목차

In the world of electrical infrastructure, conduit systems play a vital role in protecting wiring, ensuring safety, and maintaining code compliance across various voltage applications. One of the most fundamental distinctions that professionals, contractors, and engineers must understand is the difference between low voltage and high voltage conduit systems.

While both serve the primary purpose of housing and shielding electrical cables, the requirements, materials, ratings, and installation standards can vary significantly depending on the voltage of the system. Misunderstanding or overlooking these differences can lead to safety hazards, code violations, equipment failure, or inefficient system performance.

This article explores the key differences between low voltage and high voltage conduit—including definitions, typical applications, code requirements, and the types of conduit suitable for each system. Whether you’re involved in commercial construction, industrial automation, utility infrastructure, or smart home installations, understanding the right conduit for the right voltage level is essential for safe and effective electrical design.

What is Low Voltage?

Low voltage generally refers to electrical systems operating at 50 volts (V) or less, though definitions can vary slightly based on region and industry. In residential and commercial applications, low voltage typically includes circuits for:

Security and surveillance systems

Thermostats and building automation

Audio/video and intercom systems

Data and communication networks (such as Ethernet or fiber optics)

Landscape lighting (commonly 12V or 24V)

From a safety standpoint, low voltage systems carry a reduced risk of electrical shock and fire. However, proper conduit selection remains essential to prevent physical damage, electromagnetic interference (EMI), and moisture ingress.

Low Voltage Conduit Purpose & Types

Low voltage conduit serves to route and protect smaller gauge wiring used in signal or control systems. While these conduits don’t require the same heavy-duty construction or insulation as those for higher voltages, they must still meet applicable standards and environmental ratings. Common types include:

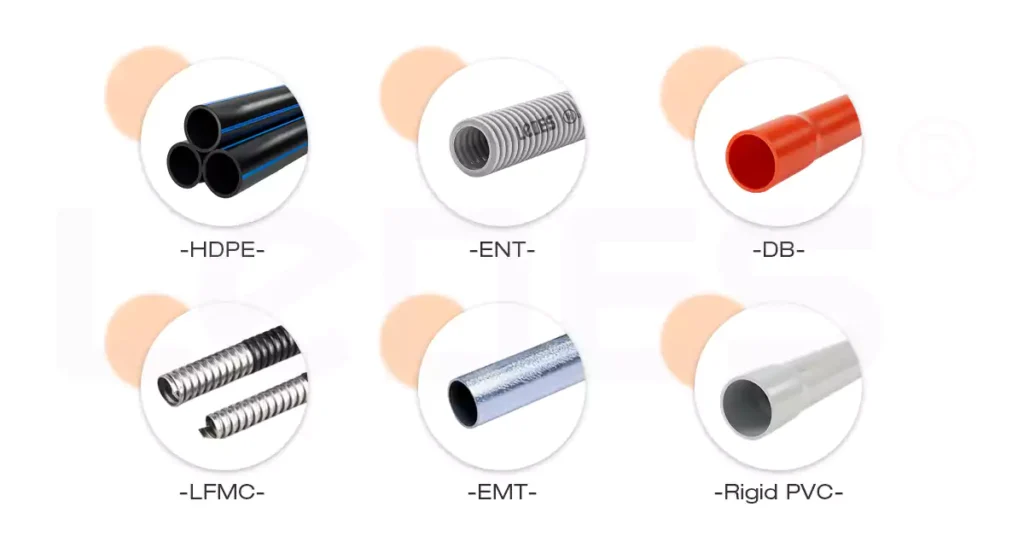

PVC 도관

재료: Polyvinyl Chloride (nonmetallic)

Rigid PVC is widely used for low voltage systems due to its corrosion resistance, affordability, and ease of installation.

Schedule 40 PVC is suitable for indoor or protected outdoor installations.

일정 80 PVC, with thicker walls, may be used in areas subject to mechanical damage or UV exposure (e.g., rooftops or utility rooms).

PVC Communication conduits, often in grey, white and orange.

DB/EB Conduit: specifically engineered for direct burial and concrete encasement applications, commonly used in telecom, CSATV, fiber networks, often color coded in grey, orange and white.

ENT (Electrical Nonmetallic Tubing)

이비인후과 is a flexible, lightweight conduit with a ribbed surface that makes it easy to install around bends and within wall cavities.

Designed for indoor low-voltage use, such as thermostat circuits, alarm systems, or communication cabling.

Must be concealed within walls, floors, or ceilings, not suitable for exposed use.

EMT(전기 금속 튜브)

Can be made from Galvanized Steel or Aluminum.

Though typically associated with power wiring, EMT is frequently used in commercial and industrial low voltage systems due to its strength and EMI shielding.

Ideal for structured cabling, fiber optics (with inner ducting), security camera runs, and fire alarm circuits.

Provides superior mechanical protection and excellent grounding path.

Requires compression or set-screw fittings and must be bonded properly.

HDPE Conduit

Made from High-Density Polyethylene

HDPE is a flexible, durable, and UV-stable conduit primarily used in outdoor and underground installations.

Commonly deployed for telecom networks, fiber optics, and control wiring in utility corridors.

Liquid-tight Flexible Metallic Conduit (LFMC)

Steel core with plastic jacket

LFMC offers the combined benefits of metallic shielding and flexibility, used in applications where conductors need extra protection from moisture, oil, or physical impact.

Suitable for low voltage circuits exposed to moisture, such as in pump rooms, rooftops, or outdoor control boxes.

Provides EMI shielding, especially helpful for sensitive electronics or communication lines.

Requires listed liquidtight fittings and proper support spacing per NEC.

What is High Voltage?

High voltage typically refers to systems operating at 1,000 volts (V) or more, especially in the context of transmission and industrial power. However, the National Electrical Code (NEC) considers circuits above 600V as high voltage for many applications. High voltage systems are common in:

Utility-scale power transmission and distribution

Large motors and industrial drives

High-capacity battery storage systems (including some EV infrastructure)

Renewable energy systems such as solar farms and wind turbines

Railway and public transport electrification

Due to the increased danger posed by high voltage, these systems demand more stringent protective measures, including insulation, separation, grounding, and fire-resistant materials.

