Tabla de contenido

Ya sea que sea electricista, ingeniero eléctrico o fabricante de productos eléctricos, como conductos y accesorios, comprender los estándares y requisitos del cableado es esencial.

En Australia y Nueva Zelanda, la norma de referencia para instalaciones eléctricas es la norma AS/NZS 3000:2018 sobre cableado. Esta norma sienta las bases para la seguridad, la fiabilidad y el rendimiento eléctrico en proyectos residenciales, comerciales e industriales. Desde el diseño de los sistemas de cableado hasta la selección de dispositivos de protección, la norma AS/NZS 3000 define cómo debe diseñarse y ejecutarse cada parte de una instalación.

Como un Proveedor de conductos de PVCHemos visto de primera mano cómo el cumplimiento de las Normas de Cableado afecta la selección de productos, el rendimiento de los materiales y los métodos de instalación. Por ejemplo, la elección de un conducto rígido de PVC resistente a los rayos UV o la garantía de protección mecánica en zonas expuestas se relacionan directamente con cláusulas específicas de la norma. Por eso es fundamental comprender el código no solo para instaladores e inspectores, sino también para fabricantes y proveedores de productos como nosotros.

El objetivo de este artículo es simple: ayudarlo a comprender claramente qué es AS/NZS 3000, por qué es importante y qué debe hacer para cumplir con los requisitos de seguridad de los sistemas eléctricos en Australia y Nueva Zelanda.

Consejos profesionales: ¿Quieres saber más sobre los códigos eléctricos de diferentes países? Puedes consultar nuestras publicaciones anteriores, incluyendo... Guía experta del código NEC (para Estados Unidos) y el Guía definitiva del Código CEC (para Canadá).

¿Qué es AS/NZS 3000:2018?

La norma AS/NZS 3000:2018, oficialmente titulada «Instalaciones Eléctricas, Conocida como las Reglas de Cableado de Australia y Nueva Zelanda», es la norma eléctrica fundamental que describe los requisitos mínimos para el diseño, la construcción y la verificación de todas las instalaciones eléctricas en Australia y Nueva Zelanda. Sienta las bases para la seguridad, la funcionalidad y el cumplimiento normativo en proyectos residenciales, comerciales e industriales.

Esta norma garantiza que las instalaciones se construyan para minimizar riesgos como descargas eléctricas, incendios y fallos de equipos. Si bien los electricistas son sus principales usuarios, también desempeña un papel fundamental para ingenieros, inspectores y fabricantes como nosotros, especialmente al desarrollar o suministrar productos eléctricos como cables, conductos y accesorios que deben cumplir con requisitos específicos de la normativa.

La norma AS/NZS 3000:2018 es conocida por establecer las normas sobre el diseño e instalación de los sistemas de cableado. Si bien abarca mucho más que el cableado eléctrico, incluye dispositivos de protección, envolventes, sistemas de canalización, puesta a tierra y técnicas de instalación. Es una norma de larga data que define prácticas de cableado seguras y conformes.

Por qué es importante para electricistas, ingenieros e inspectores

La norma AS/NZS 3000:2018 no es solo una guía técnica, sino una referencia diaria y un requisito legal. Para los electricistas, garantiza que las instalaciones cumplan con los estándares de seguridad. Para los ingenieros y consultores, proporciona claridad en el diseño. Para los inspectores, sirve como referencia para evaluar la calidad de la instalación.

El papel de Standards Australia y Standards New Zealand

Standards Australia y Standards New Zealand son las dos organizaciones nacionales independientes responsables del desarrollo de la norma AS/NZS 3000:2018. Si bien la norma en sí no constituye una ley, está regulada por las leyes de seguridad eléctrica de todos los estados y territorios australianos, así como por las regulaciones neozelandesas, lo que hace que su cumplimiento sea prácticamente obligatorio.

Este desarrollo binacional garantiza la coherencia entre ambos países y al mismo tiempo permite a las autoridades locales aplicarlo mediante regímenes regionales de licencias e inspección.

Descripción general de AS/NZS 3000:2018

Para garantizar instalaciones eléctricas seguras y conformes, la norma AS/NZS 3000:2018 está estructurada de forma lógica y práctica. Guía a los usuarios desde los principios básicos de seguridad hasta las prácticas específicas de instalación, pruebas y verificación. Comprender la estructura general es importante, no solo para electricistas e ingenieros, sino también para algunos usuarios domésticos y fabricantes de productos eléctricos. Esto ayuda a garantizar que todos los materiales o productos que ofrecemos cumplan con la normativa en cada etapa de la instalación.

Cómo está estructurada la norma

La norma se divide en dos partes principales:

Parte 1: Alcance, aplicación y principios fundamentales

Esta sección establece los objetivos generales y los principios fundamentales de seguridad de la norma. Explica los tipos de instalaciones que abarca, las responsabilidades de los profesionales y los objetivos esenciales de la seguridad eléctrica, como la prevención de descargas eléctricas, incendios y daños mecánicos. También describe los conceptos fundamentales de diseño para garantizar que los sistemas sean fiables, fáciles de mantener y energéticamente eficientes.

Parte 2: Prácticas de instalación (Secciones 2 a 8)

Esta sección contiene las normas técnicas y los métodos prácticos para cumplir con los requisitos establecidos en la Parte 1. Abarca temas como métodos de cableado, protección contra sobrecorrientes y fallas, puesta a tierra, instalación de equipos y requisitos específicos para ubicaciones especiales como baños o áreas peligrosas. También incluye procedimientos para probar y verificar las instalaciones y confirmar su cumplimiento antes de la energización.

Juntas, estas dos partes proporcionan una guía completa para lograr la seguridad eléctrica y el cumplimiento normativo, formando la columna vertebral del trabajo de instalación eléctrica moderna en Australia y Nueva Zelanda.

En conjunto, estas secciones forman un conjunto completo de reglas que se aplican a todo tipo de instalaciones eléctricas, ya sean domésticas, comerciales, industriales o de infraestructura.

Secciones clave de la norma AS/NZS 3000 que debe conocer

Comprensión de la Parte 1: Principios fundamentales de seguridad

La Parte 1 de la norma AS/NZS 3000:2018 establece los principios fundamentales para lograr instalaciones eléctricas seguras y funcionales. Describe los objetivos básicos de seguridad para proteger a las personas, los bienes y el ganado de los peligros asociados con los sistemas eléctricos durante su uso habitual o en caso de fallo. Estos requisitos fundamentales sustentan el diseño, la instalación y la verificación de todas las instalaciones eléctricas contempladas en la norma.

Protección contra riesgos eléctricos comunes

La norma identifica tres riesgos principales en las instalaciones eléctricas y proporciona orientación para mitigar cada uno de ellos:

Descarga eléctrica (corriente de choque):

Se requiere protección tanto contra el contacto directo (partes con tensión normal) como contra el contacto indirecto (partes que se activan en caso de fallo). Esto incluye:

Protección básica: Prevenir el acceso a partes activas mediante aislamiento, barreras o colocando los componentes fuera del alcance.

Protección contra fallos: Evitar que las piezas conductoras expuestas se activen en condiciones de falla mediante métodos adecuados de conexión a tierra y desconexión.

Protección mejorada: Sistemas como SELV (tensión extra baja separada) o PELV (tensión extra baja protegida) pueden proporcionar ambos tipos de protección en condiciones específicas.

Temperaturas excesivas y riesgos de incendio:

Las instalaciones deben evitar quemaduras, daños al equipo o ignición de materiales debido al calor de los equipos eléctricos. Las medidas incluyen una gestión térmica adecuada, el espaciamiento y el uso de materiales no combustibles cerca de componentes calientes.

Atmósferas explosivas:

En áreas con gases o polvos inflamables, los equipos deben estar diseñados para evitar fuentes de ignición, asegurando la compatibilidad con ambientes peligrosos.

Medidas básicas de protección adicionales

Protección contra sobrecorriente:

La sobrecorriente causada por sobrecarga o cortocircuito puede provocar incendios o daños. La norma exige la desconexión automática o la limitación de corriente para mantener las temperaturas y la tensión mecánica dentro de límites seguros.

Protección contra corrientes de falla a tierra:

Las corrientes de falla a tierra deben ser transportadas de manera segura por conductores de protección dimensionados para soportar la corriente esperada sin sobrecalentarse.

