Tabla de contenido

Cuando un proyecto requiere un tendido de conductos flexible, dos tipos de conductos se destacan constantemente como soluciones ideales: conducto metálico flexible (FMC) y Tubería eléctrica no metálica (conducto de otorrinolaringología). Ya sea que esté navegando en espacios reducidos, sorteando obstáculos o diseñando un sistema con accesibilidad futura en mente, tanto los conductos FMC como los tubos ENT ofrecen la flexibilidad y la protección necesarias para una instalación eléctrica segura y eficiente.

Estos conductos se utilizan ampliamente en entornos residenciales, comerciales e industriales ligeros, donde los conductos rígidos simplemente no son prácticos. Si bien comparten cierto grado de flexibilidad, difieren significativamente en cuanto a material, requisitos normativos, durabilidad física y rendimiento ambiental.

Por qué es importante comprender la diferencia

Elegir entre conductos eléctricos FMC y conductos ENT no es solo una cuestión de preferencia, sino una decisión que afecta la seguridad, el cumplimiento normativo, el costo y la confiabilidad a largo plazo. El FMC, con su resistente construcción metálica, ofrece excelente protección mecánica y conexión a tierra inherente. El conducto ENT, por otro lado, es ligero, fácil de instalar e ideal para entornos de bajo impacto, como cavidades en paredes interiores o techos.

Comprender las fortalezas, las limitaciones y los mejores escenarios de uso de los conductos metálicos flexibles y los tubos eléctricos no metálicos le garantiza que puede diseñar e instalar un sistema que cumpla con los requisitos técnicos y reglamentarios de su proyecto y, al mismo tiempo, optimice los costos de mano de obra y materiales.

¿Qué es FMC Conduit?

El conducto metálico flexible (FMC), también conocido informalmente como Greenfield o simplemente flexible, es un tipo de conducto metálico diseñado para el tendido flexible del cableado eléctrico. A diferencia de los sistemas de conductos rígidos que requieren codos y cortes extensos, el conducto eléctrico FMC ofrece una vía flexible y adaptable que simplifica la instalación en zonas estrechas, irregulares o propensas a vibraciones.

Definición y construcción

El FMC se construye enrollando helicoidalmente una tira metálica acanalada y autoenclavada, generalmente de aluminio o acero, para formar un tubo hueco. Esta construcción en espiral crea un conducto flexible, pero con protección mecánica, a través del cual se pueden introducir conductores eléctricos. El interior suele ser lo suficientemente liso como para minimizar la abrasión del cable, y la forma del conducto le permite doblarse libremente sin mantener una forma fija, lo que resulta ideal para sortear obstáculos o atravesar espacios arquitectónicos reducidos.

El FMC no mantiene una curvatura permanente, lo que lo distingue de otros tipos de conductos flexibles. Esta característica le permite adaptarse a las vibraciones del sistema y a las estructuras móviles, lo que lo hace ideal para instalaciones en conexiones de equipos, cavidades en techos o proyectos de modernización.

Materiales utilizados en FMC

El conducto FMC generalmente está hecho de:

- Acero galvanizado: Ofrece alta resistencia mecánica y resistencia a la corrosión, adecuado para lugares interiores secos.

- Aluminio: Ligero y resistente a la corrosión, a menudo elegido cuando es importante minimizar el peso o la interferencia magnética.

Ambos materiales son resistentes al fuego y cumplen con los estándares UL clave en términos de rendimiento mecánico y eléctrico.

Características y ventajas clave de FMC

El conducto metálico flexible (FMC) es valorado por su adaptabilidad y protección mecánica, especialmente en entornos donde los conductos rígidos resultan demasiado restrictivos. Desde edificios comerciales hasta entornos industriales y renovaciones residenciales, el FMC ofrece diversas ventajas que lo convierten en la opción preferida para ciertas instalaciones eléctricas.

1. Alta flexibilidad

Una de las ventajas más significativas del conducto FMC es su capacidad de doblarse libremente sin herramientas especiales. A diferencia de los sistemas rígidos que requieren codos prefabricados o cortes precisos, el FMC se puede instalar fácilmente alrededor de obstáculos estructurales, a través de cavidades en paredes y en armarios eléctricos con un mínimo esfuerzo. Esta flexibilidad se traduce en:

- Instalaciones más rápidas

- Modernizaciones simplificadas

- Necesidad reducida de accesorios y juntas

El FMC es particularmente útil en áreas sujetas a vibraciones, como conexiones de motores y equipos, donde los conductos rígidos serían más propensos a sufrir fatiga o daños.

2. Protección mecánica y durabilidad

A pesar de su flexibilidad, el conducto eléctrico FMC ofrece un alto nivel de protección mecánica. Su construcción metálica ayuda a proteger los conductores contra:

- Impacto físico

- Fuerzas aplastantes

- roedores o insectos

Esto hace que FMC sea una opción inteligente en entornos que exigen tanto flexibilidad de enrutamiento como un grado de protección del conductor, como salas mecánicas, espacios de servicios públicos y techos comerciales.

3. Resistencia al fuego y seguridad

El FMC se fabrica con metales incombustibles, como el acero galvanizado o el aluminio, lo que significa que ofrece propiedades ignífugas que muchas alternativas plásticas o no metálicas no pueden ofrecer. Esto puede ser un factor crítico en instalaciones de alto riesgo o sensibles a las normativas.

Además, FMC es adecuado para su uso en sistemas que requieren protección contra interferencias electromagnéticas (EMI), ya que su cuerpo metálico puede ayudar a reducir la transmisión EMI, especialmente en entornos sensibles a los datos.

4. Capacidad de puesta a tierra (condicional)

Según el Código Eléctrico Nacional (NEC), el FMC puede servir como conductor de puesta a tierra de equipos, pero solo bajo ciertas condiciones, basadas en la longitud, el tamaño y el amperaje del circuito. En tramos cortos con calibres comerciales adecuados, el FMC puede eliminar la necesidad de un cable de puesta a tierra independiente, ahorrando tiempo y costos de material.

Sin embargo, para recorridos más largos o circuitos de mayor amperaje, se debe tender un conductor de tierra dedicado a través del conducto para garantizar el cumplimiento del código y la seguridad.

5 aplicaciones comunes del conducto FMC

El conducto metálico flexible (FMC) es una solución versátil que se utiliza en una amplia gama de instalaciones eléctricas. Su combinación única de flexibilidad, protección mecánica y blindaje metálico lo hace especialmente adecuado para diseños complejos, conexiones de equipos y trabajos de modernización. A continuación, se presentan las aplicaciones más comunes y casos reales donde el conducto FMC resulta ser la opción ideal.

1. Conexiones de equipos

El FMC suele ser el conducto ideal para conectar motores, transformadores, unidades de climatización (HVAC) y generadores. Estos tipos de equipos suelen producir movimiento o vibración durante su funcionamiento, lo que podría dañar el conducto rígido con el tiempo. La capacidad del FMC para flexionarse y absorber el movimiento ayuda a prevenir:

Aflojamiento de terminaciones

Fatiga del conductor

Grietas o roturas de conductos

Esto hace que el FMC sea esencial en salas mecánicas, plantas industriales e instalaciones comerciales donde la confiabilidad es fundamental.

2. Espacios de instalación estrechos o irregulares

En edificios con espacio limitado o estructura irregular, FMC simplifica el tendido de una forma que los conductos rígidos no pueden. Su diseño flexible permite a los electricistas serpentear el conducto alrededor de obstrucciones.

