Table of Contents

When it comes to protecting electrical wiring, PVC conduit has become a go-to choice for homeowners, electricians, and engineers alike. Lightweight yet durable, it offers an excellent balance between performance, cost, and ease of installation. But two features often determine whether a conduit installation will last decades or fail prematurely: corrosion resistance and sunlight (UV) resistance.

They’re essential performance characteristics that directly impact safety, reliability, and compliance with electrical codes. In the wrong environment, a conduit without adequate protection can crack, discolor, or even lose its mechanical strength, putting the wiring system at risk.

In this guide, we’ll break down:

- What corrosion resistance really means for PVC conduit and how it differs from metals.

- How sunlight (UV) resistance is achieved and tested in industry standards.

- The standards and codes, from UL and CSA to AS/NZS that define and verify these properties.

- Practical installation and selection tips to ensure your conduit performs over the long term.

Whether you’re pulling your first run of conduit or reviewing specifications for a large industrial project, this article will give you a clear, practical understanding of corrosion and sunlight resistance, two features that can make or break your electrical installation.

Pro Tips: Want to learn more about the PVC conduit? Check out the last posts to quickly become an industry expert.

PVC Conduit Fire & UV Resistance Rating

PVC Conduit Impact Resistance & Tensile Strength

What is PVC Conduit?

Polyvinyl chloride (PVC) conduit is a rigid, non-metallic piping system designed to protect and route electrical wiring in a wide range of applications. Available in various wall thicknesses, diameters, and ratings, it’s valued for being lightweight, easy to cut and join, non-conductive, and resistant to many environmental hazards. You’ll find it in residential basements, commercial rooftops, industrial plants, and even buried beneath city streets.

It's Primary Role is Twofold:

• Mechanical protection

Mechanical protection – shielding electrical cables from physical impact, abrasion, and crushing forces.

• Environmental protection

Environmental protection – guarding against moisture, chemical exposure, UV radiation, and temperature extremes that could damage the wiring insulation.

Among its many properties, corrosion resistance and sunlight (UV) resistance are particularly important for performance and safety. Here’s why:

• Corrosion resistance

Corrosion resistance ensures that the conduit maintains its mechanical strength and insulation protection even when exposed to moisture, salts, and certain chemicals. While PVC doesn’t rust like metal, it can still degrade under certain environmental conditions if not properly formulated or certified.

• Sunlight resistance

Sunlight resistance prevents the conduit from becoming brittle, cracking, or losing its impact strength when exposed to prolonged ultraviolet radiation. This is especially critical for outdoor installations, solar projects, and rooftop wiring runs.

Without these features, a PVC conduit system can suffer premature deterioration, leading to costly maintenance, potential code violations, or, in worst cases, unsafe electrical conditions.

Understanding Corrosion Resistance in PVC Conduit

What Is Corrosion in Electrical Conduits?

When most people think of corrosion, they picture rusted steel—orange flakes, weakened structure, and eventual failure. While that’s true for metals, corrosion in non-metallic materials like PVC looks different. In plastics, “corrosion” refers to chemical or environmental degradation that alters the surface or structure of the material.

For PVC conduit, corrosion can mean:

- Chemical exposure from acids, alkalis, solvents, or industrial contaminants.

- Moisture and humidity, especially in constantly damp or submerged locations.

- Salt spray or coastal environments where airborne salts can be aggressive to many materials.

- Industrial fumes containing reactive chemicals.

Even though PVC is naturally resistant to many forms of attack, under the wrong conditions its physical and mechanical properties can still deteriorate.

Why PVC Has Natural Corrosion Resistance

PVC’s strength against corrosion comes from its polymeric structure. Being a non-metallic, chlorine-containing thermoplastic:

It does not oxidize like steel or aluminum, so there’s no rusting.

It has high resistance to many common chemicals, including salts, acids, and alkalis.

It maintains performance in moisture-rich environments like underground installations, coastal areas, or wet utility rooms.

This is why PVC conduit is often preferred over metallic conduit in:

Underground direct burial applications.

Coastal installations exposed to salty air.

Agricultural or food processing facilities where cleaning chemicals are used.