Protección contra la propagación del fuego:

Los componentes eléctricos no deben iniciar ni propagar incendios. Esto incluye el uso de materiales ignífugos y la minimización de la generación de arcos eléctricos durante su funcionamiento.

Resistencia a las influencias externas:

Las instalaciones deben ser adecuadas para su entorno, resistiendo daños causados por la humedad, la temperatura, el impacto mecánico y otras condiciones externas esperadas durante el uso normal.

Principios de diseño y selección de equipos

La norma exige que todas las instalaciones deben:

Garantizar la seguridad y evitar daños en todas las condiciones previsibles.

Realizar sus funciones previstas sin comprometer la confiabilidad.

Ser compatible con la fuente de alimentación conectada y las características de la red.

Permitir procedimientos seguros de inspección, pruebas y mantenimiento.

Todo equipo eléctrico utilizado debe ser:

Seleccionado e instalado para evitar riesgos tanto en condiciones normales como anormales.

Instalado de acuerdo con el estándar y las especificaciones del fabricante.

Verificación y cumplimiento continuo

Antes de poner en servicio cualquier nueva instalación o modificación, debe someterse a una inspección y pruebas exhaustivas para verificar el cumplimiento de la norma. En Australia, el cumplimiento total de la Parte 2 se considera conforme con la Parte 1. Además, las instalaciones pueden cumplir con otras normas de referencia, como se describe en las secciones pertinentes del documento.

Parte 2: Prácticas de instalación

Sección 2: Disposición general, control y protección

La Sección 2 de la Parte 2 de la norma AS/NZS 3000:2018 establece los requisitos mínimos para la selección, instalación, control y protección de los equipos de conmutación y control en una instalación eléctrica. Esta sección es fundamental para garantizar la seguridad, la fiabilidad operativa, la mantenibilidad y el cumplimiento de los objetivos generales definidos en la Parte 1 de la norma.

Requisitos generales para equipos de control y protección

Esta sección se aplica a la correcta selección e instalación de equipos de conmutación y control, que son elementos críticos para controlar, aislar y proteger las instalaciones eléctricas. Estos componentes deben garantizar un funcionamiento seguro durante el mantenimiento, la detección de fallas o las paradas de emergencia.

Criterios de selección e instalación

Los equipos de conmutación y control deben seleccionarse e instalarse para:

- Permitir el control y aislamiento de circuitos, aparatos o toda la instalación para permitir mantenimiento y pruebas seguras.

- Desconectar automáticamente el suministro en caso de sobrecargas, cortocircuitos o corrientes de fuga a tierra excesivas.

- Proporciona protección contra sobretensión y subtensión para salvaguardar tanto al equipo como a los usuarios.

- Agruparse de forma lógica en cuadros eléctricos, con envolventes que ofrezcan protección adecuada contra las condiciones ambientales externas y posicionados de forma que el acceso sea fácil.

- Controlar y proteger de forma independiente los arreglos de circuitos, garantizando que una falla en una sección no comprometa el funcionamiento de las demás.

- Cumplir con esta norma y las especificaciones del fabricante para garantizar la integridad funcional y de seguridad.

Disposición de la Instalación Eléctrica

Las instalaciones eléctricas deben dividirse en un número adecuado de circuitos separados, en función de:

- Agrupación funcional de equipos, incluyendo cualquier necesidad definida por el usuario u operaciones agrupadas.

Características de carga y demandas operativas, que influyen en la clasificación de cables, dispositivos de protección y otros componentes.

- Tolerancia a fallos, limitando las consecuencias de un fallo en un circuito en el resto del sistema.

- Previsión de mantenimiento, modificaciones y futuras ampliaciones sin interrumpir el suministro eléctrico a zonas críticas.

- Los servicios de seguridad, como la iluminación de emergencia o las alarmas contra incendios, deben tener circuitos completamente separados de los circuitos generales de suministro eléctrico.

Protección contra fallas

AS/NZS 3000 reconoce tres métodos principales de protección contra fallas:

Desconexión automática del suministro

Uso de equipos de Clase II o aislamiento equivalente

Separación eléctrica

Desconexión automática del suministro

El método más común implica:

Sistemas de puesta a tierra que conectan partes conductoras expuestas a un conductor de tierra protector.

Dispositivos de protección como disyuntores o dispositivos de corriente residual (RCD) que desconectan la energía cuando ocurre una falla, limitando así los voltajes de contacto peligrosos.

Protección contra sobrecorriente

General

Los conductores activos deben estar protegidos contra sobrecorriente para evitar sobrecalentamiento, incendios o daños mecánicos. La protección debe cubrir:

Corrientes de sobrecarga (causada por una carga excesiva a lo largo del tiempo)

corrientes de cortocircuito (causada por condiciones de falla)

Los dispositivos de protección deben:

Desconecte el suministro rápidamente antes de que se produzcan daños o lesiones.

Evite el uso de fusibles en conductores neutros, excepto donde esté específicamente permitido

Coordinarse para garantizar el correcto funcionamiento en diferentes escenarios de falla

Nota: La protección contra sobrecorriente debe tener en cuenta los métodos de instalación, el tamaño de los cables y los efectos térmicos. El Apéndice I de la norma ofrece orientación para los conductores existentes en sistema imperial.

Protección contra sobretensión

Las sobretensiones pueden ser causadas por rayos, fallos de aislamiento, sobretensiones de conmutación o resonancia. Cuando estas condiciones representen un peligro para las personas o la propiedad, se deben instalar dispositivos de protección contra sobretensiones (SPD) adecuados.

Se deberá prestar especial consideración a:

- Regiones geográficas con actividad frecuente de rayos

- Instalaciones sensibles a tensiones transitorias

Protección contra subtensión

Se requiere protección contra subtensión cuando las caídas de tensión o el restablecimiento de la energía podrían:

- Provoca reinicios peligrosos (por ejemplo, equipos industriales como prensas o compuertas)

- Provocar daños en el equipo o la imposibilidad de operar de forma segura

Las causas comunes de subtensión incluyen sobrecargas, fallos de alimentación o conexiones de alta impedancia. Si el riesgo es aceptable, se puede omitir la protección contra subtensión.

Protección contra fallas de arco

Las fallas de arco, que pueden provocar riesgos de incendio, en particular en dormitorios, edificios de madera o lugares con materiales inflamables, se pueden mitigar mediante el uso de dispositivos de detección de fallas de arco (AFDD).

AFDD:

- Detectar y desconectar la energía cuando se detecta un arco eléctrico.

- Se recomiendan para mejorar la seguridad contra incendios, especialmente en entornos de alto riesgo.

Sección 3: Selección e instalación de sistemas de cableado

La Sección 3 de AS/NZS 3000:2018 establece los requisitos mínimos para la selección e instalación de sistemas de cableado para garantizar la seguridad eléctrica, el rendimiento y el cumplimiento de los principios fundamentales de seguridad establecidos en la Parte 1 de la Norma.

Requisitos generales de la Sección 3

Esta sección comienza estableciendo que todos los sistemas de cableado deben seleccionarse e instalarse para proteger a los usuarios y la propiedad, considerando tanto las condiciones mecánicas como las ambientales. Los requisitos funcionales clave incluyen:

- Protección contra el contacto con partes activas, mediante aislamiento o barreras físicas.

- Cumplimiento de la capacidad de transporte de corriente y límites de caída de tensión.

- Conexiones, uniones y terminaciones confiables para garantizar la continuidad eléctrica.

- Soporte mecánico y métodos de fijación adecuados.

- Idoneidad para condiciones específicas, como resistencia al fuego o entornos peligrosos.

- Durabilidad frente a daños mecánicos e influencias ambientales.

- Instalación de acuerdo con las instrucciones del fabricante y los criterios de la norma.

También deben considerarse características como el material del conductor, la identificación del núcleo, el rendimiento del aislamiento, el aumento de temperatura y la flexión o tensión admisibles.

Influencias externas

El entorno de instalación desempeña un papel fundamental en la selección del sistema de cableado. Se deben evaluar factores como la temperatura ambiente y la clasificación de la zona peligrosa. En particular:

- Para cables instalados en el aireLa temperatura ambiente de referencia es de 40 °C en Australia y 30 °C en Nueva Zelanda.

- Para cables enterrados o recintos subterráneosLas temperaturas de referencia son 25°C (Australia) y 15°C (Nueva Zelanda).

- Se aplican disposiciones adicionales a las zonas peligrosas, como se describe en la Cláusula 7.7.

