脆,高温下软化,不如低烟无卤导管。 |

成本 | 初始成本较高,但长期来看成本效益更高。 | 更具成本效益 |

正确安装低烟无卤 (LSZH) 导管对于确保其性能、安全性和长期可靠性至关重要。虽然 LSZH 系统与传统 PVC 导管有很多相似之处,但其独特的性能要求采用专门的处理和技术。以下是行业专家和标准机构认可的全面最佳实践。.

由于低烟无卤导管的性能与标准PVC或金属导管不同,安装人员应接受专门培训,内容包括:

- 正确的弯曲和切割技巧

- 使用与低烟无卤(LSZH)兼容的接头或无溶剂粘合剂进行连接组装

- 在不同环境下处理温度敏感材料

经过认证的培训可确保安装符合消防安全和材料完整性要求,并最大限度地降低安装后发生故障的风险。.

- 粘合剂兼容性: 仅使用导管制造商认可的无卤溶剂或机械接头。标准PVC溶剂胶可能会破坏低烟无卤化合物的阻燃和无卤性能。.

- 配件和附件: 使用 LSZH 认证的连接器、弯头、适配器和接线盒,以确保整个系统具有一致的防火性能。.

安装过程中定期进行质量检查和检验,可确保低烟无卤导管保持其性能。记录安装程序和性能指标,不仅有力地证明了符合严格的安全法规,也强化了公司对质量的承诺。.

对现有电气系统进行改造或升级时:

- 确认低烟无卤导管在尺寸、壁厚、配件和膨胀性能方面与任何传统导管材料(例如,PVC、金属)兼容。

- 在易燃环境中,应保持无卤导管和含卤导管之间适当的隔离,以避免污染。

- 确保标签清晰,并提供最新的示意图,以便日后维护人员使用。

- 温度: LSZH导管本身可以承受极端温度,Ledes LSZH导管在-45°C至+150°C范围内性能良好,但在极寒条件下可能会变脆。.

- 紫外线照射: 在室外或阳光照射的环境中,使用紫外线稳定的低烟无卤导管,以防止过早老化。.

低烟无卤 (LSZH) 导管正逐渐成为对防火安全、人身健康和设备保护要求极高的电气安装环境的首选。LSZH 导管的特性和功能使其成为封闭、人流密集或敏感场所的理想之选。.

以下是一些低烟无卤管道发挥关键作用的场景:

学校里有大量的儿童和教职员工,空间相对密集,而且通常出口通道有限。.

烟雾减少可确保更好的能见度和更安全的疏散。

零卤素含量避免了吸入有毒气体,这对儿童尤其重要。

医疗设施内通常氧气充足,电缆密集,而且收治的病人脆弱,无法迅速撤离。.

无毒排放物可保护患者、医护人员和设备。

耐火性能可以更好地阻止火势蔓延。.

地下和封闭式交通基础设施人员密度高,通风有限。.

低烟雾释放量可以防止烟雾积聚,保护人们免受有毒烟雾吸入的危害。.

旅客航站楼和空中交通管制系统需要不间断运行和安全的疏散路线。.

低烟无卤导管可提供更佳的防火性能。.

电动汽车充电站,特别是直流快速充电站,会产生高压电流,通常安装在商业车库、地下室和封闭空间内。.

LSZH导管可以更好地降低电缆故障引起的火灾风险,并支持可持续发展目标和智能基础设施集成。.

太阳能发电厂和屋顶光伏系统在紫外线照射、高温和长期直流负载下运行。.

LSZH导管具有抗紫外线、使用寿命长、环境安全等优点,适用于住宅和公用事业规模的太阳能系统。.

重工业环境和重要公用设施面临着更高的火灾、化学和电气危险。.

LSZH 提供了一种安全、耐腐蚀的解决方案,既能保护人员,又能保护关键任务操作。.

These facilities demand 24/7 uptime and protection of high-value digital infrastructure, have very strict fire safety requirement.