High Voltage Conduit Purpose & Types

High voltage conduit must be designed to withstand elevated electrical stress, heat, and environmental exposure. Key characteristics of high voltage conduit include:

Thicker wall construction (e.g., Rigid Metal Conduit or Schedule 80 PVC)

Dielectric strength and insulation properties

Fire resistance and UV protection for outdoor or exposed installations

Code compliance with UL, CSA, or IEC standards depending on region

Typical conduit types for high voltage include:

- RMC (Rigid Metal Conduit), 아이엠씨 (Intermediate Metal Conduit), and 응급구조사 (Electrical Metallic Tubing)

- 고밀도 폴리에틸렌(HDPE) 또는 fiberglass conduit for underground power transmission

- Steel or aluminum conduit for substations and industrial facilities

- Thermosetting Resin Conduit (RTRC), fiberglass-reinforced composite conduit

- Specialized fire-rated conduits for critical systems like emergency power

Low Voltage Vs. High Voltage Conduit Summary

측면 | Low Voltage Conduit | High Voltage Conduit |

Voltage Range | ≤ 1000V AC, typically 660V or less (≤ 50V AC considered as extra low voltage) | > 600V, often ≥1000V in utility/industrial |

Common Applications | Data, telecom, security, controls, HVAC, lighting | Power distribution, industrial motors, renewables, utility |

NEC Article | Article 725 (Class 1-3), 800 (Communications) | Article 305 |

도관 크기 조정 | Based on conductor fill, easier flexibility allowed | Precise sizing critical for heat dissipation & insulation |

Conductor Separation | Low voltage require a minimum separation from different power sources | Must be separated from LV and signal systems |

접지 요구 사항 | Not always required to be grounded, but certain conditions do. | Requires bonding and grounding |

Common Conduit Types | Rigid and flexible PVC, ENT, EMT, HDPE, LFMC, DB/EB conduit | Rigid and flexible PVC, ENT, EMT, RMC, IMC, LFMC, HDPE, RTRC (fiberglass) |

Primary Safety Risks | Arc flash burns, electric shock, muscle contractions | Electric shock, arc flash, overloading and equipment failure, electrical burns |

It’s important to recognize that the boundary between “low” and “high” voltage is not always fixed. Voltage classification depends on application context, risk level, and local electrical code.

The Purpose of Electrical Conduit System

Electrical conduit plays a vital role in electrical infrastructure by providing a safe, organized, and durable pathway for electrical conductors. Whether the system is low voltage or high voltage, conduit serves as the primary line of defense against physical damage, environmental exposure, and electrical hazards.

1. Protection and Safety

기계적 보호

Conduit shields electrical conductors from external impacts, abrasion, vibration, and crushing forces. In high voltage systems, where failures can result in catastrophic arcs or power outages, conduit must have enhanced structural integrity

And for low voltage systems, such as data and control wiring, typically use PVC, ENT, or HDPE conduit that prioritizes flexibility, corrosion resistance, and ease of installation.

Environmental Protection

Conduit ensures that wiring remains safe from moisture, chemicals, UV radiation, and temperature extremes. For instance:

In outdoor or underground applications, HDPE and DB-rated PVC conduits are ideal for low voltage signal cabling.

High voltage feeders, especially in substations or utility corridors, require watertight, fire-resistant, and UV-rated conduits to maintain circuit integrity under extreme conditions.

Fire and Electrical Hazard Reduction

Conduit contains sparks, prevents arc flash propagation, and limits the spread of flame in case of electrical faults. High voltage conduits must often comply with flame propagation, smoke emission, and dielectric strength standards, while low voltage conduits may be designed to meet plenum rating, or Class 2/3 circuit containment requirements.

2. Electrical System Organization and Code Compliance

Conduit provides a structured method for routing, separating, and accessing different voltage levels safely. This is crucial for:

Avoiding cross-interference

especially between low voltage control/data systems and high voltage power circuits.

Enabling future upgrades or maintenance

By allowing easy pull-out and replacement of wires without demolishing walls or underground ducting.

Meeting code requirements

Such as National Electrical Code, Canadian Electrical Code, and IEC electrical installation requirements.

3. Grounding and EMI Shielding

For systems that demand electromagnetic compatibility, the conduit itself can act as a grounding path and EMI shield, especially in metal conduit types.

고전압 전선관 시스템

Particularly in industrial and utility settings, often use RMC or EMT to establish a robust equipment grounding path that protects personnel and sensitive components.

Low voltage conduit systems

Low voltage communication or control systems may incorporate EMT or LFMC conduit for EMI shielding when run near high power circuits or in electrically noisy environments.

Low Voltage Conduit: Applications and Best Practices

Low voltage conduit systems are the structural and protective backbone for a wide range of modern electrical applications. Despite operating at 50 volts or less, these systems are critical for data integrity, safety, and efficient building operations. Selecting and installing the correct conduit ensures both functional reliability and compliance with safety codes, especially as demand for smart technology, communications infrastructure, and automation continues to rise.

7 Common Low Voltage Conduit Applications

Low voltage wiring runs behind much of the technology used in residential, commercial, and industrial environments. Conduits in these systems protect delicate wiring and maintain signal quality.

Data Transmission Systems

Conduit is used to house Ethernet, fiber optic, and coaxial cables in LAN setups, server rooms, and telecom closets.

HDPE, ENT, and PVC communication conduit (such as DB and EB types) are commonly used for routing structured cabling safely, especially underground or in long horizontal runs.

Security and Access Control

Surveillance cameras, motion sensors, keypads, alarms, and door access systems rely on low voltage cables protected in conduit.

Flexible PVC, ENT, or EMT (for EMI shielding) is often chosen, depending on environmental exposure and building layout.

Communication Infrastructure

Systems such as intercoms, telephone wiring, and voice/data systems benefit from conduit use to prevent physical and EMI damage.

화재 경보 시스템

Class 1 and Class 2 fire alarm circuits, though low voltage, require robust protection to ensure life safety performance.

NEC requires proper conduit selection, especially in areas where mechanical damage or EMI interference is a concern.

Building Automation and Smart Systems

Includes wiring for HVAC control, lighting automation, energy management, and IoT systems.

Residential Uses

Common for doorbells, thermostats, garage door openers, home security, and landscape lighting (12V/24V).

Industrial Control Systems

In industrial settings, low voltage wiring enables sensors, PLC controls, machine monitoring, and safety interlocks. Conduits are vital for enhanced automation and safety in manufacturing and process control environments.

Best Practices for Low Voltage Conduit Installation

Proper installation is key to protecting low voltage cabling from damage and interference. Here are essential guidelines:

Conduit Selection Based on Environment

Indoor use: Flexible conduits (ENT, PVC) for ease of routing behind walls and in ceilings.

Outdoor or underground: Rigid PVC conduit for outdoor installations or DB/EB types and HDPE for underground wiring.