Capacidad de conducción de corriente

Los conductores deben tener una capacidad de conducción de corriente adecuada según la serie AS/NZS 3008.1. Esto incluye tolerancias para cambios ambientales previsibles, como el futuro aislamiento térmico, que pueden afectar la disipación de calor en entornos domésticos.

Caída de tensión

Los niveles de tensión en las terminales del equipo deben mantenerse dentro de los límites de seguridad de funcionamiento. La caída de tensión máxima admisible en cualquier instalación de baja tensión es de 5% de la tensión nominal en el punto de suministro.

Conexiones eléctricas

Todas las conexiones eléctricas deben garantizar la continuidad eléctrica, la integridad mecánica y un aislamiento adecuado. Los cables deben unirse mediante métodos adecuados e instalarse sin someter las terminaciones a esfuerzos mecánicos.

Requisitos de instalación

Las instalaciones deben seguir prácticas de ingeniería rigurosas para resistir fallos mecánicos o eléctricos. Los aspectos más destacados incluyen:

- Métodos de instalación debe coincidir con las condiciones ambientales y seguir las instrucciones del fabricante (Tabla 3.1).

- Soporte y fijación debe evitar tensiones o daños y mantener el cumplimiento de los códigos de construcción.

- Protección contra daños mecánicos Se requiere donde es probable que haya impacto o desgaste.

- Segregación de niveles de tensión debe evitar la interacción entre circuitos de diferentes voltajes a menos que se utilicen barreras o aislamientos específicos.

- Mitigación de incendios Debe abordarse mediante la selección y el diseño de materiales para evitar la propagación de llamas o productos de combustión.

- Interferencia electromagnética (EMI) Debe minimizarse cuando estén involucrados equipos sensibles, utilizando cables, gabinetes o configuraciones adecuados.

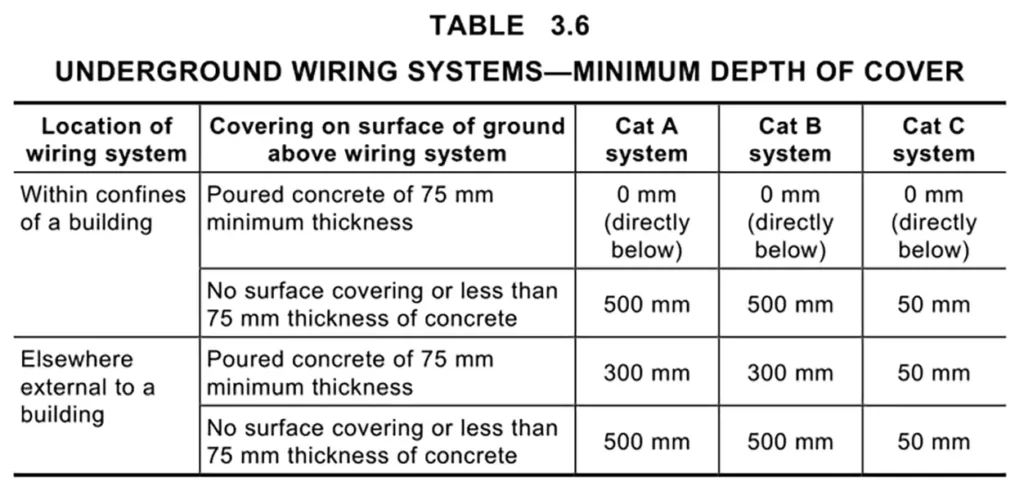

Sistemas de cableado subterráneo

Los sistemas de cableado instalados bajo tierra deben ser:

Adecuado para el medio ambiente y

Protegido contra daños accidentales, como por ejemplo, excavaciones.

Los cables deben incluir indicadores de advertencia y cumplir con las profundidades mínimas de cobertura definidas en la Tabla 3.6. Los sistemas subterráneos se clasifican en:

Categoría A – Inherentemente adecuado sin protección adicional.

Categoría B – Requiere protección mecánica adicional.

Categoría C – Instalado en canales de roca.

Notas: ¿Quieres saber más sobre el Sistemas de cableado subterráneoEste artículo explica en detalle el propósito, los beneficios y la instalación del cableado con conductos ocultos.

Sección 5: Disposiciones de puesta a tierra y conductores

La Sección 5 describe los requisitos mínimos para la selección e instalación de sistemas y conductores de puesta a tierra, según lo requerido para cumplir con las disposiciones fundamentales de seguridad de AS/NZS 3000 Parte 1. Estos requisitos se aplican a todo tipo de instalaciones eléctricas y son esenciales para garantizar un funcionamiento seguro, protección contra fallas y mitigación del riesgo de descarga eléctrica.

Selección e instalación

Los dispositivos de puesta a tierra deben seleccionarse e instalarse cuidadosamente para cumplir varias funciones críticas:

- Desconexión automática del suministro en caso de falla a tierra o corriente de fuga a tierra excesiva.

- Soporte de sistemas de tierra funcional (FE) para equipos que requieren una referencia de tierra estable para su funcionamiento.

- Mitigación de las diferencias de tensión entre partes conductoras expuestas y partes conductoras extrañas mediante una conexión equipotencial efectiva.

- Provisión de una ruta de falla confiable de baja impedancia capaz de conducir de manera segura corrientes de falla y fuga en diversas condiciones físicas y ambientales.

- Habilite conexiones seguras tanto para partes conductoras expuestas como extrañas.

Sistema de puesta a tierra MEN

La norma se basa principalmente en el sistema de neutro múltiple a tierra (MEN), el método de conexión a tierra predeterminado en Australia y Nueva Zelanda. En esta configuración:

- El conductor neutro (PEN) se conecta a tierra en la fuente de suministro, en puntos regulares a lo largo de la red de distribución y nuevamente en cada instalación eléctrica.

- Dentro de la instalación, el sistema de puesta a tierra se mantiene separado del conductor neutro, lo que garantiza la conexión adecuada de todas las partes conductoras expuestas a una referencia de tierra dedicada.

Otros sistemas de puesta a tierra

Los sistemas de puesta a tierra alternativos pueden ser aceptables siempre que cumplan con los resultados de seguridad fundamentales de la Parte 1 y no afecten negativamente las características del sistema de distribución de suministro.

Funciones de puesta a tierra

Puesta a tierra de protección garantiza que si ocurre una falla, los voltajes de contacto se minimizan y el suministro se desconecta rápidamente para evitar daños.

Puesta a tierra funcional (PE) Se utiliza para facilitar el correcto funcionamiento de ciertos equipos, no necesariamente por motivos de seguridad. Por ejemplo, algunos sistemas electrónicos o de datos necesitan una tierra limpia.

Si se combinan la puesta a tierra protectora y funcional, los requisitos de protección siempre tienen prioridad.

Componentes del sistema de puesta a tierra

Un sistema de puesta a tierra completo normalmente incluye:

Conductores de puesta a tierra de protección para conectar partes conductoras expuestas.

El conductor de tierra principal, que une el sistema a tierra.

El terminal o barra de puesta a tierra principal (un punto de conexión central).

Un enlace (conexión MEN) entre la barra de tierra principal y el neutro.

Un electrodo de tierra enterrado en el suelo.

Unión equipotencial para conectar otras partes metálicas y reducir las diferencias de tensión.

Materiales y tipos de conductores

Cobre Es el material más común y debe ser cobre de alta conductividad en forma trenzada, trenzada o sólida.

Aluminio También se pueden utilizar, pero con limitaciones como tamaños mínimos y restricciones de uso húmedo o subterráneo.

Otros materiales Se pueden utilizar si su rendimiento en conductividad y resistencia a la corrosión es al menos tan bueno como el del cobre.

Dimensionamiento del conductor de puesta a tierra

Los conductores de puesta a tierra deben ser lo suficientemente grandes para:

Conduce la corriente de falla de forma segura sin sobrecalentamiento.

Mantenga la impedancia del bucle de tierra lo suficientemente baja para poder activar los dispositivos de protección.

Soportar tensiones mecánicas y ambientales.

Puesta a tierra de equipos

Todas las partes metálicas expuestas del equipo eléctrico que podrían energizarse durante una falla deben estar conectadas a tierra, a menos que:

Doblemente aislado y marcado como tal.

Suministrado por sistemas SELV o PELV (baja tensión, seguro por diseño).

Separado eléctricamente de tierra de manera conforme.