Limits of PVC Corrosion Resistance

While PVC is tough, it’s not indestructible. Certain environments can challenge its resistance:

- Solvent and petroleum-based chemical exposure — Prolonged contact with fuels, oils, or strong organic solvents can soften or damage the material.

- Physical degradation — Abrasion, scraping, or impact can remove surface protection, making the conduit more vulnerable to environmental attack.

- Long-term chemical leaching — In heavily contaminated industrial zones, slow chemical absorption over time can affect mechanical strength.

Understanding these limits is essential when selecting conduit for demanding environments, especially in facilities with chemical processing, heavy machinery, or high contamination risk.

Understanding Sunlight (UV) Resistance in PVC Conduit

How Sunlight Damages PVC

While PVC is durable in many environments, prolonged exposure to sunlight, specifically ultraviolet (UV) radiation can degrade its surface and mechanical properties.

UV rays break down the molecular bonds in PVC, leading to:

- Surface chalking — a powdery residue that appears as the outer layer erodes.

- Discoloration — fading or yellowing, which may indicate surface oxidation.

- Loss of flexibility and impact strength — the material becomes brittle and prone to cracking.

This degradation happens gradually, but in high-sunlight regions or rooftop installations, damage can occur faster if the conduit is not UV-protected.

How Sunlight Resistance Is Achieved

Manufacturers improve PVC’s UV performance by:

- Adding UV inhibitors — compounds such as titanium dioxide or carbon black that absorb or reflect harmful UV radiation.

- Using stabilizers — chemical additives that slow down molecular breakdown.

- Optimizing color and formulation — darker colors (like black) generally offer better UV resistance, while light gray formulations are often stabilized for outdoor use.

Some conduits are also available with special surface coatings or protective over-sheaths to enhance long-term UV durability.

Signs of UV Damage

In the field, signs that PVC conduit has been compromised by UV exposure include:

Fading or surface chalking beyond normal weathering.

Cracking or splitting, especially around bends or joints.

Loss of flexibility, making the conduit more prone to fracture during handling.

Identifying and replacing damaged sections promptly is essential to maintain system integrity and safety.

Standards and Testing Methods for PVC Conduit

There are many standards that outline requirements and testing methods for conduit corrosion and sunlight resistance. Here are some key standards’ requirements:

UL 651

The U.S. standard UL 651 covers Schedule 40 conduit and Schedule 80 PVC conduit, specifying performance requirements for strength, impact, and environmental durability.

1. Resistance to Specific Reagents

While it does not include a direct “corrosion resistance” test, but does assess chemical resistance, which may cover some corrosion-like degradation when relevant chemicals are used.

This test evaluates how the conduit holds up when in contact with chemicals, oils, or other substances that could degrade its material—conditions often linked to corrosion in real-world applications.

Two main procedures are used:

- Reagent Absorption Test:

Small conduit samples are immersed in the specified chemical for 60 and 120 days. Weight changes must remain within strict limits (≤ 2.5% gain or loss), and long-term absorption after 120 days must not increase disproportionately compared to the 60-day results. - Crush Strength Test After Chemical Exposure:

After immersion for 60 and 120 days, the samples are mechanically tested for crush strength. They must retain at least 85% of the strength of unaged samples, with no cracking or collapse before reaching the test limits.

These tests simulate the effects of corrosive or degrading substances on PVC conduit, providing assurance that the material can withstand exposure without losing integrity.

2. Sunlight Resistance

For outdoor applications, UL 651 requires the conduit to pass a sunlight resistance test, which measures how UV exposure affects its impact strength.

- Test Method:

Machined samples are subjected to controlled xenon-arc light exposure (ASTM G155), simulating long-term sunlight and weather conditions, with cycles of light and water spray. Samples are tested at 720, 1,080, and optionally 1,440 hours. - Acceptance Criteria:

After exposure, the conduit must maintain Izod impact strength values that meet or exceed the limits specified in the standard (minimum 0.5 ft·lbf/in of notch width for unaged samples, with retention requirements for aged samples).

This ensures the conduit resists embrittlement and surface degradation from prolonged UV exposure, making it suitable for rooftop, pole-mounted, and other outdoor installations.

