Inhaltsverzeichnis

1. Introduction

Choosing the right type of conduit for any electrical or plumbing project can be more challenging than it seems.

With a variety of options available – Sch 40 vs Sch 80 vs Type A vs Type EB PVC Conduit – it’s easy to get overwhelmed by technical details like wall thickness, pressure ratings, material durability, and certification standards.

Selecting the wrong conduit can not only affect the longevity and safety of your installation but also lead to unnecessary costs and complications during construction.

Rather than looking at each type in isolation, we’ll examine them side by side across multiple key factors—such as wall thickness, pressure rating, durability, environmental suitability, cost, and certification.

By presenting all this information in one place, we aim to make your conduit selection process faster, clearer, and more reliable. By the end of this post, you will:

Know how to choose the right conduit type: Quickly understand the differences between Sch 40, Sch 80, Type A, and Type EB, and when to use each one.

Apply this knowledge to real projects: See how each type performs in residential, commercial, and industrial applications — whether it’s indoor, outdoor, or underground.

Avoid common mistakes: Find out how to prevent issues like using the wrong conduit type or mismatching fittings.

Make confident, data-based choices: Use technical data to balance cost, durability, and performance in every installation.

2. Conduit Comparison: Sch 40 vs Sch 80 vs Type A vs Type EB

Choosing the right conduit begins with understanding the two major classification systems used throughout the United States and Canada: Schedule Und Typ. Although these systems sometimes appear side by side, they describe very different characteristics. Knowing how they work—and how each conduit class performs—creates the foundation for accurate conduit selection.

2.1 What “Schedule” Really Means (Sch 40 & Sch 80)

Der Schedule rating refers primarily to wall thickness, a specification that directly affects a conduit’s strength, impact resistance, and mechanical protection.

- Sch 40 represents the standard wall thickness commonly used in residential wiring, commercial projects, and above-ground installations.

- Sch 80 has significantly thicker walls, giving it higher durability and better resistance to external forces like impact or equipment contact.

Because wall thickness increases with the schedule number, these conduits differ in several practical ways:

- Mechanischer Schutz: Sch 80 provides greater protection in exposed locations or areas with potential physical damage.

- Heat & pressure tolerance: Thicker walls retain their shape better under load or elevated temperatures.

- Weight & installation effort: Sch 40 is lighter and easier to handle, making it suitable for routine wiring routes.

2.2 What “Type” Represents (Type A & Type EB)

While Schedule ratings describe a physical dimension, Type classifications are defined around the conduit’s intended purpose and performance environment. These classifications are widely recognized across the U.S. and Canada and are commonly associated with CSA standards.

Type A conduits are designed for general-purpose indoor electrical systems.

Their characteristics include:

- Moderate wall thickness

- Easy handling and cutting

- Compatibility with standard fittings

- Sufficient protection for controlled environments

This makes Type A ideal for walls, ceilings, utility rooms, equipment rooms, and other areas where conductors do not face external mechanical stress.

Type EB, short for Encased Burial, is specifically engineered for underground electrical installations where the conduit is embedded in concrete or similarly protective encasements. It is not intended for exposed above-ground use.

Key performance characteristics include:

- Thicker wall construction compared to Type A conduit

- Enhanced resistance to impact during installation

- Improved ability to withstand soil loads and external pressure

- Long-term durability in moisture-prone underground environments

Type EB conduit is commonly installed beneath sidewalks, landscaped areas, parking lots, and roadways, where it is concrete-encased to provide structural support and long-term system reliability in accordance with applicable electrical codes.

2.3 Why the Two Systems Coexist in North America

Both Schedule and Type classifications are widely used in the United States and Canada, but each evolved to address different needs:

- Der Schedule system aligns with ASTM/UL standards and emphasizes dimensional consistency and mechanical strength.

- Der Typ system aligns more closely with CSA performance categories, focusing on where and how the conduit will be used.

In practice, electricians, engineers, and inspectors encounter both systems regularly. Many PVC conduit manufacturers offer Sch 40/80 products alongside Type A and Type EB lines because UL and CSA approvals often complement each other in North American projects.

This dual-standard environment allows project designers to choose conduits based on function, not just wall thickness.