EMI-sensitive areas: Use metallic conduit like EMT or LFMC in EMI shielding is needed.

Plan for Future Capacity

Conduit should not be overfilled, allow room for future expansion.

NEC Chapter 9, Table 1, and Annex C specify conduit fill capacities based on wire type and size.

Separation from High Voltage Circuits

Electrical code requires separation between low and high voltage systems to prevent interference and ensure safety.

Use dedicated conduits or barriers where crossover is unavoidable.

Support and Spacing

Install conduit straps or clamps to keep runs secure. Follow applicable NEC article spacing rules.

Running Through Walls or Ceilings

Low voltage wiring can often be bundled and routed through cavities, but bundling should not exceed fill and heat limits.

Fire-rated penetrations must be sealed per NEC or local fire code.

High Voltage Conduit: Applications and Safety Tips

While low voltage conduit plays a critical role in supporting modern communication and automation systems, high voltage conduit systems are essential for power distribution, energy transmission, and the operation of heavy-duty industrial equipment. High voltage circuits carry significantly greater electrical potential, typically above 600 volts per NEC definitions, and in some contexts, starting at 1,000 volts, which demands a higher level of safety, mechanical strength, and environmental resistance in conduit design.

Selecting the correct conduit for high voltage applications is not just a matter of compliance, it’s about protecting life, equipment, and infrastructure from risks such as electric shock, arc flash, thermal degradation, and mechanical failure.

6 Common High Voltage Conduit Applications

High voltage conduit is integral in both utility-scale and industrial environments, where electrical loads are substantial, and failures can have serious consequences. Typical high voltage installations include:

Power Generation and Transmission

Conduit systems in utility-scale transmission and distribution networks protect high-voltage cables that transport electricity across long distances. These applications involve voltages ranging from 1 kV up to hundreds of kilovolts. Conduit helps manage conductor spacing, prevent physical contact, and provide mechanical protection.

Utility and Grid Infrastructure

Overhead-to-underground transitions, feeder lines, and riser poles often require rigid steel, HDPE, or specialized PVC conduit (e.g., EB- and DB-rated) for burial and weather resistance.

Often paired with concrete encasement and grounding conductors to meet codes requirements.

Industrial Power Systems

Heavy-duty machinery, arc furnaces, and large-scale motors typically require high voltage power delivered via conduit-rated cabling.

Critical Infrastructure

Airports, hospitals, data centers, and energy facilities often implement high voltage backup and distribution circuits with robust conduit systems.

Design must address redundancy, EMI shielding, and fire separation.

EV 충전소

EV infrastructure — especially Level 3 DC Fast Chargers — operates at 480V three-phase or higher. These systems require conduit capable of managing high current loads, thermal output, and outdoor environmental factors

Renewable Energy Installations

Utility-scale solar farms, wind power systems, and battery energy storage systems (BESS) routinely use high voltage conduit (600V–1500V DC typical).

7 Critical Safety Tips

Due to the elevated risks involved in high voltage systems, conduit design must prioritize personnel safety, equipment protection, and code compliance.

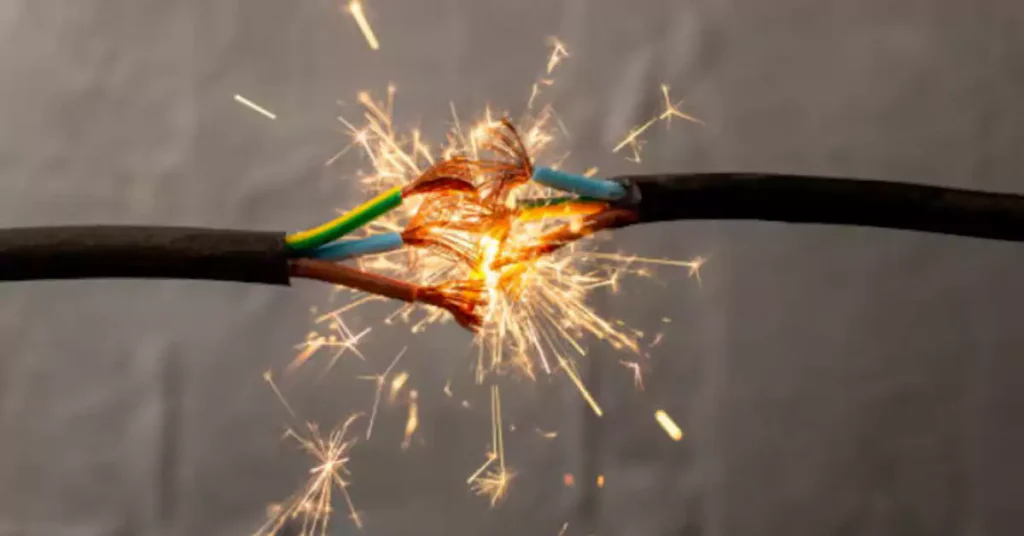

Arc Flash Mitigation

An arc flash, an explosive event caused by an unintended electrical discharge — can reach temperatures over 35,000°F, vaporize metal, and cause severe injury or death. Proper conduit systems mitigate this risk by:

Containing electrical faults (especially with metallic conduits).

Enabling grounding paths to quickly dissipate fault current.

Reducing arc flash incident energy when paired with switchgear, current-limiting breakers, and arc-resistant enclosures.

Heat Dissipation and Conduit Fill

High current loads can generate substantial heat. Improper conduit fill or tight bundling of cables may trap this heat, degrading insulation or reducing ampacity. Best practices include:

Avoiding overfilled or unventilated conduit runs.

Employing active cooling techniques (e.g., thermal backfill, forced-air or fluid cooling in underground high-voltage ducts).

Using materials with high thermal resistance, especially for enclosed or densely packed installations.

Robust Insulation and Grounding

High voltage requires insulation systems with excellent dielectric strength and tracking resistance. Rigid metallic conduits such as RMC and IMC inherently contribute to ground fault path integrity, whereas nonmetallic systems (like HDPE or PVC) must include dedicated grounding conductors inside the conduit.

Proper bonding and grounding to ensure fault currents are safely diverted, reducing risk of shock or fire.

Overcurrent Protection

Conduit systems must match the ratings and routing of cables used with overcurrent protection devices (fuses or breakers), ensuring that conductors do not overheat during faults.

Fire Resistance and Environmental Sealing

High voltage conduits in buildings must maintain fire barriers. Use firestop materials at penetrations.

Outdoor installations may require weatherproof fittings, sealed boxes, and temperature-rated conduits.

