Table des matières

Lorsqu'un projet nécessite un acheminement de conduits flexibles, deux types de conduits se distinguent systématiquement comme des solutions incontournables : les conduits métalliques flexibles (FMC) et les conduits métalliques flexibles (FMC). Tubes électriques non métalliques (conduits ENT)Que vous naviguiez dans des espaces restreints, que vous travailliez autour d'obstacles ou que vous conceviez un système en tenant compte de l'accessibilité future, les conduits FMC et les tubes ENT offrent la flexibilité et la protection nécessaires à une installation électrique sûre et efficace.

Ces conduits sont largement utilisés dans les environnements résidentiels, commerciaux et industriels légers, où les conduits rigides ne sont tout simplement pas pratiques. Malgré une certaine flexibilité, ils diffèrent considérablement en termes de matériaux, d'exigences réglementaires, de durabilité physique et de performances environnementales.

Pourquoi il est important de comprendre la différence

Choisir entre un conduit électrique FMC et un conduit ENT n'est pas seulement une question de préférence : c'est une décision qui impacte la sécurité, la conformité, le coût et la fiabilité à long terme. Grâce à sa construction métallique durable, le FMC offre une excellente protection mécanique et une mise à la terre intégrée. Le conduit ENT, quant à lui, est léger, facile à installer et idéal pour les environnements à faible impact tels que les cavités murales intérieures ou les plafonds.

Comprendre les points forts, les limites et les meilleurs scénarios d'utilisation des conduits métalliques flexibles et des tubes électriques non métalliques vous garantit de pouvoir concevoir et installer un système qui répond aux exigences techniques et réglementaires de votre projet tout en optimisant les coûts de main-d'œuvre et de matériaux.

Qu'est-ce que FMC Conduit ?

Le conduit métallique flexible (FMC), également appelé Greenfield ou simplement Flex, est un type de conduit métallique conçu pour un acheminement flexible du câblage électrique. Contrairement aux systèmes de conduits rigides qui nécessitent des coudes et des découpes importantes, le conduit électrique FMC offre un chemin flexible et adaptable qui simplifie l'installation dans les espaces restreints, irréguliers ou sujets aux vibrations.

Définition et construction

Le FMC est construit en enroulant en hélice une bande métallique nervurée auto-ajustée, généralement en aluminium ou en acier, pour former un tube creux. Cette construction en spirale crée un conduit flexible, mais mécaniquement protecteur, à travers lequel les conducteurs électriques peuvent être tirés. L'intérieur est généralement suffisamment lisse pour minimiser l'abrasion des fils, et la forme du conduit lui permet de se courber librement sans conserver une forme fixe, ce qui est idéal pour contourner les obstacles ou traverser des espaces architecturaux confinés.

Le FMC ne présente pas de courbure permanente, ce qui le distingue de certains autres types de conduits flexibles. Cette caractéristique lui permet de s'adapter aux vibrations du système et aux structures mobiles, ce qui le rend idéal pour les installations dans les raccordements d'équipements, les cavités de plafond ou les projets de rénovation.

Matériaux utilisés dans FMC

Le conduit FMC est généralement fabriqué à partir de :

- Acier galvanisé: Offre une résistance mécanique et une résistance à la corrosion élevées, adapté aux endroits secs à l'intérieur.

- Aluminium: Léger et résistant à la corrosion, souvent choisi lorsque la minimisation du poids ou des interférences magnétiques est importante.

Les deux matériaux sont résistants au feu et répondent aux principales normes UL en matière de performances mécaniques et électriques.

Principales caractéristiques et avantages du FMC

Les conduits métalliques flexibles (FMC) sont appréciés pour leur adaptabilité et leur protection mécanique, notamment dans les environnements où les conduits rigides sont trop contraignants. Des bâtiments commerciaux aux environnements industriels, en passant par la rénovation résidentielle, les FMC offrent de nombreux avantages qui en font un choix privilégié pour certaines installations électriques.

1. Grande flexibilité

L'un des principaux avantages des conduits FMC est leur capacité à se plier librement sans outils spéciaux. Contrairement aux systèmes rigides qui nécessitent des coudes préfabriqués ou une découpe précise, les conduits FMC peuvent être acheminés facilement autour des obstacles structurels, à travers les cavités murales et dans les armoires électriques, avec un minimum d'effort. Cette flexibilité se traduit par :

- Installations plus rapides

- Rénovations simplifiées

- Besoin réduit de raccords et de joints

Le FMC est particulièrement utile dans les zones soumises à des vibrations, telles que les connexions de moteurs et d'équipements, où les conduits rigides seraient plus sujets à la fatigue ou aux dommages.

2. Protection mécanique et durabilité

Malgré leur flexibilité, les gaines électriques FMC offrent un haut niveau de protection mécanique. Leur construction métallique protège les conducteurs contre :

- Impact physique

- Forces écrasantes

- Rongeurs ou insectes

Cela fait du FMC un choix judicieux dans les environnements qui exigent à la fois une flexibilité de routage et un certain degré de protection des conducteurs, tels que les locaux techniques, les espaces utilitaires et les plafonds commerciaux.

3. Résistance au feu et sécurité

Le FMC est fabriqué à partir de métaux incombustibles comme l'acier galvanisé ou l'aluminium, ce qui lui confère des propriétés de résistance au feu que de nombreuses alternatives en plastique ou non métalliques ne peuvent offrir. Cela peut être un facteur critique dans les installations à haut risque ou sensibles aux réglementations.

De plus, le FMC convient à une utilisation dans des systèmes nécessitant un blindage contre les interférences électromagnétiques (EMI), car son corps métallique peut aider à réduire la transmission EMI, en particulier dans les environnements sensibles aux données.

4. Capacité de mise à la terre (conditionnelle)

Conformément au Code national de l'électricité (NEC), le FMC peut servir de conducteur de mise à la terre des équipements, mais uniquement sous certaines conditions, basées sur la longueur, la taille et l'ampérage du circuit. Pour les petites séries et les dimensions commerciales appropriées, le FMC peut éliminer le besoin d'un fil de mise à la terre séparé, ce qui permet de gagner du temps et de réduire les coûts de matériel.