CSA C22.2 No. 211.2

The Canadian standard CSA C22.2 No. 211.2 outlines performance criteria for rigid PVC conduit. Like UL 651, it addresses environmental durability, but it does not include a corrosion resistance test. Instead, it focuses on chemical resistance and weather (sunlight) resistance evaluations.

1. Chemical Resistance

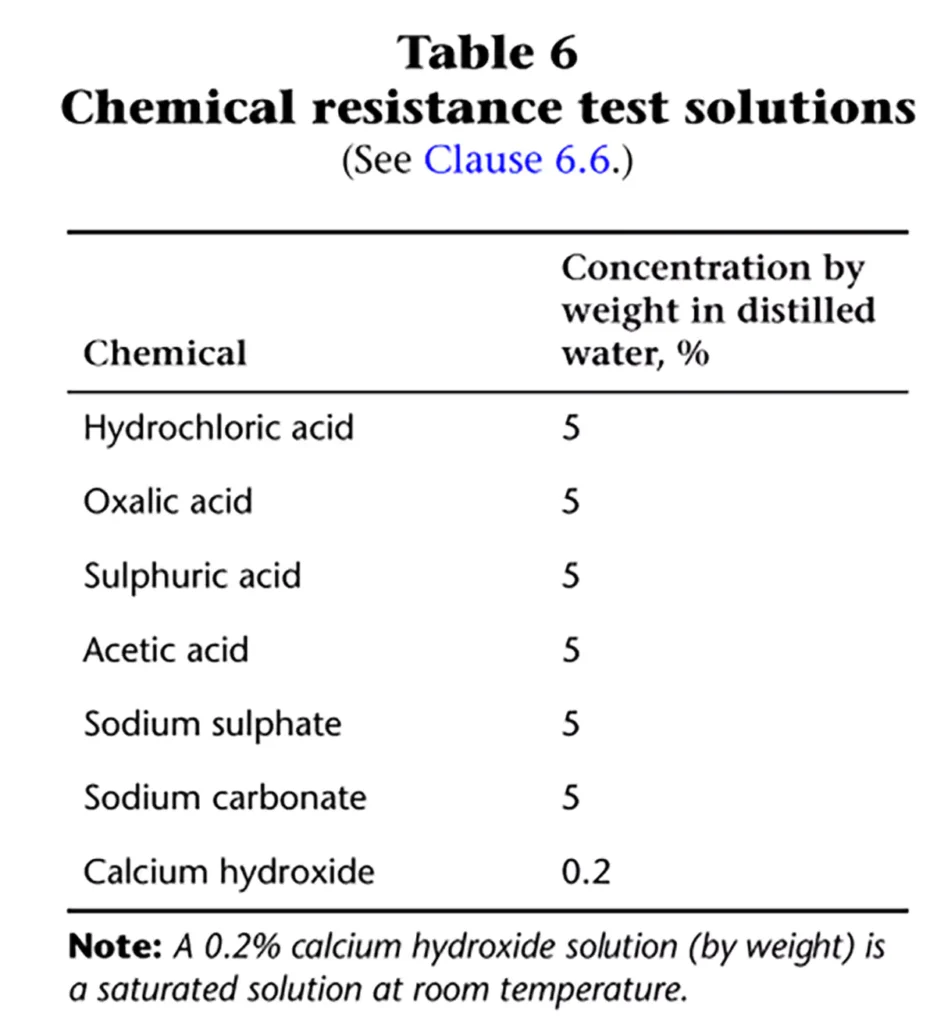

PVC conduit, elbows, and bends must show no evidence of softening or disintegration when tested according to the procedure in CSA C22.2 No. 211.0 using solutions specified in Table 6.

Test Setup

- Short specimens (25 ± 3 mm) are immersed in specified solutions at 23 ± 2 °C for 30 days.

- After immersion, samples are rinsed, visually inspected for disintegration, and checked for softening.

- The requirement is purely qualitative – pass/fail based on visual and tactile examination rather than weight change or strength retention.

This is a chemical compatibility test, not a corrosion test, and it ensures that the PVC material resists degradation from contact with common damaging substances.