3. Dimensions and Wall Thickness: Schedule 40, Schedule 80, Type A, and Type EB Conduits

Accurate dimensional control is one of the most important quality indicators for PVC electrical conduits. Although Schedule 40, Schedule 80, Type A, and Type EB conduits follow different structural requirements and performance expectations, their diameter and wall-thickness evaluations share the same fundamental objective: ensuring proper fit, mechanical strength, and compliance with electrical installation standards.

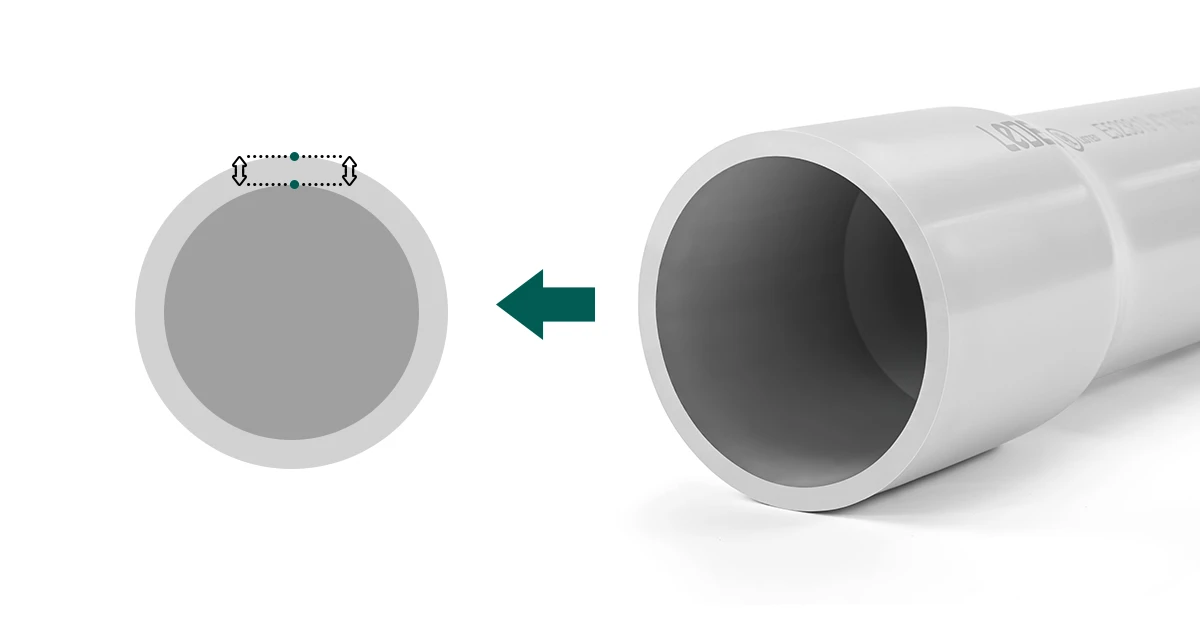

All conduit types are measured using precision micrometer calipers, with outside diameters recorded to the nearest 0.0001 inch and wall thickness averaged across multiple measurement points. This unified measurement method provides a consistent basis for comparing the dimensional performance of different conduit classifications.

Schedule 40 and Schedule 80 conduits typically exhibit the thickest walls because they are intended for applications that require stronger mechanical protection.

Schedule 80, in particular, features substantially increased wall thickness across all trade sizes, offering greater crush resistance and higher tensile strength.

Type A conduit, by comparison, is manufactured with lighter-duty wall thickness requirements, supporting installations where flexibility and ease of handling are prioritized over heavy-duty protection.

Type EB conduit—designed primarily for concrete encasement or underground duct systems—features its own dimensional range, with wall thickness generally thinner than Schedule 40/80 but controlled to meet burial and encasement requirements.