Cependant, pour les trajets plus longs ou les circuits à ampérage plus élevé, un conducteur de mise à la terre dédié doit toujours être tiré à travers le conduit pour garantir la conformité au code et la sécurité.

5 applications courantes des conduits FMC

Le conduit métallique flexible (FMC) est une solution polyvalente utilisée dans une large gamme d'installations électriques. Sa combinaison unique de pliabilité, de protection mécanique et de blindage métallique le rend particulièrement adapté aux configurations complexes, aux raccordements d'équipements et aux travaux de modernisation. Vous trouverez ci-dessous les applications les plus courantes et les scénarios concrets où le conduit FMC s'avère le choix idéal.

1. Connexions de l'équipement

Le FMC est souvent le conduit de prédilection pour le raccordement de moteurs, de transformateurs, d'unités CVC et de générateurs. Ces types d'équipements produisent généralement des mouvements ou des vibrations pendant leur fonctionnement, ce qui peut endommager les conduits rigides à long terme. La capacité du FMC à fléchir et à absorber les mouvements permet d'éviter :

Assouplissement des terminaisons

Fatigue du conducteur

Fissuration ou fendillement du conduit

Cela rend le FMC essentiel dans les salles mécaniques, les usines industrielles et les installations commerciales où la fiabilité est essentielle.

2. Espaces d'installation restreints ou irréguliers

Dans les bâtiments où l'espace est limité ou la structure irrégulière, le FMC simplifie le routage, contrairement aux conduits rigides. Sa conception flexible permet aux électriciens de contourner les obstacles.

Cela rend FMC idéal pour les projets de rénovation, de rénovation ou toute installation qui doit naviguer dans des espaces confinés ou finis sans construction majeure.

3. Bâtiments commerciaux et institutionnels

Dans les immeubles de bureaux, les écoles et les hôpitaux, le FMC est utilisé pour :

Câblage de circuit de dérivation

Connexions d'éclairage

Mangeoires pour cloisons modulaires

Distribution d'énergie par réseau de plafond

Sa protection métallique conforme au code et sa flexibilité discrète le rendent pratique dans ces environnements, en particulier lorsque l'esthétique ou une perturbation minimale sont requises.

4. Systèmes d'alimentation temporaires

Dans les installations temporaires telles que les chantiers ou les événements, le FMC permet un câblage flexible et rapide entre les équipements et les panneaux. Sa facilité de manipulation et sa réutilisation permettent aux entrepreneurs de :

Ajustez rapidement les configurations

Minimiser le gaspillage de matériaux

Conforme aux exigences de sécurité pour le câblage exposé

5. Centres de données et salles de communication

Le FMC peut assurer un blindage électromagnétique dans les environnements où l'intégrité des données est essentielle. Son boîtier métallique permet de contenir et de bloquer les interférences électromagnétiques, un élément essentiel lors de l'installation de lignes électriques à proximité d'équipements de communication ou informatiques sensibles.

En résumé, les conduits FMC offrent la flexibilité, la résistance et la protection conforme aux normes requises par les systèmes électriques spécialisés et performants. Que ce soit pour des environnements dynamiques comme les salles des machines ou pour des rénovations de plafonds de bureaux aux espaces restreints, les conduits FMC offrent une valeur ajoutée pratique dans de nombreux secteurs.

Option de conduit métallique flexible étanche aux liquides

Dans les applications où l'humidité, l'huile ou l'exposition extérieure sont des facteurs préoccupants, les conduits métalliques flexibles (FMC) standard peuvent ne pas être suffisants. C'est pourquoi les conduits métalliques flexibles étanches aux liquides (LFMC) deviennent la solution privilégiée. Les LFMC s'appuient sur la flexibilité et la résistance des FMC traditionnels, tout en y ajoutant une protection environnementale importante.

Qu'est-ce que LFMC ?

Le conduit métallique flexible étanche aux liquides (LFMC) est un type de conduit métallique flexible doté d'une gaine extérieure protectrice, généralement en PVC (polychlorure de vinyle). À l'intérieur, il utilise le même noyau hélicoïdal en acier ou en aluminium que le FMC standard, mais l'extérieur est étanche à l'humidité, aux huiles et aux agents corrosifs.

Cette construction permet à LFMC de combiner :

- La protection mécanique et la capacité de mise à la terre des conduits métalliques

- La résistance à l'humidité d'un système scellé et recouvert de plastique

- La flexibilité d'une structure de type bobine

Où LFMC est-il utilisé ?

Le LFMC est particulièrement utile dans les environnements humides ou dangereux, où les tubes FMC ou ORL standard ne répondent pas aux exigences du code. Applications typiques :

- Connexions d'équipements extérieurs (par exemple, unités de climatisation, éclairage, pompes)

- Stations de lavage de voitures, usines de transformation alimentaire ou zones de lavage industriel

- Raccordements souterrains (lors de la transition d'un conduit enterré vers un équipement de surface)

- Installations marines et à bord des navires

- Toits commerciaux et parkings

- Installations de l'industrie pétrolière et gazière

4 avantages du conduit LFMC

Le LFMC offre plusieurs avantages clés par rapport au FMC standard :

- Étanche et résistant à la corrosion : Idéal pour les environnements humides ou corrosifs

- Veste résistante aux UV : Convient pour une exposition prolongée à l'extérieur

- Ignifuge : Ajoute une protection contre l'incendie là où cela est nécessaire

- Maintient la flexibilité : Facile à installer dans des espaces restreints ou difficiles d'accès

Pour garantir la sécurité et la conformité, il est essentiel d'utiliser des raccords homologués UL LFMC et des raccords approuvés adaptés à l'environnement.

Codes et normes pour les conduits FMC

Pour garantir la sécurité et la conformité des installations électriques, les conduits métalliques flexibles (FMC) doivent respecter des normes et des codes réglementaires spécifiques aux États-Unis et au Canada. Ces réglementations définissent les applications autorisées, les caractéristiques de construction, les règles d'installation et les exigences de sécurité pour les FMC et certaines pour les LFMC.

