목차

In electrical infrastructures, PVC 전기 도관 plays a vital role in protecting wiring systems from mechanical damage, moisture, chemicals, and environmental factors. But beyond basic material properties, the mechanical performance of a conduit, particularly its ability to maintain integrity under physical stress is crucial to safety and durability in the field.

Bending and collapse tests are two important tests among the many mechanical tests. These two tests reflect the conduit’s behavior under two of the most critical real-world conditions:

- 그만큼 bending test assesses how well the conduit resists cracking or deformation when flexed, a common requirement during installation, especially in cold weather or tight spaces.

- 그만큼 collapse test evaluates a conduit’s resistance to deformation or inward buckling when exposed to high temperatures and pressure, such as when encased in concrete or buried under heavy soil loads.

These tests are not only key performance indicators but also serve as predictive benchmarks for installation safety and long-term service reliability. Poor performance in either can lead to premature conduit failure, compromised wire protection, or costly rework in the field.

This article explores how bending and collapse tests are defined and applied across different types of PVC conduits, including:

It also compares how major international standards implement or omit these tests, such as UL, CSA, IEC 61386, and AS/NZS.

Whether you’re an electrical engineer, specifier, or contractor, understanding these two test types provides essential insight into conduit performance and code compliance.

Bending Test of PVC Conduit

In electrical installations, PVC conduit systems must not only protect wiring but also maintain flexibility and mechanical performance across various conditions. Among the essential evaluations is the bending test, which helps determine whether a conduit can perform as intended during handling, installation, and throughout its service life.

What Is a Bending Test?

A bending test is a mechanical test used to assess the ductility, flexibility, and deformation resistance of PVC conduit under bending stress. The main purpose is to ensure that the conduit can withstand handling during installation, particularly when navigating around obstacles or fitting into complex layouts without cracking or collapsing.

Bending Test Purpose

Installation practicality: Determines whether the conduit can be bent without tools (for flexible types) or whether it holds up during mechanical bending (for rigid types).

Material integrity: Ensures no fractures, splits, or deformations occur that could compromise insulation or wire pulling.

Code compliance: Aligns the product with regional or international standards to ensure it meets safety and reliability benchmarks.

Bending Test for Rigid PVC Conduits

Rigid PVC conduits, including Schedule 40/80 and other rigid PVC electrical conduit specified, may evaluated for bendability per different standards, and there are may have no bending requirements for some rigid PVC conduits.

IEC 61386-21

The IEC 61386-21 standard establishes detailed test methods for evaluating the bendability and mechanical behavior of non-metallic rigid conduits, such as PVC conduit, under simulated installation conditions. Specifically, Section 10.4.102 outlines the bending test procedure for conduit sizes 16, 20, and 25, which are among the most commonly installed in light and medium duty applications.

Test Apparatus:

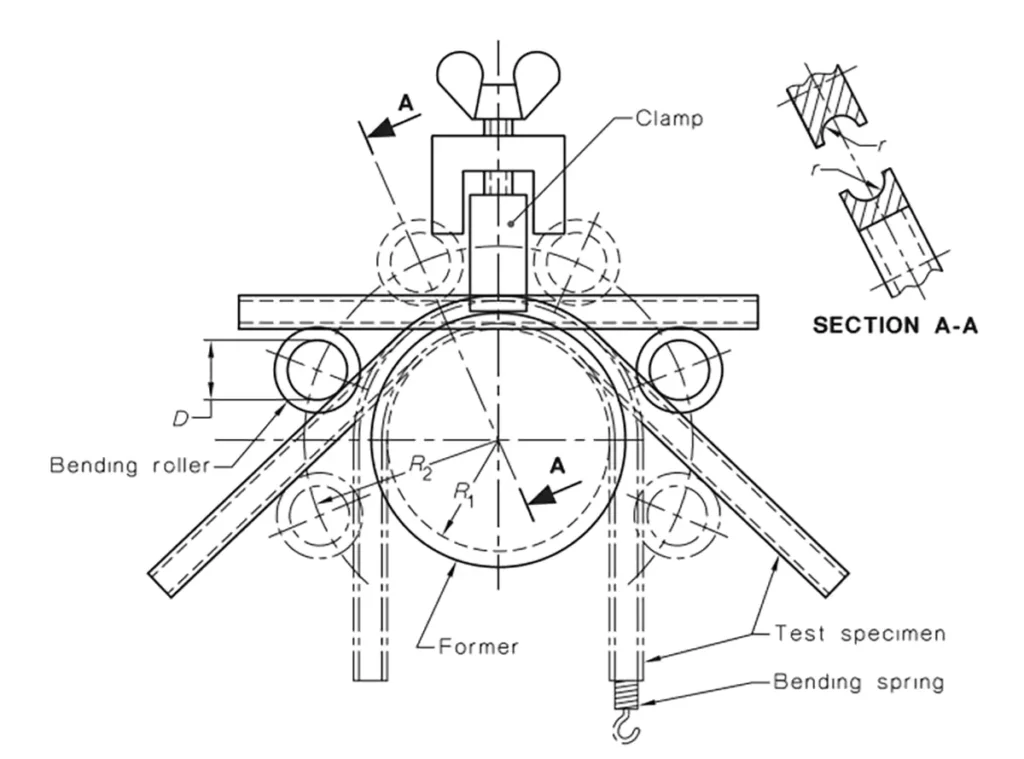

The test uses a specialized bending jig as illustrated in Figure 103 of IEC 61386-21.

테스트 조건:

The sample is pre-conditioned for at least 2 hours at a low declared temperature (based on the conduit’s classification, typically between –5°C to –25°C) in a temperature-controlled chamber.

Within 12 ±2 seconds of removal from the chamber, the sample is mounted and bent to a 90° angle (±5°) using the apparatus.

The bending must occur smoothly, and the conduit should naturally hold the bent shape upon release.

Pass/Fail Criteria:

After the bend:

- No visible cracks must appear on the conduit surface under normal or corrected vision.

- The bending aid must be removable easily and without damaging the conduit.

- A gauge (as defined in IEC Figure 102) must pass through the entire length of the bent sample under its own weight, confirming that the internal diameter has not collapsed or distorted.

AS/NZS 2053.2

In Australia and New Zealand, the bending capability of rigid PVC conduits is addressed under AS/NZS 2053.2, which outlines performance requirements for conduits subject to mechanical stresses during installation. This test is especially relevant for conduits less than 32 mm in diameter that are classified for very light, light, or medium mechanical stress.

메모: Conduits that are 32 mm or larger, or rated as heavy duty or very heavy duty, are excluded from this bending test. These are typically not expected to be field-bent and should instead use prefabricated elbows or mechanical bends.

Apparatus:

A bending device conforming to Figure 102 as shown in the AS/NZS 2053.2 (similar to IEC Figure 103), featuring:

A central former with defined radius.

Two bending rollers to apply symmetrical force.

A clamp to hold the conduit lightly in position.

A bending aid:

Typically a square-section coiled spring, free from burrs.

Must have an outer diameter 0.7 mm to 1.0 mm smaller than the conduit’s minimum internal diameter.

Alternatively, a manufacturer-approved aid may be used.

시험 방법

Insert the bending aid into the conduit sample.

Position the conduit into the bending device, securing it gently with the clamp.

Bend the conduit by rotating the rollers around the central former to create a 180° sweep, so that the conduit holds a 90° bend upon release.

Carefully remove the bending aid without damaging the conduit.

승인 기준:

- The conduit must exhibit no cracks when visually inspected under normal or corrected vision without magnification.

- The bending aid should be removable without force or damage.

- While internal clearance or gauge testing is not specifically mentioned in this standard (unlike IEC), the absence of cracking or deformation is critical.

UL 651 / CSA C22.2 No.211.2

Notably, UL and CSA standards for rigid PVC conduits do not require a bending test. This is because:

UL 651 conduits (such as Schedule 40/80) are not designed to be bent in the field.

Installers are expected to use prefabricated elbows or heat-bending tools in controlled conditions.

Flexibility testing is deemed unnecessary due to the rigidity and intended handling methods of the product.

Bending Test for Flexible PVC Conduits

Unlike rigid systems, flexible PVC conduits, such as Electrical Nonmetallic Tubing (ENT) and corrugated conduit, are expected to be bent manually during installation. Therefore, bending tests are critical to determine usability, durability, and resistance to fracture in both hot and cold conditions.