Esto hace que FMC sea ideal para proyectos de modernización, remodelación o cualquier instalación que deba transitar por espacios confinados o terminados sin una construcción mayor.

3. Edificios comerciales e institucionales

En edificios de oficinas, escuelas y hospitales, el FMC se utiliza para:

Cableado del circuito derivado

Conexiones de iluminación

Alimentadores para tabiques modulares

Suministro de energía a través de la rejilla del techo

Su protección metálica que cumple con el código y su flexibilidad de bajo perfil lo hacen práctico en estos entornos, particularmente donde se requiere estética o una interrupción mínima.

4. Sistemas de energía temporales

En instalaciones temporales, como obras de construcción o eventos, el FMC permite un cableado flexible y rápido entre equipos y paneles. Su fácil manejo y reutilización permiten a los contratistas:

Ajuste las configuraciones rápidamente

Minimizar el desperdicio de material

Cumplir con los requisitos de seguridad para cableado expuesto

5. Centros de datos y salas de comunicaciones

FMC puede proporcionar blindaje EMI en entornos donde la integridad de los datos es crucial. Su carcasa metálica ayuda a contener y bloquear las interferencias electromagnéticas, lo cual es esencial al instalar líneas eléctricas cerca de equipos de comunicación o TI sensibles.

En resumen, los conductos FMC ofrecen la flexibilidad, la resistencia y la protección homologada que requieren los sistemas eléctricos especializados y de alto rendimiento. Ya sea para entornos dinámicos como salas de máquinas o para renovaciones con espacio limitado en techos de oficinas, FMC ofrece un valor práctico en diversos sectores.

Opción de conducto metálico flexible hermético

En aplicaciones donde la humedad, el aceite o la exposición a la intemperie son un problema, el conducto metálico flexible (FMC) estándar puede no ser suficiente. Es aquí donde el conducto metálico flexible hermético (LFMC) se convierte en la solución preferida. El LFMC aprovecha la flexibilidad y la resistencia del FMC tradicional, pero añade una importante capa de protección ambiental.

¿Qué es LFMC?

El conducto metálico flexible hermético (LFMC) es un tipo de conducto metálico flexible con una cubierta exterior protectora, generalmente de PVC (cloruro de polivinilo). En su interior, utiliza el mismo núcleo helicoidal entrelazado de acero o aluminio que el FMC estándar, pero el exterior está sellado contra la humedad, los aceites y los agentes corrosivos.

Esta construcción permite a LFMC combinar:

- La protección mecánica y la capacidad de puesta a tierra de los conductos metálicos

- La resistencia a la humedad de un sistema sellado y recubierto de plástico

- La flexibilidad de una estructura tipo bobina

¿Dónde se utiliza LFMC?

El LFMC es especialmente valioso en lugares húmedos o peligrosos, donde los tubos FMC o ENT estándar no cumplen con los requisitos de la normativa. Sus aplicaciones típicas incluyen:

- Conexiones de equipos exteriores (por ejemplo, unidades de aire acondicionado, iluminación, bombas)

- Lavaderos de automóviles, plantas de procesamiento de alimentos o áreas de lavado industrial

- Conexiones subterráneas (cuando se hace la transición de conductos enterrados a equipos de superficie)

- Instalaciones marinas y a bordo

- Azoteas comerciales y estacionamientos

- Instalaciones de la industria del petróleo y el gas

4 ventajas del conducto LFMC

LFMC ofrece varias ventajas clave sobre el FMC estándar:

- Resistente al agua y a la corrosión: Ideal para ambientes húmedos o corrosivos.

- Chaqueta resistente a los rayos UV: Adecuado para exposición prolongada al aire libre.

- Retardante de llama: Añade protección contra incendios donde sea necesario

- Mantiene la flexibilidad: Fácil de instalar en espacios reducidos o incómodos.

Para garantizar la seguridad y el cumplimiento, es esencial utilizar LFMC listados por UL y accesorios aprobados adecuados para el entorno.

Códigos y normas para conductos FMC

Para garantizar instalaciones eléctricas seguras y conformes, los conductos metálicos flexibles (FMC) deben cumplir con las normas y códigos regulatorios específicos de Estados Unidos y Canadá. Estas regulaciones definen las aplicaciones permitidas, las características de construcción, las normas de instalación y los requisitos de seguridad para los FMC y, en algunos casos, para los LFMC.

Descripción general de los códigos y normas FMC

- Código Eléctrico Nacional (NEC) – Artículo 348 (CMF)

- Código Eléctrico Canadiense (CEC) – Sección 12-1000 a 12-1012 (FMC)

- UL 1 – Conducto metálico flexible

- CSA C22.2 N.º 56-17 – Conducto metálico flexible y conducto metálico flexible estanco a líquidos

Artículo 348 del NEC: Conducto metálico flexible (FMC)

El Artículo 348 del Código Eléctrico Nacional (NEC) es la principal norma que rige las instalaciones de FMC en EE. UU. A continuación, se presenta un resumen de sus principales disposiciones:

Usos permitidos

El FMC se puede utilizar tanto en zonas expuestas como ocultas dentro de edificios. Es ideal para tramos cortos de luminarias o equipos que puedan necesitar ser trasladados o ajustados posteriormente.

Usos no permitidos

No se puede instalar FMC:

En lugares húmedos o mojados

En entornos peligrosos o inflamables (a menos que esté específicamente permitido)

Empotrado en hormigón o bajo tierra

Donde pueda estar expuesto a aceite, gasolina u otras sustancias dañinas.

En huecos de ascensor, a menos que se apliquen excepciones

Cuando esté sujeto a daños físicos

Limitaciones de tamaño

El tamaño comercial máximo permitido para FMC es de 4 pulgadas (designador métrico 103).

El tamaño más pequeño (3/8 de pulgada) solo está permitido en aplicaciones específicas de longitud corta, como cables de motor o conexiones de accesorios, y generalmente no supera los 6 pies de largo.

Límites de llenado del conductor

La cantidad de cables dentro del conducto está limitada por las tablas de llenado NEC para evitar el sobrecalentamiento.

Hay una tabla de llenado especial para FMC de 3/8 de pulgada, según el tipo de cable y el aislamiento.

Sólo se permite un conductor de puesta a tierra del equipo, además de los cables que transportan corriente.

Reglas de flexión

El FMC se puede doblar a mano, pero el radio de curvatura debe ser lo suficientemente amplio para evitar dañar el conducto.

La cantidad total de curvatura (en grados) de caja a caja no puede superar los 360 grados.

Apoyo y protección del FMC

El FMC debe estar bien fijado:

- Dentro 12 pulgadas de cada caja, gabinete o terminación

- Al menos cada 4,5 pies (1,4 metros) a lo largo su carrera

Hay excepciones para lugares donde el soporte no es práctico, como dentro de paredes terminadas o para conexiones de accesorios flexibles.

Requisitos de conexión a tierra y unión

El FMC puede servir como ruta de conexión a tierra, pero sólo si no se necesita flexibilidad después de la instalación.

Si el FMC se utiliza para equipos que se mueven o vibran, se debe instalar un conductor de tierra de equipo separado.

Los puentes de unión y los conductores de puesta a tierra deben seguir las reglas NEC.