Aperçu des codes et normes FMC

- Code national de l'électricité (NEC) – Article 348 (FMC)

- Code canadien de l'électricité (CCE) – Articles 12-1000 à 12-1012 (FMC)

- UL 1 – Conduit métallique flexible

- CSA C22.2 n° 56-17 – Conduit métallique flexible et conduit métallique flexible étanche aux liquides

Article 348 du Code national de l'électricité (NCE) – Conduits métalliques flexibles (FMC)

L'article 348 du Code national de l'électricité (NEC) est la principale autorité aux États-Unis régissant les installations FMC. Voici un résumé de ses principales dispositions :

Utilisations autorisées

Le FMC peut être utilisé dans les zones exposées et dissimulées des bâtiments. Il est idéal pour les courts trajets vers des luminaires ou des équipements nécessitant un déplacement ou un réglage ultérieur.

Utilisations non autorisées

FMC ne peut pas être installé :

Dans des endroits mouillés ou humides

Dans des environnements dangereux ou inflammables (sauf autorisation spécifique)

Encastré dans le béton ou enterré

Où il peut être exposé à l'huile, à l'essence ou à d'autres substances nocives

Dans les gaines d'ascenseur, sauf exceptions

En cas de dommages physiques

Limitations de taille

La taille commerciale maximale autorisée pour FMC est de 4 pouces (désignation métrique 103).

La plus petite taille (3/8 pouce) n'est autorisée que dans des applications spécifiques de courte longueur, comme les câbles de moteur ou les connexions de luminaires, et ne dépasse généralement pas 6 pieds de long.

Limites de remplissage du conducteur

Le nombre de fils à l'intérieur du conduit est limité par les tableaux de remplissage NEC pour éviter la surchauffe.

Il existe un tableau de remplissage spécial pour le FMC 3/8 pouces, en fonction du type de fil et de l'isolation.

Un seul conducteur de mise à la terre de l'équipement est autorisé en plus des fils conducteurs de courant.

Règles de contournement

Le FMC peut être plié à la main, mais le rayon de courbure doit être suffisamment large pour éviter d'endommager le conduit.

La quantité totale de flexion (en degrés) d'une boîte à l'autre ne peut pas dépasser 360 degrés.

Soutenir et sécuriser FMC

Le FMC doit être solidement fixé :

- Dans 12 pouces de chaque boîte, armoire ou terminaison

- Au moins tous les 4,5 pieds (1,4 mètre) de long its run

There are exceptions for places where support is impractical, like inside finished walls, or for flexible fixture connections.

Grounding and Bonding Requirements

FMC can serve as a grounding path, but only if flexibility after installation is not needed.

If the FMC is used for equipment that moves or vibrates, a separate equipment grounding conductor must be installed.

Bonding jumpers and grounding conductors must follow NEC rules.

Canadian Electrical Code Requirements for FMC

Under the Canadian Electrical Code (CEC), FMC is grouped together with rigid metal conduit (RMC), and both are governed by specific rules (Section 12-1000 to 12-1014). Here’s what you need to know when working with FMC in Canadian installations:

Uses

You can use FMC in buildings made of either combustible or non-combustible materials.

It’s often used in short, flexible connections to equipment or fixtures, particularly where some movement or repositioning is expected.

Minimum Size Limits

In general, conduits smaller than trade size 16 are not allowed.

However, trade size 12 FMC is permitted for short runs up to 1.5 meters to connect equipment.

This makes FMC ideal for final connections where flexibility is needed.

Support and Securing Requirements

- FMC must be secured at intervals no greater than 1.5 meters.

- It also needs to be fastened within 300 mm of every outlet box or fitting.

- Exceptions: You don’t need to secure FMC when it’s “fished” through walls or for short lengths (under 900 mm) at connection points that need flexibility.

Conductors Inside FMC

Wires installed in FMC must comply with Rule 12-910, ensuring proper insulation, temperature rating, and fill limits.

FMC is treated as a raceway and must be sized appropriately to prevent overheating of conductors.

UL 1 - Standard for Flexible Metal Conduit (FMC)

The UL 1 standard outlines essential construction and performance requirements for FMC, ensuring safety, flexibility, and durability in electrical installations. Below is a simplified overview of the key areas covered by the standard.

Construction & Materials

FMC is made from steel or aluminum strip.

Acier: Must be carbon steel with a minimum tensile strength of 34,000 psi, and free of rust or scale before being zinc-coated.

Aluminium: Must also meet 34,000 psi minimum tensile strength and have ≤0.40% copper content.

Strip Quality:

The strip must be uniform in width and thickness. Splices (if any) must not affect conduit strength or inside diameter.

Convolutions:

The number of convolutions (spiral ridges) must meet minimum requirements for flexibility and strength.

Interior Surface:

The inside surface must be smooth and free from burrs or sharp edges to protect wiring during installation.

Dimensions

Strip Thickness:

Minimum thickness is defined per trade size. Special types like XRWFMC may use thinner strips if they meet all required tests.

Inside & Outside Diameters:

Both internal and external diameters must fall within UL-specified tolerances to ensure proper fitting and safety in application.

Exigences de performance

To ensure the durability, safety, and compliance of flexible steel and aluminum conduit, several key performance tests are conducted in accordance with the standards. These include:

Zinc Coating Test

This evaluates the quality of the zinc coating on both the steel strip before forming and the finished conduit. The coating must resist copper deposition during immersion in a copper sulphate solution, ensuring corrosion protection and long-term performance.

Essai de tension

Finished conduit must withstand a specified tensile load (300 lbf) without opening or separation, verifying its mechanical strength under stress.

Flexibility Test

The conduit is bent around a cylindrical surface of a designated radius to confirm it maintains structural integrity and does not open or expose the inner surface.