Spacing and Segregation

High voltage conduit must be physically separated from low voltage and communication systems to prevent inductive interference and crosstalk.

Adequate working clearances are required for installation and maintenance access.

Fire Resistance and Environmental Sealing

High voltage conduits in buildings must maintain fire barriers. Use firestop materials at penetrations.

Outdoor installations may require weatherproof fittings, sealed boxes, and temperature-rated conduits.

Codes Compliance of Low Voltage Conduit Installations

Low voltage systems, typically operating below 1000 volts, are widely used in control circuits, fire alarms, security systems, data communication, audio/video, and Class 2 and Class 3 power-limited systems. Although these circuits pose fewer shock hazards than higher-voltage systems, they still require compliance with national and regional electrical codes to ensure safe, efficient, and code-compliant installations.

This section introduces key code frameworks for low voltage conduit installations, including the National Electrical Code (NEC), and Canada’s CEC.

NEC Requirements for Low Voltage Conduit Installations

The NEC, published by the National Fire Protection Association (NFPA 70), provides comprehensive rules for all wiring methods, including conduit installations for low voltage systems. The two most relevant parts for low voltage conduits are:

- Chapter 3 – Wiring Methods and Materials

- Article 725 – Class 2 and Class 3 Power-Limited Circuits

- Chapter 8 – Communications systems

General Installation Requirements (Chapter 3)

Chapter 3 applies to all wiring methods, including low voltage and outlines general conduit installation requirements:

- Conductor Fill and Derating: Follow NEC Chapter 9, Table 1 to limit conduit fill (typically 40% max for three or more conductors) to prevent overheating, even at low voltage.

- 접지 및 본딩: NEC requires that metallic conduits (like EMT or RMC) be properly bonded to ensure a continuous path to ground. Even low-voltage circuits must follow these rules if installed in metallic conduit.

- Underground Installations & Burial Depth: NEC 300.5 specifies minimum burial depths:

All locations not specified: Minimum cover requirements for PVC conduit, DB conduit, and metallic tubing is 18 in.

Under a building: PVC conduit, DB conduit, and metallic tubing is 18 in.

Under streets and roads: PVC conduit, DB conduit, and metallic tubing is 24 in.

- Protection Against Corrosion and Deterioration: All conduit exposed to moisture or corrosive conditions must be properly coated or rated (e.g., PVC-coated FMC, corrosion-resistant PVC).

- 물리적 보호: Conduits must be protected from physical damage, this may require rigid conduit or protective plating near framing members.

- Support and Secure: Conduit must be securely fastened at required interval to avoid movement.

Class 2 and Class 3 Power-Limited Circuits (Article 725)

Class 2 and Class 3 circuits, as defined by the NEC, are power-limited circuits that operate at low voltage and current levels. These systems are commonly used in building automation, security, environmental controls, intercoms, and similar low-power applications. Their limited energy output reduces the risk of fire and electric shock, allowing for more flexible installation methods compared to traditional power circuits.

- Class 2 Circuits: These circuits operate at up to 30 volts with a power limit of 100 VA. Due to their inherent power limitations, Class 2 circuits are considered safe from both fire initiation and electric shock, allowing for more relaxed installation methods, such as running cables directly along structural elements without extensive conduit protection in many cases.

- Class 3 Circuits: Similar to Class 2 but permit slightly higher voltage and current levels, up to 150 volts. While considered safe from a fire initiation standpoint, they do not provide acceptable protection from electric shock, necessitating additional safeguards and more robust insulation.

Conduit Protection

Regarding conduit requirements for Class 2 and 3 circuits, in many cases, these cables can be run outside of conduit, provided they are adequately supported and protected. However, the NEC mandates conduit or raceway installation in environments where cables are susceptible to mechanical damage, such as in high-traffic areas or industrial sites.

Plenums Installations

For installations in plenums (air handling spaces), cables must possess a plenum rating to comply with stringent fire safety standards.

Outdoor or Damp Installations

Outdoor or damp locations require cables with moisture-resistant insulation and UV protection (if exposed to sunlight), often necessitating conduits or raceways for mechanical protection or secure attachment to building structures.

Conductor Separation

725.136 prohibits placing Class 2/3 conductors in the same cable, conduit, or enclosure as power conductors unless:

A barrier is present,

The conductors are in separate raceways, or

The circuits are part of the same associated system.

And power-limited circuits (Class 2 and Class 3) should be kept separate from higher-voltage circuits.

This prevents electromagnetic interference and unintended energization.

Raceway Sharing

Class 2 and Class 3 conductors may share a raceway only when insulation ratings match and cables are listed for shared use.

Mixing with communications conductors is permitted only in listed communications cables installed per Article 800.

Communications Systems (Chapter 8)

Chapter 8 of the NEC governs communications systems, including voice, data, video, broadband, and optical fiber networks. It covers the installation and electrical requirements for various communications systems, including those operating at low voltage.

Physical Protection

Communications cables must be protected from physical damage, especially in exposed, commercial, or industrial environments. NEC permits the use of raceways, such as:

Rigid PVC or EMT for mechanical protection

ENT for concealed indoor applications

LFMC or HDPE for outdoor or corrosive environments

Plenum and Air-Handling Spaces

When communications cables are installed in plenums, ducts, or air-handling spaces, they must:

Be plenum-rated (CMP, OFNP), or

Be installed in metallic or nonmetallic conduit

This requirement limits the spread of smoke and fire products in HVAC systems and aligns with broader fire safety standards seen in high voltage conduit design.

Separation from Power

Communications conductors must be physically separated from power and Class 1 circuits unless:

They are in a listed combination cable, or

Separated by a barrier, or

Routed in separate raceways

Using conduit is one of the most effective ways to meet this separation requirement, particularly in mixed-use cable pathways like ceiling voids or riser shafts.

Wet and Outdoor Locations

Where communication cables are installed in wet, damp, or outdoor environments:

Conduit is required to provide moisture and UV protection

NEC specifies use of listed cables or raceways suited for wet locations

Outdoor riser runs or underground raceways typically use PVC Schedule 40/80, LFMC, DB/EB or HDPE conduit

Fiber Optic Cabling

Fiber optic systems, although non-electrical, follow similar routing and protection principles. Conduits are used when:

Cables are exposed to potential crushing, chemicals, or vermin

Installations must comply with strict aesthetic or structural constraints, especially in data centers or medical facilities

Identification and Labeling

Though not as rigorous as high voltage systems, low voltage communication raceways may still require identification in shared spaces or junctions to avoid interference and ensure maintainability.

