جدول المحتويات

مع تزايد تعقيد البنية التحتية الكهربائية ومتطلباتها، يُعد اختيار نظام التوصيلات المناسب أمرًا بالغ الأهمية لضمان السلامة والمتانة والأداء على المدى الطويل. بالنسبة للتركيبات تحت الأرض، أنبوب DB2، ويشار إليه أيضًا باسم أنبوب DBII، أو أنبوب DB2، أو قناة DB2، أصبح الخيار الأول بين المقاولين والمهندسين ومقدمي الخدمات في جميع أنحاء كندا والمناطق الأخرى.

مصنوع من مادة PVC الصلبة، ومُصمم خصيصًا لتطبيقات أنابيب الدفن المباشر، يوفر أنبوب DB2 PVC توازنًا مثاليًا بين الكفاءة من حيث التكلفة ومقاومة التآكل وسهولة التركيب. سواء كنت تُصمم مشروعًا سكنيًا أو شبكة مرافق واسعة النطاق، فإن أنبوب DB2 PVC يُلبي المعايير الصارمة المطلوبة لأنظمة الكهرباء تحت الأرض.

في هذا الدليل الشامل لعام ٢٠٢٥، سنستكشف كل ما تحتاج لمعرفته حول أنابيب DB2، بما في ذلك مواصفاتها الفنية، وأنواعها، وفوائدها، ومعاييرها، ونصائح تركيبها، ومقارنتها بأنواع الأنابيب الأخرى. لنبدأ بفهم ماهية أنابيب DB2 ولماذا تُعدّ الحل الأمثل للعديد من مشاريع الكهرباء تحت الأرض اليوم.

ما هو DB2 Conduit؟

قناة DB2، والمعروفة أيضًا باسم أنابيب DBII، أو قنوات DB2، أو أنابيب الكهرباء DB2، هي نوع من أنابيب PVC الصلبة، مصممة خصيصًا لتركيبات كابلات الكهرباء والاتصالات تحت الأرض. يرمز حرف "DB" في DB2 إلى "الدفن المباشر"، مما يشير إلى أن هذه الأنابيب مصممة لتُوضع مباشرة في الأرض دون الحاجة إلى غلاف واقٍ إضافي، مثل الخرسانة.

أنابيب DB2 مصنوعة من بولي فينيل كلوريد (PVC) عالي الجودة، وهي مادة بلاستيكية حرارية خفيفة الوزن ومتينة، تُعرف بمقاومتها الممتازة للتآكل والمواد الكيميائية والرطوبة. يشير تصنيف DB2 عادةً إلى أنابيب النوع DB2/ES2، المتوافقة مع معيار CSA C22.2 رقم 211.1 ومعايير إقليمية أخرى، وتُستخدم في تطبيقات الدفن المباشر أو تغليف الخرسانة. تتوفر هذه الأنابيب بأقطار مختلفة، وتأتي إما بنهايات جرسية لسهولة التوصيل أو بنهايات عادية للتركيبات المخصصة.

مواصفات قناة DB2

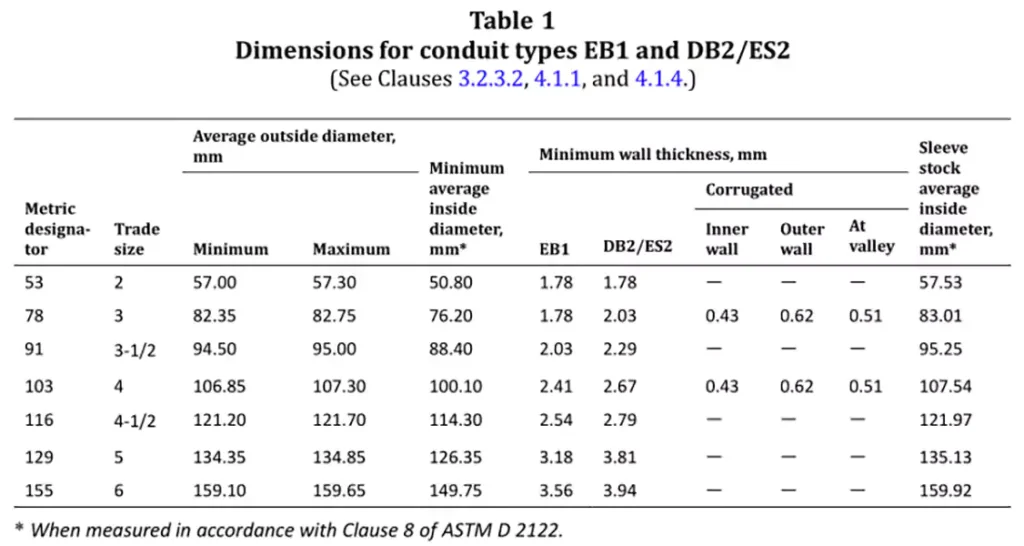

عند اختيار أنابيب DB2/ES2 لنظام كهربائي أو اتصالات تحت الأرض، من الضروري فهم مواصفات المنتج. صُنعت أنابيب DB2 وفقًا لمعايير CSA C22.2 No.211.1 الصارمة، والتي تضمن أداءً طويل الأمد في البيئات تحت الأرض.

أحجام تجارة أنابيب DB2

ال ""حجم التجارة" يشير مصطلح "قناة" إلى تسمية الحجم الاسمي أو الموحد، وليس القطر الخارجي أو الداخلي الفعلي. تُستخدم هذه الأحجام التجارية على نطاق واسع في جميع أنحاء أمريكا الشمالية للمساعدة في توحيد معايير التركيبات، وممارسات التركيب، وحسابات التصميم.

على سبيل المثال:

- لا يحتوي أنبوب DB2 بحجم تجاري "2 بوصة" على قطر داخلي أو خارجي يبلغ 2 بوصة.

تختلف الأقطار الخارجية والداخلية الفعلية قليلاً حتى بالنسبة لنفس حجم التجارة.