Requisitos del Código Eléctrico Canadiense para FMC

Según el Código Eléctrico Canadiense (CEC), el FMC se agrupa con el conducto metálico rígido (RMC), y ambos se rigen por normas específicas (Secciones 12-1000 a 12-1014). Esto es lo que necesita saber al trabajar con FMC en instalaciones canadienses:

Usos

Se puede utilizar FMC en edificios construidos con materiales combustibles o no combustibles.

Se utiliza a menudo en conexiones cortas y flexibles a equipos o accesorios, especialmente cuando se espera algún movimiento o reposicionamiento.

Límites de tamaño mínimo

En general, no se permiten conductos de tamaño comercial menor al 16.

Sin embargo, se permite el tamaño comercial 12 FMC para tramos cortos de hasta 1,5 metros para conectar equipos.

Esto hace que FMC sea ideal para conexiones finales donde se necesita flexibilidad.

Requisitos de soporte y seguridad

- El FMC debe asegurarse a intervalos no mayor de 1,5 metros.

- También debe fijarse a una distancia de 300 mm de cada caja de salida o accesorio.

- Excepciones: No es necesario asegurar el FMC cuando se “pesca” a través de paredes o en tramos cortos (menos de 900 mm) en puntos de conexión que necesitan flexibilidad.

Conductores dentro de FMC

Los cables instalados en FMC deben cumplir con la Regla 12-910, garantizando un aislamiento adecuado, clasificación de temperatura y límites de llenado.

El FMC se considera como una canalización y debe dimensionarse adecuadamente para evitar el sobrecalentamiento de los conductores.

UL 1 - Norma para conductos metálicos flexibles (FMC)

La norma UL 1 describe los requisitos esenciales de construcción y rendimiento para FMC, garantizando la seguridad, flexibilidad y durabilidad en las instalaciones eléctricas. A continuación, se presenta una descripción general simplificada de las áreas clave que abarca la norma.

Construcción y materiales

El FMC está hecho de tiras de acero o aluminio.

Acero: Debe ser de acero al carbono con una resistencia a la tracción mínima de 34 000 psi y libre de óxido o sarro antes de ser recubierto con zinc.

Aluminio: También debe cumplir con una resistencia a la tracción mínima de 34 000 psi y tener un contenido de cobre ≤0,40%.

Calidad de la tira:

La tira debe ser uniforme en ancho y espesor. Los empalmes (si los hay) no deben afectar la resistencia del conducto ni su diámetro interior.

Convoluciones:

El número de circunvoluciones (crestas espirales) debe cumplir requisitos mínimos de flexibilidad y resistencia.

Superficie interior:

La superficie interior debe ser lisa y libre de rebabas o bordes afilados para proteger el cableado durante la instalación.

Dimensiones

Espesor de la tira:

El espesor mínimo se define según el tamaño comercial. Tipos especiales como XRWFMC pueden usar tiras más delgadas si cumplen con todas las pruebas requeridas.

Diámetros interiores y exteriores:

Tanto los diámetros internos como externos deben estar dentro de las tolerancias especificadas por UL para garantizar un ajuste adecuado y seguridad en la aplicación.

Requisitos de desempeño

Para garantizar la durabilidad, seguridad y conformidad de los conductos flexibles de acero y aluminio, se realizan diversas pruebas de rendimiento clave de acuerdo con las normas. Estas incluyen:

Prueba de recubrimiento de zinc

Esto evalúa la calidad del recubrimiento de zinc, tanto en la banda de acero antes del conformado como en el conducto terminado. El recubrimiento debe resistir la deposición de cobre durante la inmersión en una solución de sulfato de cobre, lo que garantiza la protección contra la corrosión y un rendimiento a largo plazo.

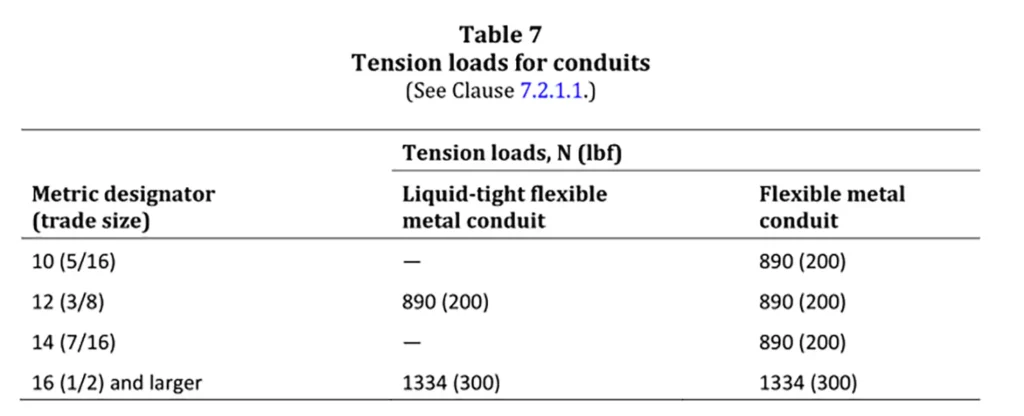

Prueba de tensión

El conducto terminado debe soportar una carga de tracción especificada (300 lbf) sin abrirse ni separarse, verificando su resistencia mecánica bajo tensión.

Prueba de flexibilidad

El conducto se dobla alrededor de una superficie cilíndrica de un radio designado para confirmar que mantiene la integridad estructural y no abre ni expone la superficie interna.

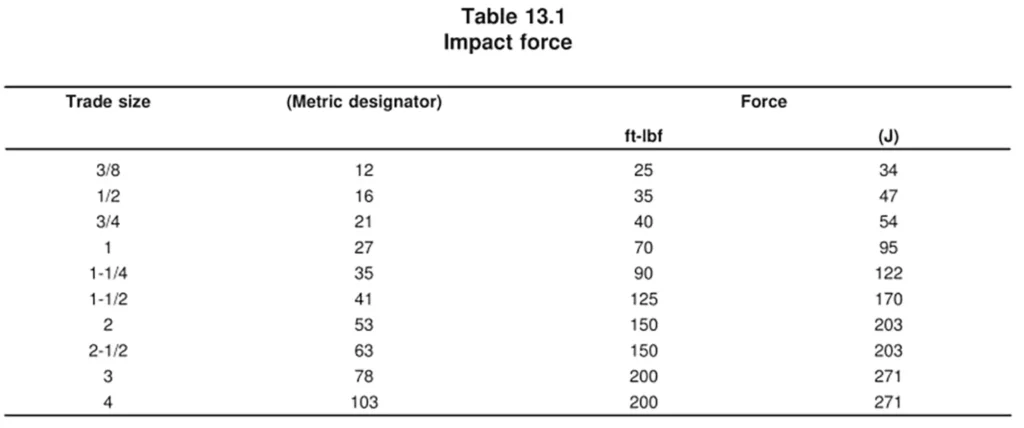

Prueba de resistencia al impacto (para tipos de pared reducida)

Esta prueba evalúa la capacidad del conducto para soportar impactos físicos sin fallar, lo cual es fundamental para entornos de instalación exigentes.

Requisitos de calificación

Identificación de fábrica (se requiere identificación si el fabricante tiene más de una fábrica):

Nombre o marca comercial del fabricante.

Identificación del material:

Los conductos flexibles de aluminio deben estar marcados con las letras “AL”.

Intervalo de marcado: No más de 12 pulgadas (305 mm).

