Table des matières

When planning or installing an electrical conduit system, managing direction changes is inevitable. This is where conduit bends and elbows come into play. Though the terms are often used interchangeably, they serve different roles in the electrical trade and are manufactured and applied in distinct ways.

Understanding the difference between a bend and an elbow is essential for code compliance, system longevity, and installation efficiency. Whether you’re routing conduit around obstacles in a residential project or laying out a commercial electrical system, knowing when and how to use each fitting will save time, reduce errors, and improve the quality of your installation.

This article explores the definitions, types, materials, pros and cons, and installation guidance for bends and elbows. We’ll also compare them side-by-side and offer tips on how to choose the right one for your job.

Key Takeaways

- Bends are usually formed in the field using a bender to create a curved section of conduit, while elbows are pre-manufactured curved fittings used to change conduit direction.

- Both bends and elbows are used to route conduit around obstacles or corners but differ in flexibility, cost, labor, and application.

- Elbows come in standard angles (typically 90°, 45°, 30°, and 22.5°), while bends can be custom-formed to fit unique installation needs.

- Material options for both include PVC, EMT, RMC, IMC, and flexible conduit types, and each has different characteristics related to strength, corrosion resistance, and workability.

- Proper use of bends and elbows is regulated under standards such as NEC (National Electrical Code) and CEC (Canadian Electrical Code), with strict rules on bend radius and number of bends per run.

- Choosing between a bend and an elbow depends on project complexity, conduit type, desired aesthetic, and required mechanical protection.

Understanding Conduit Elbows and Bends

In electrical conduit systems, changes in direction are inevitable. That’s where conduit elbows and bends come into play. While they both serve the same basic function – changing the direction of a conduit run—they differ in form, fabrication, and field application.

Although some electricians may casually use “elbow” and “bend” to refer to any directional change, it’s important to understand the technical differences between the two. This is especially true when selecting components for long cable pulls, high-performance systems, or installations requiring code compliance and mechanical integrity.

What is a Conduit Elbow?

UN coude de conduit is a factory-made, preformed conduit fitting with a specific angle—most commonly 90°, 45°, 30°, or 22.5°. The defining feature of an elbow is its short or fixed-radius turn, which typically forms a sharp angle.

Elbows are used to provide precise, quick changes in conduit direction without requiring on-site bending tools or heat forming. Because they’re pre-made, they offer consistent dimensions and are useful in situations where spacing is tight or bends need to be replicated exactly.

3 Common Types of Conduit Elbows:

- Coude à 90 degrés (Right Angle Elbow)

Most commonly used to make a sharp turn in conduit runs, such as from a wall to a ceiling.

- Coude à 45 degrés

Used for smoother directional changes, often in situations requiring less strain on conductors.

- 22.5° and 30° Elbows

Provide gradual turns and are commonly used in underground or complex layouts to meet bend radius requirements.

Key Characteristics of Conduit Elbows:

Short-radius or fixed-radius curves.

Common angles: 90°, 45°, 30°, 22.5°.

Used in PVC, EMT, RMC, and IMC conduit systems.

Designed for use where sharp turns or space constraints exist.

May include specialty types like inspection elbows (LB, LL, LR) with access covers.

Conseils de pro : Vous souhaitez en savoir plus sur electrical conduit elbow types, sizes, and buying guide? Click the link above to read our last post.

