목차

1. 서론

When planning an EV charger installation, it’s easy to focus on the charger itself — its power output, brand, or smart features. But behind every successful installation lies an essential yet often overlooked element: the conduit system.

A conduit is a protective pathway that houses electrical wiring, shielding it from physical damage, moisture, and other environmental factors. In EV charging systems, conduits play a crucial role in ensuring that electrical connections remain safe, reliable, and code-compliant throughout the system’s lifespan.

Conduit use isn’t just about protection — it’s also about organization and safety. By routing wires through a defined path, conduits reduce the risk of accidental contact, improve accessibility for maintenance, and help installations meet the National Electrical Code (NEC) or Canadian Electrical Code (CEC) standards. For residential garages, parking lots, or commercial charging hubs, choosing the right conduit layout can make the difference between a clean, professional setup and a cluttered, unsafe one.

Importantly, how the conduit is installed — whether hidden within walls or exposed on surfaces — affects not only aesthetics but also cost, flexibility, and maintenance. Understanding these differences is the foundation for making informed design choices in your EV charger project.

By reading this post, whether you are a homeowner, a facility manager, or an EV charger installer, you will learn:

- The differences between hidden and exposed conduit systems in EV charger installations.

- How each option affects installation complexity, appearance, and maintenance.

- The advantages and limitations of both conduit types in real-world residential and commercial scenarios.

- Practical guidance to help you choose the most suitable conduit layout for your EV charging setup.

2. Hidden Conduit for EV Chargers: A Clean and Protected Installation

When it comes to installing an EV charger, many homeowners and developers prefer a clean, seamless look — one where cables are invisible and the wall remains visually uncluttered. This is where hidden conduit installation, also known as concealed wiring, plays its role. In this setup, the electrical conduit is routed inside walls, ceilings, or underground, keeping it completely out of sight.

What Hidden Conduit Actually Means

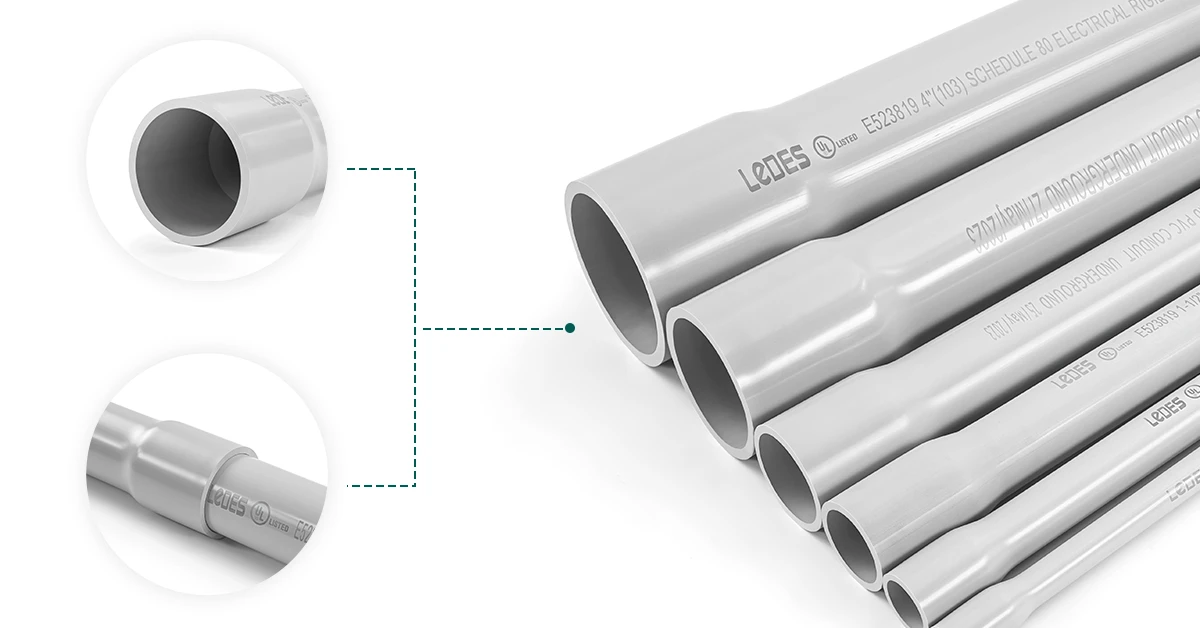

Hidden conduit refers to the installation method where PVC or EMT conduit is embedded within concrete, drywall, or underground pathways before the final finishing of the structure.