Handelsgröße | Min Wall Thickness(Schedule 40, inch) | Min Wall Thickness (Schedule 80,inch) | Min Wall Thickness (Type A,inch) | Min Wall Thickness (Type EB,inch) |

1/2 | 0.109 | 0.147 | 0.060 | – |

3/4 | 0.113 | 0.154 | 0.060 | – |

1 | 0.133 | 0.179 | 0.060 | – |

1-1/4 | 0.140 | 0.191 | 0.070 | – |

1-1/2 | 0.145 | 0.200 | 0.080 | – |

2 | 0.154 | 0.218 | 0.100 | 0.060 |

2-1/2 | 0.203 | 0.276 | 0.110 | – |

3 | 0.216 | 0.300 | 0.125 | 0.061 |

3-1/2 | 0.226 | 0.318 | 0.145 | 0.072 |

4 | 0.237 | 0.337 | 0.150 | 0..82 |

5 | 0.258 | 0.375 | – | 0.103 |

6 | 0.280 | 0.432 | – | 0.125 |

Notiz: The above data is for reference only. Actual values may vary depending on the standards and the manufacturer’s specifications. Differences between suppliers are normal, as long as they comply with the relevant codes and standards.

4. Testing Requirements and Performance Comparison: Schedule 40, Schedule 80, Type A, and Type EB

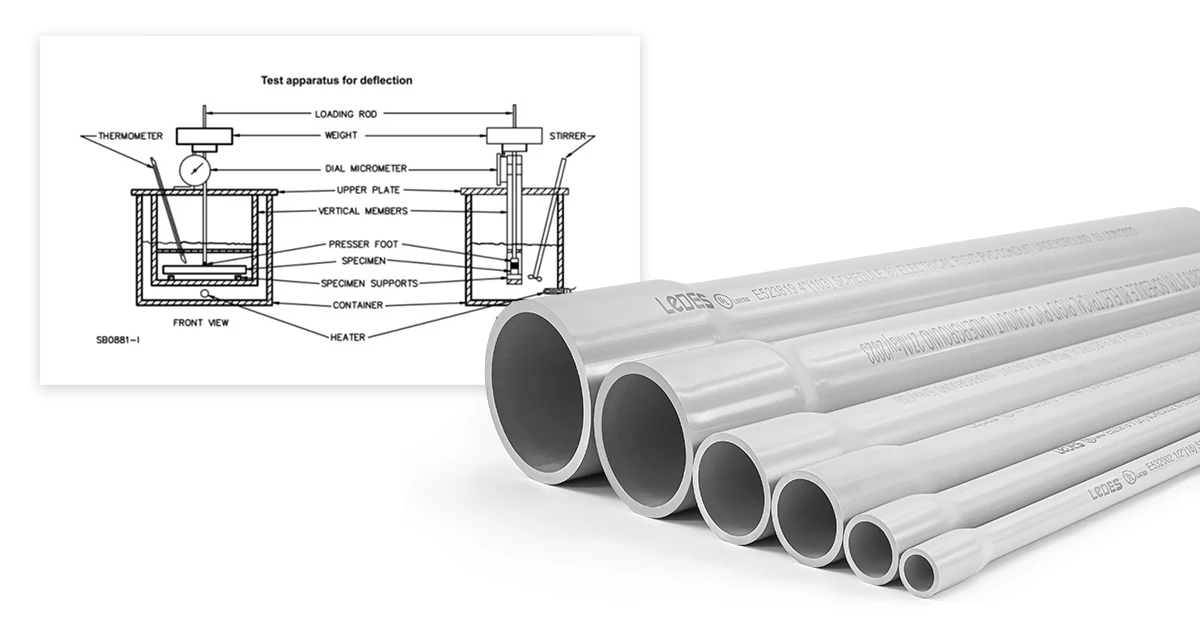

Testing for rigid PVC conduit—whether Schedule 40, Schedule 80, Type A, or Type EB—follows a unified framework based on UL 651 requirements.

All conduit types undergo several core mechanical tests designed to verify material quality, dimensional stability, and long-term structural performance. However, the standard also introduces type-specific procedures, especially in tensile specimen preparation, where the geometry of each conduit dictates different machining methods.

This section explains both the shared tests across all conduit types and the key differences that distinguish Schedule 40/80 from Type A and Type EB.

Profi-Tipps: Want to know more about UL 651 test items and the different between CSA? Read our expert insight by click the above link.

Tensile Strength Test (UL 651 Section 6.2)

All conduits must be tested for tensile strength, comparing unaged vs. aged specimens.

The aged samples must retain at least 95% of the tensile strength of unaged samples.