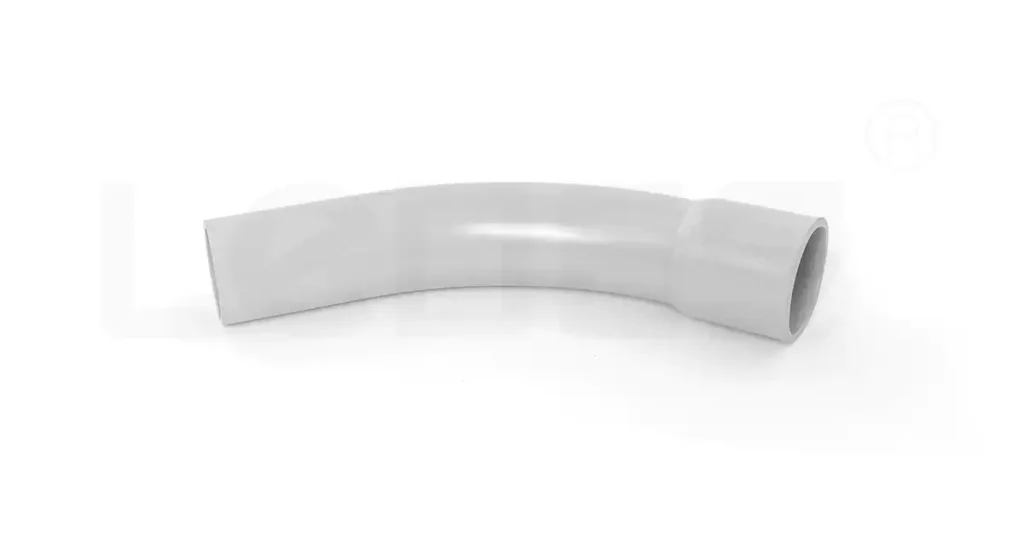

What Is a Conduit Bend?

UN coude de conduit is a curved section of conduit formed on-site using a manual or mechanical bender (for EMT, RMC, IMC) or a heat gun (for PVC). Unlike elbows, bends are not separate fittings – they are formed into the conduit itself.

The key feature of a bend is its smooth, gradual curve, even if it ultimately redirects the conduit by 90°, 45°, or another angle. This reduces friction and stress during conductor pulls.

5 Common Types of Conduit Bends:

- Stub-Up Bend: 90° bend rising from the floor or ceiling, connecting to boxes from below or above.

- Back-to-Back Bend: Two 90° bends in opposite directions, creating U-shaped conduit paths.

- Offset Bend: Two equal-angle bends to shift conduit, avoiding obstacles or moving conduit out of plane.

- Saddle Bend (3-point): A center bend flanked by two equal outer bends, passing over obstructions like pipes or beams.

- Custom Radius Bends: Smooth, user-defined curves, applications needing long pull radius or aesthetics.

The radius of the bend is critical in determining code compliance. NEC and CEC require minimum bend radii depending on the conduit size and conductor type.

Key Characteristics of Conduit Bends:

Gradual curves with varying radii, depending on the tool used.

Often formed on-site, allowing for flexibility in routing.

Suitable for use with EMT, RMC, IMC, and PVC.

Preferred in situations where pulling large conductors or minimizing resistance is important.

Where Do Sweeps Fit In?

While the term “sweep” is often used casually, in industry context, a sweep is simply a long-radius version of a bend or elbow. These are typically either:

Factory-formed sweeps, or

Field-made long-radius bends.

Sweeps are used when:

Long cable runs are involved

Friction must be minimized (e.g., fiber optics, communication cables)

Underground conduit systems require smoother transitions.

Conduit Bends vs. Elbows: What’s the Difference?

While both bends and elbows serve the same essential function — changing the direction of electrical conduit runs, and are often used interchangeably, they differ in many critical ways, including form, creation method, flexibility, cost, and installation practices. This section provides a side-by-side comparison to help determine which option is better suited for specific project needs.

1. Form and Function

Elbows are pre-fabricated fittings, typically made from PVC, steel, or aluminum, that provide a precise directional change, most commonly 90° or 45°. They often feature a shorter radius and are used for tight turns.

Bends, although also available as pre-formed components, are often created by bending a length of conduit using mechanical or heat-assisted methods. They can offer gentler curves and longer radii, sometimes also made as “sweep bends.”

Important note: In many cases, bends can also be supplied as independent pre-formed fittings, complete with bell ends. These bends are still considered “bends” because they are made from conduit (not from molded fittings) and retain the original conduit integrity during the forming process.