CSA C22.2 No. 227.1 / UL 1653

The CSA C22.2 No.227.1 / UL 1653 standard applies to ENT used in the U.S. and Canada.

Condition:

The ENT should be conditioned at least 24 hours in room temperature (23±2℃) before testing.

요구 사항:

ENT must maintain a circular internal shape with no more than 15% distortion.

테스트 절차:

Each ENT size is cut into a 750 mm (30 in.) length.

The sample is bent 90° around a mandrel with a radius corresponding to its trade size, as specified in Table 2 of the standard.

After bending:

A rigid sphere, per the size listed in Table 3 of the standard, must pass freely through the entire inner bore of the bent ENT.

The test confirms that the internal diameter has not collapsed or been distorted beyond 15% of its nominal value.

콜드 벤드

ENT is often installed in environments where cold weather is a factor. To simulate such conditions, the cold bend test assesses the conduit’s low-temperature flexibility and impact resistance.

테스트 조건:

Six samples of each trade size are conditioned for 4 hours at –20 ±1°C (–4 ±1.8°F).

While still at that temperature, each sample is bent 360° around the appropriate mandrel (same radius as in Table 2).

합격 기준:

No visible cracks, chips, or ruptures are permitted in any of the samples during or after bending.

AS/NZS 2053.5

The AS/NZS 2053.5 standard outlines performance requirements for corrugated and flexible PVC conduits used in electrical installations across Australia and New Zealand, including bending test.

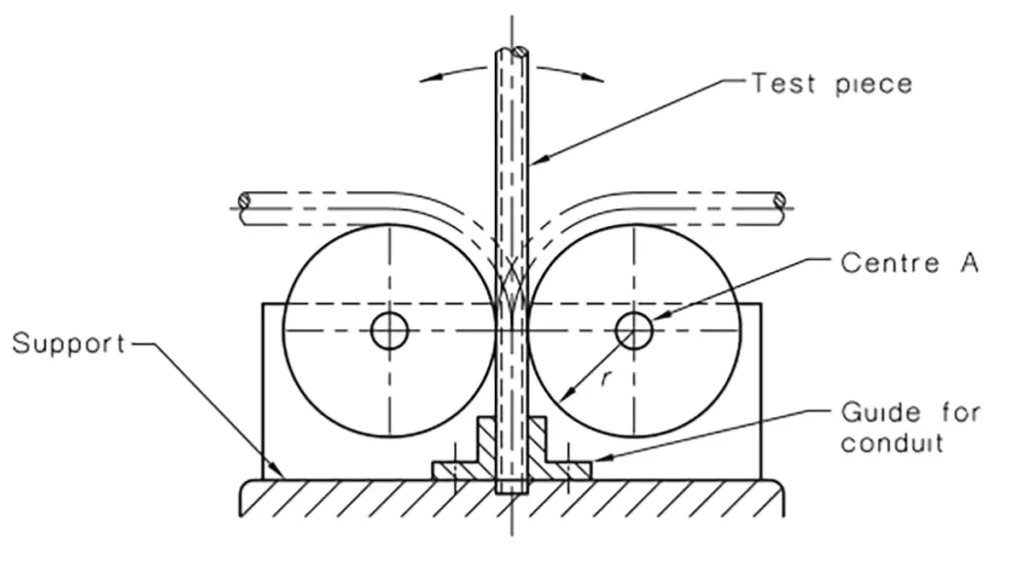

Apparatus Requirements:

- A bending apparatus capable of holding the conduit vertically and rotating it for side-to-side bending.

- A gauge to verify that the internal diameter remains unobstructed.

- A conditioning chamber that can maintain:

Standard test temperature of 20 ±1°C, and the lowest installation temperature specified by the conduit manufacturer (typically down to –5°C or lower), with a tolerance of ±2°C.

Bending Procedure:

- At Room Temperature (20°C):

- 조절: Samples and apparatus are stabilized at 20 ±1°C for 2 hours.

- Manual Bending Sequence (performed 4 times):

Bend the conduit left ~90°, hold for 1 minute.

Return to vertical, hold for 1 minute.

Bend right ~90°, hold for 1 minute.

Return to vertical, hold for 1 minute.