2. Weather Resistance

Weather resistance in CSA C22.2 No. 211.2 is assessed through accelerated sunlight exposure followed by impact strength testing. The goal is to confirm that PVC retains adequate mechanical performance after prolonged outdoor exposure.

- Test Procedure

Longitudinal strips are cut from conduit, machined into bar specimens, and some are tested unaged.

Other specimens are exposed for 720 h, 1,080 h, and (if applicable) 1,440 h using either:

Carbon-arc exposure (ASTM G152, Cycle 1)

Xenon-arc exposure (ASTM G155)

Exposure cycles combine UV radiation and intermittent water spray at controlled temperatures.

After conditioning, specimens are notched and tested for Izod impact strength (ASTM D256).

- Performance Requirement

Unaged specimens: ≥ 27 J/m notch impact strength.

Aged specimens: Must meet minimum values in Table 8 after weathering.

This ensures that PVC conduit can withstand long-term UV and moisture exposure without losing critical impact resistance.

AS/NZS 2053.1

The joint Australian/New Zealand standard AS/NZS 2053.1 covers general requirements for conduit systems used in electrical installations, including rigid and flexible types made from various materials. While the standard includes provisions for environmental durability, it does not prescribe a sunlight (UV) resistance test for PVC conduit.

Corrosion Resistance

Clause 13.4 addresses “Corrosive and polluting substances,” but its detailed test methods (Appendix I) are intended for steel conduits and fittings only. For conduits and fittings made from other materials, such as PVC, the clause simply directs users to consult other parts of the AS/NZS 2053 series for specific requirements. In other words, there is no dedicated corrosion resistance test for PVC conduit in AS/NZS 2053.1 itself.

IEC 61386-1

The international standard IEC 61386-1 specifies general requirements for conduit systems used in electrical installations, covering a wide range of materials, including metallic, non-metallic, and composite systems. It sets out mechanical, electrical, and environmental performance criteria but does not prescribe a sunlight (UV) resistance test for PVC conduit.

Corrosion Resistance

Clause 14.2 of IEC 61386-1 deals with resistance against corrosion — but its requirements and test methods are intended for metallic and composite conduit systems. For PVC conduit, this section is not applicable, as non-metallic conduits are not subject to the corrosion classifications and test procedures described.

- Metallic and composite conduit systems

Classified for corrosion protection according to Table 10 (low, medium, high).

Low protection: Visual inspection for completeness of coating.

Medium protection: Immersion in a potassium ferricyanide/ammonium persulphate solution; inspection for blue spot corrosion indicators.

High protection: Degreasing, acid cleaning, and repeated immersion in copper sulphate solution; inspection for copper deposition as an indicator of steel exposure.

- Non-ferrous metals: Manufacturers must declare corrosion protection but no test is specified.

- Non-metallic conduits (including PVC): IEC 61386-1 does not define a corrosion test; performance requirements are found in material-specific parts of the IEC 61386 series.

Applications Where Corrosion and Sunlight Resistance Matter Most

The ability of PVC conduit to resist both chemical attack and long-term UV exposure directly impacts its reliability and service life in challenging environments. Below are common scenarios where these performance features are not just beneficial, but critical to safe and cost-effective operation:

1. Outdoor Electrical Installations

Exposed runs on building exteriors, parking lots, or utility poles are subject to direct sunlight, rain, wind, and fluctuating temperatures. UV-resistant PVC conduit ensures that embrittlement and cracking are minimized over decades of service.

2. Underground and Direct Burial

Buried conduit faces potential contact with soil moisture, fertilizers, and naturally occurring salts. Corrosion-resistant PVC helps maintain insulation integrity without the need for additional protective coatings.

3. Marine and Coastal Environments

Salt-laden air and occasional wave splash are extremely aggressive toward metallic conduit. In docks, piers, coastal pump stations, and waterfront lighting, PVC offers a lightweight, non-corrosive alternative that minimizes maintenance.

4. Chemical Processing Plants

In industrial settings where acids, alkalis, or solvents are present, PVC conduit resists many common corrosive agents better than unprotected metals. Its chemical compatibility reduces the risk of conduit degradation from spills, vapors, or washdowns.