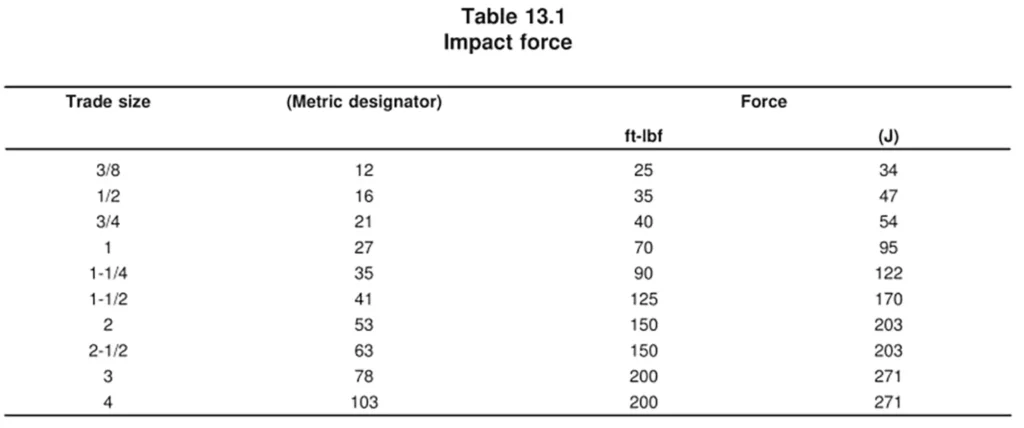

Impact Resistance Test (for reduced-wall types)

This test assesses the conduit’s ability to withstand physical impacts without failure, which is critical for demanding installation environments.

Exigences en matière de marquage

Factory Identification (required id the manufacturer has more than one factory):

Manufacturer name or trademark.

Material Identification:

Flexible aluminum conduit must be marked with the letters “AL”.

Marking interval: No more than 12 inches (305 mm).

Tag on Each Coil:

Each coil of flexible steel or aluminum conduit must have a tag or marking showing:

a) Manufacturer Identification

Name, trade name, or other distinctive identification.

b) Date of Manufacture

By month and year.

c) Trade Size

Nominal size of the conduit.

d) Connector Compatibility Notice

A warning: “Use only with connectors intended for this type of conduit.”

Connector packaging should also be marked to indicate compatibility:

“FMC,” “FEFMC,” “ALFMC,” etc., based on type and material.

CSA C22.2 No.56-17 - Standard for FMC and LFMC

CSA C22.2 No. 56-17 is a standard for flexible metal conduit and liquid-tight flexible metal conduit, it outlines the requirements for their construction, dimensions, marking and performance. Here are some key information for them.

Construction and Material

FMC is made from zinc-coated steel or aluminum strips (LFMC can use bronze, zinc-coated steel, or aluminum).

All strips must have uniform thickness and width.

Inside of the conduit must be smooth and free of sharp edges to prevent wire damage.

Both internal and external diameters must meet specific limits to ensure proper fit and safe conductor fill.

Thermoplastic Jacket (LFMC only)

LFMC must have an overall thermoplastic jacket:

Minimum thickness required (per Table 4).

Outer diameter must stay within limits (per Table 5).

Jacket provides liquid-tight protection.

Exigence de marquage

Compliant FMC must be clearly marked with the manufacturer’s name or trademark, trade size.

FMC made from aluminum must be marked with “AL”, embossed or indented every 150 mm (6 in).

For LFMC: Should include “LIQUID-TIGHT CONDUIT” on the outer jacket,

LFMC must marked with temperature ratings, SUN RES if rated.

Performance Testing Requirements

FMCs are primarily tested to verify their mechanical robustness and electrical continuity under normal and extreme installation conditions. The following tests are required:

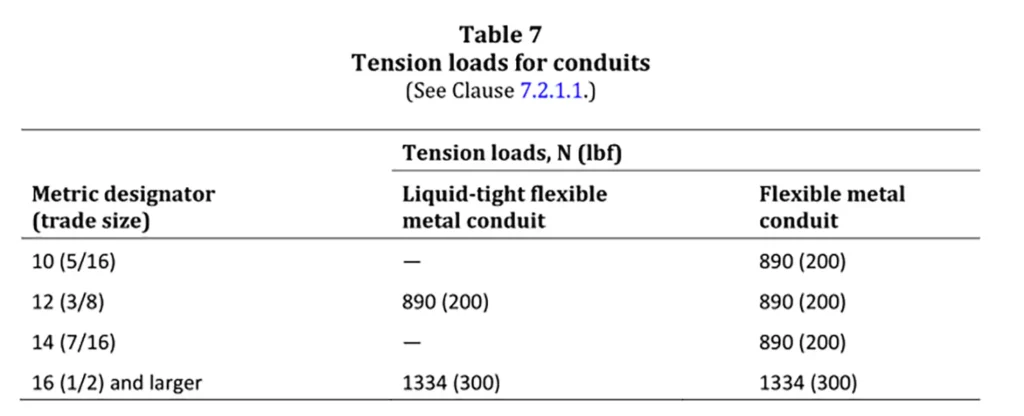

Essai de tension

Finished FMC must withstand an axial tension load (as outlined in the CSA table) for a specific duration without opening its convolutions or sustaining damage. This test verifies that the conduit can endure pulling forces during installation or operation, ensuring mechanical integrity and protection of the enclosed wiring.

Flexibility Testing

FMCs must maintain mechanical integrity without opening their convolutions when bent around a specified mandrel. This test ensures that the conduit can withstand tight bends in real-world installations without compromising its structure or safety. The testing follows the Flexibility of Armored Cable and Metal-Sheathed Cable protocol outlined in CSA C22.2 No. 2556.

Protective Zinc Coating Performance

The protective galvanized zinc coating applied to the steel strip (used in FMC manufacturing) must pass corrosion resistance testing using the Copper Sulfate Test (Preece Test). The standard specifies no fixed copper deposits after immersion cycles, ensuring the conduit’s durability in harsh or corrosive environments.

Extra Test for Liquid-Tight Flexible Metal Conduit (LFMC)

LFMC undergoes a more comprehensive set of tests due to its added components (like a thermoplastic outer jacket) and intended usage in wet, corrosive, or outdoor conditions. The relevant testing follows CSA C22.2 No. 56 and cross-references to CSA C22.2 No. 2556.