On the final repetition, stop at the third step (bent right) and maintain for 5 minutes.

- Angle Repositioning: Rotate the bending apparatus so that straight conduit sections sit at 45° to vertical.

- Gauge Test: Allow the specified gauge to pass through the conduit under its own weight without external force or velocity.

- At Lowest Installation Temperature:

Repeat the exact same bending and gauge procedure as above, but after conditioning at the manufacturer’s minimum installation temperature (e.g., –5°C to –20°C) for 2 hours.

승인 기준

A sample passes if:

No visible cracks are observed under normal or corrected vision without magnification.

The gauge passes freely through the entire conduit under its own weight, confirming the internal geometry is preserved after bending.

IEC 61386-23

IEC 61386-23 does not provide bending requirements for flexible conduit, but provide flexing test methods, which serves a similar purpose to bending tests, evaluating conduit durability under deformation.

Summary

Here are 8 commons electrical code bending test comparing chart as below,

기준 | 도관 유형 | Test Type | Temp Conditions | Key Method | Pass Criteria |

IEC 61386-21 | Rigid PVC (≤25 mm) | Static Bending | Declared low temp (e.g. -5°C) | Bend 90° using jig (Fig. 103); remove bending aid | No cracks; bending aid removable; gauge passes through conduit |

AS/NZS 2053.2 | Rigid PVC (<32 mm) | Manual Bending (x4) | 20°C and lowest install temp | Hand-bend left/right; hold; gauge test at 45° | No cracks; gauge passes freely |

UL 651 / CSA 211.2 | Rigid PVC (Sch 40/80) | Not Required | N/A | N/A | N/A |

UL 1653 / CSA 227.1 | ENT (Flexible) | Static Bending + Cold | Room temp and -20°C | Bend 90° or 360° around mandrel; sphere clearance check | No more than 15% internal distortion; no cracks; sphere passes after cold bend |

AS/NZS 2053.5 | Corrugated/Flexible PVC | Manual Bending (x4) | 20°C and lowest install temp | Bend left/right; hold; final 5-min hold; gauge test | No cracks; gauge passes freely |

IEC 61386-23 | Flexible PVC | Not applicable | N/A | N/A | N/A |

Collapse Test of PVC Conduit

What Is a Collapse Test?

A collapse test, also referred to as a heat deformation or thermal collapse test that evaluates the ability of a PVC electrical conduit to maintain its circular cross-sectional shape when exposed to elevated temperatures under mechanical pressure. This is particularly important for rigid conduits installed in high-temperature environments, such as attics, rooftops, or near industrial heat sources.

Purpose and Importance

Thermal Stability: PVC materials tend to soften under heat. Collapse testing ensures the conduit retains its mechanical integrity under such conditions.

Mechanical Safety: A deformed conduit could restrict wire pulling, reduce current-carrying capacity due to insulation contact, or violate minimum bend radius constraints.

Application Suitability: Identifies which conduits are suitable for in-wall, ceiling, or outdoor installations where elevated temperatures are expected.

Collapse Test for Rigid PVC Conduits

IEC 61386-1 / -21

Under IEC 61386-1, the collapse test for rigid PVC conduits is known as the “heat deformation test under pressure”. It simulates the combination of thermal exposure and mechanical load to verify the conduit’s ability to resist ovalization or flattening.