Etiqueta en cada bobina:

Cada bobina de conducto flexible de acero o aluminio debe tener una etiqueta o marca que muestre:

a) Identificación del fabricante

Nombre, nombre comercial u otra identificación distintiva.

b) Fecha de fabricación

Por mes y año.

c) Tamaño del comercio

Tamaño nominal del conducto.

d) Aviso de compatibilidad del conector

Advertencia: “Utilizar únicamente con conectores destinados a este tipo de conducto”.”

El embalaje del conector también debe estar marcado para indicar la compatibilidad:

“FMC”, “FEFMC”, “ALFMC”, etc., según el tipo y el material.

CSA C22.2 No.56-17 - Norma para FMC y LFMC

La norma CSA C22.2 n.º 56-17 es una norma para conductos metálicos flexibles y conductos metálicos flexibles estancos a líquidos. Describe los requisitos de construcción, dimensiones, marcado y rendimiento. A continuación, se presenta información clave.

Construcción y material

El FMC está hecho de tiras de acero recubiertas de zinc o aluminio (el LFMC puede utilizar bronce, acero recubierto de zinc o aluminio).

Todas las tiras deben tener un espesor y ancho uniformes.

El interior del conducto debe ser liso y libre de bordes afilados para evitar dañar los cables.

Tanto los diámetros internos como los externos deben cumplir límites específicos para garantizar un ajuste adecuado y un llenado seguro del conductor.

Chaqueta termoplástica (solo LFMC)

LFMC debe tener una cubierta termoplástica general:

Espesor mínimo requerido (según Tabla 4).

El diámetro exterior debe permanecer dentro de los límites (según la Tabla 5).

La chaqueta proporciona protección hermética a los líquidos.

Requisito de marcado

Los FMC que cumplan con las normas deben estar claramente marcados con el nombre o la marca comercial del fabricante y el tamaño comercial.

Los FMC fabricados en aluminio deben estar marcados con “AL”, en relieve o sangrado cada 150 mm (6 pulgadas).

Para LFMC: Debe incluir “CONDUCTO HERMÉTICO” en la cubierta exterior,

LFMC debe estar marcado con clasificaciones de temperatura, SUN RES si está clasificado.

Requisitos de pruebas de rendimiento

Los FMC se prueban principalmente para verificar su robustez mecánica y continuidad eléctrica en condiciones de instalación normales y extremas. Se requieren las siguientes pruebas:

Prueba de tensión

El FMC terminado debe soportar una carga de tensión axial (como se indica en la tabla CSA) durante un tiempo específico sin abrir sus circunvoluciones ni sufrir daños. Esta prueba verifica que el conducto pueda soportar fuerzas de tracción durante la instalación o el funcionamiento, lo que garantiza la integridad mecánica y la protección del cableado protegido.

Pruebas de flexibilidad

Los FMC deben mantener su integridad mecánica sin abrir sus circunvoluciones al doblarse alrededor de un mandril específico. Esta prueba garantiza que el conducto pueda soportar curvas cerradas en instalaciones reales sin comprometer su estructura ni su seguridad. La prueba sigue el protocolo de flexibilidad de cables blindados y cables con revestimiento metálico descrito en la norma CSA C22.2 n.º 2556.

Rendimiento del recubrimiento protector de zinc

El recubrimiento protector de zinc galvanizado aplicado a la banda de acero (utilizado en la fabricación de FMC) debe superar la prueba de resistencia a la corrosión mediante la prueba de sulfato de cobre (prueba Preece). La norma especifica que no se forman depósitos de cobre fijos después de los ciclos de inmersión, lo que garantiza la durabilidad del conducto en entornos hostiles o corrosivos.

Prueba adicional para conductos metálicos flexibles herméticos (LFMC)

El LFMC se somete a un conjunto de pruebas más exhaustivo debido a sus componentes adicionales (como una cubierta exterior termoplástica) y a su uso previsto en condiciones de humedad, corrosión o intemperie. Las pruebas pertinentes cumplen con la norma CSA C22.2 n.º 56 y hacen referencia a la norma CSA C22.2 n.º 2556.

1. Propiedades físicas de la cubierta termoplástica

El material de la cubierta debe cumplir con estándares específicos de resistencia a la tracción y elongación, tanto antes como después del envejecimiento acelerado. Estos criterios de rendimiento físico se prueban mediante los métodos de la norma CSA C22.2 n.° 2556 (cláusula 4.2), lo que garantiza que la cubierta exterior conserve su flexibilidad y resistencia a lo largo del tiempo.

2. Resistencia a la deformación

Las camisas LFMC deben resistir la deformación bajo calor y presión. Al someterse a 121 °C con una carga de 2000 g durante 1 hora, el espesor de la camisa no debe disminuir en más de 351 TP3T. Esto simula escenarios reales de estrés térmico.

3. Prueba de resistencia a la intemperie opcional

Para los productos marcados como aptos para uso en exteriores, la chaqueta debe conservar su resistencia a la tracción y elongación después de 1000 horas de exposición al arco de xenón, simulando los efectos de los rayos UV y la intemperie a largo plazo.

4. Rendimiento de tensión axial

El LFMC terminado debe soportar la tensión axial especificada (según el tamaño comercial del conducto) durante 60 segundos sin dañar la camisa ni abrir las convoluciones metálicas. Esto garantiza su durabilidad durante el tendido o la instalación.

5. Resistencia a la corrosión del recubrimiento de zinc

Al igual que FMC, la tira de acero de LFMC (tanto antes como después del formado) debe cumplir con los estándares de recubrimiento protector bajo la Prueba de Sulfato de Cobre, verificando la efectividad de la capa de zinc para resistir la corrosión.

6. Flexibilidad en condiciones de frío

El LFMC debe conservar su integridad estructural al someterse a doblado en frío. El conducto se acondiciona a una temperatura baja especificada y luego se dobla alrededor de un mandril en ambas direcciones. No deben producirse grietas ni separaciones ni en los componentes metálicos ni en los plásticos. Esta prueba de doblado en frío evalúa el rendimiento real en instalaciones a baja temperatura.

7. Resistencia al fuego

LFMC debe pasar pruebas de resistencia a las llamas:

Prueba de llama vertical FT1: El conducto debe autoextinguirse en un minuto tras cinco aplicaciones de llama de 15 segundos. No se puede quemar más de 25% de un indicador de marcado.

Prueba de llama de bandeja vertical FT4 opcional: Cuando corresponda, el conducto de una bandeja portacables (sin relleno) no debe exceder 1,5 metros de longitud de carbón. Esta prueba proporciona una garantía adicional para instalaciones donde la resistencia a la propagación del fuego es crucial.

8. Resistencia al impacto en frío

Después del acondicionamiento a temperaturas frías (según la Tabla 9 de la norma), el LFMC se somete a un impacto de 40 N. El conducto no debe agrietarse ni romperse, lo que demuestra robustez ante un posible abuso de campo durante condiciones de congelación.

¿Qué son los tubos eléctricos no metálicos (ENT)?

Tubos eléctricos no metálicos (ENT) es un sistema de canalización de plástico corrugado, flexible y ligero, diseñado para instalaciones de cableado eléctrico en edificios residenciales, comerciales e institucionales. Sirve como canal de protección para conductores y cables eléctricos, ofreciendo una alternativa eficiente a los sistemas tradicionales de conductos rígidos o metálicos.