CEC Requirements for Low Voltage Installation

In Canada, the Canadian Electrical Code, Part I (CEC) is the governing standard for electrical installations, including those involving low voltage systems. While many low voltage circuits operate with less risk of shock or fire, the CEC still imposes detailed safety and installation requirements, especially when these circuits are routed through buildings or exposed to environmental hazards.

Three core sections of the CEC provide guidance for low voltage conduit installations:

- Section 12: General Wiring Methods

- Section 16: Class 1 and Class 2 Circuits

- Section 30: Installation of Lighting Equipment

Section 12 - General Requirements for Wiring Methods

Section 12 of the CEC sets out general rules for electrical wiring, including installation methods, conduit use, mechanical protection, spacing, and support for both high and low voltage systems. For low voltage installations, the following rules are especially relevant:

Protection of Wiring

All conductors and cables, including low voltage types, must be protected from mechanical damage.

Where exposed to possible damage or where required by the Authority Having Jurisdiction (AHJ), rigid conduit, EMT, PVC, or other raceways must be used.

This applies to exposed installations, vertical risers, or areas accessible to the public.

Conduit Use and Installation

Electrical raceways (e.g., rigid PVC, EMT, ENT) are acceptable for low voltage applications if:

Proper fittings are used

Bends conform to allowable radii (especially important for data/fiber systems)

ENT (Electrical Nonmetallic Tubing) is permitted for low voltage in non-combustible buildings where not subject to damage.

Underground Installations

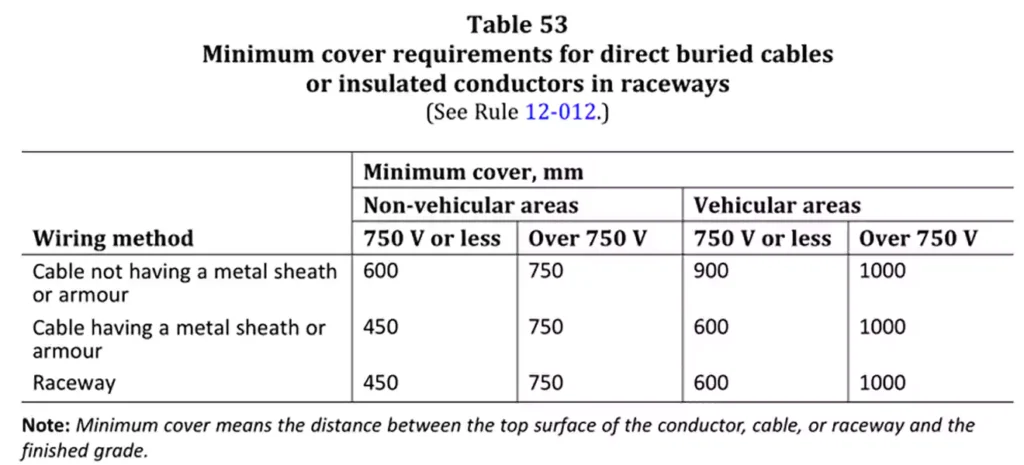

Direct buried low voltage cables or conduit systems must meet minimum burial depths from Table 53.

Depth can be reduced if mechanical protection (e.g., treated planking, concrete slabs, or encasement) is provided.

When low voltage circuits (e.g., for outdoor lighting or controls) rise above grade, they must be enclosed in rigid conduit for at least 2 meters above ground and securely protected at the transition point.

Entry into Buildings

All low voltage conduits or raceways entering building envelopes (roofs or walls) must be sealed to prevent moisture ingress.

This is especially critical for telecom, control, and lighting circuits routed into basements or attics.

Wiring Under Raised Floors

Applies to low voltage data and IT equipment (e.g., PoE, Ethernet, UPS control circuits).

Low voltage cables may run freely under raised floors if:

The floor is non-combustible and grounded.

The cord length ≤ 4.5 m.

The cables are listed in CEC Table 11 and terminated in appropriate junction boxes or connectors.

Branch circuits under the floor must use metallic raceways or armored cables.

Spacing and Support Requirements

Conduits must be securely supported at intervals

Low voltage conduits still need to follow rules for securing, spacing from thermal sources, and entry into enclosures to maintain integrity.

Separation

Lightning down conductors: Low voltage conduit installations must maintain at least 2 meters separation from lightning grounding unless bonded.

Section 16 – Class 1 and Class 2 Circuits

Section 16 of the Canadian Electrical Code (CEC) governs the installation requirements for low voltage (LV) and extra low voltage (ELV) electrical systems, which include Class 2 power and data communication circuits. These circuits are widely used in modern electrical applications such as telecommunications, fire alarm systems, HVAC controls, security systems, and building automation, where safety and precise control of power and signal levels are paramount.

Class 1 Circuits

Class 1 Circuits refer to wiring systems that operate at voltages up to 600 V and typically include power, control, and lighting circuits that require conventional electrical protection and installation practices. These circuits are usually part of the building’s main electrical distribution and carry higher energy levels.

For Class 1 extra-low-voltage power circuits, the power source must have a rated output not exceeding 30 V and 1000 volt-amperes (V•A).

Class 2 circuits

Class 2 circuits are extra-low-voltage circuits designed to limit current and power to very safe levels, reducing risks of electric shock and fire.

They have strict limits on both voltage and current based on the open-circuit voltage:

From 0 to 20 volts, current is limited to a maximum of 5 amperes (with some exceptions);

From over 20 to 30 volts, current limits are set based on a formula: the overcurrent protection rating must not exceed 100 V•A divided by the open-circuit voltage;

From over 30 to 60 volts, the same formula applies;

From over 60 to 150 volts, overcurrent protection is limited similarly, and additional current-limiting devices are required.

Class 2 circuits are often used for control circuits, signal wiring, and applications where very low power is needed to minimize hazard.

This section provides essential regulations to ensure the safe and reliable installation of low and extra low voltage wiring, addressing critical aspects such as:

- Overcurrent protection specifically designed for Class 2 circuits, ensuring that protection devices are correctly rated and properly located to prevent electrical hazards.

- Proper conductor selection and cable usage, including minimum conductor sizes, types of acceptable cables such as equipment wire and ELC cables, and conditions for their use depending on voltage levels and environmental factors.

- Separation and segregation of Class 2 circuits from other electrical circuits (lighting, power, Class 1 circuits) to reduce interference and enhance safety, with detailed requirements on minimum separation distances and acceptable barriers like metal raceways or armored cables.