أحجام التجارة القياسية لـ DB2

تتوفر أنابيب DB2 PVC بمجموعة متنوعة من الأحجام التجارية الاسمية، عادةً بالبوصة. تناسب هذه الأحجام مختلف سعة تعبئة الكابلات ومتطلبات التركيب. تشمل أحجام DB2 التجارية الشائعة ما يلي:

حجم التجارة (بوصة) | المُعَيِّن المتري (مم) |

2 | 53 |

3 | 78 |

3-1/2 | 91 |

4 | 103 |

4-1/2 | 116 |

5 | 129 |

6 | 155 |

هذه الأحجام الأكبر مخصصة لتمرير الكابلات تحت الأرض ذات السعة المتوسطة والعالية، مثل توزيع الطاقة، وإضاءة الشوارع، والبنية التحتية للاتصالات.

معلمات الأبعاد الأساسية لأنبوب DB2

يتم تعريف كل حجم تجاري لقناة DB2 من خلال ثلاث قيم أبعاد حرجة وفقًا لـ CSA C22.2 رقم 211.1:

- متوسط القطر الخارجي (OD): متوسط القطر الخارجي لجدار القناة. يؤثر هذا على كيفية تركيب القنوات داخل مجموعات القنوات وكيفية توصيل التجهيزات.

- الحد الأدنى لمتوسط الداخل (ID): الحد الأدنى للقطر الداخلي المسموح به، والذي يحدد المساحات المتوفرة لسحب الموصلات أو الكابلات.

- الحد الأدنى لسمك الجدار: أرق جدار موصل مسموح به في أي نقطة، مما يضمن سلامة البنية التحتية في ظل ظروف الدفن المباشر وضغط التربة.

يتم تنظيم هذه المعلمات بعناية لضمان الملاءمة المتسقة والقوة الميكانيكية وسعة ملء الكابل.

ملاحظات إضافية:

- طول: يتم توفير معظم أنابيب DB2 في أطوال 10 أقدام (3.05 م)، مع طرف جرس واحد للسماح بالربط السهل بدون وصلات.

- مادة: مصنوع من مادة PVC الصلبة، مما يوفر مقاومة ممتازة للتآكل والعزل.

- لون: عادة رمادي للاستخدام الكهربائي؛ يمكن استخدام اللون البرتقالي والألوان الأخرى لتطبيقات الاتصالات أو الألياف اعتمادًا على متطلبات المرافق.

6 تطبيقات شائعة لـ DB2 Conduit

صُممت أنابيب DB2 خصيصًا لتطبيقات الدفن المباشر في البنية التحتية للكهرباء والاتصالات في كندا. صُممت أنابيب DB2 لتلبية متطلبات الأداء تحت الأرض، حيث توفر مقاومة للتآكل، وقوة ميكانيكية، وعمرًا افتراضيًا طويلًا.

وفيما يلي التطبيقات الأكثر شيوعًا:

- المرافق الكهربائية: خطوط توزيع الطاقة تحت الأرض، والكابلات الثانوية وكابلات مدخل الخدمة

- الاتصالات السلكية واللاسلكية: كابلات الألياف الضوئية، والكابلات المحورية، وخطوط الهاتف

- البلدية والبنية التحتية: دوائر إنارة الشوارع وأنظمة إشارات المرور وأنظمة الطاقة في منطقة المشاة

- البناء التجاري: الأسلاك تحت الأرض من المباني إلى مصادر المرافق

- الطاقة المتجددة: خطوط تحت الأرض لمزارع الطاقة الشمسية وتوربينات الرياح

- منشأت صناعية: قنوات طاقة تحت الأرض عالية السعة لمحطات الطاقة الفرعية أو المصانع

طباعة ووضع علامات على أنابيب DBII

وفقًا لمعايير CSA، يجب وضع علامة دائمة وقابلة للقراءة على كل طول من أنابيب DB2 باستخدام:

- اسم الشركة المصنعة أو العلامة التجارية

- حجم التجارة

- تسمية "PVC DB2/ES2"

- المعيار: CSA C22.2 رقم 211.1

- تاريخ الصنع

تضمن هذه العلامات إمكانية فحص المنتج والموافقة عليه للاستخدام في أنظمة الأنفاق الخاضعة للتنظيم.

موصل DB2 مقابل موصلات DB الأخرى

عند اختيار أنابيب الدفن المباشر، تُعدّ أنابيب PVC المصنفة بتصنيف DB الخيار الأكثر شيوعًا، حيث صُممت كل منها بسماكة جدار وتوقعات أداء مختلفة. في حين أن أنابيب DB2 هي المعيار في كندا، إلا أن السوق الأمريكية تستخدم أنابيب DB60 وDB100 وDB120 بشكل أكثر شيوعًا، خاصةً في تركيبات المرافق تحت الأرض، وإنارة الشوارع، والألياف الضوئية.

- DB60: أرق جدار؛ الأفضل للتطبيقات الخفيفة للدفن الضحل دون حركة مرور كثيفة.

- DB100: قوة وسمك معتدلين، أكثر تنوعًا ويُستخدم في التركيبات الكهربائية والاتصالات.

- DB120: الجدار الأكثر سماكة بين قنوات PVC المصنفة DB في الولايات المتحدة؛ مصمم للدفن على عمق أكبر أو في أماكن تحت الطرق حيث توجد أحمال ضغط عالية.

- قاعدة بيانات 2: متوسطة في سمك الجدار والقوة؛ مناسبة لمجموعة واسعة من التطبيقات تحت الأرض.