In residential settings, this often means the conduit runs behind the garage wall or through the slab before the wallboard is installed. In commercial sites or public charging stations, it can be routed beneath the pavement or inside columns for a neat architectural finish.

Because the conduit is not accessible after installation, every bend, junction box, and connection must be planned and fixed in advance. The system becomes part of the building’s infrastructure — durable and permanent, but not easily altered.

Advantages of Hidden Conduit in EV Charger Installations

Superior Aesthetic Appeal

Hidden conduit installations are visually unobtrusive, maintaining a clean and high-end appearance. For new residential garages or retail parking structures, the absence of visible conduit enhances both property value and visual harmony, especially when EV chargers are integrated into architectural design.

Enhanced Protection from Damage and Weather

Since the conduit is shielded behind walls or beneath surfaces, it’s less exposed to physical impact, UV light, or moisture. This makes it ideal for long-term reliability in harsh environments or outdoor setups where weather resistance is essential.

Improved Safety and Longevity

Concealed systems minimize the risk of accidental damage or tampering — an important consideration for public-access charging areas. Properly installed buried conduit also reduces the likelihood of corrosion or mechanical wear, extending the lifespan of the installation.

Better Cable Management and Structural Integration

Hidden conduit allows cables to be routed logically through building frameworks. This not only helps maintain code compliance but also simplifies grounding and bonding when planned correctly during the construction phase.

Challenges and Considerations

While hidden conduit offers clear advantages, it also comes with significant planning and cost implications.

Installation Cost and Labor: Because the conduit must be embedded before surfaces are finished, labor and material costs are higher. Retrofitting hidden conduit into existing buildings often requires wall demolition or concrete trenching.

제한된 접근성: Once walls are sealed, maintenance or upgrades (e.g., moving to a higher charger amperage or adding new outlets) become complex and costly.

Precise Planning Required: Electricians must predefine conduit routes, junction points, and box placements before construction begins. Any oversight could delay project schedules or require reconstruction.

When Hidden Conduit Makes the Most Sense

Hidden conduit is most suitable when:

The EV charger is part of a new home or commercial build, allowing conduit routes to be embedded from the start.

The appearance of the installation is a design priority — such as premium residential garages, corporate facilities, or showrooms.

The installation is permanent and expected to remain unchanged for many years.

The site is exposed to harsh conditions (e.g., direct sunlight, public access) and needs extra protection against wear or vandalism.

3. Exposed Conduit for EV Chargers: Practical and Flexible Installation

While hidden conduit installations deliver a sleek, integrated finish, not every project has the budget, timeline, or structure to make that possible. In many retrofit or commercial settings, exposed conduit installation becomes the more practical and adaptable option. In this method, the conduit runs visibly along walls or ceilings, securely fastened with straps, clamps, or mounting brackets, and typically connects directly to a surface-mounted junction box or charger enclosure.

What Exposed Conduit Installation Involves

Exposed conduit, sometimes referred to as surface-mounted wiring, is installed on top of existing walls or structures, without embedding it into concrete or drywall. It is common in retrofit EV charger projects, older buildings, or parking areas where running conduit through the wall is impractical or not permitted by building constraints.

For example, in a residential retrofit, the electrician may route PVC Schedule 80 or 40 or IMT/RMC conduit along the garage wall to connect the power source to the EV charger. In commercial applications, such as parking decks or warehouse facilities, RMC or IMC conduit might be chosen for its strength and resistance to impact.

Advantages of Exposed Conduit

Easy Installation and Accessibility

Exposed conduit is much faster to install, as it doesn’t require cutting into walls or pouring new concrete. Electricians can measure, bend, and secure conduit directly onto the surface, significantly reducing labor time.

Accessibility is another major benefit — any future maintenance, upgrades, or repairs can be carried out without structural work.

Lower Cost and Faster Project Turnaround

Because exposed systems require fewer construction steps, overall project costs are lower. For homeowners adding an EV charger post-construction, or contractors outfitting a fleet parking lot, exposed conduit can make installation financially viable while still meeting safety codes.

Flexibility for Upgrades and Expansion

As EV charging technology evolves, flexibility becomes essential. Exposed conduit allows contractors to add new circuits or reroute power lines easily — ideal for growing commercial sites or shared charging facilities.

Durable and Code-Compliant Options

Exposed conduit doesn’t mean unprotected. PVC, EMT, and metal conduit types can all be used in exposed setups, provided they meet local codes for mechanical protection, grounding, and UV resistance.