Conductor de puesta a tierra principal

Este conductor conecta la barra principal de puesta a tierra del cuadro eléctrico al electrodo de tierra. Debe tenderse lo más directamente posible y no conectarse directamente a ningún aparato ni terminal auxiliar.

Enlace equipotencial

La conexión equipotencial conecta componentes conductores (como tuberías de agua o estructuras metálicas) al sistema de puesta a tierra para reducir el riesgo de descarga eléctrica. Esto ayuda a igualar las diferencias de potencial que podrían surgir debido a:

Fallos externos (como fallas en las tuberías de entrada de agua o gas).

Corrientes de tierra del sistema eléctrico.

Caídas de rayos o subidas de tensión cercanas.

Sección 7: Instalaciones Eléctricas Especiales

La Sección 7 de la norma AS/NZS 3000:2018 establece requisitos específicos para la selección e instalación de equipos eléctricos en instalaciones eléctricas especiales. Estas instalaciones se consideran "especiales" debido a sus condiciones operativas únicas, requisitos de seguridad o entornos de riesgo. Esta sección complementa, sustituye o modifica los requisitos generales de instalación que se encuentran en otras partes de la Norma para garantizar que se mantengan la seguridad y el rendimiento funcional en estas circunstancias específicas.

Servicios de seguridad

Esta cláusula trata de los sistemas eléctricos esenciales para emergencias y seguridad de vida, tales como:

- Sistemas de detección, alerta y extinción de incendios

- Sistemas de control de humo y ventilación

- Sistemas de evacuación de emergencia

- Sistemas de elevación utilizados durante emergencias

El objetivo principal es garantizar la continuidad del suministro eléctrico durante eventos críticos. Los requisitos específicos incluyen sistemas de cableado robustos que resistan incendios y daños mecánicos, así como disposiciones claras para la continuidad del suministro, la redundancia y la clasificación de equipos según las clasificaciones WS (Sistema de Cableado), según lo descrito en la norma AS/NZS 3013.

Sistemas de generación de electricidad

La cláusula 7.3 cubre varios sistemas de generación de energía en el sitio, incluidos:

- Sistemas de suministro alternativos y complementarios (por ejemplo, generadores de reserva)

- Sistemas autónomos (no conectados a la red eléctrica)

- Sistemas inversores interactivos (sistemas conectados que utilizan fuentes de energía renovables como la solar o la eólica)

- Sistemas de baterías

Establece estándares mínimos de seguridad y rendimiento para garantizar un funcionamiento seguro durante la operación, tanto en red como aislada. También aborda el control del flujo de energía, la compatibilidad de voltaje, la gestión de la carga y las condiciones para la exportación de energía a la red.

Instalaciones eléctricas de muy baja tensión

Aquí se describen los sistemas de muy baja tensión (VLE), como el VLE (VLT separado) y el VLE (VLT protegido). Estos sistemas se utilizan ampliamente en:

- Telecomunicaciones

- Sistemas de seguridad

- Circuitos de control

La cláusula describe los criterios para la limitación de voltaje, el aislamiento de la fuente, la separación de circuitos, la protección contra sobrecorrientes y las prácticas de cableado adecuadas para garantizar la seguridad contra descargas eléctricas e incendios. También aclara cuándo las instalaciones de vehículos eléctricos fuera de uso pueden estar exentas de ciertas protecciones.

Instalaciones eléctricas de alta tensión

Instalaciones de alta tensión (operando por encima de 1000 V CA o 1500 V CC) Exigir consideraciones específicas de seguridad y rendimiento. La cláusula 7.6 aborda:

- Distancias de seguridad requeridas, niveles de aislamiento y sistemas de puesta a tierra

- Medidas de acceso y protección contra incendios

- Pruebas y etiquetado

- Coordinación de diseño con la norma AS 2067 (Australia) y el Reglamento de Seguridad Eléctrica (Nueva Zelanda)

Asegura que los sistemas de alto voltaje, a menudo utilizados en entornos industriales o de servicios públicos, se integren de forma segura en instalaciones eléctricas más amplias.

Áreas peligrosas

Esta cláusula describe los requisitos para los equipos eléctricos utilizados en áreas peligrosas, es decir, lugares donde hay gases, vapores o polvos combustibles inflamables, como:

- refinerías de petróleo

- Plantas químicas

- Silos de grano

- talleres de pintura

Se basa en la serie AS/NZS 60079 para la clasificación, selección e instalación de equipos eléctricos protegidos contra explosiones. La clasificación de áreas, la certificación de equipos y los métodos de instalación adecuados son fundamentales para mitigar el riesgo de ignición y explosión.

Carga de vehículos eléctricos

A medida que se acelera la adopción de vehículos eléctricos, esta sección proporciona un marco integral para garantizar una infraestructura segura y que cumpla con los estándares para los sistemas de carga de vehículos eléctricos residenciales y comerciales.

La Sección 7.9 complementa los requisitos generales de las Secciones 2 a 7 al abordar las consideraciones específicas de seguridad, suministro e instalación de los sistemas de carga de vehículos eléctricos. Se proporciona orientación adicional en:

Apéndice P – sobre los modos de carga de vehículos eléctricos.

Apéndice C – sobre cómo la carga de vehículos eléctricos afecta los cálculos de demanda máxima.

Sistema de Abastecimiento

Todos los sistemas de carga de vehículos eléctricos deben utilizar un sistema de puesta a tierra TN-CS (MEN). Cabe destacar que, debido a riesgos de seguridad para la puesta a tierra, no pueden suministrarse a través de subredes que utilicen conductores PEN a edificios anexos. Esto garantiza el correcto funcionamiento de los mecanismos de detección de fallos de puesta a tierra de los sistemas de carga de vehículos eléctricos.

Instalaciones residenciales:

Modo 1 de carga No se permite el uso de enchufes generales.

Cargadores de modo 2 debe utilizar un circuito dedicado de 20 A, un RCD tipo B y una toma de corriente compatible instalada al menos a 800 mm sobre el suelo.

Cargadores de modo 3 y 4 (tipos de carga más rápida) requieren un circuito dedicado de 32 A, cableado directo, un interruptor de aislamiento y un RCD tipo B para protección.

Instalaciones no residenciales:

Todos los cargadores de vehículos eléctricos deben tener protección RCD tipo B, que garantiza la seguridad frente a corrientes de CC y de falla.

Consejos profesionales: ¿Quieres saber más sobre los códigos eléctricos globales para la carga de vehículos eléctricos? Consulta nuestra última... Guía experta sobre los 4 estándares para la carga de vehículos eléctricos Para más información.

Apéndice N – Conductos eléctricos

El Apéndice N de la norma AS/NZS 3000:2018 describe las directrices esenciales sobre los sistemas de conductos eléctricos utilizados para la gestión de cables en instalaciones eléctricas de Australia y Nueva Zelanda. Detalla dos conjuntos paralelos de normas que rigen el diseño, el rendimiento y el marcado de los conductos, garantizando así la compatibilidad con las exigencias regulatorias y ambientales de la región. Estas normas se aplican a una amplia gama de tipos de conductos, incluyendo sistemas rígidos, flexibles y corrugados, utilizados en aplicaciones residenciales, comerciales, industriales y de infraestructura.

Tipos de conductos

Conductos rígidos (AS/NZS 2053.2 / AS/NZS 61386.21)

Los conductos rígidos son tubos rectos de paredes duras fabricados generalmente de PVC o termoplásticos libres de halógenos. Se utilizan para cableado expuesto o empotrado en instalaciones fijas donde se necesita protección mecánica.

Usos comunes: Instalaciones subterráneas, huecos en paredes, entornos industriales.

Conductos flexibles (AS/NZS 2053.4 / AS/NZS 61386.23)

Los conductos flexibles se pueden doblar fácilmente sin deformación permanente, lo que los hace ideales para tramos cortos, instalaciones dinámicas o áreas que requieren resistencia a la vibración.

Usos comunes: Cableado de máquinas, envolventes modulares, conexión a motores y HVAC.

Conductos corrugados (AS/NZS 2053.5)

Los conductos corrugados presentan un diseño flexible y acanalado que permite doblarlos sin necesidad de accesorios. Se utilizan frecuentemente en aplicaciones domésticas y comerciales ligeras, y son más fáciles de instalar en espacios reducidos o curvos.

Usos comunes: Espacios de techo, bajadas de cables, cableado de cuadros eléctricos.