نوع القناة | منطقة | سمك الجدار | الاستخدام الأساسي | المعايير ذات الصلة |

دي بي 2 | كندا | واسطة | الدفن المباشر للكهرباء والاتصالات | CSA C22.2 رقم 211.1 |

دي بي 60 | الولايات المتحدة الأمريكية | ضوء | الاتصالات والألياف وكابلات المرافق الخفيفة | نيما تي سي 6 و 8 |

دي بي 100 | الولايات المتحدة الأمريكية | واسطة | الكهرباء والاتصالات والمرافق والطرق | نيما تي سي 6 و 8 |

دي بي 120 | الولايات المتحدة الأمريكية | ثقيل | الدفن المباشر عالي الحمولة، معابر الطرق | نيما تي سي 6 و 8 |

مقارنة بين أنابيب DB2 وأنابيب EB

هناك نوعان من الأنابيب المستخدمة تحت الأرض، بجانب أنابيب DB، هناك أنابيب EB، وهي اختصار لـ قناة دفن مغلفة. إنه نوع من أنابيب PVC الصلبة المصممة خصيصًا للدفن في الخرسانة بدلاً من دفنها مباشرة في التربة.

فيما يلي مقارنة بين قناة DB وقناة EB لتتمكن من تحديد القناة المناسبة لمشروعك.

ميزة | قناة DB | قناة EB |

نوع الدفن | مباشرة في التربة أو الردم | التغليف المطلوب في الخرسانة |

سمك الجدار | أكثر سمكًا، مصمم لمقاومة ضغط التربة والصدمات | أرق، ويعتمد على الخرسانة للحماية الميكانيكية |

القوة الميكانيكية | أعلى | أدنى |

تكلفة التركيب | أقل، لا يتطلب الخرسانة | أعلى، يتطلب صب الخرسانة والتفتيش |

يحتوي كل من أنبوب EB وأنابيب DB نفسها على العديد من الأنواع المختلفة في مناطق مختلفة، ابحث وتحقق من الأنبوب المناسب الذي تحتاجه.

الامتثال لقانون DB2 Conduit

لضمان السلامة الكهربائية، وحماية البيئة، والأداء طويل الأمد، يجب أن تستوفي أنابيب DB2 متطلبات الامتثال الصارمة للكود الكندي. وتخضع هذه المتطلبات بشكل أساسي لما يلي:

- CSA C22.2 رقم 211.1 - أنابيب PVC الصلبة (نوع DB2)

- لجنة الانتخابات المركزية - قانون الكهرباء الكندي، الجزء الأول

يعمل كلا المعيارين معًا لضمان أن يكون أنبوب DB2 آمنًا وموثوقًا به للاستخدام في الدفن المباشر في الأنظمة الكهربائية تحت الأرض.

متطلبات الأداء - CSA C22.2 رقم 211.1

لضمان قدرة أنابيب DB2 على تحمل قسوة التركيب تحت الأرض والتعرض البيئي طويل الأمد، يتطلب معيار CSA C22.2 رقم 211.1 سلسلة من الاختبارات الميكانيكية والمادية. وتشمل هذه الاختبارات:

مقاومة التأثير

يقيس قدرة القناة على تحمل الصدمات الميكانيكية في درجات الحرارة المنخفضة (عادة عند -18 درجة مئوية)، ومحاكاة تأثيرات المناولة والدفن دون حدوث تشققات.

مقاومة السحق

يُقيّم هذا الاختبار مدى ثبات الأنبوب تحت تأثير الأحمال الخارجية، مثل ضغط التربة أو أحمال المرور. ويُختبر بتطبيق قوة ضغط حتى حدوث تشوه مُحدد.

اختبار الإجهاد المتبقي

يُقيّم الإجهادات الداخلية المتبقية في مادة PVC بعد التصنيع. قد يؤدي الإجهاد المفرط إلى الانحناء أو التشقق أو الفشل المبكر مع مرور الوقت.

المقاومة الكيميائية

يضمن مقاومة الأنابيب للمواد الكيميائية الشائعة في التربة، مثل الأحماض والقلويات والأملاح. وهذا أمر بالغ الأهمية للأداء طويل الأمد في البيئات المسببة للتآكل.

اختبار الصلابة

يقيس صلابة الأنبوب. يلزم حد أدنى من الصلابة لمنع الترهل أو الانهيار عند دفنه تحت الأرض.

اختبار قوة الرابطة

بالنسبة لموصلات DB2 ذات الأجراس المتكاملة (الوصلات الملحومة بالمذيبات)، يؤكد هذا الاختبار قوة وسلامة المنطقة الملتصقة، مما يضمن توصيلات خالية من التسرب تحت الضغط.

تعتبر هذه الاختبارات أساسية للتأكيد على أن قناة DB2 تلبي توقعات السلامة والأداء الكندية، وخاصة لتطبيقات الدفن المباشر في المناخات القاسية.

نصائح احترافية: لمعرفة متطلبات الاختبارات الأكثر تفصيلاً، انقر هنا للاطلاع على مقالتنا السابقة مقدمة عن معيار موصل DB2.

متطلبات تركيب DB2 Conduit من CEC

يُنظّم الجزء الأول من قانون الكهرباء الكندي (CEC)، الصادر عن مجموعة CSA، تركيبَ واستخدامَ المنتجات الكهربائية، بما في ذلك أنابيب DB2. وقد اعتمدته المقاطعات والأقاليم في جميع أنحاء كندا كأساس قانوني للأعمال الكهربائية.

يتضمن تركيب قناة DB2 PVC في كندا أكثر من مجرد حفر الخنادق ووضع الأنابيب، بل يتطلب الالتزام الصارم بقواعد السلامة والأداء المحددة في قانون الكهرباء الكندي (CEC)، القسم 12-012، الذي يحكم التركيبات تحت الأرض.