테스트 절차

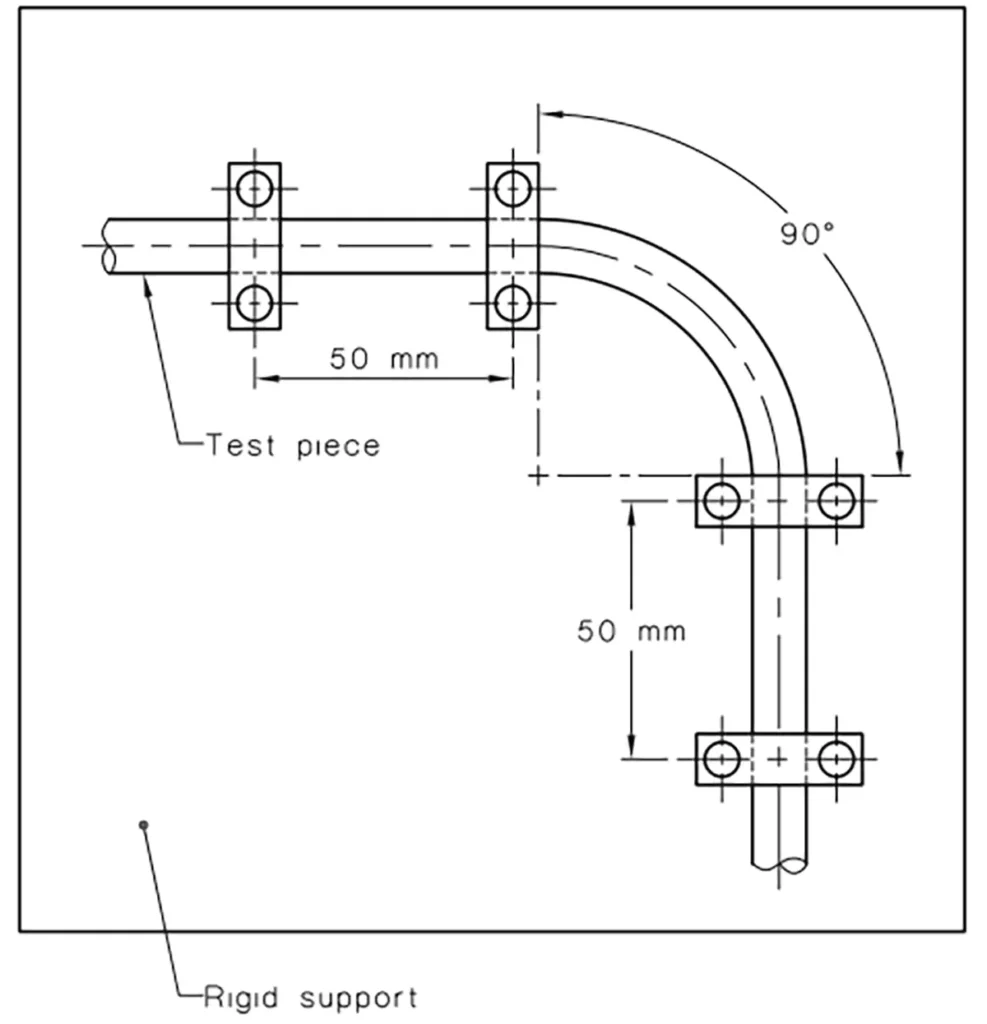

- Bending and Mounting: Prior to testing, each conduit sample is mechanically bent following the procedure outlined in the standard, and the bent sample is mounted onto a rigid support structure using four evenly spaced straps.

- 열 조절: The entire setup (support and conduit) is placed in a heating cabinet at the declared maximum application temperature (typically between 60°C to 90°C) for 24 hours ± 15 minutes, with a tolerance of ±2°C.

- Gauge Clearance Test: After conditioning, the support is rotated so the conduit’s straight portions are at approximately 45° to the vertical axis, with one end pointing upward and the other downward.

A standardized gauge must pass through the conduit under its own weight, without any additional force or speed.

합격/불합격 기준

A conduit passes the IEC collapse test if:

The gauge passes completely through the conduit without obstruction, confirming that the internal diameter has not collapsed or become distorted due to thermal softening.

There are no cracks or mechanical failures visible after the test.

AS/NZS 2053.1 / .2

The collapse test in AS/NZS 2053 evaluates whether a rigid PVC conduit can maintain its internal cross-sectional geometry when subjected to thermal conditions after being bent, replicating the real-life scenario where a field-bent conduit is installed in warm environments, such as under roofs or in concrete slabs.

This test is mandatory for:

- Conduits with diameters less than 32 mm

- Rated as very light, light, or medium mechanical stress

Heavy-duty and very heavy-duty conduits, or those with diameters ≥32 mm, are exempt from this test because they are not intended to be field-bent.

Apparatus

A bending device matching the conduit’s classification (see AS/NZS 2053.2 Figure 102).

A rigid support with four straps, to hold the bent conduit in place during thermal exposure.

A conditioning chamber capable of maintaining the conduit’s maximum service temperature ±2°C (usually 60–90°C).

A gauge (from AS/NZS 2053.2 Figure 103) to verify the internal diameter.