Conductos de pared de perfil y de paso liso (AS/NZS 2053.6)

Estos conductos combinan una pared exterior estructurada (que proporciona flexibilidad y resistencia) con un orificio interior liso, lo que facilita el tendido de cables. Ofrecen un equilibrio perfecto entre flexibilidad y alta resistencia mecánica.

Usos comunes: Instalaciones de infraestructura, energía solar, datos y telecomunicaciones.

Conductos flexibles (AS/NZS 61386.22)

Los conductos flexibles mantienen su forma al doblarse, a diferencia de los flexibles, que recuperan su forma original. Son menos comunes, pero se utilizan en aplicaciones de enrutamiento especializadas o personalizadas.

Usos comunes: Paneles de control, sistemas de cableado personalizados, cableado de vehículos o equipos.

Comprensión de las clasificaciones de servicio

Los conductos, según ambas normas, se clasifican según su resistencia mecánica y ambiental. Estas clasificaciones ayudan a los especificadores a elegir el producto adecuado para la aplicación prevista:

VLD – Trabajo muy ligero: Zonas de bajo riesgo, cableado interno

LD – Trabajo ligero: Cableado residencial general

MD – Servicio mediano: Espacio comercial, techo/azotea

HD – Trabajo pesado: Entender, áreas expuestas

VHD – Trabajo muy pesado: Zonas industriales de alto tráfico

Números de clasificación en AS/NZS 61386

Si bien las clasificaciones de servicio se utilizan ampliamente en la práctica, la serie AS/NZS 61386 también permite la clasificación mediante códigos de cuatro dígitos, que representan:

Resistencia a la compresión

Resistencia al impacto

Temperatura mínima de funcionamiento

Temperatura máxima de funcionamiento

Guía paso a paso para el cumplimiento de la norma AS/NZS 3000

Cumplir con la norma AS/NZS 3000:2018 (Reglas de Cableado) no es solo un requisito regulatorio, sino que es fundamental para garantizar la seguridad, la fiabilidad y el rendimiento a largo plazo de las instalaciones eléctricas en Australia y Nueva Zelanda. Ya sea electricista, ingeniero eléctrico, contratista o inspector colegiado, comprender los pasos para el cumplimiento le ayudará a evitar costosas modificaciones, evitar riesgos y realizar instalaciones que cumplan con las normas modernas.

Paso 1: Comprender el alcance y los requisitos del proyecto

Antes de comenzar cualquier trabajo físico, defina claramente el tipo de instalación y la aplicación prevista. Determine si se trata de:

Nueva construcción residencial

Renovación comercial

Modernización industrial

Instalación de carga de vehículos eléctricos

Sistema de energía solar o de batería

Ubicación peligrosa (se requiere clasificación de zona)

Paso 2: Diseñar la instalación eléctrica

La fase de diseño debe reflejar tanto el cumplimiento normativo como la viabilidad. Utilice las directrices AS/NZS 3000 para:

Determinar los métodos de cableado (por ejemplo, conducto, bandeja para cables, cableado TPS)

Seleccionar dispositivos de protección (por ejemplo, disyuntores, RCD, protección contra sobretensiones)

Dimensionar conductores y cables Basado en la capacidad de transporte de corriente, caída de tensión y condiciones de instalación

Elija disposiciones de puesta a tierra adecuadas y la vinculación según la Sección 5

Plan de seguridad contra incendios y protección mecánica de cableado

Paso 3: Seleccionar materiales y componentes compatibles

Asegúrese de que todos los materiales cumplan con las normas australianas y neozelandesas. Para conductos, interruptores, disyuntores, cables, cajas y conectores:

Utilice productos certificados AS/NZS (por ejemplo, AS/NZS 2053 para conductos, AS/NZS 3191 para cables flexibles)

Confirmar la idoneidad ambiental (resistencia a los rayos UV, libre de halógenos, clasificación IP, etc.)

Utilice componentes con clasificación eléctrica y mecánica para las aplicaciones previstas

Elija productos resistentes al fuego donde sea necesario (especialmente en espacios de techo o paredes resistentes al fuego)

Paso 4: Instalar según las pautas AS/NZS 3000

Realice la instalación según el diseño y las reglas de cableado:

Asegure correctamente el cableado y los conductos con clips, monturas y cajas

Evite dañar el aislamiento, doblar demasiado los cables o sobrecargar los conductos.

Mantenga distancias mínimas de fuentes de calor, tuberías de agua o materiales inflamables.

Instale interruptores de seguridad (RCD) según lo exige la Sección 2 para todos los subcircuitos finales que suministren tomas de corriente, iluminación o electrodomésticos fijos.

Siga las reglas de zona para baños y áreas húmedas (Sección 6.2)

Consejo: La documentación fotográfica durante la instalación puede ayudar en futuras inspecciones y detección de fallas.

Paso 5: Realizar pruebas y verificación

Una vez finalizada la instalación, las pruebas y la verificación garantizan el cumplimiento y la seguridad. Según la Sección 8 (Verificación), se deben realizar pruebas para:

Continuidad de los conductores

Resistencia de aislamiento

Impedancia de bucle de falla a tierra

Polaridad

Protección correcta del circuito

Paso 6: Registrar y certificar la instalación

En la mayoría de las jurisdicciones, los electricistas deben entregar un Certificado de Cumplimiento (COC) al finalizar el trabajo. Asegúrese de que toda la documentación sea clara y precisa, e incluya:

Disposición y horarios del circuito

Resultados de la prueba

Fichas técnicas de equipos

Certificaciones y marcados de productos

Evaluaciones de riesgos para instalaciones especiales

Consejo: Algunos estados o regiones también pueden requerir la presentación a través de portales regulatorios.

Paso 7: Mantenimiento y cumplimiento continuos

La norma AS/NZS 3000 también hace hincapié en la mantenibilidad, especialmente en espacios comerciales, industriales o públicos:

Instalar sistemas que permitan futuras inspecciones, accesos y servicios.

Documentar cambios o actualizaciones para futuras evaluaciones de cumplimiento

Asegúrese de que cualquier alteración o ampliación cumpla con las normas actuales (no solo con la fecha de instalación original)

5 infracciones comunes de AS/NZS 3000

A pesar de la exhaustiva guía de las Reglas de Cableado AS/NZS 3000:2018, muchas instalaciones en Australia y Nueva Zelanda aún no cumplen con la normativa debido a detalles pasados por alto, mala interpretación de cláusulas o mano de obra deficiente. Identificar infracciones comunes no solo ayuda a mejorar la seguridad y la fiabilidad, sino que también ahorra tiempo y costes durante la inspección o la certificación.

A continuación se presentan algunos de los problemas de incumplimiento de AS/NZS 3000 más frecuentes y cómo evitarlos.

Protección RCD inadecuada

La violación:

RCD (dispositivos de corriente residual) no instalados donde son necesarios o se utilizan tipos incorrectos (por ejemplo, tipo AC en lugar de tipo A o B para cargadores de vehículos eléctricos y electrodomésticos con controles electrónicos).

Cómo evitarlo:

Instalar RCD en todos los subcircuitos finales que alimentan tomas de corriente, iluminación y electrodomésticos fijos en instalaciones domésticas y comerciales.

Para cargadores de vehículos eléctricos o equipos con cargas electrónicas, utilice siempre RCD tipo A o tipo B según se especifica en la norma.

Pruebe periódicamente el funcionamiento del RCD y etiquételo adecuadamente.

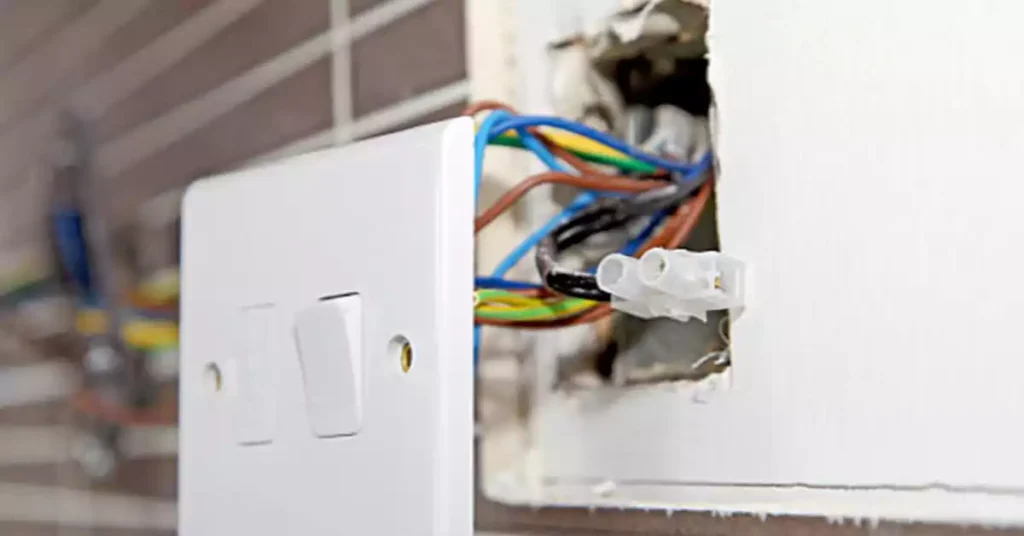

Soporte de cable o protección mecánica inadecuados

La violación:

Cables instalados sin la fijación adecuada, sin soporte en espacios del techo o expuestos a daños mecánicos sin protección de conductos.