ENT se fabrica con materiales no metálicos, generalmente cloruro de polivinilo (PVC) u otros compuestos termoplásticos, que ofrecen una combinación única de durabilidad, flexibilidad y resistencia a la corrosión. Su diseño corrugado permite doblarlo fácilmente sin necesidad de herramientas ni accesorios adicionales, lo que reduce el tiempo de instalación y los costos de mano de obra.

4 Características del conducto ENT

- Construcción flexible: La estructura corrugada de ENT permite un fácil paso a través de paredes, pisos y techos, incluso en espacios reducidos o complejos, sin codos ni equipos para doblar.

- Ligero: Significativamente más liviano que el conducto de metal, el ENT es más fácil de manipular, transportar e instalar.

- Material no metálico: Resistente a la corrosión, al óxido y a la degradación química, lo que lo hace adecuado para ambientes húmedos o corrosivos.

- Retardante de llama: ENT está diseñado para cumplir con los requisitos de rendimiento de llama y humo verticales según las normas de seguridad pertinentes de América del Norte.

5 ventajas del conducto ORL

- Instalación rápida y sencilla: ENT se puede cortar con una herramienta manual e instalar sin necesidad de equipos especiales para doblar o roscar, lo que reduce el tiempo de mano de obra y los costos.

- Reducción del manejo de materiales: Su peso ligero hace que sea más fácil de transportar y maniobrar en lugares de trabajo.

- Menor costo: En comparación con los sistemas de conductos metálicos, ENT ofrece menores costos de material e instalación.

- Resistencia a la corrosión y la humedad: Ideal para ambientes húmedos o corrosivos donde los conductos metálicos pueden degradarse con el tiempo.

- Cumplimiento del código: ENT está aprobado por las normas estadounidenses y canadienses (por ejemplo, UL 1653 y CSA C22.2 No. 227.1) y está reconocido en el Código Eléctrico Nacional (NEC) y el Código Eléctrico Canadiense (CEC).

Códigos y normas para conductos otorrinolaringológicos

Para garantizar la seguridad y el cumplimiento de ENT para sistemas eléctricos, ENT debe cumplir con los estándares y códigos de la industria relacionados.,

Lista de códigos y normas de conductos de otorrinolaringología

- Código Eléctrico Nacional (NEC) – Artículo 362 (ENT)

- Código Eléctrico Canadiense (CEC) – Sección 12-1500 a 12-1514 (ENT)

- UL 1653 / CSA C22.2 N.° 227.1 – Norma de seguridad para tuberías eléctricas no metálicas

Artículo 362 del NEC - Tubería eléctrica no metálica (ENT)

El Artículo 362 del NEC describe los requisitos para los conductos de entrada de cables (ENT), una canalización flexible, corrugada y no metálica utilizada en instalaciones eléctricas. Según la Sección 362.1, este artículo describe las especificaciones de uso, instalación y construcción para los ENT y sus accesorios. Cabe destacar que la Sección 362.6 exige que los ENT y sus accesorios estén homologados, lo que garantiza que cumplan con las normas reconocidas de seguridad y rendimiento.

Usos permitidos

La ENT está permitida en diversas aplicaciones, siempre que se cumplan condiciones específicas:

- Restricciones de altura del edificio: En edificios que no excedan los tres pisos sobre el nivel del suelo, se puede utilizar ENT para trabajos expuestos u ocultos, siempre que no esté prohibido por la Sección 362.12.

- Instalaciones ocultas: En cualquier edificio, independientemente de su altura, se permite ENT cuando está oculto dentro de paredes, pisos y techos que brindan una barrera térmica con una clasificación de acabado de al menos 15 minutos.

- Excepción de protección contra incendios: Si se instala un sistema automático de protección contra incendios aprobado en todos los pisos, se podrá utilizar ENT expuesto u oculto en edificios que superen los tres pisos sobre el nivel del suelo.

- Revestimiento de hormigón: ENT puede ser revestido en hormigón vertido o empotrado en una losa de hormigón sobre el terreno, siempre que se utilicen accesorios identificados para este propósito.

- Ubicaciones húmedas: Se permite el uso de ENT en lugares húmedos cuando se instala en losas de concreto a nivel del suelo o por debajo de él, utilizando accesorios indicados para tal fin.

- Consideraciones de temperatura: Se podrán instalar conductores o cables con una temperatura nominal superior a la indicada en la lista de ENT, siempre que no se utilicen a una temperatura que exceda dicha clasificación de ENT.

Usos no permitidos

ENT no es adecuado para determinados entornos y aplicaciones:

- Ubicaciones peligrosas: La otorrinolaringología está prohibida en ubicaciones peligrosas (clasificadas) a menos que lo permitan otros artículos del NEC.

- Soporte de Equipos: ENT no se puede utilizar para soportar luminarias u otros equipos.

- Altas temperaturas ambiente: ENT no debe utilizarse donde la temperatura ambiente supere los 50 °C (122 °F), a menos que se indique lo contrario.

- Entierro directo en la tierra: No se permite el entierro directo en la tierra.

- Ubicaciones expuestas: Por lo general, no se permite la otorrinolaringología en lugares expuestos, con excepciones específicas descritas en la Sección 362.10.

- Teatros y lugares similares: La otorrinolaringología está restringida en teatros y lugares similares, excepto lo dispuesto en las Secciones 518.4 y 520.5.

- Exposición a la luz solar: ENT no debe utilizarse en lugares expuestos a la luz solar directa, a menos que esté identificado como resistente a la luz solar.

- Daño físico: ENT no es adecuado para áreas donde pueda sufrir daños físicos.

Requisitos de tamaño y relleno

- Tamaños mínimos y máximos: Los tamaños comerciales de otorrinolaringología varían de ½” (métrica 16) a 2½” (métrica 63).

- Relleno del conductor: La cantidad de conductores o cables en ENT debe cumplir con el Capítulo 9, Tabla 1 del NEC para el porcentaje de llenado permitido (362.22).

Especificaciones de construcción

- Requisitos materiales: ENT debe estar hecho de un material que no exceda las características de inflamabilidad, inflamabilidad, generación de humo y toxicidad del cloruro de polivinilo rígido (no plastificado).

- Calificación: El ENT debe estar marcado de forma clara y duradera al menos cada 3 metros (10 pies), según lo exige la Sección 110.21(A). El tipo de material también debe incluirse en el marcado.

Requisitos de la CEC para conductos de otorrinolaringología

En Canadá, el uso y la instalación de tuberías eléctricas no metálicas (TNE) están regulados por la Sección 12 del Código Eléctrico Canadiense (CEC), Parte I, específicamente las Reglas 12-1500 a 12-1514. Estos requisitos rigen los usos permitidos, las restricciones, las prácticas de instalación y las disposiciones de seguridad.

Usos permitidos

ENT está permitido en las siguientes condiciones, sujeto al cumplimiento de las reglas generales de cableado:

Instalaciones Subterráneas:

ENT puede utilizarse bajo tierra, incluida la profundidad del entierro, la protección mecánica y el relleno.

Ubicaciones expuestas u ocultas:

ENT es adecuado tanto para instalaciones expuestas como ocultas dentro de edificios, siempre que se cumplan otras disposiciones CEC.

Restricciones de uso

El ENT no se debe utilizar en lugares donde pueda sufrir daños físicos, a menos que se proporcione protección mecánica adecuada. Esto incluye áreas susceptibles a impactos durante o después de la construcción.