2. Degree and Radius Options

Elbows are generally available in standard angles: 90°, 45°, 30°, and 22.5°. They typically come with standard or short radii.

Bends can be custom-formed to nearly any angle or radius, including long sweep configurations that help reduce cable pulling tension. However, standard bend angles like 90° sweep bends or 45° conduit bends are also sold in ready-to-use form.

3. Method of Creation

Elbows are molded or factory-manufactured fittings made separately from the conduit. They are often glued or coupled onto conduit ends.

Bends can be formed from straight conduit sections using a bending machine (for metal) or heat gun (for PVC). However, as you pointed out, they can also be pre-fabricated by manufacturers using heat-formed conduit, not mold-based processes, making them distinct from molded elbows.

4. Customization and Flexibility

Elbows offer limited flexibility, installers are restricted to the set angle and radius.

Bends allow for custom radii and angles depending on project needs, minimizing the number of fittings and joints in a run.

5. Standardization vs. Application-Specific Design

Elbows follow tight industry standards (e.g., UL, NEMA, CSA) for angle, wall thickness, and performance.

Bends, while still needing to meet certain performance requirements, offer greater freedom in design, ideal for complex layouts or long conduit runs with minimal cable stress.

6. Strength and Durability

Elbows, being separate molded pieces, may introduce potential stress points at the connection joints.

Bends, especially long sweeps made from continuous conduit, often provide better mechanical strength and reduce the risk of joint failure or pull damage.

7. Cost and Labor Considerations

Elbows are quicker and easier to install, especially for small directional changes, and cost-effective for basic jobs.

Bends, while potentially requiring more labor or equipment, can save time in cable pulling and reduce coupling needs in longer runs, especially in buried or solar applications.

8. Installation Complexity

Elbows are plug-and-play: just glue or thread them on.

Bends may require on-site bending tools or careful routing, unless using pre-made bend products.

Summary Table

Fonctionnalité | Elbow | Bend |

Pre-fabricated | Yes (molded) | Yes (heat-formed or bent) |

Common Angles | 90°, 45°, others | Any angle, customizable |

Radius | Short or standard | Standard, long, or custom sweep |

Method | Molded fitting | Heat-formed conduit or field-bent |

Flexibilité | Faible | Haut |

Standardization | Haut | Varies |

Force | Joint-dependent | Often stronger as continuous conduit |

Coût | Lower for standard jobs | Higher for custom or long-radius needs |

Installation | Facile | May require bending tools or planning |

Final Note:

Bends and elbows sometimes look the same, and can be called the same, and some elbows are marketed as sweep elbows, which blurs the naming. What matters more than the term is the function and manufacturing method: whether it’s molded as a fitting (elbow) or formed from conduit (bend). Always check product specs, especially when considering cable pulling distances or burial depth.

Pros and Cons of Elbows and Bends

When designing or installing an electrical conduit system, choosing between elbows and bends impacts performance, ease of installation, long-term maintenance, and cost. Both serve the same basic function, changing the direction of the conduit run, but offer different advantages and limitations depending on the application.

Pros and Cons of Elbows

Avantages:

- Standardization and Compliance:

Elbows are manufactured according to industry standards (e.g., ANSI, UL, AS/NZS), ensuring consistent radius, angle, and wall thickness for safety and compatibility. This makes them reliable and code-compliant in regulated environments. - Facilité d'installation :

As pre-formed fittings, elbows save time and reduce the skill needed on-site. Electricians can easily connect elbows with straight conduit sections using couplings or bell ends. - Availability in Multiple Angles:

Standard elbow types (e.g., 90°, 45°, 30°, 22.5°, 11.25°) are widely available in rigid PVC, EMT, IMC, steel, and LSZH, simplifying material selection. - Cost-Effective for Standard Applications:

For common directional changes, elbows are an economical and labor-saving solution, especially in repetitive or modular installations.