Non-corrosive and low-smoke conduit reduces damage to servers, control panels, and networking gear during a fire.

Selecting the right LSZH conduit supplier is critical for ensuring your project meets all performance, safety, and compliance expectations. Here’s what you should consider:

A trustworthy supplier must provide LSZH conduits that comply with major standards like NFPA 130, UL1685 (FT4/IEEE1202 flame tests), and other relevant local and industry-specific regulations. Certifications and third-party test reports should be readily available to verify product quality.

Suppliers with a proven track record in critical infrastructure projects—such as subways, tunnels, railways, airports, and hospitals—are more reliable.

For example, Ledes’ LSZH conduit has been successfully used in projects like the Melbourne Metro Tunnel, a project with extremely high fire safety and environmental requirements.

Good LSZH conduit suppliers invest in strict raw material control and rigorous mechanical and fire performance testing, including:

High and low temperature resistance

UV resistance (for exposed applications)

Compression and impact strength

A good supplier should offer not only rigid LSZH conduits but also corrugated versions, plus all matching fittings. A complete system ensures easier installation, better performance, and compliance across the whole project.

Every project has unique needs. A strong supplier should be able to offer:

Custom sizes or colors

Special formulations (e.g., enhanced UV stability)

Engineering support for product selection and installation advice

While safety and compliance are critical, cost matters too — especially for large-scale projects.

A good supplier offers a competitive price without sacrificing essential performance requirements. LSZH conduit is typically more expensive than standard PVC conduit, but pricing among LSZH options can still vary significantly depending on material formulation and manufacturing quality.

Large infrastructure projects often have tight deadlines. Choose suppliers who:

Maintain strong inventory levels

Offer reasonable lead times

Provide good after-sales support, including warranty and problem resolution services

At Ledes, we are driven by a simple but powerful mission: to create safer, smarter, and more sustainable electrical infrastructure for the world. As a trusted global manufacturer specializing in Low Smoke Zero Halogen (LSZH) conduits and fittings, we have built our reputation on delivering high-performance solutions that meet the most rigorous international safety and environmental standards.

With decades of experience in the electrical conduit industry, Ledes has developed a comprehensive portfolio of LSZH rigid and corrugated conduit systems designed to serve a wide range of demanding applications. Our LSZH products are engineered not only for low flame propagation, minimal smoke release, and zero halogen content, but also for long-term mechanical durability, flexibility, and ease of installation.

Ledes offers a full line of LSZH conduit solutions, including:

- Rigid LSZH Conduit – Heavy-duty and medium-duty rigid LSZH conduit for structured commercial and industrial systems

- Flexible LSZH Corrugated Conduit – Heavy-duty and medium-duty corrugated conduit for dynamic installations or tight-space routing

- Low Smoke Halogen-Free Fittings – such as elbows, couplings, adaptors, tees, boxes, and mounting hardware—all designed for compatibility and system integrity

- Expert Formulation: Our R&D team is constantly innovating to refine material performance. Every LSZH compound we use is carefully tested and benchmarked against leading safety standards like UL 94, IEC 61034, and IEC 60754-1/2, ensuring superior flame resistance and ultra-low smoke and toxicity.

- Certified Safety and Compliance: Ledes LSZH conduits and accessories carry IEC, CE and ASTM certifications and test reports, offering global customers the assurance of top-tier quality control and international code compliance.

- Customer-Centric Solutions: From initial consultation to product delivery, we offer tailored conduit solutions that fit each client’s exact specifications. Our knowledgeable team supports every stage of the project with technical guidance, product customization, and fast, responsive service.

- Sustainable Manufacturing: Environmental responsibility is at the heart of our operations. Our LSZH products are fully environmental friendly and produced with minimized carbon footprint—meeting the growing demand for green construction practices.

With reliable quality and excellent performance, Ledes LSZH products are widely used in some global projects.