Soportes

El otorrinolaringólogo debe estar fijado de forma segura en su lugar utilizando métodos aprobados:

El soporte debe colocarse a 1 metro de cada caja de salida, caja de conexiones, gabinete, acoplamiento o accesorio.

La distancia máxima entre soportes es de 1 metro.

Número de conductores

La capacidad de llenado del conductor dentro de ENT debe cumplir con la Norma 12-910, que especifica las cantidades admisibles de conductores según el área de la sección transversal y el tipo de aislamiento. El llenado excesivo del conducto puede provocar sobrecalentamiento e incumplimiento de las normas de reducción de capacidad de corriente.

Limitaciones de temperatura

ENT tiene limitaciones de instalación basadas en la temperatura:

- ENT no debe utilizarse en áreas donde los tubos puedan estar expuestos a temperaturas superiores a 75 °C en condiciones normales de funcionamiento.

- Se pueden utilizar conductores aislados con clasificación para temperaturas más altas (por encima de 75 °C), pero la capacidad de corriente debe limitarse a la de los conductores con clasificación para 90 °C, independientemente de la clasificación del conductor.

Conexiones y acoplamientos

Juntas sobre el suelo:

Cuando ENT se une o conecta a accesorios, cajas o gabinetes, solo se permiten accesorios diseñados específicamente para ENT.

Juntas subterráneas:

Cuando se utilizan bajo tierra, los acoplamientos ENT deben cementarse con solvente utilizando un cemento adecuado para garantizar la resistencia a la humedad y la resistencia mecánica.

Soporte de Equipos

No se permite que ENT apoye equipos eléctricos como luminarias, cajas o armarios. Todos los equipos deben apoyarse de forma independiente para evitar tensiones estructurales en las tuberías.

Continuidad de enlace

ENT es un canal no conductor y, por lo tanto, se debe instalar un conductor de conexión a tierra separado de acuerdo con las reglas para garantizar la continuidad eléctrica y la ruta de retorno de la corriente de falla.

UL1653 / CSA C22.2 No.227.1 - Normas para otorrinolaringología

Los tubos eléctricos no metálicos (ENT) se fabrican para cumplir con rigurosos requisitos de seguridad, rendimiento mecánico y de materiales según las normas UL 1653 y CSA C22.2 n.º 227.1. Estas normas norteamericanas armonizadas garantizan la seguridad de los productos ENT en los sistemas de cableado de edificios de EE. UU. y Canadá.

Requisitos de construcción y materiales

No metálico y corrugado, lo que permite flexibilidad durante la instalación.

Fabricado con materiales termoplásticos como PVC o polipropileno, formulado para cumplir con los requisitos de resistencia a la llama, resistencia mecánica y rendimiento de temperatura.

ENT se utiliza a una temperatura ambiente de 50°C, si se utiliza en áticos, debe tener un índice térmico relativo de 60°C.

Dimensiones

A continuación se presenta una breve descripción general de las pruebas de rendimiento más críticas requeridas por UL1653 / CSA C22.2 No.227.1:

Prueba de llama vertical

Evalúa la capacidad ignífuga de ENT. El tubo debe autoextinguirse y limitar la propagación de la llama al someterse a una prueba de combustión vertical.

Prueba de flexión

Asegura que el tubo conserve la integridad estructural y no se agriete al doblarse a un radio específico a temperatura ambiente.

Prueba de deflexión

Mide la deformación bajo carga aplicada. ENT debe resistir un aplanamiento excesivo cuando se aplica presión.

Prueba de impacto

Se verifica la tenacidad dejando caer un peso sobre el tubo, tanto a temperatura ambiente como a baja temperatura. El tubo no debe agrietarse ni romperse.

Prueba de flexión en frío

Esta prueba, realizada a bajas temperaturas (normalmente -20 °C), verifica la fragilidad. El ENT debe permanecer flexible e intacto.

Prueba de tensión

Garantiza que los accesorios y las conexiones de conductos resistan las fuerzas de extracción típicas en las condiciones de instalación.

Prueba de rigidez

Evalúa la rigidez mecánica para evitar el pandeo o colapso durante la instalación y el funcionamiento. En Canadá, el ENT debe tener una rigidez mínima de 300 kPa con una deflexión de 5%. En EE. UU. no se especifica ningún requisito.

Para obtener descripciones detalladas, criterios de aprobación y procedimientos de prueba, consulte nuestro artículo: Tubos ENT para cumplimiento de códigos y elementos de prueba.

FMC vs. Otorrinolaringología: Una comparación completa

La elección del tipo correcto de conducto, conducto metálico flexible (FMC) o tubería eléctrica no metálica (ENT), depende de varios factores clave, incluidos el entorno de aplicación, los requisitos de protección mecánica, el cumplimiento del código, la facilidad de instalación y el costo.

Tanto el FMC como el ENT cumplen funciones similares en la protección y el tendido del cableado eléctrico, pero sus materiales, construcción y características de rendimiento difieren significativamente. Comprender estas diferencias es esencial para seleccionar la solución más adecuada para su proyecto específico.

La siguiente tabla comparativa describe las distinciones críticas entre FMC y ENT en términos de materiales, flexibilidad, resistencia ambiental, rendimiento al fuego, resistencia, necesidades de instalación y aplicaciones típicas.

Característica | FMC | Otorrinolaringología |

Material | Acero galvanizado o aluminio | CLORURO DE POLIVINILO |

Flexibilidad | Alto; se dobla fácilmente, pero requiere más esfuerzo que ENT | Muy alto; se dobla fácilmente con la mano sin herramientas. |

Resistencia a la corrosión | Moderado; mejor con FMC recubierto o aluminio | Excelente; inherentemente no corrosivo |

Protección mecánica | Superior; proporciona protección robusta contra daños físicos | Limitado; necesita protección adicional si se expone a daños. |

Comportamiento ante el fuego | Inherentemente resistente al fuego (alto punto de fusión, no combustible) | Resistente al fuego, retardante de llama, autoextinguible (moderado) |

Instalación | Relativamente fácil; requiere herramientas de corte (sierra para metales/amoladora) y, a veces, dobladoras. | Más fácil; se puede doblar con las manos, herramientas de corte sencillas, accesorios a presión |

Conexión/Puesta a tierra | El cuerpo metálico puede servir como tierra si está indicado | Requiere conductor de unión separado |

Peso | Más pesado | Ligero |

Costo | Mayores costos de material y mano de obra | Más rentable |

Códigos y normas | NEC, ECE, UL 1, CSA C22.2 No.56 | NEC, CEC, UL 1653, CSA C22.2 N.° 227.1 |

Aplicaciones comunes | Lugares secos, cables de motor, áreas propensas a vibraciones | Losas de hormigón, paredes, techos, cableado residencial y comercial. |

FMC o ENT: la elección correcta para su proyecto

Al elegir entre conductos metálicos flexibles (FMC) y tuberías eléctricas no metálicas (ENT), es fundamental ir más allá del simple cumplimiento normativo. La elección correcta depende de un cuidadoso equilibrio entre las condiciones específicas del sitio, los objetivos de la instalación, las necesidades de rendimiento y la adaptabilidad futura.