Les inconvénients:

- Limited Customization:

Elbows are fixed-angle components and cannot be modified easily to accommodate non-standard bends or on-site obstacles. - Potential for Joint Weakness:

Every elbow introduces a joint that could become a potential point of mechanical or moisture failure if not properly sealed or supported. - Increased Flow Resistance:

Compared to large-radius bends, some elbows may create more resistance for cable pulls, especially sharp 90° elbows.

Pros and Cons of Bends

Avantages:

- Customizable Radius and Angle:

Bends can be fabricated to specific angles and radii using conduit bending tools. This makes them ideal for non-standard layouts, retrofits, or when minimizing cable tension is important. - Fewer Joints:

Bending the conduit reduces the number of fittings and joints, improving structural integrity and reducing potential points of failure. - Improved Cable Pulling Performance:

Long-radius bends offer smoother transitions, reducing friction and stress on cables—particularly important in high-voltage, fiber optic, or long conduit runs. - Visual Continuity:

Bends create a more streamlined appearance, especially in exposed conduit installations in data centers, public buildings, or solar arrays.

Les inconvénients:

- Requires Skilled Labor:

On-site bending needs experienced electricians and proper tools (e.g., hydraulic benders, heat benders for PVC), which can increase labor costs and time. - Inconsistent Results if Done Poorly:

Manual or inconsistent bending can result in deformation, buckling, or out-of-spec geometry, affecting performance and code compliance. - Higher Upfront Cost for Custom Bends:

Custom-fabricated or factory-supplied long-radius bends are typically more expensive than standard elbows. - Storage and Handling Challenges:

Long or large-radius bends can be more difficult to transport, store, and maneuver on-site compared to compact elbow fittings. - Space Considerations: Long-radius bends may require more space than standard elbows, which can be a constraint in tight enclosures.

Summary Table

Aspect | Elbows | Bends |

Personnalisation | Limited to standard angles/radii | Highly customizable |

Installation Time | Quick and easy | Slower due to fabrication |

Labor Skill | Minimal | Requires skilled labor |

Wire Pulling Friction | Higher (sharper turns) | Lower (smoother curves) |

Structural Strength | Adequate | Often stronger (fewer joints) |

Availability | Widely available | May need pre-order or on-site creation |

Conformité au code | Pre-certified | Must ensure compliance for field bends |

Coût | Lower for standard uses | Higher for custom setups |

Materials and Construction of Bends and Elbows

Understanding the materials and construction methods of conduit bends and elbows is critical when selecting the right solution for your electrical installation. These components must meet the demands of mechanical stress, environmental exposure, and electrical safety. Here’s how they compare:

Common Materials Used

Both bends and elbows are available in a range of materials, depending on the application and environmental requirements. The most common materials include:

- Rigid PVC (Polyvinyl Chloride): Lightweight, non-conductive, corrosion-resistant. Widely used in indoor/outdoor, dry, damp, or underground settings.

- Acier galvanisé: Offers high mechanical strength and protection against impact; suitable for heavy-duty industrial applications.

- Aluminium: Lightweight and corrosion-resistant; often used where weight is a concern.

- Stainless Steel: Best for highly corrosive environments; offers excellent durability and chemical resistance.

- Low Smoke Halogen-Free (LSZH) Thermoplastics: Ideal for confined spaces (e.g., transit, data centers); reduces toxic smoke in fire events.

Construction of Elbows

Elbows are factory-manufactured fittings, pre-formed to specific angles—typically 90°, 45°, 30°, and 22.5°. They often come in standard radii (e.g., short-radius, long-radius, or sweep-radius) and may be offered with:

Bell ends for solvent welding (in PVC)

Threaded ends (in metallic elbows)

Smooth ends for coupling or gluing

Manufacturing methods vary based on material:

PVC elbows: injection molded or heat-formed and cooled in pre-set molds.

Metallic elbows: bent using hydraulic or mandrel benders with precision to avoid kinks or structural weakening.