1. Thermoplastic Jacket Physical Properties

The jacket material must meet specific tensile strength and elongation standards both before and after accelerated aging. These physical performance criteria are tested using methods from CSA C22.2 No. 2556 (Clause 4.2), ensuring that the outer jacket retains flexibility and strength over time.

2. Deformation Resistance

LFMC jackets must resist deformation under heat and pressure. When subjected to 121°C with a 2000g load for 1 hour, the jacket thickness must not decrease by more than 35%. This simulates real-world thermal stress scenarios.

3. Optional Weather Resistance Test

For products marked as suitable for outdoor use, the jacket must retain 80% of its tensile strength and elongation after 1000 hours of xenon-arc exposure, simulating long-term UV and weathering effects.

4. Axial Tension Performance

Finished LFMC must withstand specified axial tension (based on conduit trade size) for 60 seconds without damage to the jacket or opening of the metal convolutions. This ensures durability during pulling or installation.

5. Zinc Coating Corrosion Resistance

Like FMC, LFMC’s steel strip (both before and after forming) must meet protective coating standards under the Copper Sulfate Test, verifying the effectiveness of the zinc layer in resisting corrosion.

6. Flexibility Under Cold Conditions

LFMC must retain structural integrity when subjected to cold bending. The conduit is conditioned at a specified low temperature, then bent around a mandrel in both directions. No cracking or separation should occur in either the metal or the plastic components. This cold bend test evaluates real-world performance in low-temperature installations.

7. Flame Resistance

LFMC must pass flame resistance testing:

FT1 Vertical Flame Test: The conduit must self-extinguish within 1 minute after five 15-second flame applications. No more than 25% of a marking indicator may be burned.

Optional FT4 Vertical Tray Flame Test: When applicable, the conduit on a cable tray (unfilled) must not exceed 1.5 meters of char length. This test provides additional assurance for installations where fire spread resistance is crucial.

8. Cold Impact Resistance

After conditioning at cold temperatures (as per Table 9 in the standard), LFMC is subjected to a 40 N impact. The conduit must not crack or rupture, demonstrating robustness under potential field abuse during freezing conditions.

What is Electrical Nonmetallic Tubing (ENT)

Tubes électriques non métalliques (ENT) is a flexible, lightweight, corrugated plastic raceway system designed for electrical wiring installations in residential, commercial, and institutional buildings. It serves as a protective pathway for electrical conductors and cables, offering an efficient alternative to traditional rigid or metallic conduit systems.

ENT is manufactured from non-metallic materials, most commonly polyvinyl chloride (PVC) or other thermoplastic compounds, that provide a unique combination of durability, flexibility, and corrosion resistance. Its corrugated design allows it to bend easily without the need for additional tools or fittings, reducing installation time and labor costs.

4 Features of ENT Conduit

- Flexible Construction: ENT’s corrugated structure enables easy routing through walls, floors, and ceilings—even in tight or complex spaces—without elbows or bending equipment.

- Poids léger: Significantly lighter than metal conduit, ENT is easier to handle, transport, and install.

- Non-metallic Material: Resistant to corrosion, rust, and chemical degradation, making it suitable for moist or corrosive environments.

- Ignifuge : ENT is designed to meet vertical flame and smoke performance requirements per relevant North American safety standards.

5 Advantages of ENT Conduit

- Quick and Easy Installation: ENT can be cut with a hand tool and installed without special bending or threading equipment, reducing labor time and costs.

- Reduced Material Handling: Its light weight makes it easier to transport and maneuver on job sites.

- Lower Cost: Compared to metal conduit systems, ENT offers lower material and installation costs.

- Corrosion and Moisture Resistance: Ideal for damp or corrosive environments where metal conduits may degrade over time.

- Code Compliant: ENT is approved by both U.S. and Canadian standards (e.g., UL 1653 and CSA C22.2 No. 227.1) and is recognized in the National Electrical Code (NEC) and Canadian Electrical Code (CEC).

Codes and Standards for ENT Conduit

To ensure safe and compliance of ENT for electrical systems, ENT should comply to related industry standards and codes,

ENT Conduit Codes and Standards List

- Code national de l'électricité (NEC) – Article 362 (ENT)

- Code canadien de l'électricité (CCE) – Section 12-1500 to 12-1514 (ENT)

- UL 1653 / CSA C22.2 No.227.1 – Safety Standard for Electrical Nonmetallic Tubing

NEC Article 362 - Electrical Nonmetallic Tubing (ENT)

NEC Article 362 covers the requirements for ENT, a pliable, corrugated, nonmetallic raceway used for electrical installations. According to Section 362.1, this article outlines the use, installation, and construction specifications for ENT and associated fittings. Importantly, Section 362.6 mandates that ENT and its fittings must be listed, ensuring they meet recognized safety and performance standards.

Utilisations autorisées

ENT is permitted in various applications, provided specific conditions are met:

- Building Height Restrictions: In buildings not exceeding three floors above grade, ENT can be used for exposed or concealed work, as long as it’s not prohibited by Section 362.12.

- Concealed Installations: In any building, regardless of height, ENT is allowed when concealed within walls, floors, and ceilings that provide a thermal barrier with at least a 15-minute finish rating.

- Fire Protection Exception: If an approved automatic fire protective system is installed on all floors, ENT may be used exposed or concealed in buildings exceeding three floors above grade.

- Concrete Encasement: ENT can be encased in poured concrete or embedded in a concrete slab on grade, provided fittings identified for this purpose are used.

- Emplacements humides : ENT is permitted in wet locations when installed in concrete slabs on or below grade, using fittings listed for the purpose.

- Considérations relatives à la température : Conductors or cables rated at a temperature higher than the listed temperature rating of ENT may be installed, provided they are not operated at a temperature exceeding the ENT’s rating.

Utilisations non autorisées

ENT is not suitable for certain environments and applications:

- Emplacements dangereux : ENT is prohibited in hazardous (classified) locations unless permitted by other NEC articles.