Cómo evitarlo:

Siga la norma que exige que los cables estén sujetos de forma segura a intervalos regulares.

Utilice conductos compatibles con AS/NZS 2053 o AS/NZS 61386 para protección mecánica en ubicaciones expuestas o subterráneas.

En los espacios del techo o en las cavidades de las paredes, instale bandejas o soportes para cables para evitar que se comben o entren en contacto con superficies afiladas.

Conexión a tierra y unión incorrectas

La violación:

Conexión incorrecta de conductores de puesta a tierra de protección, falta de unión a tuberías o estructuras metálicas o uso de tamaños de conductores incorrectos.

Cómo evitarlo:

Cumpla con las Secciones 5.5 y 5.6, asegurándose de que todas las partes conductoras expuestas estén conectadas a tierra.

Utilice conductores del tamaño y material correctos según la Tabla 5.1.

Una todas las partes conductoras extrañas (por ejemplo, tuberías de agua, acero estructural) de acuerdo con la Cláusula 5.6.2.5.

Caída de tensión que excede los límites

Los cables de larga longitud generan caídas de tensión que superan el rango aceptable, lo que provoca un rendimiento deficiente de los electrodomésticos y un posible sobrecalentamiento.

Cómo evitarlo:

Calcule la caída de tensión para todos los subcircuitos finales utilizando la Cláusula 3.6.2.2, asegurándose de que se mantenga dentro del límite recomendado de 5%.

Utilice cables de mayor tamaño para recorridos largos o circuitos de alta carga, como cargadores de vehículos eléctricos o unidades HVAC.

Conductos de tamaño insuficiente o incorrectos

Utilizar conductos de tamaño insuficiente que no permitan el movimiento de cables ni futuras actualizaciones, o utilizar materiales de conductos no conformes.

Cómo evitarlo:

Seleccione el tamaño del conducto según la Cláusula 3.10, dejando al menos 40% de capacidad disponible.

Utilice conductos y accesorios de PVC rígidos o corrugados que cumplan con AS/NZS 2053, o la serie AS/NZS 61386 para sistemas clasificados por rendimiento (por ejemplo, HD o VHD).

Utilice conductos resistentes a los rayos UV y a los impactos para instalaciones externas (marcados con “T” para rayos UV y “HD” o “VHD” para protección mecánica).

Novedades de la versión 2023 de AS/NZS 3000

La actualización de 2023 de la norma AS/NZS 3000:2018, comúnmente conocida como las Reglas de Cableado, refleja la evolución del panorama de la seguridad y la tecnología eléctrica en Australia y Nueva Zelanda. Esta revisión incluye más de 200 cambios, destinados a mejorar la claridad, la seguridad y la adaptación a tecnologías emergentes como los vehículos eléctricos (VE), los sistemas solares fotovoltaicos y la infraestructura eléctrica inteligente.

Cambios clave en la norma AS/NZS 3000:2023

Estas son algunas de las actualizaciones notables en la versión 2023:

1. Requisitos aclarados del RCD

Se han aclarado y ampliado las normas sobre dispositivos de corriente residual (RCD):

La protección RCD ahora es obligatoria para todos los subcircuitos finales en instalaciones residenciales, incluidas alteraciones y reparaciones.

Se proporcionan mayores detalles sobre la protección RCD en tomas de corriente y circuitos de iluminación.

2. Instalación de cables revisada a través del aislamiento

Se proporciona una guía actualizada para la instalación de cables con aislamiento térmico masivo, con énfasis en evitar el sobrecalentamiento y garantizar el cumplimiento de las normas de seguridad a largo plazo. La norma introduce nuevas tolerancias y medidas de protección según el tipo de cable y el entorno de uso.

3. Zonas de exclusión de baños y lavandería

La norma ahora incluye zonas de exclusión actualizadas para enchufes e interruptores de luz en áreas húmedas como:

Baños

Lavanderías

Estos cambios garantizan un menor riesgo de descarga eléctrica en zonas expuestas a la humedad.

4. Controles de estufas y sistemas de agua caliente

Se introducen nuevos requisitos de conmutación para:

Cocinas eléctricas, que ahora requieren interruptores de aislamiento accesibles.

Calentadores de agua, con requisitos actualizados de desconexión y control.

Además, las zonas de exclusión de enchufes e interruptores cerca de las cocinas ahora están más claramente definidas para minimizar el riesgo de incendio.

5. Requisitos mejorados de puesta a tierra

La revisión de 2023 refuerza los requisitos para:

Sistemas generales de puesta a tierra

Puesta a tierra de piscinas (donde la ecualización de potencial es fundamental para la seguridad)

Procesos de verificación relacionados con la continuidad de la puesta a tierra

6. Mejoras en el cuadro de distribución y el espacio libre

Para respaldar instalaciones más seguras y accesibles, la actualización incluye:

Requisitos mínimos claros de espacio libre para cuadros de distribución

Prácticas de instalación mejoradas para aplicaciones residenciales y comerciales

7. Energía renovable y generación distribuida

La norma revisada incorpora sistemas de generación modernos, incluidos:

Sistemas solares fotovoltaicos (PV) en azoteas

Otros recursos energéticos distribuidos (DER)

8. Nuevas disposiciones sobre la carga de vehículos eléctricos

Por primera vez, la norma aborda explícitamente la infraestructura de carga de vehículos eléctricos (VE), incluyendo:

Tomas de corriente exclusivas para vehículos eléctricos

Consideraciones sobre el control de carga

Requisitos del interruptor de aislamiento

Esto se alinea con la creciente adopción de vehículos eléctricos y garantiza que la infraestructura esté preparada para el futuro y sea segura.

AS/NZS 3000 vs. otros códigos eléctricos (NEC y CEC)

Las Reglas de Cableado AS/NZS 3000:2018 (comúnmente conocidas como Reglas de Cableado de Australia/Nueva Zelanda) establecen los requisitos esenciales de seguridad para las instalaciones eléctricas en Australia y Nueva Zelanda. Si bien comparten una filosofía de seguridad similar a la de otros códigos importantes, como el Código Eléctrico Nacional (NEC) de EE. UU. y el Código Eléctrico Canadiense (CEC) de Canadá, existen diferencias importantes en estructura, terminología, detalles técnicos y adaptación regional.

Estructura del Código y Jurisdicción

AS/NZS 3000: Desarrollada conjuntamente por Australia y Nueva Zelanda, y legalmente obligatoria o referenciada en las normativas nacionales o estatales, la norma integra las mejores prácticas de seguridad, diseño e instalación adaptadas a las condiciones locales.

Norma nacional de certificación (NFPA 70): Publicado por la Asociación Nacional de Protección contra Incendios (NFPA) y adoptado en todo Estados Unidos, el NEC se actualiza cada tres años y se centra principalmente en la prevención de incendios y la seguridad eléctrica.

CEC (CSA C22.1): Publicado por la Asociación Canadiense de Normas, el CEC se utiliza en todas las provincias canadienses con modificaciones específicas para cada provincia.

Sistemas de tensión y puesta a tierra

AS/NZS 3000: Se utiliza comúnmente el sistema de puesta a tierra TN-CS (MEN), obligatorio en entornos residenciales y comerciales. La conexión a tierra de protección (PE) y el neutro (N) se conectan en el cuadro eléctrico principal.

NEC y CEC: Permitir varios sistemas de conexión a tierra, incluidos TN, TT e IT, con requisitos detallados para conductores de electrodos de conexión a tierra, unión y separación neutro-tierra.