- Installation methods for Class 2 conductors in various environments, including restrictions on placing such conductors in ducts or plenums, and special provisions for vertical shafts, fire separations, and underground installations to limit fire spread and ensure mechanical protection.

- Power and data communication circuit specifics, including limitations on power sourcing equipment output (maximum 100 VA and 60 V DC), ampacity and bundling requirements for cables, and strict guidelines on conductor connection and marking to maintain system integrity and compliance.

Section 30 – Wiring of Lighting Equipment

Section 30 of the electrical code outlines the requirements for the safe wiring, installation, and operation of luminaires (lighting fixtures), including standard, discharge, and extra-low-voltage systems. This section ensures the safety, durability, and compliance of lighting systems in residential, commercial, and industrial settings.

1. Low Voltage Lighting Systems (≤1000 V)

For electric-discharge lighting systems and other low voltage luminaires, the CEC outlines several essential safety and performance requirements:

Prohibited Equipment

Oil-filled transformers are not permitted in low-voltage discharge lighting systems due to fire and environmental hazards.

Use of DC Equipment

Luminaires must not be connected to direct current (DC) systems unless specifically designed, equipped, and marked for DC operation, including necessary resistors or auxiliary equipment.

High Voltage Protection in Dwellings

Luminaires or associated equipment with open-circuit voltages exceeding 300 V must not be installed in dwelling units unless fully enclosed and designed to prevent exposure to live parts during lamp insertion or removal.

Lighting Control Requirements

Lighting installations operating at ≤1000 V must be controlled by appropriate switches, circuit breakers, or contactors with:

A current rating ≥200% of the load.

Proper markings such as “SWD” for circuit breakers used in fluorescent applications.

Branch Circuit Capacity

When lighting branch circuits supply luminaires with ballasts or transformers, the circuit load must be calculated based on total amperage, not just lamp wattage. Additionally, connected luminaires must not exceed 80% of the branch circuit’s overcurrent protection rating.

2. Extra-Low Voltage Lighting Systems

Rules 30-1200 to 30-1208 specifically govern the installation of extra-low voltage (ELV) lighting systems, typically operating below 30 V AC or 60 V DC. These systems are commonly used for landscape lighting, undercabinet lighting, and decorative cable lighting.

Key requirements include:

Isolated Power Supply:

ELV systems must be powered from branch circuits rated ≤150 V-to-ground, with an isolating transformer that provides no direct electrical connection between primary and secondary. The ELV portion must remain ungrounded.

Landscape Lighting Installations:

Flexible cords are permitted on the secondary side of the transformer.

Unenclosed electrical connections are allowed where not exposed to mechanical damage.

Conductor routing through structural elements like holes is permitted.

Cable Lighting Systems:

Dry locations only; not permitted in bathrooms or wet areas.

Cables must be rigidly supported and must not come in contact with combustible materials.

Installation through walls, ceilings, floors, or partitions is prohibited.

Bare conductors must be installed at least 2.2 m above the floor for safety.

Cabinet and Undercabinet Lighting:

Similar to landscape lighting, flexible cords may be used and secured within cabinet structures. Electrical connections without enclosures are permitted where not mechanically vulnerable.

These rules address common ELV installation environments, focusing on mechanical protection, safe clearances, and transformer isolation, while providing design flexibility for architectural and specialty lighting applications.

Codes Compliance of High Voltage Conduit Systems

High voltage electrical systems, typically defined as those operating above 1000V AC or 1500V DC, require specialized design, materials, and installation practices to ensure safe operation under increased electrical stress. Conduit systems in high voltage environments must meet strict standards for insulation, mechanical strength, separation from low voltage circuits, and accessibility for maintenance.

NEC (National Electrical Code – USA):

Article 300 – General Wiring Methods:

Applies to all wiring installations, including spacing, protection, and mechanical integrity of conduits.

Article 305 – High Voltage Systems (>1000V AC / 1500V DC):

Covers requirements for overcurrent protection, circuit separation, insulation coordination, and mechanical protection for conduits in high voltage systems.

CEC (Canadian Electrical Code – Canada):

Section 36 – High Voltage Installations:

Specifically addresses installations above 750V. It includes provisions for conduit materials, grounding, conductor spacing, enclosures, mechanical protection, and high voltage signage.

AS/NZS 3000 (Australia/New Zealand Wiring Rules):

Clause 7.8 – High Voltage Electrical Installations:

Refers to systems above 1000V AC, requiring compliance with AS 2067. Covers conduit routing, mechanical protection, separation from low voltage systems, earthing, and access requirements.

Common Requirements Across Standards:

- Use of non-conductive or metallic conduit with proper insulation properties.

- Minimum burial depths or concrete encasement for underground conduit.

- Physical separation from low voltage and communication circuits.

- Robust mechanical protection to withstand thermal expansion, fault currents, and environmental stress.

- Grounding and bonding to reduce step and touch voltage risks.

These codes help ensure that high voltage conduit systems maintain safety, reduce the risk of electrical failure, and comply with regional regulations.

If you want to learn about Codes and standards requirements for High Voltage Conduit Systems, please check on our article on High Voltage Conduit Expert Insights.

Codes List of LV and HV Conduit Systems

Codes | Low Voltage Systems | High Voltage Systems |

국립전기기술원 | Article 300: General Wiring Methods Article 725: Class 2 and Class 3 Power-Limited Circuits Chapter 8: Communications Systems | Article 300: General Wiring Methods Article 305: General Requirements for Systems Rated Over 1000 Volts AC, 1500 Volts DC |

CEC | Section 12: General Requirements for Wiring Methods Section 16 – Class 1 and Class 2 Circuits Section 30 – Wiring of Lighting Equipment | Section 36: High Voltage Installations

|

AS/NZS 3000 | Clause 7.7: Extra-low Voltage Electrical Installations | Clause 7.8: High Voltage Electrical Installations

|

Risks to Run Low and High Circuits in the Same Conduit

Running low voltage and low voltage circuits in the same conduit can sometimes be permissible, but not always safe or code-compliant, depending on the type of circuits, their insulation ratings, and function. If improperly done, it can lead to several risks:

When is it allowed?

If all low-voltage conductors have compatible insulation ratings, and are part of the same system or functionally related systems, NEC/CEC may allow them in the same raceway.

Risks of running unrelated voltage circuits together

1. Signal Interference (EMI/Noise Coupling)

Communication cables (e.g., Ethernet, audio, fire alarm) are highly sensitive.

Running them alongside switching power circuits or dimmer control wires can introduce induced noise, causing data loss, static, or false triggering.

2. Troubleshooting Difficulty

Sharing a conduit can make it harder to isolate faults or perform repairs.