Minimum tensile strength requirements differ by product type:

- Schedule 40 & Schedule 80: ≥ 5,000 psi

- Type A & Type EB: ≥ 4,000 psi

All conduit types also follow the same environmental conditioning (23 ± 2°C), measurement accuracy (0.0001 in), and material smoothness requirements.

Dimensional Measurement Tests

Every conduit sample must undergo consistent dimensional measurement procedures:

- Outside diameters measured at both ends and center

- Minimum four readings per location, 45° apart

- Wall thickness measured using hemispherical anvils

These measurements ensure concentricity, proper sizing, and compliance with published diameter/wall thickness limits.

Aging, Conditioning, and Surface Quality Requirements

Before testing:

- Samples must remain clean and thermally stabilized

- Cutting surfaces must be smooth, scratch-free, and sanded along the longitudinal axis

These shared requirements ensure uniformity and remove processing defects that could affect mechanical results.

Additionally,under UL 651 and corresponding CSA standards, rigid PVC conduit intended for use with 90°C wiring must undergo an extended accelerated aging and impact performance evaluation, which can span up to 360 days. These tests are designed to verify that the conduit does not experience significant degradation in mechanical properties—particularly impact strength—when exposed to elevated operating temperatures over time.

Importantly, this testing is conducted by independent third-party certification bodies, such as UL, CSA, or ETL, rather than by the manufacturer itself. Only conduit products that successfully pass these evaluations are permitted to carry permanent print-line markings indicating suitability for “maximum 90°C wire”.

Certified products, including Ledes rigid PVC conduit, are manufactured and tested to meet these stringent requirements, providing confidence for engineers, contractors, and inspectors across a wide range of applications.

5. Mechanical Strength Tests (Impact, Flattening, Tensile) – Mechanical Performance Analysis

While Section 3 focused on the dimensional characteristics of Schedule 40, Schedule 80, Type A, and Type EB conduits, this section compares their mechanical performance under standardized testing conditions, highlighting both the shared test procedures and the differences that distinguish each conduit type.

5.1 Shared Testing Procedures

All four conduit types follow the UL 651 framework for mechanical testing, ensuring consistency in evaluating material quality, structural stability, and long-term durability. The core tests—tensile strength, impact (Izod), and flattening/compressive resistance—are conducted under controlled environmental conditions with precise measurement tools to maintain comparability.

Key shared procedures include:

- Dimensional verification before testing: all specimens are measured for outside diameter and wall thickness using micrometer calipers and hemispherical anvils to ensure compliance with nominal sizes.

- Specimen preparation: cut surfaces must be smooth, scratch-free, and parallel to the longitudinal axis. Any defect in curvature or machining leads to specimen rejection.

- Environmental conditioning: specimens are thermally stabilized before testing to eliminate residual stresses from manufacturing or handling.

- Impact testing method: Izod pendulum impact tests are performed following ASTM D 256, using notched specimens to assess energy absorption and brittleness.

- Flattening/compressive tests: conduits are compressed between parallel plates at controlled rates to evaluate buckling resistance, ensuring the pipe withstands external loads.

Leitungstyp | Minimum Tensile Strength | Notes on Performance |

Anhang 40 | ≥ 5,000 psi | Designed for general mechanical protection; retains ≥95% of strength after aging. |

Anhang 80 | ≥ 5,000 psi | Thicker walls provide superior crush resistance and higher ultimate strength. |

Type A | ≥ 4,000 psi | Lighter-duty wall allows easier handling; tensile retention slightly lower than Schedule 40/80. |

Type EB | ≥ 4,000 psi | Optimized for concrete encasement or burial; performance balanced with dimensional control. |

All conduit types undergo the same specimen geometry verification and environmental conditioning, but the minimum tensile thresholds differ according to the intended application and wall thickness.

5.2 Impact (Izod) Strength Comparison

- Schedule 40/80: higher wall thickness contributes to higher energy absorption and greater resistance to cracking.

- Type A: moderate impact resistance, sufficient for standard installations but lower than Schedule 80.

- Type EB: impact resistance comparable to Type A but optimized for underground or encased applications.

Notched specimens for all types are tested identically; differences arise primarily from wall thickness and material formulation, influencing the absolute impact values.

5.3 Flattening/Compressive Resistance

- Anhang 80: demonstrates the highest resistance to buckling under axial loads, followed by Schedule 40.