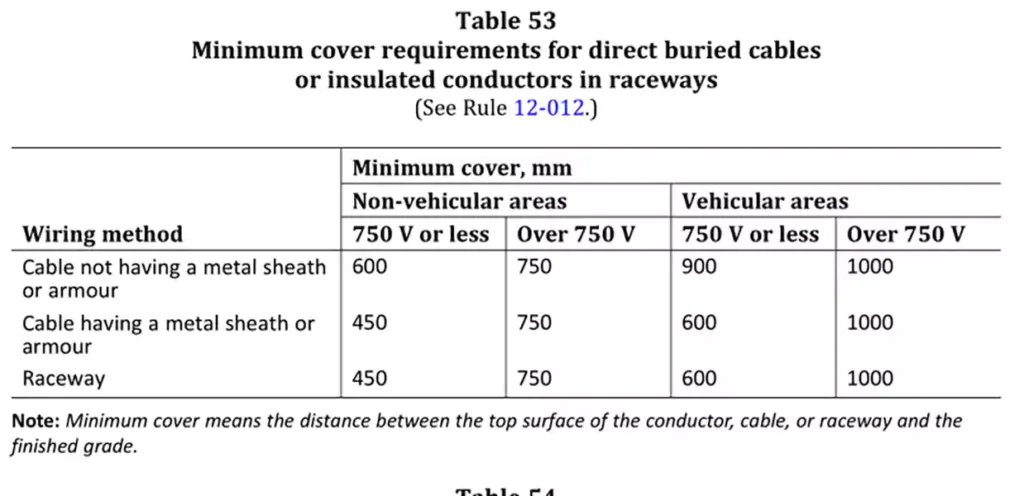

أعماق الدفن الدنيا

لحماية الكابلات والمسارات المائية تحت الأرض من التلف المادي، تحدد لجنة الطاقة الذرية الكندية (CEC) أعماق دفن دنيا حسب نوع التركيب. على سبيل المثال:

- عادةً ما يحتاج أنبوب DB2 الموجود أسفل الممر السكني أو الحديقة إلى ما لا يقل عن 450 ملم من الغطاء

- تحت الطرق أو المناطق التجارية، 600 ملم أو قد تكون هناك حاجة إلى المزيد

تم تعريف هذه القيم في جدول CEC 53، وتنطبق سواء كنت تقوم بتثبيت قناة DB2 لأنظمة الطاقة أو البيانات أو الإضاءة.

التثبيت الأقل عمقًا

إذا كنت بحاجة إلى التثبيت على عمق أقل (على سبيل المثال، بسبب الصخور أو البنية التحتية الموجودة)، يُسمح لك بتقليل الحد الأدنى للغطاء هو 150 ملم، ولكن فقط إذا تمت إضافة الحماية الميكانيكية فوق القناة.

تشمل الحماية الميكانيكية المقبولة ما يلي:

- ألواح خشبية معالجة بسمك 38 مم

- غلاف خرساني أو بلاطة أو طبقة مصبوبة بسمك 50 مم

- مواد أخرى معتمدة من قبل السلطة المختصة

يجب أن تمتد المادة الواقية بمقدار 50 مم على الأقل خارج كل جانب من جوانب مسار القناة إذا كان شكلها مسطحًا.

الفراش والردم

إن التغطية الصحيحة والردم يحمي القناة من الأشياء الحادة وضغط الحمل غير المتساوي:

- قم بتثبيت طبقة من الرمل المنخل أو الأرض المنخلية (حجم الجسيمات ≤ 4.75 مم) بعمق 75 مم على الأقل فوق وتحت القناة

- تجنب استخدام الصخور الكبيرة أو الرماد أو الخرسانة المكسورة أو المواد المسببة للتآكل في ردم الخندق، مما قد يؤدي إلى إتلاف القناة أو إعاقة الضغط

يساعد هذا في الحفاظ على محاذاة القناة ويمنع الضرر المادي أثناء التثبيت وبعده.

التوجيه والتخطيط

يجب توجيه الكابلات داخل الأنابيب بشكل متوازي، وعدم تقاطعها بشكل غير ضروري. هذا يضمن ثبات أنصاف أقطار الانحناء، ويقلل من المخاطر أثناء الصيانة أو إعادة السحب مستقبلًا.

حماية الرافعات الرأسية

عندما ينتقل أنبوب DB2 من تحت الأرض إلى فوق الأرض (على سبيل المثال، للاتصال بصندوق تقاطع أو مبنى)، يتطلب الكود ما يلي:

- مسار عمودي صلب (مثل الأنابيب البلاستيكية الصلبة أو المعدنية)

- تم إنهاؤها ببطانة أو تركيب طرف جرس في الجزء السفلي لمنع تلف الكابل

- الحد الأدنى 2 متر فوق مستوى سطح الأرض، مع حماية إضافية عند الحاجة

- ارتخاء الكابل بدرجة كافية بحيث يمكن للموصلات الدخول من زاوية رأسية دون توتر

يؤدي هذا إلى حماية الكابل من التلف الميكانيكي في إحدى أكثر نقاطه ضعفًا.

الوصل في الخنادق

عمومًا، يجب إجراء الوصلات تحت الأرض في صناديق يسهل الوصول إليها. ومع ذلك، في حال الموافقة على أي تعديل بموجب القاعدة 2-030، يُسمح بالوصلات المدفونة مباشرةً بدون صناديق، ولكن فقط باستخدام طرق معتمدة لمقاومة الرطوبة والتآكل.

التثبيت في الصخر

إذا كنت تقوم بتثبيت قناة DB2 مباشرة على الأساس الصخري:

- حفر خندق على الأقل 150 ملم في الصخر

- قم بملء القناة في مكانها باستخدام الخرسانة لمنع الحركة والأضرار المادية

وهذا يسمح بتقليل العمق عندما لا تكون ظروف التربة متاحة.

تحت ألواح الخرسانة

يمكن تركيب قناة DB2 مباشرة أسفل بلاطة خرسانية على مستوى الأرض إذا:

- يجب أن يكون سمك البلاطة 100 مم على الأقل

- يتم تحديد موقع وعمق القناة بشكل دائم وواضح

- يتم حماية القناة من التلف أثناء البناء

وهذا أمر شائع في المباني التجارية أو مواقف السيارات حيث يتم تضمين مسارات الأنابيب تحت الأرضيات.

تجنب الحماية الميكانيكية الضارة

ليست كل وسائل الحماية الميكانيكية آمنة. إذا كان الغطاء الواقي يُهدد بسحق الأنابيب أو تدهورها كيميائيًا، فلا يُنصح باستخدامه.