For outdoor applications, PVC Schedule 80 is often preferred due to its corrosion resistance and UL 651 compliance, while metal conduit types are used when higher mechanical protection or grounding continuity is required.

Challenges and Limitations

Despite its practicality, exposed conduit systems also have drawbacks that need to be weighed carefully:

Aesthetic Considerations: Visible conduit runs may not fit with modern interior design or luxury garage aesthetics.

Potential for Damage: Being exposed means greater risk from accidental impact, corrosion, or vandalism, especially in public or high-traffic areas.

Environmental Exposure: Outdoor runs must be properly sealed and supported to prevent water ingress, UV degradation, and thermal expansion issues.

Where Exposed Conduit Works Best

Exposed conduit installations are ideal when:

The EV charger is added after construction, such as in existing homes, parking lots, or garages.

Budget and time constraints are major considerations.

The site environment allows visible conduit routing without affecting safety or usability.

Future scalability — adding more chargers or higher load capacity — is a likely scenario.

4. Hidden vs. Exposed Conduit: How to Choose the Right Option for Your EV Charger

Now that you understand what each conduit type involves, the next step is deciding which installation method fits your EV project best.

Both hidden and exposed conduits are fully compliant with electrical codes and can deliver reliable performance when installed properly.

Let’s break down the most important factors that determine your choice.

Project Type and Construction Stage

The first and often most decisive factor is whether your EV charger is being installed during new construction or as part of a retrofit project.

For new construction, hidden conduit is the clear winner. Since walls and floors are still open, conduit can be embedded easily during rough-in, creating a clean and permanent result. Developers and architects often specify concealed conduit for aesthetic consistency and future-proofing.

For retrofit or existing buildings, exposed conduit is almost always more practical. It avoids wall demolition and enables fast installation without disrupting finished spaces. For home garages, commercial parking structures, or fleet retrofits, surface-mounted conduit saves both time and cost.

Budget and Labor Considerations

Financial factors play a major role — conduit choice directly affects total installation cost.

Hidden conduit generally comes with higher labor costs, longer installation times, and potentially more materials (junction boxes, concrete cutting, patching). It is best suited for long-term, permanent setups where aesthetics justify the expense.

Exposed conduit, on the other hand, is more cost-effective and flexible, particularly for short lead times or phased installations. Materials are similar, but less manpower and construction coordination are needed. In short: hidden conduit is a design investment; exposed conduit is an operationally efficient solution.

Aesthetic and Functional Priorities

If your EV charger is installed in a visible or premium location, aesthetics might outweigh convenience. For residential garages, hotels, or retail facilities, hidden conduit keeps walls visually clean and aligns with modern design expectations.

In industrial or parking structures, functionality and durability matter more than appearance — here, visible conduit runs are acceptable and even expected. Put simply, choose hidden conduit when design matters, and exposed conduit when efficiency matters.

Environmental and Safety Conditions

Environmental exposure can also guide your decision.

For outdoor or high-impact areas, exposed conduit (PVC Schedule 80 or metal types) can handle mechanical stress and weather better when properly supported.

Indoor or protected locations benefit from hidden conduit, which is safer from tampering, vandalism, and environmental degradation. Both systems can meet NEC (National Electrical Code) standards when installed correctly — the difference is in how they protect the wiring under real-world conditions.

Maintenance, Upgrade, and Scalability

If you foresee future upgrades — for example, switching from a 40A charger to an 80A charger or adding more charging points — exposed conduit offers a clear advantage.

You can easily reroute cables, add junctions, or expand capacity. Hidden conduit, while durable, requires structural work for any modification, making it less flexible in evolving systems.

Local Codes and Inspection Requirements

Some jurisdictions have specific conduit requirements based on seismic safety, fire rating, or accessibility. Always consult a licensed electrician or local authority having jurisdiction (AHJ) before finalizing your design.

In most North American contexts, both hidden and exposed conduit types are allowed — as long as they use UL Listed materials (e.g., UL 651 PVC conduit) and are installed per NEC standards.

전문가 팁: 더 자세히 알고 싶으신가요? expert tips & code details to choose the electrical conduit for an EV charging station? Click the above link to read our last post.

5. Professional Tips for a Safe and Code-Compliant EV Charger Conduit Installation

Choosing between hidden and exposed conduit is only part of the equation — proper installation practices determine whether your EV charger system performs safely and reliably for years to come.

Use Code-Compliant Materials

The foundation of any safe EV charging setup starts with certified conduit and fittings.

For nonmetallic conduit, look for products like marked UL 651 — covering Schedule 40 and Schedule 80 PVC rigid conduit.