- Type A: lower compressive strength due to reduced wall thickness; suitable for non-heavy-duty environments.

- Type EB: tailored to encasement conditions; thinner walls than Schedule 40/80 but sufficiently stiff to meet burial and concrete embedding requirements.

5.4 Environmental & Durability Tests – UV, Heat, Cold, and Weathering Performance

Following the mechanical performance analysis in Section 3.2, this section compares the environmental resistance and durability of Schedule 40, Schedule 80, Type A, and Type EB PVC conduits. The aim is to highlight shared testing standards while identifying key differences in how each conduit type withstands UV exposure, high temperature, low temperature, and weathering conditions.

Shared Environmental Testing Procedures

All conduit types are evaluated according to UL 651 and ASTM-referenced practices, ensuring a consistent basis for comparison:

- UV-Beständigkeit: Conducted with Xenon-arc light exposure (ASTM G 155), simulating sunlight and including intermittent water spray to replicate outdoor weathering. Notched specimens are exposed for defined cycles (e.g., 720, 1080, 1440 hours), with impact strength measured after each interval.

- Hitzebeständigkeit: Samples are aged in a circulating-air oven at controlled temperatures. After thermal conditioning, tensile and impact properties are measured to verify that the conduit maintains ≥95% of its original mechanical performance.

- Cold Resistance: Low-temperature performance is verified by conditioning samples in chilled environments and performing impact or flattening tests to ensure the conduit remains ductile and does not crack.

- Water, Oil, and Chemical Resistance: Specimens are immersed in water, oil, or other relevant liquids at controlled temperatures for specified periods, then tested for tensile strength, dimensional stability, and surface quality.

Across all conduit types, specimen preparation, measurement accuracy, and test cycles are identical, allowing a direct comparison of environmental durability.

Leitungstyp | UV & Weathering Behavior | Notes on Performance |

Anhang 40 | Good resistance; moderate impact retention after extended UV exposure | Suitable for above-ground installations where moderate mechanical protection is needed. |

Anhang 80 | Excellent resistance; maintains higher impact strength after prolonged UV and weathering | Thicker walls enhance energy absorption and reduce surface degradation. |

Type A | Moderate resistance; impact strength slightly reduced after prolonged UV exposure | Designed for non-exposed or indoor applications where handling convenience is prioritized. |

Type EB | Very good resistance in encased or buried conditions; less UV degradation due to limited exposure | Optimized for underground or concrete-encased installations; UV exposure is minimal, so aging concerns are focused on temperature and moisture. |

Key Observations: Schedule 80 consistently outperforms others under UV due to thicker walls, while Type EB’s performance is application-optimized rather than wall-thickness-dependent. Type A’s moderate resistance reflects its lighter-duty wall design.

5.5 Heat and High-Temperature Resistance

- Schedule 40/80: Both retain mechanical integrity and tensile strength ≥95% after 240–360 hours at high temperature. Schedule 80 shows slightly higher resistance due to increased wall thickness.

- Type A: Retains ≥95% tensile strength, but impact resistance may degrade more rapidly under prolonged high-temperature exposure.

- Type EB: Maintains sufficient mechanical performance for concrete encasement or burial conditions, where heat exposure is moderate but continuous.

5.6 Cold and Low-Temperature Resistance

- All conduit types are tested for brittleness and cracking under low-temperature conditions.

- Schedule 40/80: Excellent ductility at low temperatures; Schedule 80 slightly superior due to thicker walls.

- Type A: Retains flexibility but more susceptible to surface microcracks under extreme cold.

- Type EB: Adequate low-temperature resistance for buried applications, where extreme cold is less common.

5.7 Water, Oil, and Chemical Conditioning

- Shared Protocols: Specimens are immersed in water or oil at controlled temperatures, then tested for tensile strength and dimensional stability.

- Performance Differences:

- Schedule 80 maintains the highest retention of mechanical properties.

- Schedule 40 and Type EB show good stability.

- Type A shows minor reductions in impact or tensile properties but remains suitable for standard installations.

6. Summary: Schedule 40 vs Schedule 80 vs Type A vs Type EB PVC Conduit

While Schedule 40, Schedule 80, Type A, and Type EB PVC conduits are all governed by similar material standards, their intended applications, mechanical strength, wall thickness, and installation environments differ significantly.