테스트 절차

The test procedure is similar to collapse test that outlined in the IEC 61386-21.

- Bending Stage (at Room Temperature)

Gradually bend the test piece 90° using the designated bending apparatus. This step mimics practical bending during installation. - Mounting

Secure the bent conduit onto the rigid support using four clamps. Ensure the bend is well-supported and symmetrical. - Thermal Conditioning

Place the entire assembly into a temperature chamber set to the conduit’s maximum declared installation temperature. Maintain this temperature for 24 hours ±15 minutes. - Post-Heating Verification

After heating, orient the support so that the straight sections of the conduit are approximately 45° from vertical. Then, insert the appropriate gauge through the bent section of the conduit under its own weight and without any added speed.

승인 기준

The sample passes if the gauge passes freely through the conduit after heat exposure, confirming that no collapse or deformation has occurred.

The test ensures that the internal diameter remains unobstructed and that wire pulling remains feasible after installation in elevated temperature environments.

UL 651 / CSA C22.2 No.211.2

UL and CSA standards do not require a dedicated collapse test for rigid PVC conduits like Schedule 40 or Schedule 80. But tested the deflection under load in specified temperature and crush resistance to evaluate the conduit’s resilience.

Collapse Test for Flexible Conduit

Flexible PVC conduits are frequently used in environments where bending, tight routing, and mechanical movement are expected. However, their thin-walled, flexible structure makes them more vulnerable to deformation under heat and load. Collapse tests for flexible conduits are therefore essential to ensure they retain sufficient internal clearance for cable pulling, even after thermal exposure or mechanical stress.

UL 1653 / CSA C22.2 No. 227.1

The UL 1653 and CSA C22.2 No. 227.1 standards for ENT (Electrical Nonmetallic Tubing) do not label this procedure explicitly as a “collapse test,: but they evaluate the collapse risk via a series of bending and cold bend tests.

AS/NZS 2053.5

AS/NZS 2053.5 applies a more direct collapse evaluation for corrugated PVC conduits, similar to the rigid conduit tests in Part 1 of the series. Just for flexible conduit, AS/NZS 2053.5 does not limit the sizes and classifications that applicable to this test as rigid conduit in the AS/NZS 2053.2.

IEC 61386-1 / -23

As the standard IEC 61386-23 indicates, PVC flexible conduit is not applicable to collapse test as non-metallic rigid conduit.

Summary

Here are 9 commons Electrical Code collapse Test tables,

기준 | 도관 유형 | Test Type | Applicable Sizes / Types | Test Conditions | 승인 기준 |

IEC 61386-21 | 강성 PVC | Heat deformation after bending | Bendable conduits | Bent conduit mounted to rigid frame, conditioned for 24 h at declared max temp | Gauge must pass under own weight, no cracks visible |

AS/NZS 2053.1 / .2 | 강성 PVC | Thermal collapse after bending | <32 mm, very light to medium duty conduits only | Bent 90°, fixed on support, conditioned 24 h at max temp, measured using standard gauge | Gauge must pass freely, no visible damage |

UL 651 / CSA 211.2 | Rigid PVC (Sch 40/80) | Not dedicated | N/A | N/A | N/A |

UL 1653 / CSA 227.1 | ENT Flexible PVC | Not dedicated | N/A | N/A | N/A |

AS/NZS 2053.5 | Corrugated / Flexible PVC | Similar to rigid | No size restriction | Bent, strapped to rigid support, heated at max temp for 24 h, gauge passed after heating | Gauge must pass freely, no collapse or obstruction |

IEC 61386-23 | Flexible PVC Conduit | Not applicable | N/A | N/A | N/A |

전문가 팁: If you want to know more about PVC conduit testing, you can read our last posts:

Bending Test vs. Collapse Test

Bending tests and collapse tests are two of the most critical mechanical assessments for PVC conduit. Although both are essential in determining a conduit’s suitability for real-world conditions, they serve distinct purposes, are performed differently.