تأكد دائمًا من توافق المواد، وخاصةً مع الأنظمة التي يتم صبها في الموقع.

شريط تحديد أو علامات تحذيرية

يجب على المثبتين توفير علامة لجميع مسارات الأنابيب تحت الأرض:

- شريط العلامات: مدفونة في منتصف المسافة تقريبًا بين مستوى الدرجة والقناة

- علامة السطح: عندما يكون الشريط غير عملي، ضع علامة دائمة ومرئية على السطح

يساعد هذا أطقم الحفر المستقبلية على تجنب إتلاف الأنظمة المدفونة.

كيفية تركيب أنابيب PVC الصلبة DB2/ES2

يُعد التركيب السليم لأنابيب DB2 PVC أمرًا أساسيًا للحفاظ على سلامة الهيكل، والسلامة الكهربائية، والمتانة على المدى الطويل. سواءً تم تركيبها بالدفن المباشر أو في قنوات مُغلَّفة بالخرسانة، يجب أن تتبع أنظمة أنابيب DB2 إجراءات دقيقة في وضع الطبقات، والوضع، والردم.

تركيب الدفن المباشر (6 خطوات)

إعداد الخندق

ابدأ بحفر خندق ذي قاع مستوٍ وثابت. أزل الأجسام الحادة والأحجار السائبة والتشوهات لتجنب نقاط الضغط المركزة على الأنبوب. في حالة الصخور أو الطبقة التحتية شديدة الضغط، يلزم حفر إضافي، عادةً بعمق حوالي 75 مم من المستوى المطلوب، يليه طبقة فرش مضغوطة لإنشاء قاعدة موحدة.

مواد الفراش

ضع طبقة من الرمل المنخل أو مادة حبيبية ناعمة بسمك ٧٥ مم (٣ بوصات) تقريبًا. توفر هذه الطبقة دعمًا ثابتًا على طول الأنبوب، وتقلل من خطر الانحراف أو التشوه تحت تأثير الحمل.

وضع الطبقة الأولى من الأنابيب

ضع الصف الأول من أنبوب DB2 مباشرةً على الفرشة. تأكد من اتساق المحاذاة والمستوى. من المهم عدم استخدام فواصل بلاستيكية أثناء تركيبات الدفن المباشر، لأنها تُسبب تحميلًا نقطيًا يُضعف الدعم طويل الأمد.

الردم حول القناة

أحط الأنبوب بحشوة نظيفة، خالية من الحجارة الحادة والحطام. يجب ألا يزيد حجم طبقة الحشو الأولية عن 10 مم (3/8 بوصة). ادكّ أو رصّ هذه الحشوة بعناية على مراحل حول الأنبوب لتثبيتها في مكانها دون تشويهها.

تثبيت طبقات متعددة (إن أمكن)

للتركيبات متعددة الطبقات، يُراعى حشو محكم بين كل طبقة، بسمك يتراوح عادةً بين 50 و75 مم (2 إلى 3 بوصات)، وفقًا للمواصفات الهندسية. ثم تُكرر عملية وضع الأنابيب والردم.

الغطاء النهائي والردم

بعد وضع الطبقة الأخيرة، يُغطى بطبقة ردم ناعمة مضغوطة لا تقل عن ١٠٠ مم (٤ بوصات). بعد ذلك، يمكن إضافة ردم عام بطبقات تتراوح بين ١٠٠ مم و٣٠٠ مم (٤ إلى ١٢ بوصة)، مضغوطة بالكثافة المحددة. يجب دفن الأنبوب بطبقة لا تقل عن ٣٠٠ مم (١٢ بوصة)، ما لم تنص مواصفات المشروع على خلاف ذلك.

التركيب المغلف بالخرسانة (4 خطوات)

عندما تكون هناك حاجة إلى حماية أكبر، كما هو الحال في الممرات التجارية أو المناطق ذات الأحمال المحتملة للمركبات، يمكن تغليف قناة DB2 بالخرسانة.

قاعدة الخندق والوسادة الخرسانية

احفر خندقًا أوسع قليلًا من مساحة ضفة القناة. صبّ قاعدة خرسانية بسمك ٧٥ مم تقريبًا (٣ بوصات)، ثمّ قم بتنعيمها قبل أن تجف. تضمن هذه القاعدة ارتفاعًا ودعمًا مناسبين.

وضع الأنابيب مع الفواصل

استخدم فواصل صلبة لمحاذاة ودعم الأنابيب في طبقات متعددة. ضع الطبقة الأولى على القاعدة الخرسانية غير المثبتة. استمر في وضع الفواصل والأنابيب للطبقات الإضافية، مع الحفاظ على تباعد ثابت. ثبّت المجموعة كاملةً باستخدام أربطة.

صب الخرسانة

يجب إدخال الخرسانة بحرص لتجنب اصطدامها بالأنابيب. استخدم مزالق أو ألواحًا لتوجيه التدفق. املأ الفراغات بين الأنابيب جيدًا. يمكن استخدام أدوات مثل القضبان المسطحة أو الملاعق المسطحة لإزالة فجوات الهواء وضمان تغليف متساوٍ.

ردم ما بعد الصب

اترك الخرسانة تجف (عادةً ٢٤ ساعة) قبل إعادة حشوها. اتبع نفس خطوات الردم المتبعة في الدفن المباشر، مع الالتزام بالضغط المناسب وسمك الطبقة.

6 أخطاء شائعة يجب تجنبها

تخطي الفراش المناسب

إن وضع الأنابيب مباشرة على قاع الخندق غير المجهز قد يؤدي إلى دعم غير متساوٍ وتشوه في النهاية.

استخدام الفواصل للدفن المباشر

الفواصل غير مناسبة للدفن المباشر، لأنها تُنشئ نقاط تلامس بدلًا من دعم فراش مستمر. قد يُسبب هذا انحرافًا في الأنابيب تحت تأثير حمولة التربة.