The following summary highlights the key functional differences to help engineers, contractors, and specifiers quickly determine the most appropriate conduit type for specific project conditions.

Leitungstyp | Wandstärke | Mechanische Festigkeit | Typical Installation Environment | Burial / Encasement | Cost Consideration |

Anhang 40 | Standard | Mäßig | Above ground, underground, concrete encased | Direct burial or encased | Balanced |

Anhang 80 | Thicker than Sch 40 | Hoch | Exposed areas, high-impact zones, industrial sites | Direct burial or encased | Höher |

Type A | Thinner | Untere | Indoor, concealed, or low-stress areas | Not intended for burial | Cost-effective |

Type EB | Thickest among Type A / EB | High (when encased) | Underground infrastructure under slabs, roads, or pavements | Concrete encasement required | Economical for encased systems |

7. Application-Based Classification (Temperature, Burial Depth, Concrete Encasing)

Rigid PVC conduits—Schedule 40, Schedule 80, Type A, and Type EB—are designed with distinct application contexts in mind, reflecting variations in mechanical performance, environmental tolerance, and installation requirements. Understanding these differences is critical for specifying the appropriate conduit type for a given project.

Temperature and Electrical Wiring Compatibility

Schedule 40 and Schedule 80 conduits are both suitable for indoor and outdoor installations, including areas exposed to moderate heat. They can accommodate electrical conductors rated for standard operating temperatures up to 90°C (194°F). Type A conduit, with slightly lower wall thickness, is optimized for installations where ease of handling and routing flexibility are more critical than extreme heat resistance. Type EB conduit, designed for concrete encasement and underground use, maintains dimensional integrity in both elevated soil temperatures and thermal load conditions caused by embedded electrical systems.

Burial Depth and Underground Use

When selecting conduit for underground applications, burial depth and external soil load are key considerations. Schedule 40 is typically sufficient for shallow installations with minimal mechanical load. Schedule 80 provides higher crush resistance, making it suitable for deeper or higher-traffic areas. Type A conduit is generally used in protected environments or shallow burial where mechanical stress is low. Type EB, with its structural design for encasement, is engineered to withstand both soil pressure and long-term ground settlement, providing consistent performance over extended service life.

Concrete Encasement and Structural Integration

Type EB conduit is specifically engineered for encasement in concrete, featuring optimized wall thickness and dimensional tolerances to resist hydrostatic pressure, concrete shrinkage, and long-term load from structural elements. Schedule 40 and 80 conduits can be embedded in concrete in certain applications, but additional spacing or protective measures may be required to prevent deformation. Type A is generally not recommended for direct concrete encasement due to its lighter wall thickness.

Selection Guidance Based on Application

- Anhang 40Standardinstallationen, mäßiger mechanischer Schutz, oberirdische oder flache Verlegung.

- Anhang 80Hoher mechanischer Schutz, tiefe Verlegetiefe, stark befahrene Gebiete oder höheres Aufprallrisiko.

- Type AGeeignet für leichte Beanspruchung, flexible Kabelführung, Umgebungen mit geringer Belastung, Installationen ohne Gehäuse.

- Type EB: Unterirdische, in Beton eingebettete oder langfristig im Boden befindliche Anwendungen, bei denen sowohl die mechanische Stabilität als auch die Dimensionsstabilität von entscheidender Bedeutung sind.

In der Praxis richtet sich die Wahl des Leitungsrohrtyps nach einer Kombination aus mechanischen Eigenschaften, Umgebungsbedingungen und Installationsbeschränkungen. Durch die Abstimmung der Leitungsrohrklassifizierung auf die geplante Anwendung gewährleisten Ingenieure langfristige Zuverlässigkeit, Einhaltung der Sicherheitsvorschriften und einfache Installation.

Im Projekt CHPE (Champlain Hudson Power Express) lieferte Ledes beispielsweise starre PVC-Rohre der Klasse Schedule 40 gemäß UL 651 und die dazugehörigen Formstücke.

Die Rohre der Serie 40 boten zuverlässige mechanische Festigkeit bei gleichzeitig geringem Gewicht für eine einfache Handhabung und boten eine nahtlose Kompatibilität mit Standardarmaturen – wodurch Installateure Projekte schnell und effizient abschließen konnten.