측면 | 굽힘 시험 | Collapse Test |

Objective | To evaluate the conduit’s flexibility, ductility, and ability to resist cracking during bending | To assess the conduit’s ability to maintain its circular cross-section under heat and mechanical stress |

Simulation of | On-site bending during installation (e.g., routing around obstacles) | Elevated temperature environments such as attics, slab embeds, rooftops |

Failure Risk | Cracking, kinking, or permanent deformation during bending | Ovalization, flattening, or blockage of the internal passage |

측면 | 굽힘 시험 | Collapse Test |

When Performed | At room temperature and low temperature, often before installation | After the conduit is bent, then thermally conditioned at elevated temperature |

Test Setup | Manual or mechanical bending over a defined radius with aids or jigs | Sample mounted on rigid support with 90° bend; heated in a chamber for 24 hours |

Conditions Simulated | Mechanical handling, routing tight curves, or hand-bending requirements | Long-term exposure to heat post-installation in fixed positions |

Evaluation Method | Check for cracks, structural damage, and free passage of internal gauge after bending | Gauge passed through after heat exposure; no collapse or obstruction allowed |

Why Both Tests Matter

In PVC conduit selection and compliance, understanding both the bending test and the collapse test is essential because they address different stages and stresses throughout the conduit’s lifecycle.

Bending tests are crucial during installation. They simulate real-world handling scenarios—such as manually routing conduit through tight spaces or around corners—ensuring the product can bend without cracking or splitting. This is especially important for flexible and smaller-diameter conduits, which are often shaped by hand or simple tools on job sites.

On the other hand, collapse tests focus on in-service performance. After installation, conduits are often exposed to elevated temperatures—inside attics, embedded in concrete, or along rooftops. Under such thermal conditions, PVC can soften. The collapse test evaluates whether the conduit can retain its internal geometry and allow for free wire passage even after prolonged heat exposure and mechanical stress. A collapsed conduit can obstruct cable pulls, reduce ventilation around wires, or fail to comply with electrical safety clearances.

Ultimately, both tests provide complementary insights: bending tests ensure safe and practical installation, while collapse tests verify long-term reliability in demanding environments. Together, they help ensure that PVC conduit systems perform safely, consistently, and in compliance with international or regional standards.

Application Guidance for Engineers and Contractors

The results of bending and collapse tests are not just technical metrics, they are practical tools that engineers, electricians, and contractors can use to make informed decisions during product selection, system design, and installation. Understanding how each type of PVC conduit responds to mechanical and thermal stress ensures code-compliant, safe, and long-lasting electrical installations.

1. Select Conduit Type Based on Installation Environment

Not all PVC conduits are created equal, especially when subject to different physical and thermal demands. Use test data to guide the right product for the job:

- Use rigid PVC conduits (e.g., Schedule 40/80) in exposed or embedded runs, especially in industrial, utility, or structural applications where physical protection and flame resistance are prioritized.

- Flexible corrugated or ENT conduits are ideal for installations in tight spaces, walls, or ceilings, where ease of bending and lightweight routing reduce labor time.

- Avoid bending rigid conduit types that are not tested or rated for manual bending. Instead, use factory elbows or heat-forming techniques as recommended.

2. Consider Temperature Ratings and Collapse Resistance

Collapse tests simulate real-world heat conditions. Use this data to avoid post-installation failures:

- For attics, rooftops, or slab-in installations, ensure the conduit has passed thermal collapse tests.

- Choose products with certified temperature ratings that match or exceed the expected ambient or service conditions.

- Avoid using flexible conduit without confirmed heat stability in areas with sustained high temperatures.

3. Evaluate Bendability During Layout and Design

Routing conduit through complex paths requires planning:

- For conduit sizes below 32 mm, bending test compliance under IEC 61386-21 or AS/NZS 2053.2 assures that installers can perform safe manual bends without cracks or deformation.

- For ENT or corrugated conduit, select products tested under UL 1653 / CSA 227.1 and AS/NZS 2053.5 to ensure they won’t collapse when hand-bent during normal and cold-weather installation.

- Understand minimum bend radius and gauge clearance to avoid over-bending and compromising conduit usability.

4. Align with Local Codes and Standards

Different jurisdictions adopt different standards. Choose conduits and installation methods that align with the applicable codes:

- IEC 61386 series is widely adopted internationally and provides guidance for both rigid and flexible PVC conduits.

- AS/NZS 2053 standards govern performance and classification of PVC conduit systems in Australia and New Zealand, with specific size/stress class implications.