Construction of Bends

Bends are generally made by heating and shaping the conduit itself, either in the field or in a controlled factory environment. Unlike elbows, which are distinct components, bends can be:

Hand-bent on-site using bending tools (for EMT or PVC)

Machine-bent to exact radii using hydraulic or electric benders

Pre-fabricated bends offered by manufacturers—these resemble elbows but are made by bending standard conduit stock, not molding

These pre-fabricated bends can also feature bell ends, be labeled with specific angles (e.g., 90°, 45°), and be sold as standalone pieces. They are smoother in curvature, often used when a sweep is required for easier cable pulling.

Code Compliance for Elbows and Bends

When installing elbows and bends in electrical conduit systems, it is critical to comply with local and international electrical codes to ensure safety, functionality, and inspection approval. Code compliance covers several key aspects including bend radius, material standards, number of bends allowed, and suitability of fittings in specific environments.

National Electrical Code (NEC) – USA

The NEC (NFPA 70) outlines detailed rules for conduit bends and fittings in Articles 344, 352, 358, and others, depending on conduit type.

Key NEC requirements include:

- Total Bend Limit: No more than 360 degrees of bends (total) between pull points, such as boxes or access points).

- Minimum Bending Radius: Specific to conduit type (EMT, PVC, RMC, etc.). Sharp bends, like those in elbows, must meet radius specifications to avoid cable damage.

- Fittings Must Be Listed or Approved: Elbows and bends should be UL Listed (such as UL 651 for PVC elbows) to ensure quality and compatibility.

- Conduit Support and Spacing: The placement of elbows affects how conduit is supported. Elbows must not violate support spacing requirements.

Canadian Electrical Code (CEC) – Canada

The CEC (CSA C22.1) provides similar provisions to the NEC, emphasizing:

- Use of CSA-certified elbows and bends (e.g., CSA C22.2 No. 211.2 for rigid PVC fittings).

- Respecting allowable bending radius and degree of total bends.

- Provisions for expansion, contraction, and fittings in outdoor or wet locations.

AS/NZS 3000 (Wiring Rules) – Australia and New Zealand

The AS/NZS 3000 outlines:

- Bends and elbows must be made without damage to the conduit or reduction of internal diameter.

- Only approved prefabricated bends and elbows complying with AS/NZS 2053 are permitted.

- Bends must not adversely affect cable installation, highlighting concerns with sharp elbows increasing friction during pulling.

International Standards (IEC)

IEC 61386 and related harmonized documents provide:

- Requirements for minimum bend radii.

- Performance classes for flexibility, compression resistance, and impact for elbows and preformed bends.

- CE marking or third-party certifications for market access.

UL/CSA/IEC Certification for Products

Most elbows and bends are subject to third-party certification:

- UL651 : For PVC elbows used with Schedule 40/80 conduit.

- CSA C22.2 No. 211.2: For rigid nonmetallic conduit fittings in Canada.

- IEC 61386-21/22: International standard for conduit systems and their fittings.

- AS/NZS2053: Covers PVC conduit fittings (Australia/New Zealand).

Best Practices for Installation & Common Mistakes

Proper installation of conduit elbows, bends, and sweeps is essential to maintain the integrity of the electrical system, ensure code compliance, and reduce long-term maintenance issues. Whether working with rigid PVC, EMT, IMC, or flexible conduit systems, the following practices can help achieve a safe, efficient, and code-compliant installation.

Best Practices for Installation

1. Plan the Path Before Bending or Fitting

Use detailed layout drawings or site markings to visualize routing and transitions.

Consider distances, obstructions, and the number of directional changes early in the design.

2. Use the Correct Radius and Angle

Follow NEC or local code requirements for minimum bending radius, especially for larger conduit sizes.

Use sweeps or large-radius bends where wire pulling is required across long runs.

3. Minimize the Number of Bends

NEC recommends a maximum of 360 degrees of total bends between pull points (including all elbows and bends).

Use junction boxes or pull boxes when more direction changes are needed.