Dank seiner hervorragenden Korrosionsbeständigkeit eignet es sich ideal für eine Vielzahl von Innen- und Außenumgebungen und bietet eine langlebige und kostengünstige Lösung für elektrische Anlagen im Wohn- und Gewerbebereich.

8. Ledes Electrical Solutions

Ledes Ledes bietet ein umfassendes Sortiment an PVC-Elektroinstallationsrohren und -Fittings, die internationalen Qualitäts- und Zertifizierungsanforderungen entsprechen. Ob Sie leichte Rohre für die Hausinstallation oder robuste Ausführungen für unterirdische und in Beton eingebettete Installationen benötigen – Ledes liefert Ihnen gleichbleibende Leistung, zuverlässige Materialien und volle Produktkompatibilität, um Ihr Projekt von Anfang bis Ende zu unterstützen.

Wenn Sie die Anhänge 40 und 80 genauer kennenlernen möchten, können Sie unsere ausführlichen Leitfäden konsultieren: PVC-Rohre der Serien 40 und 80 – Der ultimative Leitfaden Und PVC-Rohrleitung nach Schedule 80: Zweck, Größe und Einhaltung der Vorschriften. Diese Artikel bieten ausführlichere Erläuterungen zum Materialverhalten, zum Einfluss der Wandstärke, zu den Bauvorschriften und zu den Installationsaspekten.

Weitere Informationen zu Normen, Anwendungsbereichen und Produktvergleichen für Elektroinstallationsrohre finden Sie in unserer umfangreichen Sammlung an Ressourcen im Ledes-Blog. Dort finden Sie hilfreiche Leitfäden, die Ihnen bei der Auswahl des richtigen Rohrs für jedes Projekt helfen.

9. Schlussfolgerung

Das Verständnis der Unterschiede zwischen PVC-Elektroinstallationsrohren der Typen Schedule 40, Schedule 80, Typ A und Typ EB ist für die Auswahl des richtigen Verkabelungsschutzsystems unerlässlich.

Von mechanischer Festigkeit und Beständigkeit gegenüber Umwelteinflüssen bis hin zu Installationsanforderungen und Anwendungsszenarien bietet jeder Leitungstyp einzigartige Vorteile, die ihn für bestimmte Projektbedingungen geeignet machen.

Die Auswahl des richtigen Schutzrohrs gewährleistet nicht nur langfristige Leistungsfähigkeit und Sicherheit, sondern trägt auch zur Einhaltung der NEC-, CSA- und lokalen Baunormen bei.

Die in diesem Artikel beschriebenen Prüfanforderungen und Normen dienen lediglich der allgemeinen Information. Die tatsächlichen Zertifizierungskriterien, Leistungsschwellenwerte und Konformitätsverfahren können je nach den neuesten Versionen von UL, CSA, NEC oder anderen regulatorischen Dokumenten variieren. Für die genauesten und aktuellsten Informationen konsultieren Sie bitte stets die offiziellen Normen, die Herstellerdokumentation und die jeweils gültigen Vorschriften. Sollten in diesem Artikel Abweichungen oder veraltete Auslegungen auftreten, gelten die ursprünglichen Normen und die offiziellen Aktualisierungen.

Vielen Dank fürs Lesen. Wir hoffen, dieser Beitrag war hilfreich. Bei Projektanfragen, Produktwünschen oder Bedarf an individuellen Lösungen, Nehmen Sie gerne Kontakt mit uns auf.

10. Häufig gestellte Fragen

Können Schedule 40 und Typ A synonym verwendet werden?

Nicht unbedingt. Obwohl beide für die Verwendung in Innenräumen geeignet sind, weist Schedule 40 eine höhere mechanische Festigkeit auf, ist gemäß NEC für anspruchsvollere Bedingungen zugelassen und auch für die Verlegung im Erdreich geeignet. Typ A ist nicht für die Erdverlegung zugelassen und nur für leichte Anwendungen in Innenräumen vorgesehen.

Warum unterscheiden sich die Bestattungscodes zwischen Schedule 40, Schedule 80 und Typ EB?