을 위한 ENT or flexible nonmetallic options, ensure they meet UL 1653 if used indoors or in protected concrete walls.

For metallic conduit, UL 1242 (IMT) or UL 6 (RMC) listings are essential.

Using compliant products not only guarantees mechanical and fire safety but also simplifies the AHJ inspection process, helping your installation pass on the first try.

참고사항: Know more about the 4 international standards & codes for EV charging stations here.

Match the Conduit Type to the Environment

Environmental factors — moisture, UV exposure, and mechanical stress — directly affect conduit performance.

For outdoor installations, PVC Schedule 80 offers superior UV resistance and impact strength. Protect all terminations with liquid-tight fittings and seal entries with appropriate gaskets or bushings to prevent moisture ingress.

Indoor or protected spaces often only require Schedule 40 PVC or RMC, provided runs are not exposed to heavy mechanical impact.

For underground runs, choose PVC conduit that can be buried like or Schedule 40/80 and warning tape to comply with NEC 300.5.

Plan Conduit Routes Before Installation

Efficient conduit routing reduces material waste and installation complexity.

Keep runs as straight and short as possible to minimize voltage drop and simplify cable pulling. Limit the number of 90-degree bends — NEC allows up to 360° between pull points, but fewer bends make maintenance easier.

In hidden systems, pre-mark all junction boxes and bends before pouring concrete or finishing walls, as rework becomes costly once surfaces are sealed. A well-designed layout not only improves safety and functionality but also reduces labor hours.

Secure Proper Support and Spacing

Loose or improperly supported conduit can strain fittings and compromise long-term stability. For PVC conduit, supports are typically required within 3 ft (0.9 m) of each box or fitting and every 3 ft thereafter. For metal conduit (EMT/RMC), support intervals can extend to 10 ft (3 m), depending on local code. Always use corrosion-resistant straps or clamps, and avoid overtightening to prevent cracking nonmetallic conduit.

Use Proper Connectors and Expansion Fittings

Thermal expansion can significantly affect PVC conduit, particularly in outdoor or rooftop installations. Incorporate expansion joints in areas subject to frequent or extreme temperature changes to prevent stress on the conduit.

Apply solvent cement or threaded fittings per manufacturer instructions, as improper bonding is a common failure point.

For exposed conduit runs, always seal threaded fittings with approved compounds to maintain watertight integrity.

Grounding, Bonding, and Inspection

Proper grounding ensures fault currents are safely carried back to the source, preventing shock hazards.

Metal conduit systems often serve as the grounding path, so ensure all joints are tight and conductive.

PVC systems require separate copper or aluminum grounding conductors inside the conduit.

전기차 충전기를 가동하기 전에 연속성 테스트를 실시하고, 면허를 소지한 전기 기술자 또는 관할 당국(AHJ)에게 설치 상태를 점검받으십시오.

전기차 충전기(EVSE) 요구사항과 연계

전기차 충전기(EVSE 장치)는 종류에 따라 전력 용량과 설치 요구 사항이 다릅니다.

충전기 사양에 맞춰 차단기 크기, 케이블 굵기 및 전선관 최대 적재 용량을 확인하십시오.

향후 업그레이드를 계획하세요. 필요한 크기보다 한 치수 큰 전선관을 사용하면 나중에 큰 재작업을 피할 수 있습니다.

차단 스위치, 접속함 및 설치 높이가 현지 규정 및 제조업체 권장 사항을 준수하는지 확인하십시오.

6. 결론: 전기차 충전기 설치에 적합한 배관 선택하기

전기차 충전기 설치는 적합한 제품을 선택하는 것 이상의 의미를 지닙니다. 배관 시스템은 설치의 안전성, 내구성, 그리고 전체적인 외관에 매우 중요한 영향을 미칩니다. 이 글에서는 매립형 배관과 노출형 배관의 차이점을 살펴보고, 각각의 장점, 한계, 그리고 실제 적용 사례를 분석했습니다.

매립형 전선관은 깔끔하고 일체감 있는 외관과 뛰어난 보호 기능을 제공하여 미관과 장기적인 내구성이 중요한 신축 건물, 고급 주택 차고 또는 상업 시설에 이상적입니다. 노출형 전선관은 유연성, 손쉬운 유지 보수 및 비용 효율성을 제공하여 기존 시설 개조 프로젝트, 산업 현장 또는 향후 업그레이드 가능성이 높은 장소에 적합합니다.