Requisitos del RCD (dispositivo de corriente residual)

AS/NZS 3000: Los RCD son obligatorios para casi todos los subcircuitos finales en instalaciones residenciales y comerciales. Los cambios recientes exigen RCD de tipo B para cargadores de vehículos eléctricos.

COMITÉ EJECUTIVO NACIONAL: Requiere protección GFCI (interruptor de circuito por falla a tierra) para áreas específicas como baños, cocinas, exteriores y tomas de corriente para vehículos eléctricos, pero las reglas son más selectivas que AS/NZS 3000.

CEC: Similar al NEC, pero incluye adiciones específicas de Canadá; los RCD se conocen como GFCI o dispositivos de Clase A, y los requisitos de EV también dependen del tipo de cargador.

Instalación y aislamiento de cables

AS/NZS 3000: Se enfatiza la reducción de la capacidad nominal de los cables en el aislamiento a granel, se definen zonas de exclusión y se exige protección física. Se utilizan tipos de cable específicos de AS/NZS.

NEC/CEC: Ofrece tablas completas de ampacidades de conductores, correcciones de temperatura y ajustes de agrupamiento. Utiliza tipos de cables norteamericanos (p. ej., NM, THHN).

Disposiciones sobre carga de vehículos eléctricos

AS/NZS 3000: Incluye la Cláusula 7.9 dedicada a la carga de vehículos eléctricos (solo Nueva Zelanda), que describe las instalaciones de Modo 2 a Modo 4, la protección RCD, las clasificaciones de los cables y las alturas de instalación.

NEC (Artículo 625): Define los requisitos de EVSE, incluidos circuitos derivados dedicados, protección contra sobrecorriente, GFCI y etiquetado.

CEC: Incorpora requisitos de cargadores de vehículos eléctricos similares a los del NEC con orientación provincial adicional; se abordan tanto la carga de nivel 1 como la de nivel 2.

Ubicaciones peligrosas

AS/NZS 3000 Sigue el sistema de zonas IEC y se remite a la serie AS/NZS 60079 para obtener información detallada sobre clasificación, selección e instalación de equipos. Estas normas garantizan un funcionamiento seguro en zonas con riesgo potencial de explosión.

Comité ejecutivo nacional Utiliza un sistema de Clases y Divisiones, aunque también se permite el sistema de Zonas. Define los peligros según la probabilidad y el tipo de materiales explosivos.

CEC Adopta principalmente el sistema de zonas IEC, similar a AS/NZS 3000, y hace referencia a las mismas normas IEC 60079 para ubicaciones peligrosas.

Cuadro comparativo de AS/NZS 3000, NEC y CEC

Aspecto | Norma AS/NZS 3000:2018 | NEC (NFPA 70) | CEC (CSA C22.1) |

Estructura del código y jurisdicción | Desarrollado conjuntamente por Standards Australia y Standards NZ; legalmente obligatorio o referenciado en regulaciones federales/estatales; integra las mejores prácticas de seguridad, diseño e instalación para las condiciones locales. | Publicado por NFPA; adoptado a nivel nacional en los EE. UU.; actualizado trienalmente; gran énfasis en la prevención de incendios y la seguridad eléctrica general. | Publicado por CSA; adoptado por las provincias con modificaciones específicas de cada provincia; se alinea con las prácticas de América del Norte al tiempo que se adapta a los climas y cargas locales. |

Sistemas de tensión y puesta a tierra | Exige sistema TN-CS (MEN) en aplicaciones residenciales/comerciales; PE y N unidos en el tablero de distribución principal; dimensionamiento detallado del conductor de puesta a tierra. | Permite sistemas TN, TT, IT; especifica el dimensionamiento del conductor del electrodo de puesta a tierra, la unión y las reglas de separación neutro-tierra. | Similar a la flexibilidad de NEC (TN, TT, IT), pero incluye consideraciones de resistividad del suelo canadiense y requisitos de adhesión adicionales. |

Requisitos de RCD/GFCI | Los RCD son obligatorios en casi todos los subcircuitos finales de hogares y muchas instalaciones comerciales; ahora se requieren RCD tipo B para cargadores de vehículos eléctricos. | Se requiere GFCI en ubicaciones específicas (baños, cocinas, exteriores, garajes, áreas húmedas, tomas de corriente para vehículos eléctricos), pero en general es más selectivo. | Se requieren dispositivos “GFCI” o Clase A en ubicaciones estilo NEC más adaptaciones para climas fríos; la protección de la salida del EV depende de la clase de cargador. |

Instalación y aislamiento de cables | Hace hincapié en la reducción de la clasificación de cables para agrupación térmica, zonas de exclusión cerca de fuentes de calor y protección mecánica obligatoria; utiliza tipos de cables especificados por AS/NZS. | Tablas de capacidad de corriente extensas, factores de corrección de temperatura y ajuste de agrupamiento; utiliza tipos de cables de América del Norte (por ejemplo, NM, THHN). | Refleja las tablas NEC pero agrega reducción de potencia para recorridos largos en climas fríos; tipos de cables aprobados por Canadá con marcas CSA. |

Disposiciones sobre carga de vehículos eléctricos | La cláusula 7.9 (solo NZ) cubre los modos 2 a 4, protección RCD, clasificaciones de cables y alturas de montaje; orientación para estaciones residenciales y públicas. | Artículo 625: circuitos derivados dedicados, protección contra sobrecorriente y GFCI, señalización y reglas de espacio libre para trabajar. | Incorpora los requisitos del Artículo 625 más los anexos provinciales; aborda la tarificación de Nivel 1 (120 V) y Nivel 2 (240 V) con enmiendas locales. |

Ubicaciones peligrosas | Follows IEC Zone system; references AS/NZS 60079 series for gas/dust classification, equipment selection & installation. | Uses Class/Division method by default (Zones permitted); defines hazards by material type & likelihood; NFPA 496 for classification. | Adopts IEC Zone system (like AS/NZS 3000); references IEC 60079 and CSA Group guidance; includes Canadian explosive-atmosphere tables. |

Practical Applications

Understanding AS/NZS 3000:2018 isn’t just about compliance—it’s about applying the Wiring Rules effectively in real-world projects. For electrical contractors and manufacturers, these applications ensure safer installations, reduce risk, and help maintain a high standard of workmanship across the industry. Here’s how the standard plays out in practice:

For Electrical Contractors

Designing and Installing Compliant Systems

Contractors must reference AS/NZS 3000 from the design stage onward to:

Ensure correct cable sizing, circuit protection, and earthing.

Meet RCD protection requirements, especially after the 2023 updates.

Follow installation methods for wiring systems in varying environments (e.g. damp locations, roof spaces, or areas with insulation).

Working with Emerging Technologies

The standard supports safe integration of new technologies, such as:

Electric Vehicle (EV) charging systems – following Section 7.9 (NZ only).

Solar and battery storage systems – ensuring isolation, fault protection, and system compatibility.

Smart home automation – where clear wiring practices and compliance with safety distances are critical.

Verifying and Certifying Installations

Post-installation, contractors must:

Conduct thorough testing and verification in line with Section 8.

Document results and keep inspection records, especially for high-risk or commercial projects.

Identify and resolve non-compliances to avoid violations.

For Manufacturers

Product Design Aligned to Standards

Electrical product manufacturers—such as those producing conduit, wiring accessories, switchboards, and EV chargers—must:

Design equipment that meets dimensional and performance standards.

Provide products compliant with IP ratings, RCD types (e.g., Type B for EV chargers), and flammability classifications where needed.

Clear Product Marking and Documentation

AS/NZS 3000 and referenced standards (e.g. AS/NZS 3100, AS/NZS 60079) require:

Legible markings for voltage, current ratings, approval numbers.

Installation guides that help contractors follow best practices.

Product compliance to AS/NZS certifications, proving safety for use in Australia and New Zealand.

Support for Installation Environments

Manufacturers must ensure that products are fit for:

Outdoor or underground use (e.g. UV-resistant conduits, IP-rated enclosures).

Hazardous areas, where compliance with AS/NZS 60079 is essential.

Residential and commercial builds, including locations like bathrooms, rooftops, and data centers.