1. Condiciones ambientales

- Ubicaciones húmedas o secas: El entorno de instalación es el factor más importante y decisivo. En interiores secos, tanto el FMC como el ENT son opciones viables. Sin embargo, en condiciones de humedad, humedad o exteriores, el FMC estándar no es adecuado; en tales casos, se requiere el conducto metálico flexible estanco (LFMC). El ENT, si bien es resistente a la humedad, no suele utilizarse enterrado directamente ni en entornos exteriores con humedad continua, a menos que cuente con una clasificación especial.

- Expuesto y oculto: La ocultación y la exposición también son importantes. El FMC está permitido tanto en zonas expuestas como ocultas. En cambio, el ENT debe estar oculto en edificios de más de tres plantas, según los requisitos del NEC, y solo puede utilizarse en zonas expuestas de edificios más pequeños si no está sujeto a daños físicos.

- Temperatura y química: La temperatura y la exposición a sustancias químicas son otros factores a considerar. El FMC, gracias a su construcción metálica, resiste mejor las temperaturas extremas y los entornos hostiles. El ENT, fabricado en PVC, puede degradarse por encima de los 50 °C, a menos que se indique lo contrario, y puede deformarse bajo cargas térmicas sostenidas, pero aun así ofrece una buena resistencia química para numerosas aplicaciones en interiores.

2. Protección mecánica

- Durabilidad mecánica: En cuanto a durabilidad mecánica, FMC tiene una clara ventaja. Su construcción metálica lo hace ideal para zonas con riesgo de impacto, vibración o abrasión, como cocinas comerciales, instalaciones industriales o ubicaciones cercanas a maquinaria. ENT es más flexible, pero ofrece una protección limitada, lo que lo hace ideal para tramos ocultos en paredes residenciales o comerciales donde las amenazas físicas son mínimas.

- Vibración: La resistencia a las vibraciones es otro aspecto crítico en el que FMC destaca. Su estructura helicoidal ayuda a absorber el movimiento, lo que lo hace ideal para conexiones a motores y equipos vibratorios.

- Blindaje EMI: Además, el FMC proporciona protección contra interferencias electromagnéticas (EMI), un requisito clave en aplicaciones que involucran electrónica sensible o sistemas de comunicación de datos. El ENT, al no ser metálico, no ofrece dicha protección.

3. Costo, mano de obra y mantenimiento

Las evaluaciones de costos deben ir más allá del precio del conducto por metro. ENT ofrece instalaciones más rápidas, con accesorios a presión y capacidad de doblado manual, lo que reduce drásticamente el tiempo de mano de obra. Es particularmente eficaz en aplicaciones de gran volumen o repetitivas, como la construcción residencial o de oficinas, donde el ahorro en mano de obra puede superar el costo del material.

Por otro lado, los mayores costos de materiales y mano de obra de FMC reflejan su robustez. En entornos que exigen mayor resiliencia y resistencia al fuego, la inversión adicional suele compensarse con una reducción del riesgo y un menor mantenimiento a largo plazo.

Las necesidades de mantenimiento también varían: el ENT es resistente a la corrosión y prácticamente no requiere mantenimiento. El FMC es resistente a la corrosión, pero puede requerir inspección y posible reemplazo con el tiempo en entornos corrosivos o húmedos.

4. Comprenda el código

Independientemente del rendimiento del material, todas las instalaciones deben cumplir con el Código Eléctrico Nacional (NEC) y las modificaciones locales. Por ejemplo:

No se permite el uso de ENT en espacios de plenum o entornos peligrosos.

Los FMC deben cumplir con los requisitos de conexión a tierra y unión, particularmente en aplicaciones de distribución de energía.

La colaboración temprana con la Autoridad Competente (AC) garantiza que los materiales seleccionados superen la inspección y que se tengan en cuenta las condiciones especiales de uso. Algunos inspectores pueden examinar las marcas o listados con mayor detenimiento que otros, por lo que una planificación proactiva es rentable.

5. Planifique el futuro

En un mundo donde las modificaciones de sistemas y las actualizaciones tecnológicas son frecuentes, una infraestructura de conductos a prueba de futuro es una decisión inteligente. La flexibilidad y el diseño pasante de ENT facilitan la instalación o redirección del cableado, minimizando el tiempo de inactividad durante las actualizaciones. Esto lo convierte en una opción sólida para espacios de inquilinos, centros educativos o sanitarios, donde la adaptabilidad es clave.

FMC, aunque es menos flexible una vez instalado, aún admite cambios y actualizaciones de cables, especialmente si se instala con puntos de unión accesibles.

5 errores comunes de instalación y mejores prácticas

Ya sea que se trabaje con conductos metálicos flexibles (FMC) o tubos eléctricos no metálicos (ENT), una instalación correcta es esencial para la seguridad eléctrica y el rendimiento a largo plazo del sistema. A pesar de sus diferencias en material y flexibilidad, ambos tipos de conductos son vulnerables a errores comunes de instalación. A continuación, analizamos estos problemas y describimos las mejores prácticas para garantizar el cumplimiento normativo, la fiabilidad y la eficiencia.

Consejos profesionales: ¿Quieres saber más sobre? ¿Relleno de conductos, corte de ENT y consejos de cableado de tracción para conductos de ENT? Puede hacer clic en el enlace de arriba para leer nuestro artículo anterior.

1. Cómo evitar el dimensionamiento incorrecto y el llenado excesivo

- Elegir la talla adecuada: Seleccionar el tamaño correcto de conducto es más que una cuestión de comodidad; es una consideración crítica de seguridad. Los conductos de tamaño insuficiente restringen el flujo de aire alrededor de los conductores, lo que aumenta el riesgo de sobrecalentamiento y dificulta el tendido de cables. Por otro lado, un conducto innecesariamente grande puede incrementar los costos del proyecto y complicar los accesorios y los sistemas de soporte.

- Capacidad de llenado: Otro problema frecuente es el sobrellenado, que consiste en la acumulación excesiva de cables en el conducto. Esto no solo dificulta la instalación, sino que también supone un riesgo real de incendio debido a la menor disipación de calor. La práctica recomendada recomienda consultar siempre las tablas de llenado del NEC para determinar el tamaño adecuado según el número y el calibre de los conductores. Como orientación general, mantener el llenado del conducto por debajo de 40% en instalaciones multicable permite lograr un equilibrio entre seguridad, facilidad de mantenimiento y futuras actualizaciones.

2. Soporte adecuado y seguro

Aunque los sistemas FMC y ENT son flexibles, requieren un soporte estructurado. Sin él, los conductos pueden combarse, desplazarse o incluso dañarse, poniendo en riesgo tanto el conducto como el cableado interno. Un anclaje seguro a intervalos adecuados mantiene la alineación, reduce la tensión mecánica y preserva la integridad del sistema a lo largo del tiempo.

El Código Eléctrico Nacional proporciona directrices claras para la separación de los soportes. El FMC generalmente debe sujetarse cada 1,37 m (4,5 pies) y a menos de 30 cm (12 pulgadas) de los puntos de terminación. El ENT requiere un control más estricto: sujetarse cada 0,91 m (3 pies) y cerca de los extremos. El uso de abrazaderas, correas o soportes adecuados al material del conducto es crucial para evitar aflojamiento, movimiento o abrasión en entornos activos.

Soporte según sus códigos locales.