One malfunctioning circuit could affect others physically or during maintenance.

3. Voltage Drop & Overheating

If multiple circuits share a raceway and aren’t properly derated, heat buildup could occur.

Even low-voltage circuits, if run in excess without derating, may exceed allowable ampacity limits.

4. Code Violations

The NEC prohibits mixing circuits of different classes or purposes unless:

All wires are rated for the maximum voltage present.

They are functionally related.

For example, Class 2 circuits cannot be mixed with power-limited fire alarm circuits in most cases.

5. Cross-Talk or Functional Disruption

In systems like security, BAS, or AV, control signals may be distorted by proximity to power pulses from other low-voltage circuits like lighting.

Choosing the Right Conduit for Low and High Voltage Installations

Selecting the appropriate conduit is a foundational decision in any electrical system design, whether low or high voltage. It influences not only the safety and regulatory compliance of the installation, but also its durability, efficiency, and cost-effectiveness over the long term. The choice must be based on a thorough assessment of environmental factors, voltage classification, mechanical and chemical stresses, and the unique needs of the application.

7 Tips to Choose Right Conduit for Installation

1. 설치 환경

Whether the system is installed indoors or outdoors, in wet or dry locations, or in hazardous or corrosive atmospheres, the conduit must withstand site-specific conditions. For instance:

- Outdoor or underground use may require UV-resistant and watertight conduits (e.g., HDPE, Schedule 80 PVC, or LFMC).

- Chemical-prone areas, such as water treatment or petrochemical plants, may benefit from fiberglass or PVC-coated metal conduits.

2. Voltage Level and Protection Needs

Low-voltage systems often use PVC, ENT, EMT, or flexible conduits.

High-voltage installations demand more robust options such as RMC, IMC, or fiberglass RTRC to handle electrical stress, fault current containment, and thermal insulation.

3. Mechanical and Environmental Protection

Conduits must be matched to the mechanical threats they may encounter—impact, vibration, crushing, or environmental risks such as fire, moisture ingress, or UV degradation. For example:

Use RMC in exposed industrial areas where impact resistance is critical.

Fiberglass RTRC offers burn-through resistance and is ideal where cable fault tolerance is a design priority.

4. Flexibility vs. Rigidity

Use rigid conduits (PVC, EMT, RMC) in long, straight runs for optimal protection.

Choose flexible options (FMC, LFMC, corrugated PVC) when dealing with tight bends, vibration, or temporary installations.

5. Thermal Performance and Heat Dissipation

High-current cables generate heat. Conduit systems must accommodate these thermal loads, especially in high-voltage environments. Metal conduits tend to dissipate heat more effectively, but ventilated designs or special coatings on nonmetallic options may also help in managing internal temperatures.

6. EMI/RFI Shielding

Where data transmission or signal integrity is critical, such as in hospitals, industrial automation, or data centers, use metallic conduits or braided shielded types to mitigate electromagnetic interference.

7. Regulatory and Project-Specific Requirements

Make sure the conduit comply with local standards, such as UL and CSA standards. And installation meet the codes’ requirements for high and low voltage systems.

9 Common Conduit Types Application Summary

도관 유형 | 재료 | Key Advantages | Primary Limitations | Typical Low Voltage Use Cases | Typical High Voltage Use Cases |

PVC Schedule 40 / 80 | Rigid Polyvinyl Chloride | Lightweight, corrosion-resistant, easy to install, suitable for wet/damp areas | Brittle in cold, UV-sensitive unless rated, lower temperature resistance | Outdoor lighting, communication, control wiring, residential and commercial runs | Underground feeders, EV charging stations, exposed industrial circuits |

응급구조사 | Steel / Aluminum | Lightweight, low-cost, good mechanical and EMI protection, easy to bend | Not for high-impact or severe environments, limited corrosion resistance | Commercial lighting, interior wiring, data cables | Occasionally used for HV indoors |

아이엠씨 | 아연 도금 강철 | Stronger than EMT, lighter than RMC, outdoor rated | Heavier than EMT, more costly | Industrial controls, outdoor commercial use | Outdoor feeders, mechanical rooms, limited industrial HV use |

RMC | Galvanized Steel or Aluminum | Maximum impact protection, suitable for hazardous or wet locations | Expensive, labor-intensive to install | Rarely used for LV unless in extreme condition | Power distribution, substations, hazardous facilities |

FMC / LFMC | Steel with/without PVC Jacket | Flexible, ideal for vibration and movement; LFMC is water- and corrosion-resistant | Limited mechanical protection (FMC), higher cost (LFMC) | Equipment connections, HVAC, lighting fixtures | Motor connections, rooftop units, exposed mechanical HV runs |

이비인후과 | 유연한 PVC | Lightweight, fast to install, good for embedding in walls or slabs | Not UV-rated, low impact protection, indoor only | Residential/commercial lighting and low-voltage control | Occasionally used for HV |

고밀도 폴리에틸렌(HDPE) | High-Density Polyethylene | Excellent chemical resistance, flexible, long continuous lengths | Generally unsuitable for exposed runs or high-heat conditions | Telecom, fiber optics, direct-burial LV wiring | Medium & high voltage underground utilities, wind farms |

RTRC (Fiberglass Conduit) | Reinforced Thermoset Resin | Fire and corrosion resistance, low thermal conductivity, high fault tolerance | More expensive, less available | Industrial data systems, corrosive indoor environments | Utilities, data centers, petrochemical HV systems |

Ledes Conduit Solutions

Ledes offers a complete portfolio of PVC conduit systems engineered to meet the demands of both low voltage and high voltage electrical installations. From residential wiring and commercial data networks to infrastructure-grade power distribution and utility-scale energy systems, Ledes conduits are built to provide mechanical protection, dielectric strength, UV resistance, and long-term durability across various environments.

Whether your project involves indoor concealed cabling, underground utility ducting, or exposed outdoor wiring, Ledes provides standardized solutions that listed by UL, CSA, IEC, and AS/NZS requirements for electrical conduit performance.

Ledes Conduit Portfolio

Schedule 40/80 PVC Conduit

Manufactured to meet UL651 and CSA C22.2 No.211.2 standards, Ledes Schedule 40/80 rigid PVC conduit is ideal for high voltage installations and also low voltage power and communication wiring. It offers excellent corrosion resistance, non-conductivity, and is approved for both aboveground and underground applications, including direct burial and concrete encasement.