- Support of Equipment: ENT cannot be used to support luminaires or other equipment.

- High Ambient Temperatures: ENT should not be used where ambient temperatures exceed 50°C (122°F) unless listed otherwise.

- Direct Earth Burial: ENT is not permitted for direct burial in the earth.

- Exposed Locations: ENT is generally not allowed in exposed locations, with specific exceptions outlined in Section 362.10.

- Theaters and Similar Locations: ENT is restricted in theaters and similar venues, except as provided in Sections 518.4 and 520.5.

- Sunlight Exposure: ENT must not be used where exposed to direct sunlight unless identified as sunlight resistant.

- Dommages physiques: ENT is unsuitable for areas where it would be subject to physical damage.

Exigences de dimensionnement et de remplissage

- Minimum and Maximum Sizes: ENT trade sizes range from ½” (metric 16) to 2½” (metric 63)。

- Conductor Fill: The number of conductors or cables in ENT must comply with Chapter 9, Table 1 of the NEC for allowable percentage fill (362.22).

Construction Specifications

- Besoins matériels : ENT must be made of material that does not exceed the ignitability, flammability, smoke generation, and toxicity characteristics of rigid (nonplasticized) polyvinyl chloride.

- Marquage: ENT must be clearly and durably marked at least every 3 meters (10 feet) as required in Section 110.21(A). The type of material should also be included in the marking.

CEC Requirements for ENT Conduit

In Canada, the use and installation of Electrical Nonmetallic Tubing (ENT) is regulated under Section 12 of the Canadian Electrical Code (CEC), Part I, specifically Rules 12-1500 to 12-1514. These requirements govern permitted uses, restrictions, installation practices, and safety provisions.

Permitted Uses

ENT is permitted in the following conditions, subject to compliance with general wiring rules:

Installations souterraines :

ENT may be used underground, including burial depth, mechanical protection, and backfilling.

Exposed or Concealed Locations:

ENT is suitable for both exposed and concealed installations within buildings, provided other CEC provisions are met.

Restrictions on Use

ENT shall not be used in locations where it may be subject to physical damage, unless adequate mechanical protection is provided. This includes areas susceptible to impact during or after construction.

Soutient

ENT must be securely fastened in place using approved methods:

Support must be placed within 1 meter of each outlet box, junction box, cabinet, coupling, or fitting.

The maximum spacing between supports is 1 meter.

Nombre de conducteurs

The conductor fill capacity inside ENT must comply with Rule 12-910, which specifies allowable conductor quantities based on cross-sectional area and conductor insulation types. Overfilling the conduit can lead to overheating and noncompliance with ampacity derating rules.

Temperature Limitations

ENT has temperature-based installation limitations:

- ENT must not be used in areas where the tubing may be exposed to temperatures exceeding 75°C under normal operating conditions.

- Higher-temperature rated insulated conductors (above 75°C) may be used, but ampacity must be limited to that of 90°C rated conductors, regardless of the conductor’s rating.

Connections and Couplings

Above-ground Joints:

When ENT is joined or connected to fittings, boxes, or cabinets, only fittings specifically designed for ENT are permitted.

Underground Joints:

When used underground, ENT couplings must be solvent-cemented using a suitable cement to ensure moisture resistance and mechanical strength.

Support of Equipment

ENT is not permitted to support electrical equipment such as luminaires, boxes, or cabinets. All equipment must be supported independently to avoid structural stress on the tubing.

Bonding Continuity

ENT is a non-conductive raceway, and therefore, a separate bonding (grounding) conductor must be installed in accordance with Rules to ensure electrical continuity and fault current return path.

UL1653 / CSA C22.2 No.227.1 - Standards for ENT

Electrical Nonmetallic Tubing (ENT) is manufactured to meet rigorous safety, mechanical, and material performance requirements under UL 1653 and CSA C22.2 No. 227.1. These harmonized North American standards ensure that ENT products are safe for use in building wiring systems across the U.S. and Canada.

Construction and Material Requirements

Non-metallic and corrugated, allowing for flexibility during installation.

Made from thermoplastic materials such as PVC or polypropylene, formulated to meet flame resistance, mechanical strength, and temperature performance requirements.

ENT is used in a ambient temperature of 50°C, if used in attics, it should have a relative thermal index of 60°C.

Dimensions

Here’s a brief overview of the most critical performance tests required by UL1653 / CSA C22.2 No.227.1:

Vertical Flame Test

Assesses ENT’s flame-retardant capability. The tubing must self-extinguish and limit flame spread when subjected to a vertical burn test.

Essai de flexion

Ensures the tubing retains structural integrity and does not crack when bent to a specified radius at room temperature.

Deflection Test

Measures deformation under applied load. ENT must resist excessive flattening when pressure is applied.

Essai d'impact

Verifies toughness by dropping a weight onto the tubing at both room and cold temperatures. ENT must not crack or shatter.

Cold Bend Test

Conducted at low temperatures (typically -20°C), this test checks for brittleness. ENT must remain flexible and unbroken.

Essai de tension

Ensures that fittings and conduit connections resist pullout forces typical in installation conditions.

Stiffness Test

Evaluates mechanical rigidity to prevent sagging or collapse during installation and operation. In Canada, the ENT should have a minimum stiffness of 300 kPa at 5% deflection. In the U.S. there’s no requirement specified.

For detailed descriptions, pass criteria, and test procedures, please refer to our article: ENT Tubing for code compliance and test items.

FMC vs. ENT: A Comprehensive Comparison

Choosing the right type of conduit, Flexible Metal Conduit (FMC) or Electrical Nonmetallic Tubing (ENT), depending on several key factors including application environment, mechanical protection requirements, code compliance, ease of installation, and cost.

Both FMC and ENT serve similar functions in protecting and routing electrical wiring, but their materials, construction, and performance characteristics differ significantly. Understanding these differences is essential to selecting the most suitable solution for your specific project.

The following comparison table outlines the critical distinctions between FMC and ENT in terms of materials, flexibility, environmental resistance, fire performance, strength, installation needs, and typical applications.