4. Match Fittings to Conduit Type and Material

Use elbows and bends made from the same material and rated for the same application (e.g., rigid PVC with PVC fittings, EMT elbows with EMT).

Ensure bell-end or threaded connections are properly sealed and seated.

5. Ensure Proper Support and Securing

Support bends and elbows according to code spacing, typically within 3 ft of a box or fitting, and every 10 ft for straight runs.

Use appropriate clamps and saddles to avoid deformation or movement.

6. Allow for Expansion and Contraction

In PVC conduit systems, consider expansion fittings especially when bends are used outdoors or exposed to temperature variations.

7. Deburr and Clean Cut Edges

Sharp edges at the bend or cut end can damage conductors. Deburr all cuts and use bushings if necessary.

8. Perform Gentle Wire Pulling

Pull wires slowly and lubricate if necessary, particularly when navigating through multiple or tight bends and elbows.

Choose bends over elbows when easier wire pulling is desired.

8 Common Installation Mistakes You Need to Avoid

1. Over-Bending or Kinking the Conduit

Over-bending can lead to flattened conduit sections or compromised strength.

Use the proper bending tools (manual benders, hydraulic benders) rated for the conduit size.

2. Using Incorrect Elbow or Bend Angle

Mistaking a 45° elbow for a 90°, or vice versa, can misalign the conduit run and increase friction on wire pulls.

3. Mixing Incompatible Materials

For example, combining steel EMT elbows with PVC conduit without proper transition fittings can result in mechanical failure and code violations.

4. Exceeding 360 Degrees of Total Bend

Failure to follow this rule makes wire pulling difficult or impossible without damaging the wire insulation.

5. Installing Without Proper Supports

Unsupported bends may shift over time, especially in outdoor or underground applications.

6. Poor Joint Sealing in Outdoor or Wet Locations

Water intrusion is a common issue when elbow or bend connections aren’t properly sealed using solvent cement (for PVC) or watertight connectors (for metal systems).

7. Tight Elbows in Long Pull Runs

Sharp elbows increase the risk of cable damage during pulls. Use sweeps or large-radius bends in long conduit runs.

8. Cutting Factory-Made Bends or Elbows

Cutting preformed elbows or sweeps to fit can alter their angle or end type, compromising their performance and compliance.

How to Choose the Right Electrical Fitting

Selecting between a conduit bend and an elbow isn’t just about personal preference, it’s about matching the fitting to the installation requirements, code compliance, cable protection, and budget. The right choice can simplify installation, reduce long-term maintenance, and improve system performance.

1. Consider the Cable Pulling Requirements

Long Runs or Large Cable Bundles: Choose bends or long-radius sweeps to reduce pulling friction and protect conductor insulation.

Short Runs or Minimal Cable Pulling: Standard elbows are often sufficient and more cost-effective.

2. Evaluate Space Constraints

Tight Spaces: Short-radius elbows allow for sharper turns in compact areas like control panels or conduit racks.

Open or Accessible Areas: Bends or sweeps can be used for smoother curves without spatial limitations.

3. Match the Application Environment

Outdoor or Direct Sunlight: Use UV-resistant PVC bends or elbows, or galvanized/stainless steel for durability.

Corrosive or Wet Locations: Opt for stainless steel, fiberglass, or LSZH thermoplastic fittings with watertight seals.

Emplacements dangereux : Select elbows or bends certified for explosive atmospheres (e.g., explosion-proof conduit fittings).

4. Check for Code Compliance

Ensure elbows and bends meet relevant NEC, CEC, AS/NZS, or IEC requirements for:

Bend radius

Total number of bends

Material and marking standards (e.g., UL, CSA, IEC, AS/NZS certifications)

5. Balance Labor Cost and Project Timeline

Tight Deadlines or Limited Skilled Labor: Prefabricated elbows save time and reduce the need for on-site bending.

Custom Routing or Non-Standard Angles: Field-bent conduit provides flexibility for complex layouts.