Melbourne Tunnel Project – Australia

This multi-billion-dollar rail project aims to ease congestion and expand the capacity of Melbourne’s public transport network. In the underground sections of the project, fire safety and smoke suppression were critical priorities due to the confined environment and high passenger volume. Ledes supplied rigid and corrugated LSZH conduits that met the AS/NZS 2053, UL94, IEC and ASTM standards offering low flammability, halogen-free materials, and exceptional performance under high-stress conditions. Our solutions played a key role in ensuring long-term safety and regulatory compliance throughout the tunnel system.

Macau Island Hospital Project – China

As one of Macau’s largest and most modern healthcare developments, the Macau Island Hospital demanded the highest standards for electrical system safety. Our LSZH conduit systems were selected to protect emergency circuits, sensitive medical equipment wiring, and backup power systems. Thanks to their low toxicity, minimal smoke emission, and high chemical resistance, Ledes LSZH products helped the facility meet strict healthcare safety codes while supporting its long-term operational resilience.

At Ledes, we don’t just manufacture conduit—we engineer confidence, safety, and peace of mind into every installation. From local builds to international projects, our LSZH solutions are trusted where it matters most.

As the global demand for safer, smarter, and greener infrastructure accelerates, the future of Low Smoke Zero Halogen (LSZH) technology lies in innovation, and at Ledes, innovation is at the core of everything we do.

Our Research & Development division is continuously advancing the science of LSZH materials. Building on decades of formulation expertise, Ledes is now developing its fourth-generation LSZH compounds, which is a major leap forward in both safety and performance.

This new generation will deliver improved thermal stability, reduced environmental impact, and greater mechanical strength, while maintaining the hallmark low smoke, zero halogen characteristics. Ensure each advancement meets or exceeds the safety and performance standards.

A next-gen flexible LSZH conduit system is expected to offer up to 50% more bendability than traditional products. Designed specifically for retrofits, tight-space installations, and dynamic environments, FlexGuard LSZH provides superior routing ease without compromising fire safety or halogen-free performance.

In smart infrastructure integration, developing LSZH conduits with embedded temperature and load sensors will be widely utilized in the future. These intelligent conduits sync with Building Management Systems (BMS) to detect overheating, cable overloading, or environmental threats in real-time, enabling predictive maintenance and early failure prevention in mission-critical facilities.

These innovations are not just technological upgrades, they reflect a deeper shift toward resilient, responsive, and future-proof electrical systems.

电视he market for LSZH compounds is rapidly expanding as regulations tighten and public awareness of fire and toxicity risks grows. According to recent industry forecasts, the Low-Smoke Zero-Halogen (LSZH) Compounds Market is projected to grow from USD 1.5 billion in 2024 to USD 2.8 billion by 2033, at a CAGR of 7.5% from 2026 to 2033.

This surge is being driven by key sectors such as:

Mass transit systems and tunnels

Data centers and telecommunications

Renewable energy and electric vehicles

Healthcare and public buildings

Smart city and infrastructure modernization initiatives

With regulatory bodies worldwide adopting stricter fire, smoke, and environmental standards, the role of LSZH conduit solutions will only become more central to the future of construction and electrical safety.

As the demand for safer, more sustainable, and higher-performing electrical infrastructure grows, Low Smoke Zero Halogen (LSZH) conduit has become a critical component in modern construction. Its ability to minimize toxic emissions, support fire safety, and meet rigorous global standards positions it as a forward-looking solution across a wide range of applications. At Ledes, we are proud to be at the forefront of this transformation, delivering advanced LSZH conduit systems backed by proven performance, industry certifications, and ongoing innovation. From landmark infrastructure projects to everyday safety upgrades, we remain committed to building a safer, smarter future—one conduit at a time.

什么是低烟无卤(LSZH)导管?它与传统的PVC导管有何不同?