Die Genehmigung für die Verlegung im Erdreich hängt von der Wandstärke des Schutzrohrs, seiner Schlagfestigkeit und seinem Langzeitverhalten unter Erddruck ab. Für den Typ EB gelten spezielle strukturelle Anforderungen an unterirdische Leitungen, während Sch 80 eine höhere Druckfestigkeit als Sch 40 aufweist und sich daher für Bereiche mit potenzieller Beschädigung eignet.

Was sind die besten Vorgehensweisen zur Befestigung von PVC-Rohren?

Der Stützabstand hängt von Art und Größe des Leitungsrohrs ab. Leitungen der Norm Schedule 40 benötigen in der Regel einen engeren Stützabstand als solche der Norm Schedule 80. Die Stützen müssen ein Durchhängen verhindern, die Wärmeausdehnung ermöglichen und Spannungen an den Verbindungsstellen vermeiden. Horizontale und vertikale Installationen erfordern unterschiedliche Stützabstände, und eingebettete Leitungen benötigen während des Betonierens zusätzliche Unterstützung.

Welche Einschränkungen gibt es bei der Verlegung von Leitungen in stark frequentierten oder hochbelasteten Bereichen?

In Bereichen mit Fahrzeugverkehr oder hohen Belastungen wird aufgrund der höheren mechanischen Festigkeit die Ausführung Schedule 80 empfohlen. Leitungen des Typs A und EB sind für stark beanspruchte Bereiche nicht geeignet. Für zusätzliche Haltbarkeit können Schutzabdeckungen oder eine Betonummantelung erforderlich sein.

Was bedeutet die 90°C-Drahtkennzeichnung in elektrischen Systemen?

Die Angabe 90 °C bezeichnet die maximale Dauerbetriebstemperatur, die die Isolierung eines elektrischen Leiters sicher aushält. Heutzutage sind die meisten modernen Installationsleitungen für einen Betrieb bei 90 °C ausgelegt und spezifiziert, insbesondere in Gewerbe-, Industrie- und Infrastrukturprojekten.

Warum muss PVC-Rohr auch für 90°C-Verkabelung ausgelegt sein?

Wird ein Schutzrohrsystem für die Verwendung mit 90 °C-Leitern spezifiziert, muss nachgewiesen werden, dass das Schutzrohr selbst denselben thermischen Bedingungen standhält. Die Verwendung von Schutzrohren ohne 90 °C-Zulassung in solchen Systemen kann zu Nichteinhaltung der Vorschriften, Reduzierung der Leiterbelastbarkeit oder Ablehnung bei der Inspektion führen.

Wer überprüft die Einhaltung der 90°C-Norm für PVC-Rohre?

Die Prüfung und Zertifizierung erfolgt durch unabhängige Drittorganisationen wie UL, ETL, CSA oder NSF. Diese Organisationen führen die Bewertungen in akkreditierten Labors durch und stellen offizielle Zulassungen oder Zertifizierungen aus, die die Einhaltung der 90°C-Anforderung bestätigen.

Wofür werden PVC-Rohre des Typs A typischerweise verwendet?

PVC-Rohre des Typs A sind primär für allgemeine elektrische Installationen in Innenräumen konzipiert. Sie werden häufig in kontrollierten Umgebungen eingesetzt, in denen keine extremen mechanischen Belastungen, Erdbeanspruchung oder hohe Stoßfestigkeit erforderlich sind. Ihre leichtere Wandstärke erleichtert die Handhabung und Installation.

Was bedeutet Typ EB bei PVC-Elektroinstallationsrohren?

Typ EB steht für „Encased Burial“ (ummantelte Verlegung). Es handelt sich dabei um PVC-Rohre, die für unterirdische Installationen konzipiert sind und bei denen die Rohre in Beton oder einem gleichwertigen Schutzmaterial ummantelt werden, anstatt direkt im Erdreich vergraben zu werden.

Worin unterscheidet sich PVC-Rohr vom Typ EB von PVC-Rohren vom Typ A?

Im Vergleich zu Typ A zeichnet sich Typ EB durch dickere Wände und eine höhere mechanische Festigkeit aus und eignet sich daher für unterirdische, in Beton eingebettete Umgebungen. Typ A wird typischerweise für oberirdische oder weniger anspruchsvolle Anwendungen eingesetzt und bietet unter struktureller Belastung nicht denselben Schutz.