3. Límites de flexión

Tanto los cables FMC como los ENT son valorados por su flexibilidad, pero eso no significa que doblarlos sea ilimitado. Un doblado inadecuado, como esquinas cerradas o ángulos acumulativos excesivos, puede provocar el aplastamiento de los conductores, la rotura del aislamiento y una mayor resistencia a la tracción. Estos problemas suelen resultar en costosos retrasos o fallos en el futuro.

Para evitar estos resultados, los instaladores deben respetar el radio mínimo de curvatura, que normalmente no debe ser inferior a tres veces el diámetro del conducto, y limitar los ángulos de curvatura totales en una sola pasada a 360 grados. El FMC suele requerir una dobladora mecánica para lograr curvas limpias y uniformes, mientras que el ENT puede doblarse manualmente, aunque con cuidado y control. El objetivo es lograr curvas suaves y graduales que permitan el movimiento del cable sin forzar los materiales.

4. Abordar los factores ambientales

Las fallas en los conductos suelen deberse a la instalación de productos en entornos para los que no fueron diseñados. Por ejemplo, el uso de FMC estándar en zonas húmedas o mojadas puede acelerar la corrosión, mientras que la exposición de ENT a la luz solar directa o a condiciones subterráneas sin las especificaciones adecuadas puede provocar grietas o deformaciones.

Una práctica recomendada clave es adaptar el tipo de conducto a las condiciones del sitio desde el principio. Para lugares húmedos o uso en exteriores, el FMC hermético es la opción ideal gracias a su revestimiento sellado. El ENT estándar funciona mejor en interiores o dentro de losas de hormigón, donde está protegido de los rayos UV y el agua. Los instaladores también deben tener en cuenta los rangos de temperatura ambiente y asegurarse de que todos los accesorios estén adecuadamente sellados para evitar la entrada de humedad.

5. Garantizar conexiones y puesta a tierra adecuadas

Incluso con el conducto y la disposición adecuados, las conexiones deficientes pueden perjudicar todo el sistema. Las conexiones sueltas pueden exponer cables, interrumpir la continuidad o provocar daños por vibración. En conductos metálicos como los FMC, la conexión a tierra es especialmente crucial para evitar riesgos de descarga eléctrica y cumplir con los requisitos de la normativa.

Todos los accesorios deben estar homologados y ser compatibles con el material del conducto, y las conexiones deben apretarse cuidadosamente. Para FMC, se debe mantener la continuidad en las juntas y utilizar técnicas de conexión adecuadas para cumplir con las normas del Artículo 250 del NEC. El ENT, al no ser metálico, no conduce la electricidad, por lo que cualquier conexión a tierra del equipo que se requiera debe realizarse mediante un conductor de tierra independiente dentro de la tubería.

Conclusión

Los conductos metálicos flexibles (FMC) y las tuberías eléctricas no metálicas (ENT) son componentes esenciales en los sistemas eléctricos modernos, cada uno con ventajas únicas para aplicaciones específicas. El FMC proporciona una protección robusta con capacidad de puesta a tierra, lo que lo hace ideal para áreas donde se requiere resistencia mecánica y blindaje EMI. Por otro lado, la ENT destaca en entornos ligeros y fáciles de instalar, como en instalaciones residenciales o con revestimiento de hormigón.

Sin embargo, los beneficios de estos sistemas de conductos solo se pueden aprovechar al máximo mediante la selección e instalación adecuadas del producto y el cumplimiento de las normativas. Errores como un dimensionamiento inadecuado, un soporte inadecuado, prácticas de doblado deficientes o una aplicación incorrecta en entornos inadecuados pueden comprometer no solo la funcionalidad del sistema, sino también la seguridad y el cumplimiento de las normativas.

Al comprender sus características, seguir las directrices locales y aplicar las mejores prácticas en el campo, los instaladores pueden garantizar que tanto FMC como ENT ofrezcan rendimiento, durabilidad y seguridad a largo plazo. Ya sea en obras nuevas o en proyectos de modernización, invertir en materiales de calidad y mano de obra de precisión se traduce en un menor mantenimiento, mayor fiabilidad eléctrica y tranquilidad.

A medida que la infraestructura eléctrica continúa evolucionando, en particular con la expansión de sistemas inteligentes y de bajo consumo energético, saber cuándo y cómo utilizar FMC y ENT seguirá siendo una habilidad crucial tanto para electricistas como para ingenieros y gerentes de proyectos.

Preguntas frecuentes

¿Qué es el conducto FMC?

FMC significa Conducto Metálico Flexible. Es un tipo de conducto eléctrico hecho de una tira metálica enrollada helicoidalmente, que proporciona flexibilidad para el tendido de cableado eléctrico en espacios reducidos o complejos. El FMC se utiliza comúnmente en entornos comerciales e industriales donde pueden producirse vibraciones o movimientos, o donde el conducto debe sortear obstáculos.

¿Cómo cortar conducto FMC?

Para cortar el conducto FMC, siga estos pasos:

- Mida y marque la longitud deseada utilizando una cinta métrica y un marcador.

- Utilice una herramienta rotatoria (como una sierra para metales o un cortador FMC especializado) para cortar a lo largo de la línea marcada.

- Desbarbe los extremos cortados utilizando una herramienta escariadora o alicates para eliminar los bordes afilados.

- Inserte un conector apropiado para garantizar una instalación segura y que cumpla con el código.

¿Se puede utilizar FMC como tierra?

Sí, el FMC puede servir como conductor de puesta a tierra de equipos (EGC) si cumple las condiciones descritas en el Artículo 250.118(5) del NEC. En concreto:

El FMC debe ser continuo y estar fijado de forma segura.

Debe tener accesorios apropiados listados para conexión a tierra.

La longitud total y el tamaño del conductor deben cumplir con las disposiciones de conexión a tierra del NEC.

¿Qué es el conducto ORL?

ENT (Tubo Eléctrico No Metálico) es una canalización flexible y no metálica fabricada en PVC. Es ligera, ignífuga y está diseñada para una fácil instalación en paredes, pisos y techos. ENT se utiliza principalmente en aplicaciones residenciales y comerciales en interiores.

¿Cuándo utilizar el conducto ORL?

Utilice el conducto ORL cuando:

Se necesita flexibilidad para curvas sin accesorios.

La instalación se realiza en lugares interiores secos, como dentro de paredes o en hormigón vertido.

Se desean propiedades no metálicas y resistentes a la corrosión.

Se prefiere una alternativa ligera y que ahorre mano de obra al EMT o al PVC.

¿Se puede utilizar el conducto ORL en exteriores?

Generalmente no. El ENT se usa a menudo en paredes, pisos, techos o en estructuras de concreto. Sin embargo, puede usarse en exteriores si cuenta con inhibidores de rayos UV y está aprobado por el fabricante y el código. Sin embargo, asegúrese de que no esté expuesto a la luz solar directa durante mucho tiempo ni a daños mecánicos.

¿El conducto ORL es impermeable?

No, el sistema ENT no es impermeable. Es resistente a la humedad, pero generalmente se recomienda para lugares secos y no está diseñado para sumergirse ni exponerse directamente al agua. Para lugares húmedos o mojados, se recomienda usar PVC o un conducto flexible estanco (LFMC).

¿El conducto ENT está clasificado como plenum?

No, ENT no está clasificado como plenum a menos que:

Específicamente probado y listado para uso en espacios de plenum.

Instalado de acuerdo con las pautas del fabricante y los códigos contra incendios locales.

En general, utilice conductos metálicos o alternativas aptas para plenum en espacios de manejo de aire.