전기차 충전기 설치 시 매설형 전선관과 노출형 전선관 중 어떤 방식을 선택할지 결정할 때는 프로젝트 유형 및 시공 단계, 예산 및 인력 제약, 미관 및 기능적 우선순위, 환경 노출 및 내구성 요구 사항, 유지 보수 및 확장성 요구 사항, 그리고 지역 전기 규정 및 안전 법규와 같은 요소를 고려하는 것이 중요합니다.

이러한 사항들을 신중하게 고려하고 전문가의 설치 모범 사례를 따르면 현재의 요구 사항과 미래의 수요를 모두 충족하는 안전하고 관련 법규를 준수하는 신뢰할 수 있는 전기차 충전 시스템을 구축할 수 있습니다.

Ledes 소개

레데스 당사는 주거용 및 상업용 건물에 사용되는 고품질 전기 배관 및 부속품을 제조 및 공급하는 선도적인 기업입니다.

수십 년의 경험을 바탕으로 Ledes는 내구성과 안전성을 고려하여 설계된 강성 및 연성 전선관을 포함하여 다양한 인증을 받은 PVC 전선관을 제공합니다.

새로운 전기차 충전기 설치를 계획하시든 기존 시스템을 업그레이드하시든, Ledes는 전문적이고 안정적인 결과를 달성할 수 있도록 신뢰할 수 있는 제품과 기술 지원을 제공합니다.

저희 비즈니스 팀에 문의하세요. 오늘 바로 프로젝트를 시작할 준비가 되셨나요?

자주 묻는 질문

전기차 충전기용 매립형 전선관과 노출형 전선관의 차이점은 무엇인가요?

매립형 전선관은 벽, 천장 또는 바닥 슬래브 아래에 설치되어 케이블을 보이지 않게 하고 깔끔한 외관과 추가적인 보호 기능을 제공합니다. 노출형 전선관은 벽이나 천장 표면에 설치되어 설치가 빠르고 유지 보수가 간편하며 향후 업그레이드에 유연성을 제공합니다.

신축 건물에는 어떤 종류의 전선관이 더 적합할까요?

매립형 전선관은 일반적으로 신축 건물에 선호되는 선택입니다. 배선 설치 시 매립하여 깔끔하고 미관상 보기 좋은 설치를 제공하는 동시에 배선을 손상으로부터 보호할 수 있기 때문입니다.

노출된 전선관은 전기차 충전기 개조에 적합한가요?

네. 노출형 전선관은 벽이나 바닥 마감이 이미 완료된 리모델링 프로젝트에 이상적입니다. 철거 없이 신속하게 설치할 수 있으며, 향후 업그레이드나 유지 보수도 용이합니다.

매립형 및 노출형 전선관에 권장되는 재료는 무엇입니까?

숨겨진 도관: 내구성, 내식성 및 규정 준수를 고려하여 Schedule 40 또는 80 PVC, RMC, IMC 재질을 선택합니다.

노출된 전선관: 환경 노출, 기계적 보호 및 미관상의 요구 사항에 따라 PVC, EMT 또는 금속 전선관을 선택하십시오. 항상 UL 인증을 받고 관련 규정을 준수하는 제품을 선택하십시오.

전기차 충전기에 맞는 전선관 크기는 어떻게 선택해야 하나요?

전선관 크기는 케이블 종류, 도체 수, 허용 전류량에 따라 달라집니다. 매립형 전선관은 케이블 인입 및 향후 업그레이드를 용이하게 하기 위해 약간 더 큰 크기를 사용하는 경우가 많습니다. 노출형 전선관은 굴곡 및 인입함 설치 시 더 많은 유연성을 제공합니다. 면허를 소지한 전기 기술자와 상담하는 것이 좋습니다.

나중에 매립형 전선관에서 노출형 전선관으로 바꿀 수 있나요?

기술적으로는 가능하지만, 매설 전선관은 보통 벽이나 슬래브 안에 묻혀 있어 나중에 교체하려면 비용이 많이 듭니다. 노출 전선관은 전력 수요 변경 시 수정, 확장 또는 재배치가 훨씬 쉽습니다.

지역 전기 규정이 매립형 전선관과 노출형 전선관 선택에 영향을 미치나요?

네. 두 종류 모두 NEC(미국 전기 규격), 지역 건축 법규 및 검사 요건을 준수해야 합니다. 일부 법규는 특정 재료, 매설 깊이 또는 기계적 보호 장치를 규정할 수 있습니다. 설치 전에 반드시 면허를 소지한 전기 기술자 또는 관할 당국(AHJ)에 문의하십시오.