ضعف الضغط حول القناة

يؤدي الضغط غير المتماسك أو غير المتناسق إلى زيادة خطر التحول أو الاستقرار، وخاصة أثناء دورات التجميد والذوبان أو تحت الأحمال السطحية الثقيلة.

مواد ردم كبيرة الحجم

إن استخدام الحصى أو الحجارة التي يزيد حجمها عن 10 مم في عملية الردم الأولية قد يؤدي إلى إتلاف الجدار الخارجي للقناة والإضرار بسلامة العزل.

وضع الخرسانة بشكل غير صحيح

قد يؤدي صب كميات كبيرة من الخرسانة على أنابيب غير مثبتة إلى انهيارها أو عدم محاذاة الأنابيب. يجب إدخال الخرسانة تدريجيًا وتوجيهها إلى مكانها.

عمق التغطية غير كافٍ

يؤدي عدم تلبية الحد الأدنى المطلوب من الغطاء (عادةً 300 مم) إلى ترك القناة عرضة للإجهاد الخارجي، بما في ذلك معدات البناء والأحمال السطحية.

كيفية اختيار مورد موصلات DB2

اختيار الحق مورد قنوات DB2 يُعدّ هذا الأمر بالغ الأهمية لضمان أداء نظامك الكهربائي على المدى الطويل، وامتثاله للمواصفات، وكفاءة تركيبه. قد تبدو أنابيب DB2 متشابهة لدى مختلف الشركات المصنعة، إلا أن الاختلافات في جودة المواد الخام، وتفاوتات الأبعاد، والشهادات، وتوافق الملحقات قد تؤثر بشكل كبير على نجاح مشروعك.

5 أخطاء شائعة يجب تجنبها عند اختيار مورد أنابيب DB2

قبل تقديم المورد المثالي، إليك بعض الأخطاء الشائعة التي يرتكبها المقاولون ومديرو المشاريع عند الحصول على قناة DB2:

بافتراض أن جميع موصلات DB2 متماثلة

لا تُلبي جميع أنابيب DB2 المعايير نفسها. اختيار مُورّد دون التحقق من شهادة CSA أو الامتثال الفعلي لمعيار CSA C22.2 رقم 211.1 قد يُؤدي إلى فشل في الفحص أو مخاطر تتعلق بالسلامة.

تجاهل شهادات الطرف الثالث

قد لا يقدم الموردون الذين يعلنون عن امتثالهم دون اختبار من طرف ثالث (على سبيل المثال، CSA، UL) أداءً ثابتًا، خاصة في التطبيقات المدفونة طويلة الأمد.

التركيز فقط على السعر

غالبًا ما تؤدي قيود الميزانية إلى اختيار أقل سعر. ومع ذلك، قد تستخدم الخيارات منخفضة التكلفة مركبات PVC رديئة الجودة، مما يؤثر سلبًا على مقاومة الصدمات، وثبات الأشعة فوق البنفسجية (في حال التعرض لها)، وتجانس الجدران.

تجاهل توافق الملحقات

قد يؤدي اختيار الأنابيب دون وجود ملحقات متطابقة مثل المرفقين أو الوصلات أو الفواصل إلى تأخير التثبيت في الموقع وزيادة تكاليف العمالة بسبب إعادة العمل أو التعديلات في الموقع.

إهمال مهلة التسليم واستقرار العرض

حتى الموردين ذوي الجودة العالية قد يواجهون صعوبات في التسليم إذا افتقروا إلى إنتاج قابل للتوسع أو توزيع محلي. يُعد التسليم في الوقت المحدد أمرًا بالغ الأهمية في مشاريع البنية التحتية لتجنب التأخيرات المكلفة.

حلول أنابيب Ledes DB2

تقدم ليديس مجموعة احترافية وعالية الجودة من أنبوب PVC الصلب DB2 والتجهيزات المصممة لتلبية الاحتياجات الصعبة لمشاريع البنية التحتية للكهرباء والاتصالات في جميع أنحاء كندا.

أنبوب PVC الصلب DB2

طول: متوفر بأطوال قياسية تصل إلى 10 أقدام (3 أمتار) مع أو بدون أطراف الجرس.

نطاق الحجم: من 2 إلى 6 بوصات

الألوان: الرمادي والبرتقالي والأحمر والأسود والأبيض.

شهادة: حاصل على شهادة CSA C22.2 رقم 211.1 للاستخدام تحت الأرض وفي الخرسانة.

DB2 المرفقين والكنس

90 درجة، 45 درجة، 22.5 درجة وزوايا مخصصة، مع نصف قطر طويل وقياسي انحناءات القناة لسحب الكابل بسلاسة.

لماذا تختار ليديس

جودة عالية

All Ledes DB2 conduits are tested and certified to CSA C22.2 No. 211.1 and relevant standards, ensuring compliance with Canadian installation standards and municipal requirements.

Durable and Reliable

Made from high quality and impact-rated PVC compounds, Ledes conduits deliver high crush strength, stiffness and long-term resistance to soil conditions.

Installation-Friendly Design

Lightweight yet strong, with bell-end factory fittings for fast solvent-weld joints, saving time and labor on site.

Fast and Flexible Supply

With strong production capabilities and a responsive logistics network, Ledes ensures on-time delivery for projects of all sizes.

Sustainable Production

Ledes follows environmentally responsible practices, including recyclable material use and clean production standards.