5. Solar PV Installations and Rooftop Systems

Photovoltaic systems often have conduit exposed continuously to high-intensity sunlight and heat. UV-resistant PVC helps maintain mechanical strength and electrical safety for the life of the array.

6. Agricultural and Irrigation Installations

Farms and irrigation systems frequently require conduit in areas with fertilizer exposure, pesticide contact, and prolonged sun exposure – conditions where PVC’s dual resistance properties are a clear advantage.

Best Practices for Ensuring Long-Term Performance

Even the most durable PVC conduit will only reach its full service life if it’s chosen, installed, and maintained correctly. Following these best practices helps ensure that corrosion resistance and sunlight resistance remain effective over decades of use.

1. Choosing the Right PVC Conduit

- Match rating to the installation environment – Use sunlight-resistant conduit for outdoor runs and rooftops; for indoor-only applications, general-purpose PVC may be suitable.

- Account for specific hazards – In marine, chemical, or agricultural settings, verify chemical compatibility against the expected substances. Some PVC formulations include additives to improve resistance to particular agents.

- Verify compliance with local codes – Building and electrical codes may mandate conduit types, wall thicknesses, or certifications (e.g., UL 651, CSA C22.2) for certain environments.

- Consider mechanical requirements – In high-traffic or exposed areas, heavier-wall (e.g., Schedule 80) conduit may be warranted to resist impact.

2. Installation Tips

- Cut cleanly and deburr – Smooth conduit ends prevent cable damage and help ensure watertight fittings.

- Seal joints effectively – Use the correct PVC solvent cement or approved fittings to prevent moisture ingress, especially in underground or outdoor runs.

- Avoid unnecessary stress – Maintain proper bending radii and use support spacing per manufacturer guidelines to prevent cracking.

- Protect from physical damage – Install in a location or with guards where it won’t be crushed, abraded, or struck.

- Enhance UV protection if needed – In extreme sunlight conditions, painting the conduit with a UV-stable coating (light color to reduce heat buildup) can extend its lifespan.

3. Maintenance & Inspection

- Conduct regular visual checks – Look for discoloration, chalking, cracking, or brittleness — signs of UV degradation or chemical attack.

- Inspect fittings and seals – Ensure joints remain watertight and free from movement that could loosen connections.

- Replace compromised sections promptly – Damaged or brittle conduit should be replaced immediately to prevent moisture ingress and cable damage.

- Document inspections – Keeping a log of inspection dates and findings helps with preventive maintenance planning.

By applying these practices from selection through ongoing maintenance, electrical professionals can ensure that PVC conduit retains its protective properties for the full intended service life, even in harsh environments.

6 Common Mistakes About PVC Conduit

Despite being one of the most widely used conduit materials, PVC is often misunderstood. Clearing up these misconceptions is key to making informed product and installation decisions.

1. “PVC Never Degrades in Sunlight”

PVC is inherently vulnerable to UV radiation. Without UV-stabilizing additives, prolonged exposure can cause the surface to chalk, discolor, and eventually become brittle. Only conduit marked as “sunlight resistant” or meeting applicable UV-resistance standards is suitable for extended outdoor exposure.

2. “Any PVC Conduit Can Be Used Outdoors”

Not all PVC conduit products are manufactured with the same formulation. Indoor-only grades may lack the UV inhibitors or wall thickness needed to handle constant sunlight, temperature swings, and moisture. Using the wrong type outdoors can lead to premature cracking and costly replacements.

3. “Corrosion Only Affects Metal”

While PVC does not rust, certain chemicals, including strong acids, solvents, or oils, can attack and weaken it over time. In industrial or agricultural environments, verifying chemical compatibility is just as important as it is for metals.

4. “Once Installed, PVC Conduit is Maintenance-Free”

PVC’s durability can create a false sense of security. However, damage from impacts, environmental stress, or chemical exposure can go unnoticed without regular inspection. Preventive checks are necessary to ensure long-term safety and performance.

5. “Painting PVC Conduit is Just for Looks”

Beyond aesthetics, painting PVC with an approved UV-resistant coating can provide a valuable extra layer of protection in intense sunlight regions. This can significantly extend service life in harsh climates.