6. Factor in Structural Strength Needs

High Mechanical Stress Areas: Continuous conduit bends may offer greater structural integrity and fewer joints.

Moderate to Low Stress Areas: Standard elbows perform adequately and are easier to replace if damaged.

Conclusion

While conduit bends and elbows may appear similar at first glance and use interchangeably, understanding their subtle differences can have a major impact on the performance, safety, and efficiency of an electrical installation. Elbows offer quick, standardized solutions for sharp changes in direction, making them a go-to choice for projects with limited space or tight schedules. Bends, with their smoother curvature, excel in protecting cables during long pulls, accommodating custom routing, and providing a cleaner visual finish in exposed runs.

Choosing between the two is not about declaring one superior to the other, it’s about matching the fitting to the project’s needs. Factors like cable pulling requirements, available space, environmental conditions, structural strength, and code compliance all influence the best choice. In many professional installations, the optimal approach blends both solutions: elbows for efficiency and precision, bends for performance and cable protection.

By understanding the definitions, types, pros and cons, materials, code requirements, and installation best practices for elbows and bends, electricians and project managers can make informed decisions that enhance both the immediate and long-term success of their conduit systems.

Frequently Asked Questions (FAQs)

Is it better to bend a pipe or use an elbow?

It depends on the project. Bending conduit (especially with a long radius) is better for long cable pulls because it reduces friction and stress on the wire. Elbows are quicker to install, standardized, and ideal for tight spaces or when consistent angles are needed.

What is the bend rule for conduit?

The NEC and many other codes limit the total bends between pull points to 360 degrees. This includes all bends and elbows in the run.

What is a conduit bend?

A conduit bend is a curved section of conduit, either formed in the conduit itself or pre-manufactured that changes the direction of the run without a sharp angle.

What is the difference between long bend and short bend?

A long bend (long-radius bend) has a gradual curve that reduces pulling tension. A short bend (short-radius bend) changes direction quickly in a smaller space but increases pulling resistance.

What are the disadvantages of pipe bending?

Requires special tools or machines

Risk of flattening or kinking if done improperly

More labor-intensive than installing a pre-made elbow

May require more skill to achieve precise angles

What are some common mistakes to avoid when bending conduit?

Over-bending or kinking the conduit

Exceeding 360° total bends between pull points

Using the wrong bending tool or shoe size

Not deburring sharp edges after cutting

Failing to account for shrinkage when bending

Can I bend PVC conduit?

Yes. You can bend PVC conduit using a heat source (like a heat blanket or hot gun) to soften it. Always follow manufacturer instructions and avoid overheating.

What is a bend or elbow conduit?

A bend is a curved section of conduit for directional change, usually with a gradual radius. An elbow is a pre-formed fitting with a set angle (like 90° or 45°), often with a sharper radius.

What is the difference between short elbow and long elbow?

Short elbow (short-radius elbow): Smaller radius, sharper turn, saves space but increases wire pulling difficulty.

Long elbow (long-radius elbow): Larger radius, smoother turn, easier for pulling wires, but requires more space.

What is a safe bend radius?

A safe bend radius is the minimum radius you can bend conduit or cable without damaging it. It’s specified by code or manufacturer and depends on conduit size and type.

What is the difference between a pipe and an elbow?

A pipe (or conduit) is a straight length used to carry fluids, gases, or electrical wiring. An elbow is a fitting that changes the direction of that pipe or conduit.

What is the function of a conduit elbow?

To change the direction of a conduit run at a fixed angle while maintaining internal diameter for wire passage.

How to bend a PVC electric pipe?

Mark the bend location

Heat the PVC evenly with a heat blanket or hot box until flexible

Bend to the desired angle using a form or jig

Hold in place until cooled and hardened

What do pipe fittings do?

Pipe fittings connect, change direction, branch, or terminate a piping or conduit system.

How to connect two pieces of PVC conduit?

Use a PVC coupling with solvent cement. Apply primer (if required), then solvent cement to both ends, push together fully, and hold until set.