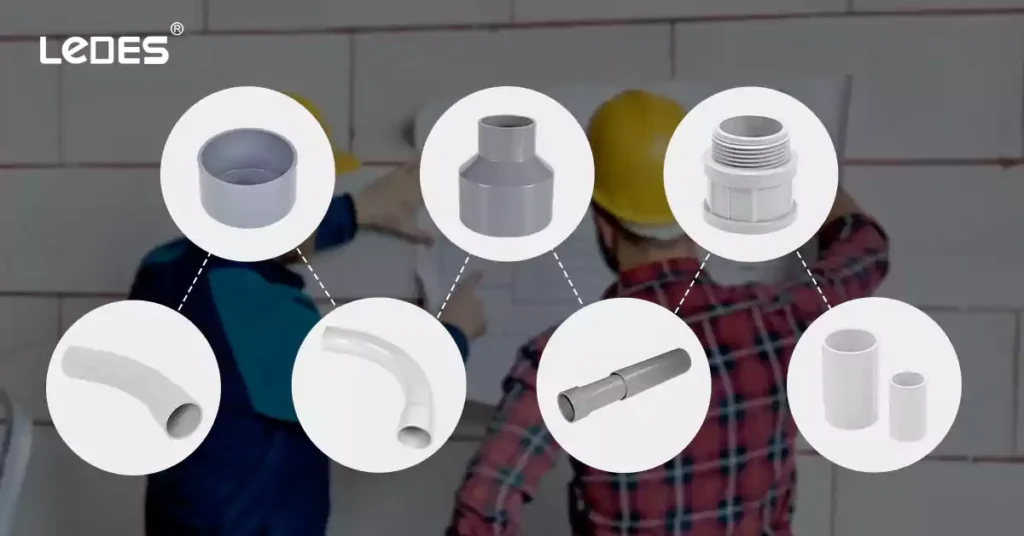

7 Recommended DB2 Conduit Fittings

To ensure a safe, code-compliant, and efficient underground electrical installation, DB2 conduit systems must be paired with compatible accessories and fittings. These components play a vital role in maintaining structural integrity, providing smooth cable routing, and simplifying installation, especially in direct burial or encased concrete applications.

Below are the most widely used DB2 conduit accessories and fittings:

DB2 Conduit Couplings

Join two lengths of DB2 conduit together in a straight line.

Types:

Solvent-Weld Couplings: Permanently bond the conduit using PVC solvent cement.

Push-Fit or Snap-In Couplings: Allow quick, tool-free installation in non-permanent setups.

Used extensively in underground trenching and duct bank installations where continuous conduit runs are required.

DB2 Conduit Elbows and Sweeps

Provide directional changes in conduit runs without damaging cables.

Types:

90-Degree Sweep Elbows

45-Degree الانحناءات

Custom Angles and Long Radius Elbows

Ideal for transitioning conduit direction around obstacles or between underground and surface systems, while allowing easy cable pulling thanks to smooth bends.

Male and Female Terminal Adapters

Facilitate secure transitions between DB2 conduit and threaded or non-threaded fittings, boxes, or enclosures.

Male Adapters: Insert into the conduit and connect to a threaded hub.

Female Adapters: Accept conduit into one end and connect to external threads.

Used in utility boxes, panel boards, and connection points for electrical enclosures or telecom pedestals.

Conduit Spacers (Duct Bank Spacers)

Maintain uniform separation between multiple parallel conduits in a duct bank.

Types:

Base Spacers: Provide a stable base.

Intermediate Spacers: Stackable layers to build multi-tier conduit banks.

Essential in concrete-encased duct bank systems for structural integrity, consistent spacing, and ease of concrete pouring.

Expansion Joints

Absorb thermal expansion and contraction in long runs of PVC conduit.

Recommended in areas subject to temperature fluctuations, especially where long conduit runs are installed straight without bends to relieve stress.

Conduit Caps and Plugs

Temporarily seal the ends of DB2 conduits during construction to prevent dirt, water, or debris from entering.

Used on job sites to protect open conduit ends until cables are pulled or fittings are attached.

Conduit Reducer

To create a secure connection between different DB2 conduit sizes, maintaining electrical and mechanical continuity.

Reducers must be solvent-welded and designed to match DB2 conduit dimensions and wall types to ensure watertight performance and consistent wall alignment for easy cable pulling.

Material and Industry Trends of DBII Conduit

The evolution of DB2 conduit materials continues to focus on enhancing mechanical strength, durability, and sustainability. Traditionally, DB2 conduits have been manufactured from rigid unplasticized polyvinyl chloride (uPVC), known for its balance of strength, flexibility, and corrosion resistance.

Recent innovations in DB2 materials include:

- Improved uPVC Formulations: Advanced compound recipes now deliver superior impact resistance at low temperatures, enhanced chemical resistance, and higher crush strength.

- Lead-Free Stabilizers: Driven by environmental regulations, modern DB2 conduits are now made using lead-free stabilizer systems, improving worker and environmental safety without compromising performance.

- Low-Smoke, Halogen-Free Additives: Though not yet standard in all DB2 applications, some manufacturers are experimenting with LSZH formulations for DB2 conduits used near sensitive utility networks or buildings.

- Color-Coded Conduits: The use of distinct color pigments (e.g., grey for electrical, orange for telecom) is becoming more prevalent to simplify field identification and ensure installation accuracy.

Industry Trends of DB2 Pipe

As urban infrastructure and digital transformation evolve, several macro-trends are shaping DB2 conduit demand and design:

Expansion of Underground Utility Networks

Urban densification and upgrades to aging power and communication grids are increasing the demand for robust, space-efficient, and easy-to-install conduit solutions. DB2 conduits are increasingly specified for deeper burial and high-traffic zones due to their high crush strength.

Green Infrastructure and Sustainable Construction

Environmental standards and LEED-certified construction are promoting the use of eco-friendly PVC formulations. Suppliers offering recyclable conduits and transparent environmental product declarations (EPDs) are gaining preference.

Compatibility with Smart Grids and 5G Networks

Modern utility networks require flexible conduit systems that can accommodate fiber-optic cables and smart sensors. DB2 conduit systems, especially when paired with smart-compatible junction boxes and flexible conduits, are helping future-proof civil infrastructure.

Code Compliance and Traceability

Regulatory bodies and municipalities are placing greater emphasis on product traceability, demanding CSA markings, manufacturing lot numbers, and clear compliance documentation. Digital platforms that track and verify conduit specs are gaining adoption.