6. “All PVC Conduit Meets the Same Standards”

Different regions and applications call for different performance standards (UL 651, CSA C22.2, IEC 61386, etc.). A conduit rated for one market or purpose may not meet the specific corrosion or sunlight resistance requirements of another. Always verify certification markings and documentation.

By addressing these myths, installers and specifiers can better match PVC conduit products to the demands of each environment, avoiding premature failures and ensuring compliance with local regulations.

Indoor PVC Conduit vs. Sunlight-Resistant PVC Conduit

While all PVC conduit shares core benefits like corrosion resistance and ease of installation, the choice between indoor-grade and sunlight-resistant types is critical to long-term performance.

Feature | Indoor PVC Conduit | Sunlight-Resistant PVC Conduit |

Primary Use | Protected environments (walls, ceilings, equipment rooms) | Outdoor, rooftop, or areas with direct sunlight |

UV Protection | None or minimal | Contains UV inhibitors to resist sunlight degradation |

Formulation | Standard PVC without sunlight stabilizers | PVC compounded with UV-stabilizing additives |

Identification | No “Sunlight Resistant” marking | Marked “SUNLIGHT RESISTANT” per applicable standards (e.g., UL 651) |

Durability in Sunlight | Degrades within a few years when exposed | Maintains mechanical strength and appearance for many years |

Cost | Lower | Slightly higher |

Best Practice | Use only where shielded from daylight | Suitable for any location, including indoor-outdoor transitions |

Selection Tip: When in doubt, choose sunlight-resistant conduit for any installation with possible daylight exposure. The additional cost is minor compared to the cost of premature replacement.

Conclusion

PVC conduit offers a strong combination of corrosion resistance, light weight, and ease of installation, making it a mainstay in electrical systems worldwide. However, its long-term performance depends heavily on understanding the environments it will face — and matching the right product to those conditions.

Corrosion resistance is not just a concern for metals; certain chemicals, soils, and pollutants can also degrade PVC over time. Similarly, sunlight can slowly break down unprotected PVC, making UV resistance an essential consideration for outdoor applications. Knowing the relevant standards — from UL 651 and CSA C22.2 to AS/NZS 2053.1 and IEC 61386 — helps ensure compliance and product reliability, even if some tests target metals rather than plastics.

In practice, success comes down to three key principles:

Select the right conduit — choosing between indoor and sunlight-resistant grades based on the installation location.

Install with care — following best practices to prevent mechanical damage and water ingress.

Maintain vigilance — inspecting periodically and replacing when signs of degradation appear.

By applying these principles, and avoiding common misconceptions, installers and specifiers can ensure that PVC conduit delivers on its promise of safety, reliability, and long service life — whether hidden inside a wall, running across a factory floor, or standing up to the elements on a sun-baked rooftop.

Frequently Asked Questions (FAQs)

Can all PVC conduit be used outdoors?

No. Only PVC conduit marked as “sunlight resistant” or tested to applicable UV-resistance standards is suitable for prolonged outdoor use. Indoor-grade conduit can become brittle and fail when exposed to sunlight for extended periods.

Does PVC conduit corrode?

PVC does not rust like metal, but it can be degraded by certain chemicals, oils, or solvents. In industrial, agricultural, or marine environments, always check the manufacturer’s chemical compatibility charts.

How can I tell if a PVC conduit is sunlight resistant?

Look for the “SUNLIGHT RESISTANT” marking or reference to compliance with standards such as UL 651. Some products may also have darker pigmentation to improve UV resistance.

Is painting PVC conduit necessary?

Painting is not mandatory if the conduit is already UV-resistant, but using a compatible UV-protective coating can extend service life, especially in high-UV regions. Always use paint recommended by the conduit manufacturer.

What is the lifespan of PVC conduit outdoors?

Sunlight-resistant PVC conduit can last decades outdoors under normal conditions. Indoor-grade PVC used outdoors may degrade within just a few years due to UV exposure.

Can I use sunlight-resistant PVC indoors?

Yes. Sunlight-resistant PVC can be used both indoors and outdoors, making it a flexible choice when installations cross between environments.

Does heat from sunlight affect PVC conduit performance?

Yes, prolonged heat exposure can reduce mechanical strength. In high-temperature climates, allow for thermal expansion during installation.