Fonctionnalité | FMC | ORL |

Matériel | Acier galvanisé ou aluminium | PVC |

Flexibilité | High; bends easily, but requires more effort than ENT | Very high; easily bends by hand without tools |

Résistance à la corrosion | Moderate; better with coated FMC or aluminum | Excellent; inherently non-corrosive |

Mechanical Protection | Superior; provides robust protection against physical damage | Limited; needs extra protection if exposed to damage |

Fire Performance | Inherently fire-resistant (high melting point, non-combustible) | Fire resistant, flame retardant, self-extinguishing (moderate) |

Installation | Relatively easy; requires cutting tools (hacksaw/grinder) and sometimes benders | Easier; hand-bendable, simple cutting tools, snap-on fittings |

Bonding/Grounding | Metal body can serve as ground if listed | Requires separate bonding conductor |

Poids | Plus lourd | Poids léger |

Coût | Higher material and labor cost | Plus rentable |

Codes and Standards | NEC, ECE, UL 1, CSA C22.2 No.56 | NEC, CEC, UL 1653, CSA C22.2 No.227.1 |

Applications courantes | Dry locations, motor leads, vibration-prone areas | Concrete slabs, walls, ceilings, residential and commercial wiring |

FMC or ENT: Making the Right Choice for Your Project

When selecting between Flexible Metal Conduit (FMC) and Electrical Nonmetallic Tubing (ENT), it’s essential to go beyond just code compliance. The right choice depends on a careful balance of site-specific conditions, installation goals, performance needs, and future adaptability.

1. Environmental Conditions

- Wet or dry locations: The installation environment is the first and most decisive factor. In dry, interior locations, both FMC and ENT are viable options. However, when dealing with wet, damp, or outdoor conditions, standard FMC is not suitable—Liquidtight Flexible Metal Conduit (LFMC) is required in such cases. ENT, while moisture-resistant, typically cannot be used in direct burial or continuously wet outdoor environments, unless specially rated.

- Exposed and concealed: Concealment and exposure also matter. FMC is permitted in both exposed and concealed areas. ENT, by contrast, must be concealed in buildings taller than three stories, per NEC requirements, and may only be used in exposed areas of smaller buildings if not subject to physical damage.

- Temperature and Chemical: Temperature and chemical exposure are further considerations. FMC, with its metallic construction, withstands temperature extremes and harsh environments better. ENT, made from PVC, can degrade above 50°C unless listed otherwise and may deform under sustained heat loads, but still offers good chemical resistance for many indoor applications.

2. Mechanical Protection

- Mechanical Durability: When it comes to mechanical durability, FMC has a clear advantage. Its metal construction makes it well-suited for areas with risk of impact, vibration, or abrasion, such as commercial kitchens, industrial facilities, or locations near machinery. ENT is more flexible but offers limited protection, making it ideal for concealed runs in residential or commercial walls where physical threats are minimal.

- Vibration: Vibration resistance is another critical area where FMC excels. Its helical structure helps absorb movement, making it ideal for connections to motors and vibrating equipment.

- EMI Shielding: Additionally, FMC provides electromagnetic interference (EMI) shielding, a key requirement in applications involving sensitive electronics or data communication systems. ENT, being non-metallic, offers no such protection.

3. Cost, Labor, and Maintenance

Cost evaluations must go beyond just the price of conduit per foot. ENT offers faster installations, with snap-in fittings and hand-bendability reducing labor time dramatically. It’s particularly effective in high-volume or repetitive applications like residential or office construction, where labor savings can outweigh material costs.

On the other hand, FMC’s higher material and labor costs reflect its robustness. For environments that demand greater resilience and fire resistance, the additional investment often pays off in reduced risk and lower long-term maintenance.

Maintenance needs also diverge: ENT is corrosion-proof and largely maintenance-free. FMC is corrosion-resistant but may require inspection and possible replacement over time in corrosive or damp environments.

4. Understand the Code

Regardless of material performance, all installations must meet the National Electrical Code (NEC) and any local amendments. For example:

ENT is not permitted in plenum spaces or hazardous environments.

FMC must meet bonding and grounding requirements, particularly in power distribution applications.

Engaging early with the Authority Having Jurisdiction (AHJ) ensures that material choices will pass inspection and that any special-use conditions are accounted for. Some inspectors may scrutinize markings or listings more closely than others, so proactive planning pays off.

5. Plan for the Future

In a world where system modifications and technology upgrades are frequent, future-proofing conduit infrastructure is a smart move. ENT’s flexibility and pull-through design make it easier to add or re-route wiring, minimizing downtime during upgrades. This makes it a strong contender for tenant spaces, education, or healthcare facilities, where adaptability is key.

FMC, while less flexible once installed, still supports cable changes and upgrades—especially if installed with accessible junction points.

5 Common Installation Mistakes and Best Practices

Whether working with Flexible Metal Conduit (FMC) or Electrical Nonmetallic Tubing (ENT), proper installation is essential for electrical safety and long-term system performance. Despite their differences in material and flexibility, both conduit types are vulnerable to common installation mistakes. Below, we explore these pitfalls and outline best practices that ensure code compliance, reliability, and efficiency.

Conseils de pro : Vous souhaitez en savoir plus sur conduit fill, cutting ENT, and pull wiring tips for ENT conduit? You can click the link above to read our previous article.

1. Avoiding Incorrect Sizing and Overfilling

- Choosing the right size: Selecting the correct conduit size is more than a matter of convenience, it’s a critical safety consideration. Undersized conduits restrict airflow around conductors, increasing the risk of overheating and making wire pulling labor-intensive. On the other hand, unnecessarily large conduit may increase project costs and complicate fittings and support systems.

- Fill Capacity: Another frequent issue is overfilling, where too many wires are packed into the conduit. This not only makes installation harder but also poses a real fire hazard due to reduced heat dissipation. Best practice dictates always referring to NEC fill tables to determine proper sizing based on conductor count and gauge. For general guidance, keeping conduit fill below 40% for multi-wire installations strikes a balance between safety, ease of maintenance, and future upgrades.