低烟无卤 (LSZH) 导管是一种经过特殊设计的电线导管,在遇到火灾或高温时,其烟雾排放量极低,且不释放任何卤代气体。与会释放氯化氢等有毒腐蚀性气体的传统聚氯乙烯 (PVC) 导管不同,LSZH 导管可显著降低火灾期间呼吸系统损伤、设备腐蚀和能见度受损的风险。.

低烟无卤导管可以在室外或工业环境中使用吗?

Yes. Modern LSZH conduits, including Ledes’ heavy-duty and UV-stabilized lines, are suitable for outdoor, industrial, and even corrosive environments. They offer:

- Excellent UV and weather resistance

- High impact strength and compression resistance

- Operating temperature ranges from -45°C to +150°C, depending on formulation

- Resistance to oils, chemicals, and mechanical abrasion

These properties make LSZH conduit a robust and versatile solution even beyond controlled indoor environments.

低烟无卤导管通常用于哪些应用领域?

LSZH conduit is especially suited for installations where human health and critical infrastructure protection are paramount. Common applications include:

Public infrastructure: subway systems, tunnels, airports, and rail stations

卫生保健: hospitals, clinics, and biomedical facilities

Education: schools, universities, and libraries

Data centers and telecom: where corrosion or smoke could damage sensitive equipment

EV and solar energy systems: especially where sustainable, low-emission materials are required

Marine and offshore installations: due to the need for non-corrosive, flame-resistant materials in confined or salt-exposed spaces

低烟无卤导管符合哪些国际标准?

High-quality LSZH conduits are developed to comply with a wide range of international standards that ensure fire resistance, low toxicity, and environmental responsibility. Ledes LSZH conduit and fittings are designed to meet required standards, including:

IEC 61386 – Performance standard for conduit systems

IEC 60754-1/2 – Measurement of halogen acid gas and acidity

IEC 61034 – Measurement of smoke density

UL 94 – Flammability rating of plastic materials

UL 1685 and ASTM E662 – Flame and smoke propagation testing

NFPA 130 – Fixed guideway transit and passenger rail systems safety standard

低烟无卤导管的关键技术特性是什么?

尽管低烟无卤(LSZH)导管具有防火性能,且不排放卤素和有毒烟雾,但它们通常还具有宽广的工作温度范围(通常为-45°C至+150°C)以及强大的机械强度,能够抵抗压缩和冲击。这些特性使其非常适合室内和严苛的室外应用。.

我该如何决定使用低烟无卤(LSZH)导管还是聚氯乙烯(PVC)导管?

Choosing between Low Smoke Zero Halogen (LSZH) and traditional PVC conduit depends on the specific requirements of your project, particularly in relation to fire safety, environmental risk, and regulatory compliance.

Use LSZH conduit when:

- The installation is in enclosed or high-occupancy spaces like subways, hospitals, airports, tunnels, schools, or data centers, where smoke and toxic gas emissions during a fire pose a serious risk.

- The project is governed by strict fire safety standards or building codes, such as NFPA 130, IEC 61034, IEC 60754, or UL 1685, which often mandate the use of halogen-free materials.

- You are working on critical infrastructure or mission-critical applications (e.g., telecoms, energy, or emergency systems) where fire-related downtime must be minimized.

- There is a requirement for environmentally sustainable materials, as LSZH compounds do not release corrosive halogens and are often recyclable.

Use PVC conduit when:

- The environment is low-risk, such as in open areas, residential buildings, commercial structures with proper ventilation, or outdoor spaces.

- Budget constraints are a primary concern, and the application does not involve sensitive electronics, densely populated areas, or strict fire codes.

- The system does not require halogen-free components, and standard code compliance (e.g., NEC for general electrical installations) is sufficient.

In many modern installations, both types may be used strategically, LSZH in interior or critical areas and PVC for outdoor or underground runs, to balance cost and compliance.

When in doubt, consult the project’s fire safety engineer or check local regulations, as requirements can vary significantly depending on jurisdiction and industry.