خاتمة

DB2 PVC conduit remains a cornerstone in underground electrical infrastructure across Canada, thanks to its balance of strength, flexibility, and long-term reliability. From understanding its CSA requirements to mastering installation techniques and selecting the right accessories, this guide has covered every critical aspect of DB2 conduit systems.

Choosing the right supplier can significantly impact the quality, compliance, and durability of your installation. With the right materials and proper installation practices, DB2 conduits provide superior protection for buried electrical systems in both commercial and utility-scale projects.

As the industry continues to move toward safer, more environmentally friendly, and more efficient solutions, staying informed about material innovations and national code updates will keep your projects ahead of the curve.

Whether you’re designing a high-voltage duct bank, upgrading an existing underground network, or installing new service in a residential subdivision, DB2 conduit offers the performance, code compliance, and ease of use that modern infrastructure demands.

الأسئلة الشائعة

ما هي استخدامات موصل DB2؟

يُستخدم أنبوب DB2 PVC بشكل أساسي في تمديد كابلات الكهرباء والاتصالات تحت الأرض. وهو مصمم للدفن المباشر أو التغليف في الخرسانة، ويوفر حماية ممتازة من التلف المادي والرطوبة والتعرض للمواد الكيميائية في التطبيقات تحت الأرض.

هل يمكن استخدام قناة DB2 فوق الأرض؟

لا. صُممت أنابيب DB2 خصيصًا للاستخدام تحت الأرض، سواءً للدفن المباشر أو التغليف بالخرسانة. لا تتمتع هذه الأنابيب بمقاومة للأشعة فوق البنفسجية، وقد تتدهور عند تعرضها لأشعة الشمس أو الظروف فوق سطح الأرض. يُنصح باستخدام أنابيب PVC الصلبة، وفقًا لمعيار CSA C22.2 رقم 211.2، للاستخدامات فوق سطح الأرض.

ما هو العمق الذي يجب أن يتم دفن قناة DB2 فيه؟

The burial depth depends on local codes and application, but typical guidelines include:

Residential or light commercial: Minimum of 450 mm (18 inches) from finished grade to the top of the conduit.

Under driveways or roadways: Minimum 600 mm (24 inches).

Always check with your local authority or utility provider for exact requirements.

هل أحتاج إلى استخدام الفواصل لتثبيت قناة DB2؟

لا يُنصح باستخدام الفواصل في تركيبات الدفن المباشر، لأنها تُولّد أحمالًا نقطية بدلًا من الدعم المستمر. بدلاً من ذلك، يُوضع أنبوب DB2 على طبقة حشو مضغوطة جيدًا، ويُحاط بردْم حبيبي لتوفير الدعم الكامل. تُستخدم الفواصل فقط عند تغليف أنبوب DB2 بالخرسانة وعند الحاجة إلى قنوات متدرجة.

هل يعتبر أنبوب DB2 مناسبًا لتطبيقات الجهد العالي؟

نعم. يُعدّ أنبوب DB2 مناسبًا لتطبيقات الجهد المنخفض والعالي، حسب تصميم التركيب. ويُستخدم عادةً في توزيع الكهرباء، بما في ذلك مداخل خدمات المرافق، وإضاءة الشوارع، والاتصالات.

هل يمكن ثني مجرى DB2 في الموقع؟

نعم، يوفر أنبوب DB2 مرونة محدودة في الموقع عند حدوث تغييرات طفيفة في المحاذاة. مع ذلك، يجب أن تتوافق جميع الانحناءات في الموقع مع قيود الشركة المصنعة والمواصفات فيما يتعلق بنصف القطر والإزاحة. للزوايا الحادة، استخدم أكواعًا أو وصلات مُشكَّلة مسبقًا.

ماذا يعني "DB" في الموصل؟

يرمز "DB" إلى الدفن المباشر، مما يعني أن الأنبوب مصمم للتركيب تحت الأرض دون الحاجة إلى تغليف إضافي (ما لم يُنص على خلاف ذلك). صُمم أنبوب DB لمقاومة ضغط التربة والرطوبة والأضرار المادية الشائعة في البيئات تحت السطحية.

ما هو موصل DB120؟

DB120 هو نوع محدد من أنابيب PVC، يُستخدم بشكل رئيسي في الولايات المتحدة الأمريكية للدفن المباشر في المنشآت غير الخرسانية. وهو مشابه في مفهومه لـ DB2 المستخدم في كندا، إلا أن DB120 هو تصنيف أمريكي، وقد يختلف في الأبعاد ومتطلبات الامتثال. تأكد دائمًا من توافق الكود المحلي.

هل أحتاج إلى قناة لسلك الدفن المباشر؟

It depends on the wire type and installation environment:

- UF (Underground Feeder) wire can be buried directly without conduit but must be at least 600 mm (24 inches) below grade.

- In rocky, corrosive, or high-traffic areas, conduit is strongly recommended to protect against mechanical damage.

- DB2 conduit is ideal for pulling and protecting electrical conductors in trench installations.

Using conduit provides additional mechanical protection, easier cable upgrades, and improved code compliance.

ما هي القناة المناسبة لمشروعي؟

Choosing the right duct depends on your specific needs:

- For underground installations without concrete encasement: Choose DB120 for its superior strength and durability.

- For above-ground or concrete-encased installations: DB2 is a cost-effective option for protecting wiring in walls, ceilings, and exposed conduit runs.

- For high-traffic areas or applications requiring extra protection: Consider DB120 even for above-ground installations due to its robust construction.

هل هناك أي عوامل إضافية ينبغي مراعاتها؟

- Local building codes: Always check and adhere to local regulations regarding the type and installation of electrical conduits.

- Temperature limitations: Both ducts have recommended temperature ranges, so ensure your application falls within those limits.

- Future expansion needs: If you anticipate future expansion of your electrical system, choose a duct size that can accommodate additional wiring.

Remember: Consulting with a qualified electrician or contractor is always recommended for specific project guidance and ensuring safe and compliant installations.