- UL 651 / UL 1653 and CSA C22.2 standards apply in North America and should be followed for compliant installations in the U.S. and Canada.

5. Prevent Common Installation Mistakes

Test standards exist for a reason, failure to follow them can lead to real-world issues. Here’s how to apply test data practically:

- Don’t field-bend rigid conduit unless it’s specifically tested and approved to do so.

- Don’t assume PVC conduit will always retain shape, verify collapse resistance under heat.

- Avoid mixing high-stress locations with low-duty conduit classes (e.g., use light-duty conduit under slab or in industrial walls).

- Always confirm conduit size and internal clearance is enough and smooth for wiring pulling.

결론

PVC electrical conduits are foundational components in modern wiring systems, used across residential, commercial, industrial, and infrastructure projects. While product catalogs often highlight size, wall thickness, and certifications, a deeper understanding of mechanical performance tests, particularly bending and collapse tests, empowers professionals to make smarter, safer choices.

This article has explored how bending tests assess a conduit’s flexibility and crack resistance during installation, while collapse tests evaluate its structural integrity under heat and stress once installed. We’ve broken down these procedures according to international and regional standards, including IEC 61386, AS/NZS 2053, UL 1653, and CSA C22.2—and clarified why these tests matter for both rigid and flexible PVC conduit types.

So when you choose the right PVC conduit for your installation, make sure they are good enough to pass the performance requirements of relevant standards, and follow the right guidance for installation.

자주 묻는 질문

What is the purpose of a bending test?

A bending test determines the ability of a conduit to withstand flexing or deformation during installation without cracking or failing. It assesses the material’s ductility, structural resilience, and suitability for routing around corners or obstacles.

What are the rules for bending conduit?

Rules vary by conduit type and local codes but generally include:

Maintain minimum bend radius based on conduit size and type.

Do not exceed the number of bends per run (typically no more than 360° between pull points per NEC).

Avoid kinking or flattening the conduit.

Use tested products and follow manufacturer recommendations for field bending.

What is the purpose of conduit bend?

Conduit bends allow for smooth changes in direction without stressing cables. Properly bent conduit ensures:

Easier wire pulling

Reduced risk of insulation damage

Clean routing in confined or structured spaces

How to bend a rigid PVC conduit?

To bend a rigid PVC conduit, there are two commonly used methods:

- Heat Bending: Use a heat gun to evenly heat conduit where you want the bend, once the conduit becomes soft and flexible, bend it gently, and hold it in place until it cools and hardens.

- Use a Bending Tool: Insert a bending spring inside the conduit, bend it into required angle, this can help prevent kinking, This is often done at room temperature.

Why is the bend test important?

The bend test ensures conduits can be bent safely without breaking, and confirms conduit performance in cold, hot, or tight installations. It also helps prevent installation errors, damaged conductors, and failed inspections.

What is conduit collapse test?

It’s a test that assesses whether a conduit can maintain its internal diameter and shape after being exposed to elevated temperatures and mechanical stress. It’s critical for ensuring the conduit remains functional and safe in heat-prone environments.

What is conduit collapse test procedure?

The general procedure involves:

Bending the conduit to a prescribed angle.

Securing it to a rigid frame using straps.

Conditioning the setup at high temperature (e.g., 60–90°C) for 24 hours.

Checking clearance with a standard gauge, which must pass through under its own weight.

This simulates real conditions where heat could cause conduit deformation.

What is the purpose of a conduit collapse test?

The collapse test can help to verify that the conduit will not deform or restrict wire space due to heat, and its structural integrity is maintained after thermal exposure. Make sure the product complies with application-specific performance standards.

참고문헌

UL 651 STANDARD FOR SAFETY Schedule 40, 80, Type EB and A Rigid PVC Conduit and Fittings

CSA C22.2 NO. 211.2:06 (R2021) Rigid PVC (unplasticized) conduit

CSA C22.2 NO. 227.1:19 (R2023) Electrical nonmetallic tubing (Binational standard with UL 1653)

UL 1653 STANDARD FOR SAFETY Electrical Nonmetallic Tubing

IEC 61386-1:2008 Conduit systems for cable management – Part 1: General requirements

AS/NZS 2053.1:2001 Conduits and fittings for electrical installations – General requirements