2. Proper Support and Secure

FMC and ENT, though flexible, require structured support. Without it, conduits can sag, shift, or even become damaged, putting both the conduit and internal wiring at risk. Secure anchoring at proper intervals maintains alignment, reduces mechanical stress, and preserves system integrity over time.

The National Electrical Code provides clear guidelines for support spacing. FMC typically must be supported every 4.5 feet and within 12 inches of termination points. ENT requires tighter control – support every 3 feet and near ends. Using appropriate clamps, straps, or hangers matched to the conduit material is crucial to prevent loosening, movement, or abrasion in active environments.

Support according to you local codes.

3. Bending Limits

Both FMC and ENT are valued for their flexibility, but that doesn’t mean bending them is without limits. Improper bending—such as tight corners or excessive cumulative angles—can lead to pinched conductors, insulation breakdown, and increased pulling resistance. These issues often translate into costly delays or failures down the line.

To avoid these outcomes, installers should respect the minimum bend radius, typically no less than three times the conduit diameter, and limit total bend angles in a single run to 360 degrees. FMC usually requires a mechanical bender for clean, consistent bends, while ENT can be bent manually, though still with care and control. The goal is smooth, gradual curves that support wire movement without stressing materials.

4. Addressing Environmental Factors

Conduit failure often stems from installing products in environments they weren’t designed to withstand. For example, using standard FMC in damp or wet areas can accelerate corrosion, while exposing ENT to direct sunlight or underground conditions without proper ratings may lead to cracking or deformation.

A key best practice is aligning conduit type with site conditions from the start. For wet locations or outdoor use, Liquid-tight FMC is the proper choice due to its sealed jacket. Standard ENT performs best indoors or within concrete slabs, where it’s protected from UV rays and water. Installers should also be mindful of ambient temperature ranges and ensure all fittings are adequately sealed to prevent moisture ingress.

5. Ensuring Proper Connections and Grounding

Even with the right conduit and layout, poor connections can undermine the entire system. Loose fittings can expose wires, interrupt continuity, or introduce vibration damage. For metallic conduit like FMC, grounding is especially critical to prevent shock hazards and meet code requirements.

All fittings should be listed and compatible with the conduit material, and connections must be tightened thoroughly. For FMC, continuity must be maintained across joints, and proper bonding techniques used to meet NEC Article 250 standards. ENT, being non-metallic, does not conduct electricity, so any required equipment grounding must be handled by running a separate ground conductor within the tubing.

Conclusion

Flexible Metal Conduit (FMC) and Electrical Nonmetallic Tubing (ENT) are essential components in modern electrical systems, each offering unique advantages for specific applications. FMC provides rugged protection with grounding capabilities, making it ideal for areas where mechanical strength and EMI shielding are required. ENT, on the other hand, excels in lightweight, easy-to-install scenarios such as residential or concrete-encased runs.

However, the benefits of these conduit systems can only be fully realized through proper product selection, installation, and adherence to code requirements. Missteps, such as improper sizing, inadequate support, poor bending practices, or misapplication in unsuitable environments can compromise not only the functionality of the system but also safety and code compliance.

By understanding their characteristics, following local guidelines, and applying best practices in the field, installers can ensure that both FMC and ENT deliver long-term performance, durability, and safety. Whether in new construction or retrofit projects, investing in quality materials and precision workmanship pays off in reduced maintenance, greater electrical reliability, and peace of mind.

As electrical infrastructure continues to evolve, particularly with the expansion of energy-efficient and smart systems, knowing when and how to use FMC and ENT will remain a crucial skill for electricians, engineers, and project managers alike.

FAQ

What is FMC conduit?

FMC stands for Flexible Metal Conduit. It is a type of electrical conduit made of a helically wound metal strip, providing flexibility for routing electrical wiring in tight or complex spaces. FMC is commonly used in commercial and industrial settings where vibration or movement may occur, or where conduit needs to navigate around obstacles.

How to cut FMC conduit?

To cut FMC conduit, follow these steps:

- Measure and mark the desired length using a measuring tape and marker.

- Use a rotary tool (like a hacksaw or specialized FMC cutter) to cut along the marked line.

- Deburr the cut ends using a reaming tool or pliers to remove sharp edges.

- Insert an appropriate connector to ensure a secure and code-compliant installation.

Can FMC be used as a ground?

Yes, FMC can serve as an equipment grounding conductor (EGC) if it meets the conditions outlined in NEC Article 250.118(5). Specifically:

The FMC must be continuous and securely fastened.

It must have appropriate fittings listed for grounding.

The total length and conductor size must comply with the NEC grounding provisions.

What is ENT conduit?

ENT (Electrical Nonmetallic Tubing) is a flexible, non-metallic raceway made from PVC. It is lightweight, flame-resistant, and designed for easy installation in walls, floors, and ceilings. ENT is used primarily in indoor residential and commercial applications.

When to use ENT conduit?

Use ENT conduit when:

Flexibility is needed for bends without fittings.

The installation is in dry, indoor locations, such as within walls or poured concrete.

Non-metallic, corrosion-resistant properties are desired.

A lightweight, labor-saving alternative to EMT or PVC is preferred.

Can ENT conduit be used outdoors?

Generally, no. ENT is often used within walls, floors, ceilings, or concrete encased. But it can be used outdoors if have UV inhibitors and approved by the manufacturer and code, but make sure it won’t exposed to direct sunlight for a long time or mechanical damage.

Is ENT conduit waterproof?

No, ENT is not waterproof. It is moisture-resistant, but it is generally recommended for dry locations and not designed to be submerged or exposed directly to water. For wet or damp locations, PVC or Liquid-tight Flexible Conduit (LFMC) should be used instead.

Is ENT conduit plenum rated?

No, ENT is not plenum rated unless it is:

Specifically tested and listed for use in plenum spaces.

Installed according to manufacturer guidelines and local fire codes.

In general, use metallic conduit or plenum-rated alternatives in air-handling spaces.