ENT (Electrical Nonmetallic Tubing)

Lightweight and flexible, Ledes ENT conduit is UL-listed to UL1653 and CSA certified to CSA C22.2 No.227.1, and engineered for easy installation in walls, floors, and ceilings. It is optimized for both high and low voltage wiring in commercial and residential buildings, especially where tight bends or complex routing are needed without the use of heat bending tools.

DB2 PVC Duct

Designed for use in Canadian underground cable systems, typically low voltage systems. Ledes DB2 덕트 features thinner walls compared to rigid Schedule 40 conduit while maintaining high impact resistance. It is CSA-certified to CSA C22.2 No.211.2 and widely used in utility, telecom, and municipal projects.

AS/NZS Medium and Heavy Duty Rigid Conduit

These 강성 PVC 도관 meet the performance requirements of AS/NZS 2053.2 and are suitable for both low and high voltage systems. With superior UV and impact resistance, they are ideal for exposed, underground, and industrial applications.

AS/NZS Medium and Heavy Duty Corrugated Conduit

For installations requiring flexibility, Ledes corrugated conduits (AS/NZS 2053.5) offer medium and heavy-duty ratings. They are widely used in solar, infrastructure, and equipment wiring, suitable for both low and high voltage insulation where allowed by local codes.

결론

The distinction between low voltage and high voltage conduit applications is not merely a technical detail, it is a fundamental factor shaping the safety, performance, and longevity of electrical systems. Throughout this article, we’ve examined how voltage classification directly influences conduit selection, design strategies, regulatory requirements, and system protection goals.

Low voltage systems, while often perceived as lower-risk, still require careful planning and strict compliance with codes such as CEC or NE. These systems are especially sensitive to issues like signal interference, insulation degradation, and fire hazards if improperly installed. Appropriate conduit solutions, such as ENT, PVC, or EMT must be chosen not only for mechanical protection but also for their suitability to low-voltage communication or control environments.

High voltage systems, on the other hand, involve far more severe electrical stresses and hazards. These applications demand conduits with enhanced physical durability, fire and arc-flash resistance, grounding performance, and thermal stability often achieved through materials like RMC, IMC, RTRC (fiberglass), or HDPE. These systems must strictly conform to standards outlined in CEC, NEC, and other voltage-specific requirements.

For electrical professionals, designers, and conduit manufacturers, recognizing these distinctions is essential, not only for technical compliance but also for delivering value in evolving applications such as EV infrastructure, smart buildings, renewable energy systems, and data centers. By sharing clear, well-informed guidance, manufacturers and marketers can support safer, more efficient, and more future-proof installations.

Choosing the right conduit is more than a material decision, it’s a strategic investment in the safety, continuity, and long-term resilience of modern electrical infrastructure.

자주 묻는 질문

What voltage ranges qualify as “low voltage” and ”high voltage” in conduit applications?

In general:

- Low voltage refers to systems operating at ≤600V or ≤1,000V.

- High voltage typically applies to systems >1,000V, extending up to 35kV for medium voltage and beyond in utility-scale transmission.

Specific thresholds vary by code and jurisdiction.

Can I run high-voltage cables through standard conduit rated for low voltage?

No. Standard conduit rated for low voltage may not provide adequate dielectric strength, heat resistance, or mechanical protection for high-voltage applications. UL listings, flame ratings, and material thickness must match the system voltage. For high-voltage installations, use conduits specifically designed and rated for those voltages, such as Schedule 80 PVC, HDPE, RTRC, or RMC.

What grounding and bonding practices are required for high-voltage conduit that differ from low-voltage systems?

High-voltage systems demand:

More stringent grounding paths to ensure fault current is safely dissipated.

Bonding of all metallic components, including enclosures and raceways.

Grounding conductors sized per fault-current levels and voltage class.

Equipotential bonding and sometimes ground grids (e.g., substations).

In contrast, low-voltage systems may allow for simpler equipment grounding but still must comply with NEC/CEC grounding rules to ensure safety and system performance.

What is the fundamental difference between low voltage and high voltage?

The primary difference lies in:

Voltage magnitude, impacting insulation needs, arc flash risk, and conductor spacing.

System design complexity: high-voltage systems require more robust components and safety clearances.

Hazard levels: high voltage can cause severe injury or death without proper mitigation, whereas low voltage poses lower risks but still demands safe practices.

Does low voltage wiring always need to be in conduit?

Not always. NEC and CEC allow certain types of Class 2/Class 3 low-voltage wiring to run without conduit in specific locations. However, conduit is often used for:

Physical protection

EMI shielding

Aesthetic or organizational purposes

Local codes or project specs may also require conduit in plenum spaces or for fire-rated assemblies.

저전압 전선과 고전압 전선을 같은 전선관에 넣어서 사용할 수 있나요?

Generally no, unless specific conditions are met. According to NEC and CEC, conductors of different voltage classes may only share a raceway if:

All conductors have insulation rated for the highest system voltage present.

They belong to systems that do not interfere with each other (e.g., control and power circuits must be isolated).

It’s best practice to separate high and low voltage to avoid EMI issues and improve safety.

What are the recommended conduit types for low voltage applications?

PVC: Affordable, corrosion-resistant, great for outdoor and underground.

응급구조사: Lightweight, easy to install, suitable for indoor dry locations.

이비인후과: Flexible and fast-install for communications/data in walls and ceilings.

LFNC: Ideal for damp locations or short runs to moving parts.

FMC: For vibration-prone equipment and tight bends indoors.

What are the recommended conduit types for high voltage applications?

RMC/IMC: Excellent mechanical and grounding performance; ideal for critical industrial environments.

RTRC (Fiberglass): Corrosion-resistant, fire-resistant, and ideal for high-fault-risk or harsh outdoor settings.

HDPE: Best for underground utility runs and long pulls.

PVC Schedule 80: Suitable for underground or corrosive environments when high fault current is not a concern.

Why is proper grounding and bonding important for conduit systems?

Proper grounding and bonding:

Ensures safe dissipation of fault current

Prevents shock hazards and voltage differences between conductive parts

Supports circuit breaker/fuse operation by creating low-resistance fault paths

Reduces EMI and protects sensitive electronics

It is especially critical in high-voltage systems, where improper bonding can result in catastrophic equipment failure or arc flash incidents.

What are the risks associated with high-voltage systems and how does conduit help mitigate them?

High voltage poses severe risks:

Electric shock

Severe arc flash burns

Arc blast pressure injuries

Equipment destruction from faults

Conduit mitigates these risks by:

Containing arc energy

Maintaining separation distances

Enabling proper grounding

Providing fire-rated physical barriers.