Ledes Products Support for AS/NZS Compliance

As the AS/NZS 3000:2018 Wiring Rules continue to guide safe and reliable electrical installations across Australia and New Zealand, selecting compliant conduit systems becomes essential for both electrical contractors and project developers. Ledes understands these evolving compliance needs and offers a full range of AS/NZS-certified conduit solutions designed to help meet the standard’s strict safety, mechanical, and environmental requirements.

AS/NZS 3000 emphasizes mechanical protection, UV resistance, flame retardancy, and durability in harsh environments. To help meet these performance benchmarks, Ledes manufactures a wide variety of conduit products that align with key sections of the standard — including provisions for wiring protection in damp locations, underground systems, commercial installations, and communication pathways.

AS/NZS - Compliant Conduit Offerings

Conducto rígido

Ledes rigid conduits are built for tough environments where strength and structural integrity are critical. Compliant with AS/NZS 2053.2 and AS/NZS 2053.1, these conduits are:

- UV-resistant, ideal for outdoor installations.

- Designed to provide mechanical impact protection in both surface-mounted and buried systems.

- Available in a range of sizes and both medium-duty and heavy-duty ratings to suit residential, commercial, and industrial settings.

Conducto corrugado

Flexible yet robust, Ledes corrugated conduit is designed to handle installations where routing through tight or uneven spaces is required. Compliant with AS/NZS 2053.5 and 2053.16, this conduit is:

- Available in both medium-duty and heavy-duty variants.

- Engineered for flexibility, crush resistance, and ease of handling.

- Suitable for indoor use, underfloor cabling, and enclosed wall systems where flexibility and compliance with flame and UV requirements are key.

Conductos de comunicación

AS/NZS 3000 requires appropriate segregation and protection of communication wiring. Ledes provides communication conduit systems in accordance with AS/NZS 2053.1 and AS/NZS 2053.2 and AS/NZS 2053.5, ideal for protecting data and low-voltage communication cables in both commercial and residential installations.

Accesorios para conductos

For a complete and compliant installation, Ledes offers a full range of matching accesorios de conductos, including elbows, couplings, adapters, tees, junction boxes, and clips. These fittings are:

- Manufactured to match the mechanical and fire resistance requirements of Ledes conduits.

- Designed for compatibility with both medium-duty and heavy-duty systems.

- Built with UV-stabilized materials for outdoor durability.

Ledes is committed to helping contractors and engineers build safer, code-compliant electrical systems. By offering a comprehensive selection of rigid and corrugated conduits, communication conduits, and fully compatible fittings, all designed to meet AS/NZS 3000 and related conduit standards. Ledes makes it easier to specify, install, and inspect compliant electrical conduit systems in Australia and New Zealand.

Conclusión

The AS/NZS 3000:2018 Wiring Rules remain the cornerstone of safe, reliable, and efficient electrical installations across Australia and New Zealand. From general wiring principles and protection requirements to provisions for hazardous areas and the integration of communication systems, this standard provides a unified framework that ensures consistency and safety in a wide range of applications — residential, commercial, and industrial alike.

As we move toward 2025 and beyond, the relevance of AS/NZS 3000 continues to grow, especially with the increasing demand for solar energy systems, electric vehicles, smart infrastructure, and communication integration. For electrical professionals, keeping up with the standard’s technical and legal requirements is not only a matter of compliance but a commitment to public and operational safety.

Ultimately, AS/NZS 3000 is more than just a rulebook, it’s a foundation for building the electrical systems of the future. Whether you’re an installer, designer, inspector, or manufacturer, staying informed and choosing compliant solutions is essential to driving safe innovation in electrical infrastructure.

Preguntas frecuentes

¿Qué es el estándar de reglas de cableado AS/NZS 3000?

La norma AS/NZS 3000, comúnmente conocida como las Reglas de Cableado, es una norma conjunta de Australia y Nueva Zelanda que describe los requisitos mínimos para el diseño, la construcción y la verificación de instalaciones eléctricas. Abarca principios de seguridad, selección de equipos, prácticas de instalación y aplicaciones específicas, como áreas peligrosas y sistemas de carga de vehículos eléctricos.

¿Es obligatorio el cumplimiento de la norma AS/NZS 3000?

Sí. El cumplimiento de la norma AS/NZS 3000 es legalmente obligatorio para las instalaciones eléctricas tanto en Australia como en Nueva Zelanda. La norma suele citarse en la legislación de seguridad eléctrica, lo que significa que su cumplimiento es un requisito para obtener aprobaciones y certificaciones.

¿Cuál es la última versión de AS/NZS 3000?

La versión más reciente es la AS/NZS 3000:2018, que incluye modificaciones hasta la Enmienda 3 (2023). A partir de 2025, esta versión sigue vigente a menos que sea reemplazada por una edición más reciente. Los usuarios deben consultar siempre con las autoridades reguladoras de Standards Australia o Nueva Zelanda para obtener las últimas actualizaciones.

¿AS/NZS 3000 incluye disposiciones para sistemas de carga de vehículos eléctricos (EV)?

Sí. La cláusula 7.9 de la norma AS/NZS 3000:2018 (solo para Nueva Zelanda) establece requisitos detallados para los sistemas de carga de vehículos eléctricos residenciales y no residenciales. Abarca el dimensionamiento de los circuitos, la protección diferencial (tipo B), los tipos de tomas de corriente y las ubicaciones de instalación para la carga en modo 2, 3 y 4. Estas disposiciones garantizan la integración segura de la infraestructura de vehículos eléctricos en las instalaciones eléctricas.

¿Cuáles son las clasificaciones de servicio para conductos en las normas AS/NZS?

Conduits under the AS/NZS 2053 and AS/NZS 61386 series are classified by duty ratings, which indicate their mechanical performance:

VLD – Very Light Duty

LD – Light Duty

MD – Medium Duty

HD – Heavy Duty

VHD – Very Heavy Duty

These classifications reflect resistance to compression, impact, and temperature.

¿Cuál es la diferencia entre un conducto para trabajo mediano y uno para trabajo pesado?

The duty rating refers to a conduit’s ability to withstand mechanical stress.

Medium-duty (MD) conduit is suitable for standard domestic or light commercial use where moderate protection is required.

Heavy-duty (HD) conduit is recommended for harsher environments, such as industrial sites or locations with frequent physical impact or exposure.

¿Se aplica la norma AS/NZS 3000 a las instalaciones solares fotovoltaicas?

Sí. La norma AS/NZS 3000 incluye requisitos generales para instalaciones solares, en particular en lo que respecta al aislamiento, la protección contra sobrecorrientes y las prácticas de cableado. Sin embargo, debe utilizarse junto con la norma AS/NZS 5033 (Requisitos de instalación y seguridad para sistemas fotovoltaicos), que proporciona normas de diseño específicas para sistemas fotovoltaicos.

¿Son necesarios los RCD en todos los circuitos?

Sí, según la revisión de 2023 de la norma AS/NZS 3000, la protección RCD es obligatoria en casi todos los subcircuitos finales de las instalaciones residenciales, incluyendo iluminación y tomas de corriente, así como en determinados circuitos comerciales e industriales. Existen exenciones específicas (p. ej., ciertos sistemas de emergencia), pero su uso generalizado es ahora la norma.

¿Qué es el sistema MEN mencionado en AS/NZS 3000?

MEN significa Neutro con Conexión a Tierra Múltiple. Es el sistema de puesta a tierra estándar utilizado en Australia y Nueva Zelanda, donde el conductor neutro se conecta a tierra en varios puntos, incluido el cuadro de distribución principal de una instalación. Esto garantiza una protección eficaz contra fallos y es un componente clave del sistema de seguridad eléctrica requerido por la norma AS/NZS 3000.

¿Cuál es el papel de AS/NZS 2053 en relación con AS/NZS 3000?

La norma AS/NZS 2053 es una norma de referencia dentro de la norma AS/NZS 3000 y define los requisitos para sistemas de conductos eléctricos y accesorios, incluyendo materiales, capacidades de servicio, resistencia mecánica y marcado. Los productos que cumplen con la norma AS/NZS 2053 ayudan a los instaladores a cumplir con los requisitos de protección física y soporte de cableado descritos en la norma AS/NZS 3000.

¿Cómo se aborda la caída de tensión en AS/NZS 3000?

La norma exige que la caída de tensión entre el punto de suministro y cualquier equipo no supere 5% de la tensión nominal. Los diseñadores deben calcular la caída de tensión en función de la longitud del circuito, la corriente de carga y el tamaño del conductor para garantizar el correcto funcionamiento de los equipos eléctricos.